8DO NOT point spray gun at yourself, at other persons or animals.

8DO NOT carry the by the air hose, or pull the hose from the air supply.

8DO NOT use the spray gun for any purpose other than for which it is designed.

8DO NOT allow untrained persons to operate the spray gun.

8DO NOT get the spray gun wet or use in damp or wet locations or areas where there is condensation.

8DO NOT operate gun if any parts are missing or damaged as this may cause failure or personal injury.

8DO NOT direct air from the air hose at yourself or others.

9 When not in use switch the spray gun off, and disconnect from the air supply.

10. TYRE INFLATOR SAFETY

9Disconnect the gauge from the air supply before changing accessories, servicing or performing any maintenance.

9Maintain the gauge in good condition (use an authorised service agent), and keep the gauge clean for best and safest performance.

9Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will invalidate

the warranty.

9Locate gauge in a suitable work area, keep area clean and tidy and free from unrelated materials and ensure there is adequate lighting.

9Keep children and unauthorised persons away from the work area.

8DO NOT direct gauge outlet at yourself or at other persons or animals.

8DO NOT carry by the hose, or yank the hose from the air supply.

8DO NOT use the gauge for a task which it is not designed to perform.

8DO NOT operate the gauge when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT operate gauge if parts are missing or the gauge is damaged, as this may cause failure and/or personal injury.

11. AIR GUN SAFETY

WARNING! Disconnect blow gun from the air supply before changing accessories, servicing or performing any maintenance.

9De-pressurise the blow gun before removing air hose from the gun.

9Maintain the blow gun in good condition (use an authorised service agent).

9 Replace or repair damaged parts. Use genuine parts only. Non genuine parts may be dangerous and will invalidate the warranty.

9Keep the work area clean, uncluttered and ensure there is adequate lighting.

9Only use the blow gun for the purpose of blowing compressed air.

WARNING! Always wear approved eye or face protection when operating the blow gun. Use a face or dust mask if dust is generated.

Wear appropriate protective clothing.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non slip shoes.

9 Remove ill fitting clothes, ties, watches, rings, other loose jewellery, and contain/tie back long hair.

9Keep children and unauthorised persons away from the working area.

9Secure non stable work piece with a clamp, vice or other adequate holding device.

9Avoid unintentional starting.

WARNING! air pressure should not exceed 90psi.

9Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use, and ensure that all connections are secure.

8DO NOT use the blow gun for any purpose other than for which it is designed.

8DO NOT operate blow gun if any parts are damaged or missing as may cause failure or personal injury.

8DO NOT carry the by the hose, or yank the hose from the air supply.

8DO NOT allow untrained persons to operate the blow gun.

8DO NOT operate blow gun when you are tired, under influence of alcohol, drugs or intoxicating medication.

8DO NOT leave the blow gun operating whilst unattended.

8DO NOT direct air from the blow gun at yourself, others or animals.

