3. SPECIFICATION

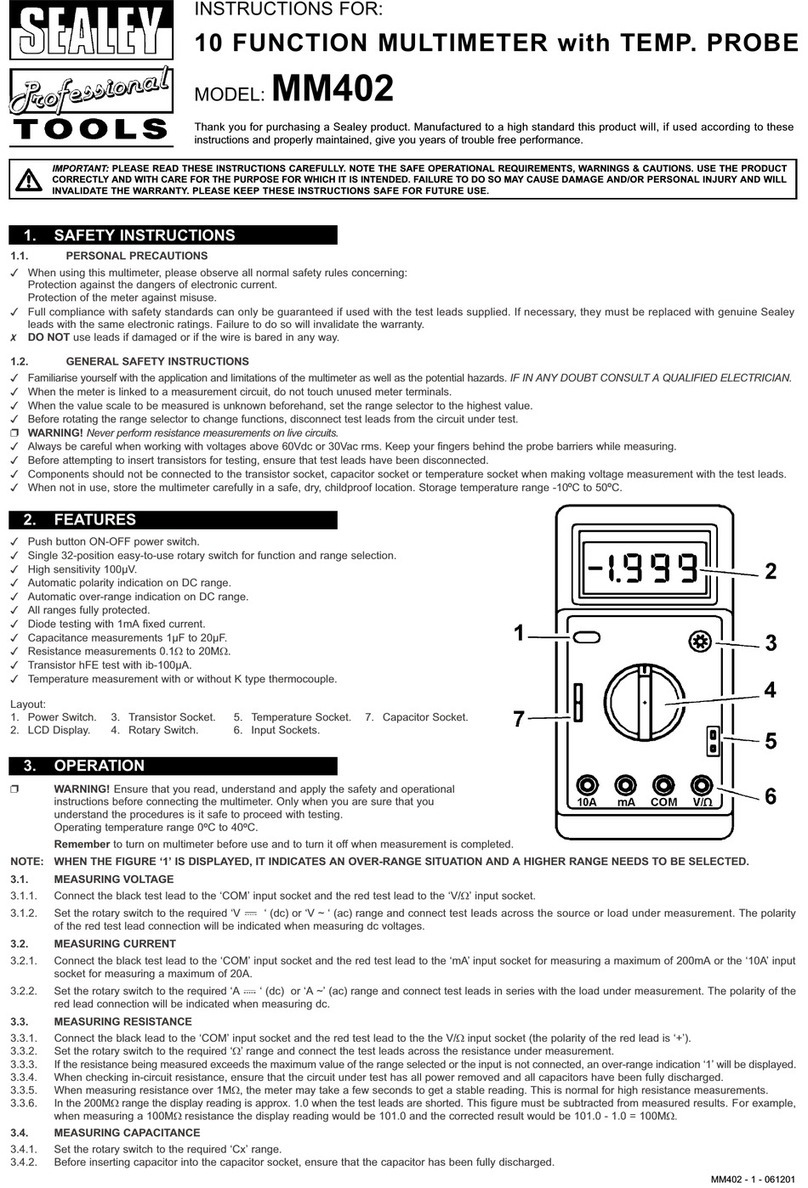

4. CONTROLS

Model No: ......................................................TM104

AC Voltage (Accuracy): .......................4V, 400V (±0.8%), 600V (±1.5%)

DC Voltage (Accuracy): ..................0-400mV, 400V (±0.7%), 600V (±1.0%)

AC Current (Accuracy): ....................40mA, 400mA (±1.5%), 10A (±3.0%)

DC Current (Accuracy): ....................40mA, 400mA (±1.2%), 10A (±2.0%)

Resistance (Accuracy):..................... 400Ω, 4MΩ (±1.2%), 40MΩ (±2.0%)

Capacitance (Accuracy): ....................... 4nF, 40µF (±3%), 200µF (±8%)

Temperature (Accuracy): .....-20°C-0°C (±5%), 0°C-20°C (±3%), 20°C-400°C (±2%)

Frequency (Accuracy): ..............9.999Hz (±2.0%), 99.99Hz, 9.999kHz(±1.5%),

.......................................... 99.99kHz, 199.99kHz (±2.0%)

Duty Cycle: ...........................................0.1%-99.9% (±3.0%)

Continuity Audible: ..................................................Ye s

Diode Test: ........................................................Yes

Digits x Height: ................................................7 x 19mm

Low Battery Indicator:................................................Ye s

Batteries (Supplied):...............................................1 x 9V

Information:.....................................Data-Hold & Auto Power Off

Size (L x W x D):......................................... 178 x 85 x 40mm

Weight: ..........................................................320g

Conformity: .........................................IEC 1010, CATIII 600V

Humidity:..................................................30-90% (±8%)

Sound Level:.....................................35-100dB (±5dB at 94dB)

