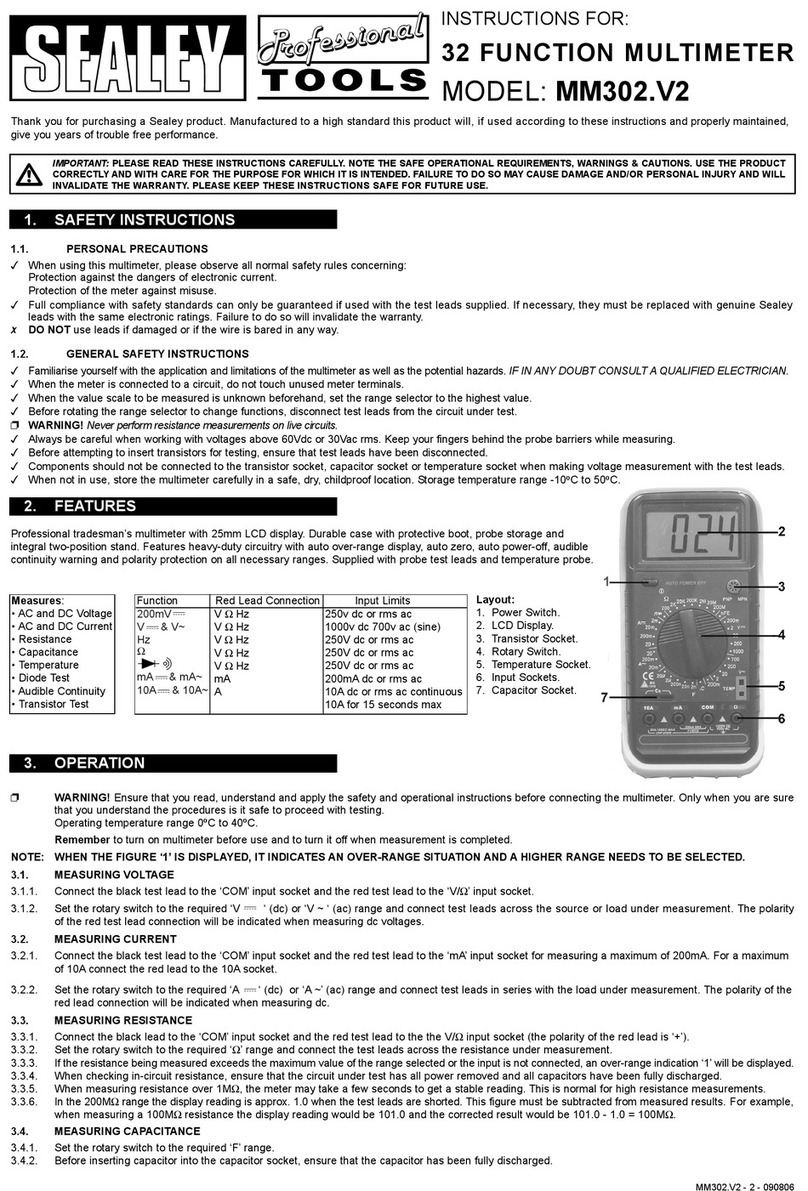

3. SPECIFICATION

Overvoltage Category: ..................................................................................................................... CAT11 1000V.

Display:......................................................................................4000 counts LCD display with function indication.

Polarity: .................................................................................................Automatic, (-) negative polarity indication.

Overrange: .............................................................................................................................“OL” mark indication.

Low Battery Indication: ............The “BAT” is displayed when the battery voltage drops below the operating level.

Measurement Rate:.....................................................................................................2 times per second nominal

Auto Power Off: .......................................... Meter automatically shuts down after approx 30 minutes of inactivity.

Operating environment:...................................................... 0°C to 50°C (32° to 122°F) at < 70%relative humidity.

Storage Temperature:....................................................... -20° to 60°C (-4°F to 140°F) at <80% relative humidity.

For Inside Use:

Max Working Height: ................................................................................................................................2000mtr.

Power: ....................................................................................................................................One 9V battery PP3.

Dimensions:...............................................................................................................195 (H) x 92 (W) x36 (D) mm

Approx Weight:................................................................................................................................................360g

Accuracy is given at 18°C to 28°C (65°F to 83°F) less than 70% relative humidity.

