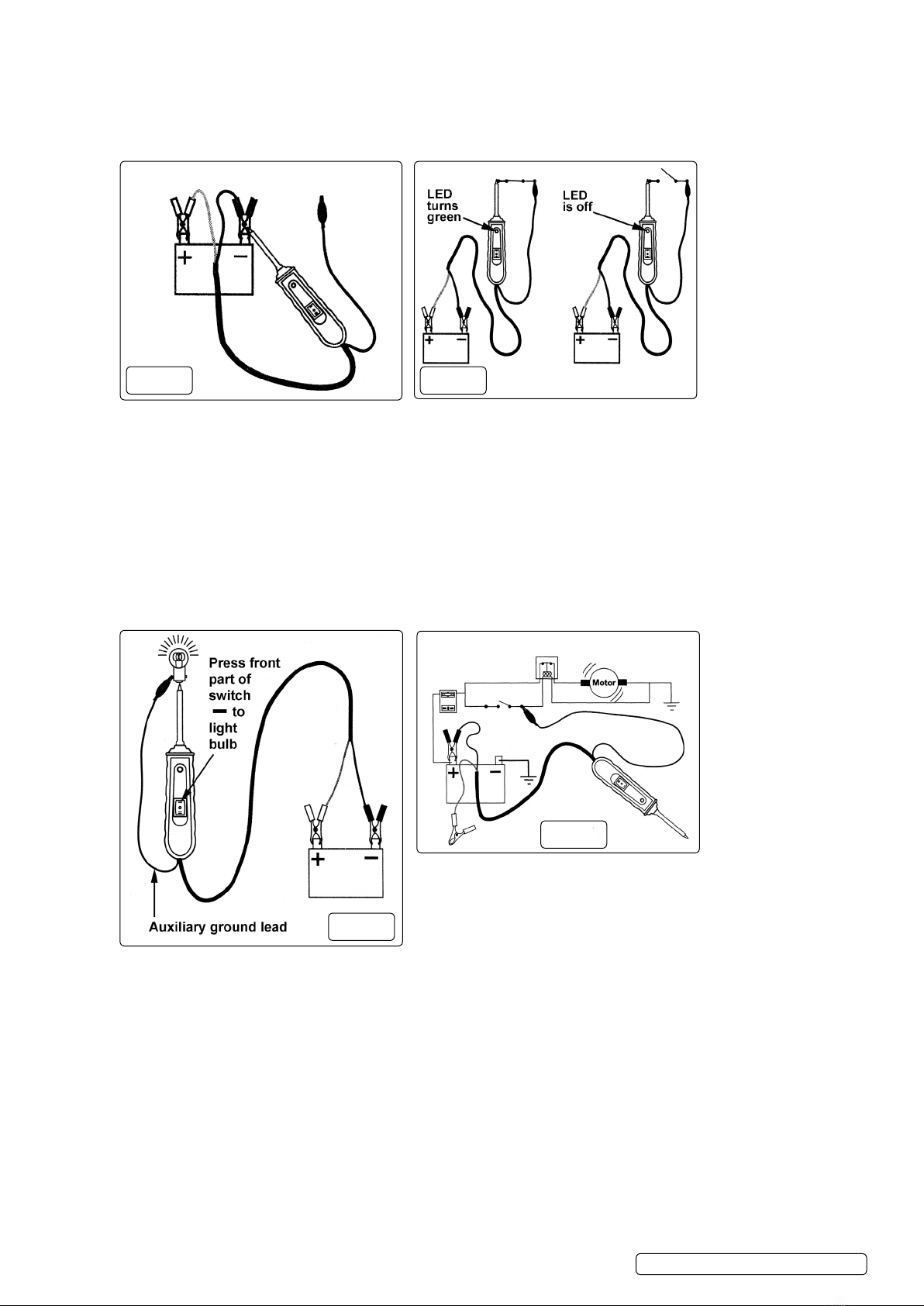

3.8. POWER LEAD FEATURE (SEE FIG.6).

WARNING! Haphazardly applying voltage to certain circuits can cause damage to

a vehicles electronic components. Therefore it is strongly advised to use the correct

wiring diagram and diagnosing procedure whilst performing tests.

3.8.1. The black clamp and the auxiliary ground lead are connected through the unit. By

leaving the red clip disconnected from the vehicles battery, the unit can be used as a

long power lead.

3.8.2. Be careful to avoid short circuits and overloading when using this power lead

function. In this conguration the leads are not protected by the units circuit breaker.