Light:............................................0-40,000Lux (±5%) (x10)

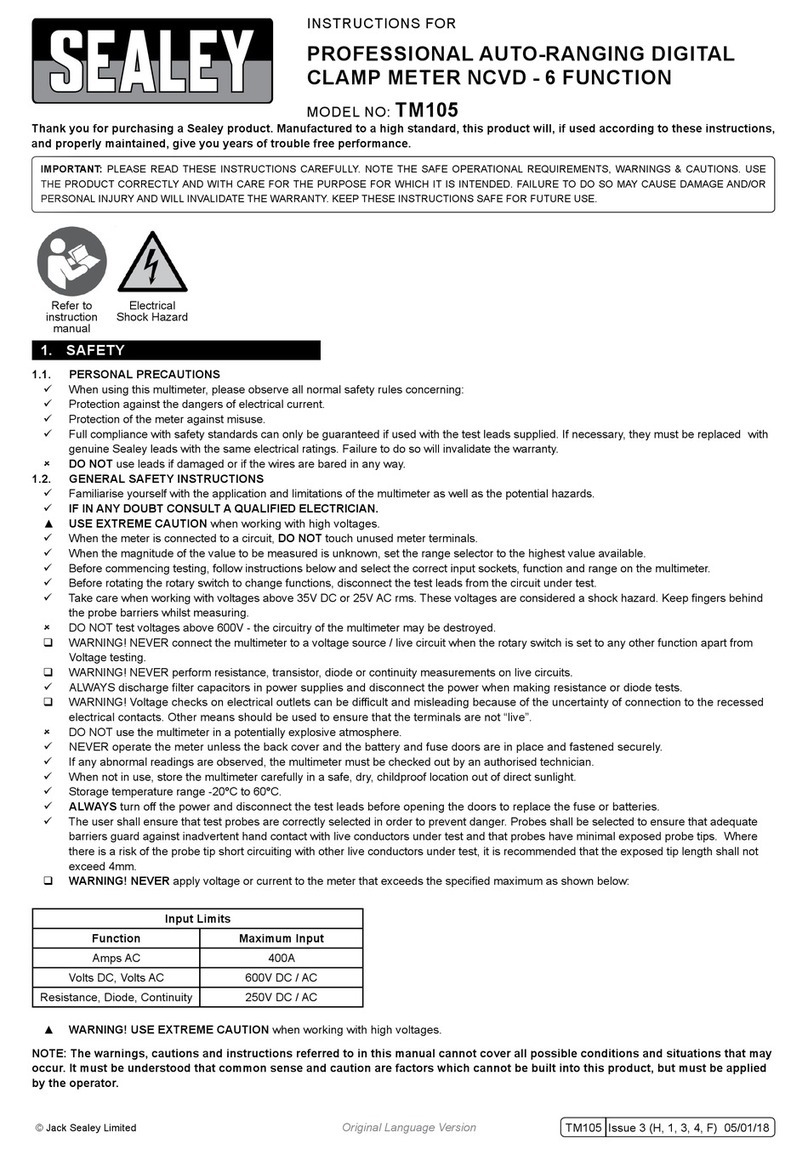

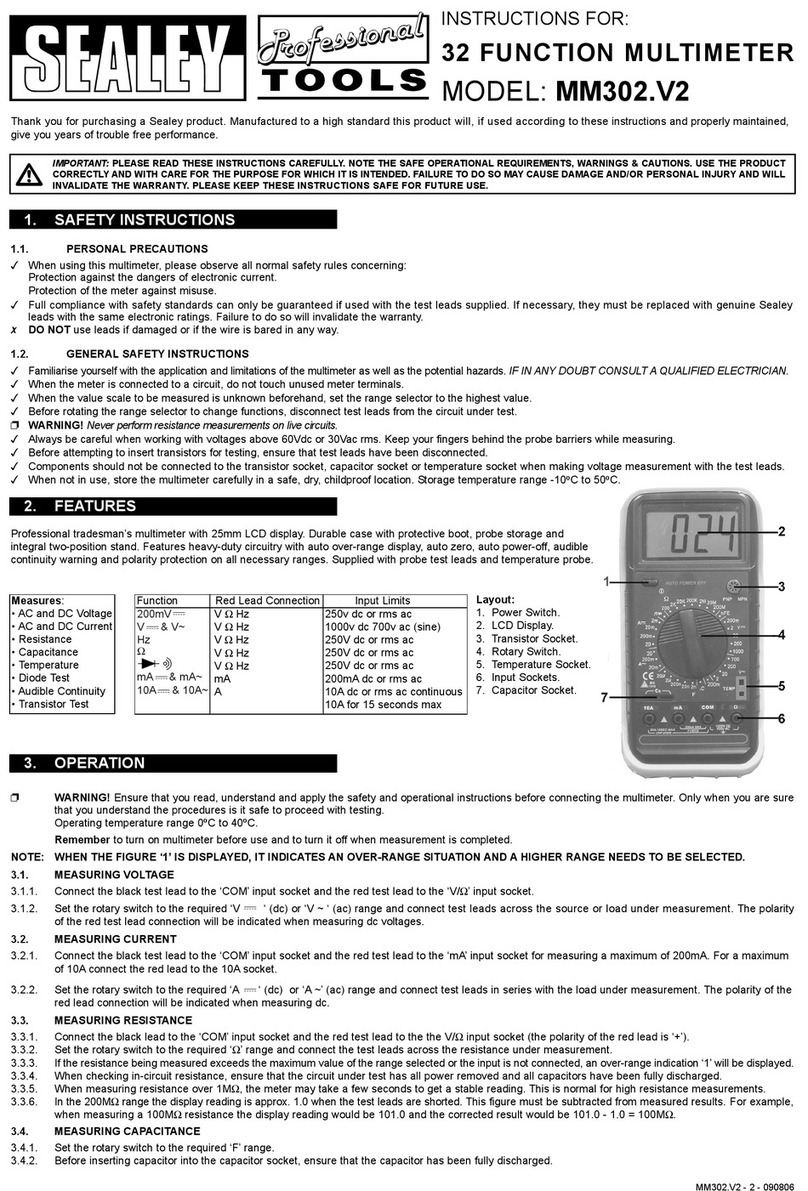

4.1. Button Functions

4.1.1. Rotary Selector (fig.1.1). Switches the meter on or off and selects the various functions.

4.1.2. HOLD Button (fig.1.2.). Pressing the hold button at any point will hold the instant display until the button is pressed again to release it.

4.1.3. FUNCTION Button. (fig.1.3). When measuring current and voltage, the function button will change between DC and AC.

When measuring resistance, capacitance, diode and continuity; the function button can be used to cycle between settings.

4.1.4. RANGE Button. (fig.1.4). The default setting for measuring current, voltage and resistance is auto-ranging. If it is desired to select

manual ranging, press the RANGE button. Each subsequent press will advance the measurement range. Pressing range for

2 seconds will revert to auto-range.

Note: When 'OL' is displayed, the reading is above the range selected manually.

4.1.5. Hz/DUTY Button (fig.1.5). By pressing the 'Hz/DUTY' button whilst in the frequency setting, the duty cycle function will be selected.

When measuring voltage or current, one press of the HZ/DUTY button will display the frequency and a second press the duty cycle of

the circuit being tested.

4.1.6. REL Button (fig.1.6). The Relative button allows comparison between circuits. Pressing the button will zero the display: a subsequent

reading will show the difference between the two readings.

4.1.7. LIGHT Button (fig.1.7). Switches on the backlight. Owing to the power demands of the backlight, it will fade and extinguish after

5 seconds. Frequent use of the backlight will shorten the life of the battery significantly.

4.2. Battery

4.2.1. Low battery voltage is indicated by the appearance of the icon on the left of the display screen.