Range Resolution Accuracy

400.0mV 0.1mV ± 0.5% of reading ± 2 digits

4.000V 1mV

40.00V 10mV ±1.5% of reading ± 2 digits

400.0V 100mV

1000V 1V ± 1.8% of reading ± 2 digits

Range Resolution Accuracy

400.0mV 0.1mV ± 1.5% of reading ± 30 digits

4.000V 1mV ± 1.0% of reading ± 3 digits

40.00V 10mV ± 1.5% of reading ± 3 digits

400.0V 100mV

700V 1V ± 2.0% of reading ± 2 digits

Range Resolution Accuracy

400.0uA 0.1uA ± 1.0% of reading ± 3 digits

4000uA 1uA

40.00mA 10uA ± 1.5% of reading ± 3 digits

400.0mA 100uA

4A 1mA ± 2.5% of reading ± 5 digits

20A 10mA

Range Resolution Accuracy

400.0Ω 0.1Ω ± 1.2% of reading ± 4 digits

4.000kΩ 1Ω ± 1.0% of reading ± 2 digits

40.00kΩ 10Ω ± 1.2% of reading ± 2 digits

400.0kΩ 100Ω

4.000MΩ 1kΩ

40.00MΩ 10kΩ ± 2.0% of reading ± 3 digits

Range Resolution Accuracy

400.0uA 0.1uA ± 1.5% of reading ± 5 digits

4000uA 1uA

40.00mA 10uA

400.0mA 100uA

4A 1mA ± 3.0% of reading ± 7 digits

20A 10mA

DC Voltage (Auto Ranging)

AC Voltage (Auto Ranging except 400mV)

Input Impedance: 10MΩ.

Maximum Input 700Vac rms or 1000Vdc.

DC Current (Auto Ranging for uA and mA)

Input Impedance: 10MΩ.

Frequency Range: 50 to 400Hz.

Maximum Input: 700Vac rms or 100Vdc.

Overload Protection: 0.5A/250V and 20A/250V

Fuse:

Maximum Input:400mAac rms or 400mAdc on uA/mA ranges

20A ac or dc rms on 10A range.

AC Current (Auto Ranging for uA and mA)

Overload Protection: 0.5A/250V and 20A/250V

Fuse:

Frequency Range:50 to 400Hz

Maximum Input: 40mA ac rms or 400mA dc on uA/m7

20A ac or dc rms on 20A range.

Resistance (Auto Ranging)

Range Resolution Accuracy

40.00nF 10pF ± 5.0% of reading ± 7 digits

400.0nF 0.1nF

4.000uF 1nF ± 3.0% of reading ± 5 digits

40.00uF 10nF

100.0uF 0.1uF ± 5.0% of reading ± 5 digits

Capacitance (Auto Ranging)

Input Protection: 250Vac rms or 250Vdc.

Input Protection: 250Vac rms or 250Vdc.

Range Resolution Accuracy

5Hz 0.001Hz

50Hz 0.01Hz ± 1.5% of reading ± 5 digits

500Hz 0.1Hz

5kHz 1Hz

50kHz 10Hz ± 1.2% of reading ± 3 digits

500kHz 100Hz

10MHz 1kHz ± 1.5% of reading ± 4 digits

Frequency (Auto Ranging)

Sensitivity: <0.5V RMS while <1MHz

Sensitivity: >3V rms while >1MHz

Overload Protection: 250Vac rms or dc.

Range Resolution Accuracy

0.1%~99.9% 0.1% ± 1.2% of reading ± 2 digits

Duty Cycle (Auto Ranging)

Pulse Width: >100us, <100ms

Frequency Width: 5Hz - 150kHz

Overload Protection: 250Vac rms or dc.

Range Resolution Accuracy

1.0~10.0ms 0.1ms ± 3% of reading ± 10 digits

Pulse Width

Overload Protection: 250Vac rms or dc.

Range Resolution Accuracy

-20°C~+760°C 1°C ± 3.0% of reading ± 3 digits

-4°F~+1400°F 1°F (Meter only, probe accuracy

not included).

Range Resolution Accuracy

RPM 4 600~4000RPM 1RPM

600~1200RPM 10RPM

(X 10PM) ±2% of rdg ± 4 digits

RPM 2 300~4000 RPM 1RPM

300~600RPM 10RPM

(x 10RPM)

Temperature

Sensor: Type K Thermocouple

Range Resolution Accuracy

0.3mA 1mV ± 10% of reading ±5 digits

typical

Diode test

Open Circuit Voltage: 1.5Vdc typical

Overload Protection: 250Vac rms or dc.

Cylinder Range Resolution Accuracy

4CYL 0~90.0° 0.1° ± 2.0% of reading ± 4 digits

5CYL 0~72.0°

6CYL 0~60.0°

8CYL 0~45.0°

Dwell Angle

Overload Protection: 250Vac rms or dc.

Effect Reading: >600RPM

RPM (Tach)

Audible Continuity

Audible threshold: Less than 150Ω

Test Current: <0.3mA

Overload Protection: 250Vac rms or dc.

Original Language Version

© Jack Sealey Limited TA202 Issue 5 (-6) 20/09/18