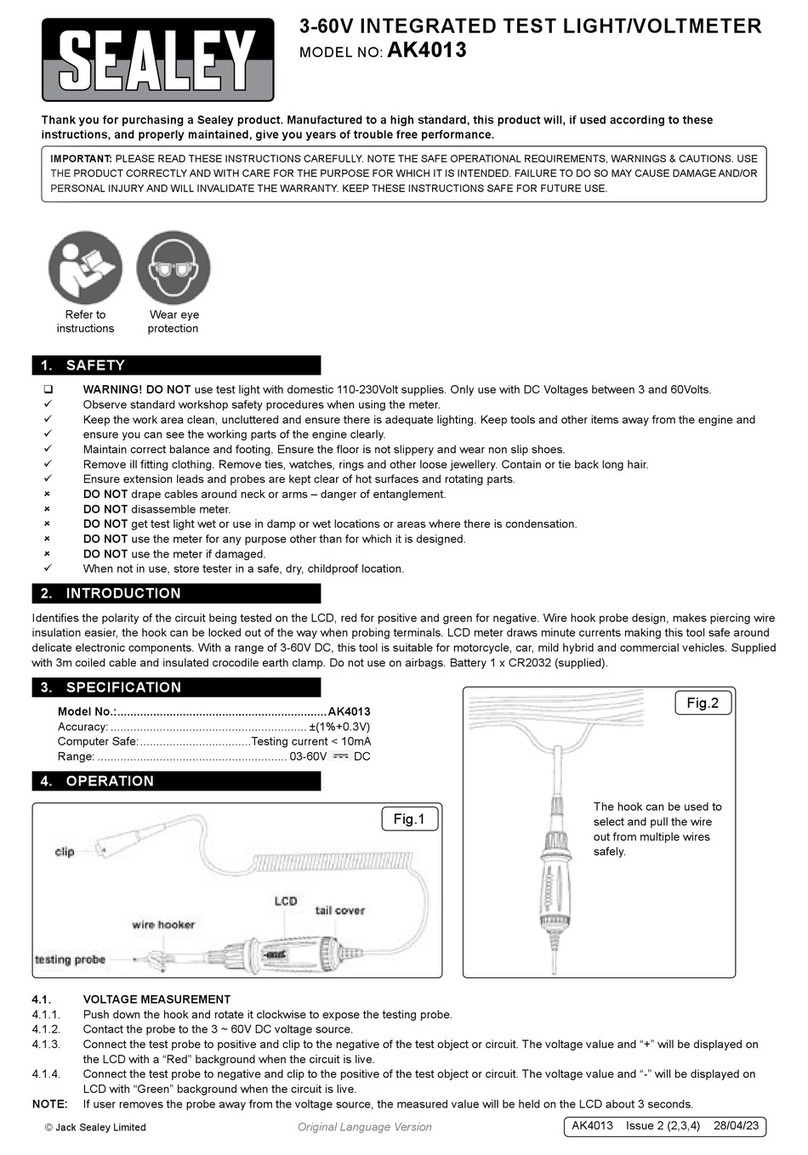

3.9. ACTIVATING COMPONENTS WITH A POSITIVE(+) VOLTAGE WITHIN THE

VEHICLE’S ELECTRICAL SYSTEM (See Fig.7).

3.9.1. Contact the probe tip to the positive terminal of the component, the LED indicator

should light GREEN. Whilst keeping an eye on the green indicator, quickly rock the

power switch forwards to the single bar position and release it. If the green indicator

changes instantly from GREEN to RED, you may proceed with further activation.

3.9.2. If the green indicator went o at that instant or if the unit sounds, the unit has been overloaded. This could happen for the following

reasons.

a) Where the tip of the tester has contacted is a direct ground or a negative voltage.

b) The component is short circuited.

c) The component requires a high amperage (e.g. a starter motor).

3.10. ACTIVATING COMPONENTS WITH A NEGATIVE(-) VOLTAGE WITHIN THE VEHICLE’S ELECTRICAL SYSTEM (See Fig.8).

3.10.1. Contact the probe tip to the negative terminal of the component, the LED indicator should light RED. Whilst keeping an eye on the red

indicator, quickly rock the power switch backwards to the double bar position and release it. If the red indicator changes instantly from

RED to GREEN, you may proceed with further activation.

3.10.2. If the red indicator went o at that instant or if the unit sounds, the unit has been overloaded. This could happen for the following

reasons.

a) Where the tip of the tester has contacted is a direct positive voltage.

b) The component is short circuited.

c) The component requires a high amperage (e.g. a starter motor).

WARNING! With this function a vehicle’s fuse can be blown or tripped if grounding the contact is in series with it.

3.11. TESTING TRAILER LAMPS AND CONNECTIONS

3.11.1. Connect the unit to a battery of the correct voltage.

3.11.2. Attach the auxiliary ground lead to the trailer ground.

3.11.3. Probe the contacts of the towing electrical connector whilst rocking the power switch to the forward single bar position. This lets you

check the function and orientation of the trailer lights. (See Fig.9).

g.8

g.9

PPLK Issue 3 12/02/19

Original Language Version

© Jack Sealey Limited

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

WEEE REGULATIONS

Dispose of this product at the end of its working life in compliance with the EU Directive on Waste Electrical and Electronic Equipment

(WEEE). When the product is no longer required, it must be disposed of in an environmentally protective way. Contact your local solid

waste authority for recycling information.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

g.7