When the battery icon is showing, readings may become unreliable; the battery should, therefore,

be changed as soon as possible.

WARNING! Remove the test leads before opening battery compartment.

4.2.2. To insert, replace or remove the battery; remove the two screws and open the battery compartment

as in fig.2.

4.2.3. Replace the battery, then refit and secure the cover

4.3. Auto Power Off

4.3.1. If the meter has been left with power on for 15 minutes, it will give an audible warning and then switch

off.

4.3.2. To restore power from this condition; switch the rotary selector to off and then back on again or press

FUNC, RANGE, Hz/DUTY or REL switch.

4.3.3. To disable the auto power off facility, press FUNC whilst the power is on.

g.2

5. OPERATION

WARNING! Ensure that the safety and operational instructions are read, understood and applied before connecting the multimeter.

Only when the procedures are understood is it safe to proceed with testing.

5.1. MEASURING VOLTAGE (AC and DC)

5.1.1. Connect the black test lead to the COM input socket (fig.1.10)and the red test lead to the V input socket (fig.1.11)

5.1.2. Set the rotary switch to V . The meter default setting is auto-ranging (denoted by AUTO in the display). To deselect auto-ranging,

see section 4.1.4.

5.1.3. Connect the test probes across the source or load being measured.

5.1.4. Turn on the power, the voltage will be displayed and the polarity of the red test lead connection will be indicated when measuring DC

voltages.

5.1.5. Press FUNC to scroll between AC and DC measurements.

5.1.6. The measured value will be displayed.

5.1.7. If measuring an unknown voltage with the manual range setting, select the highest voltage scale first and work down to the voltage

measured.

Original Language Version

© Jack Sealey Limited TM104 Issue No: 1 10/06/15

FIG.1