9 When not in use disconnect from the blow supply and store in a safe, dry, child proof area.

12. INTRODUCTION

Kit contains: Gravity feed spray gun, tyre inator, air blow

gun, 5m air hose1/4”BSP

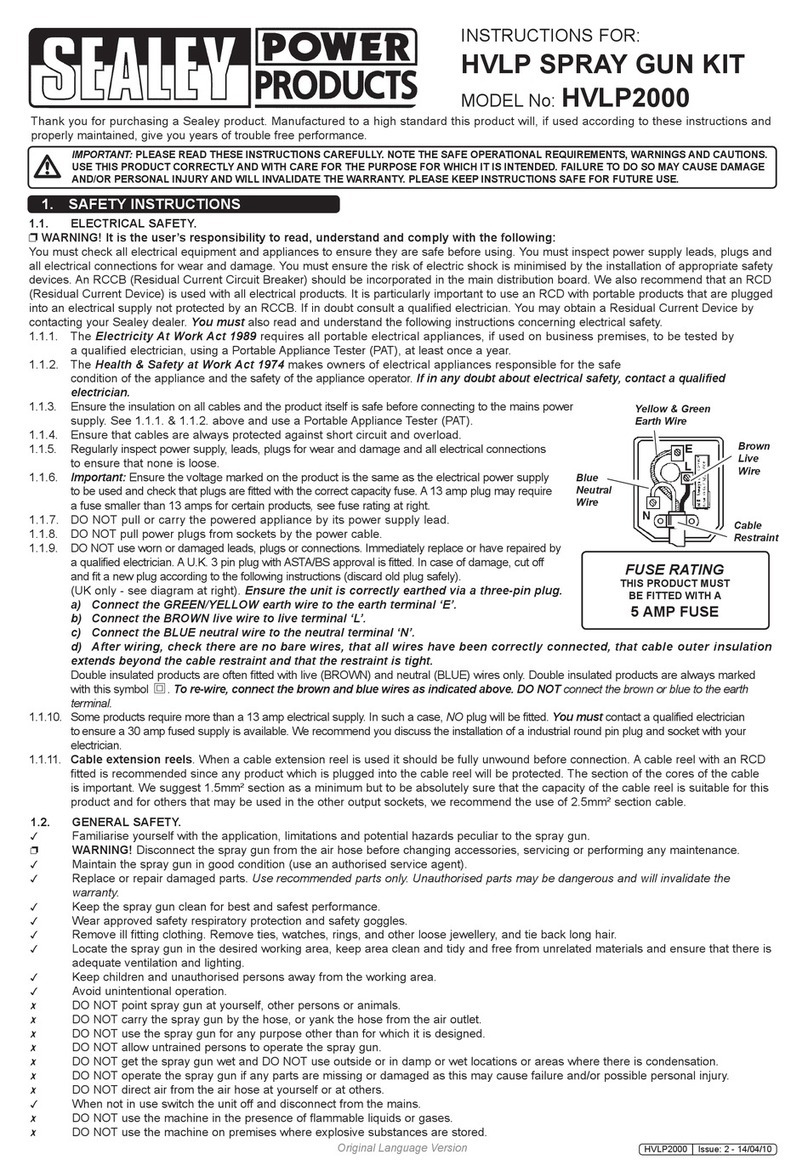

13. SPECIFICATION

Rated air pressure for all tools in the Air kit................... 90psi

Max. working pressureof PE Hose ................................90bar

14. AIR SUPPLY

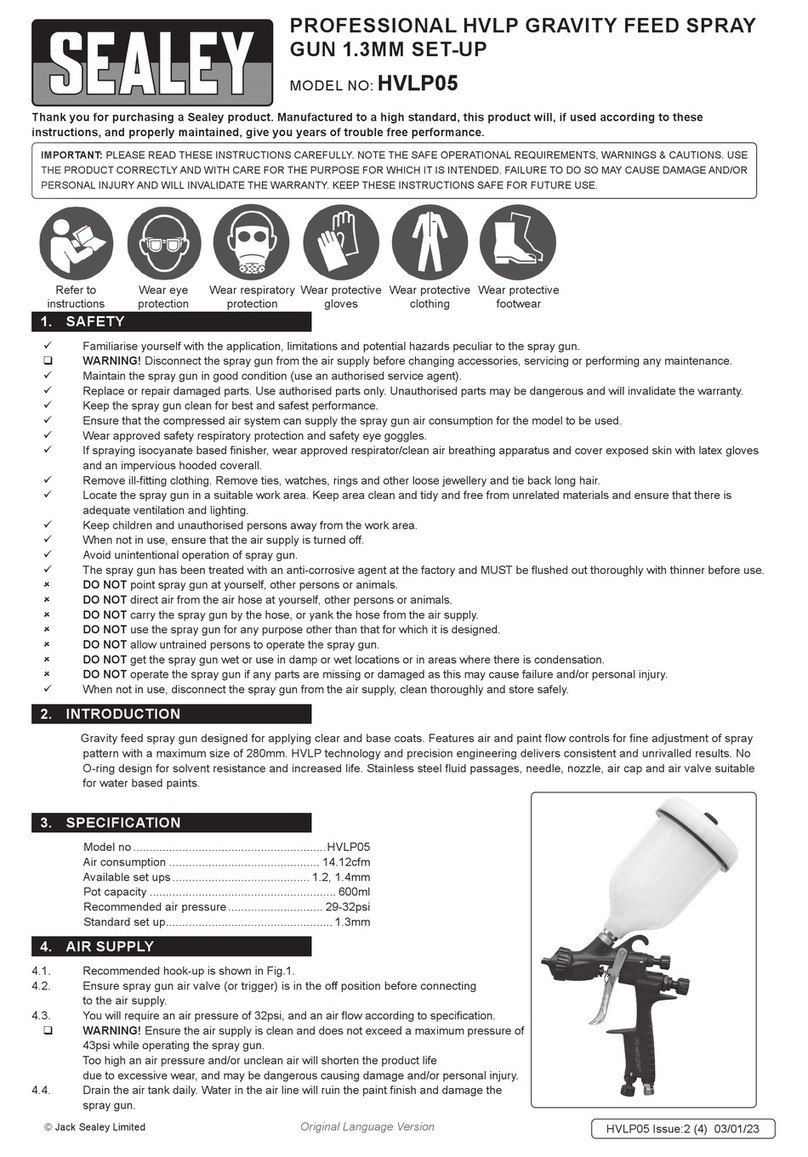

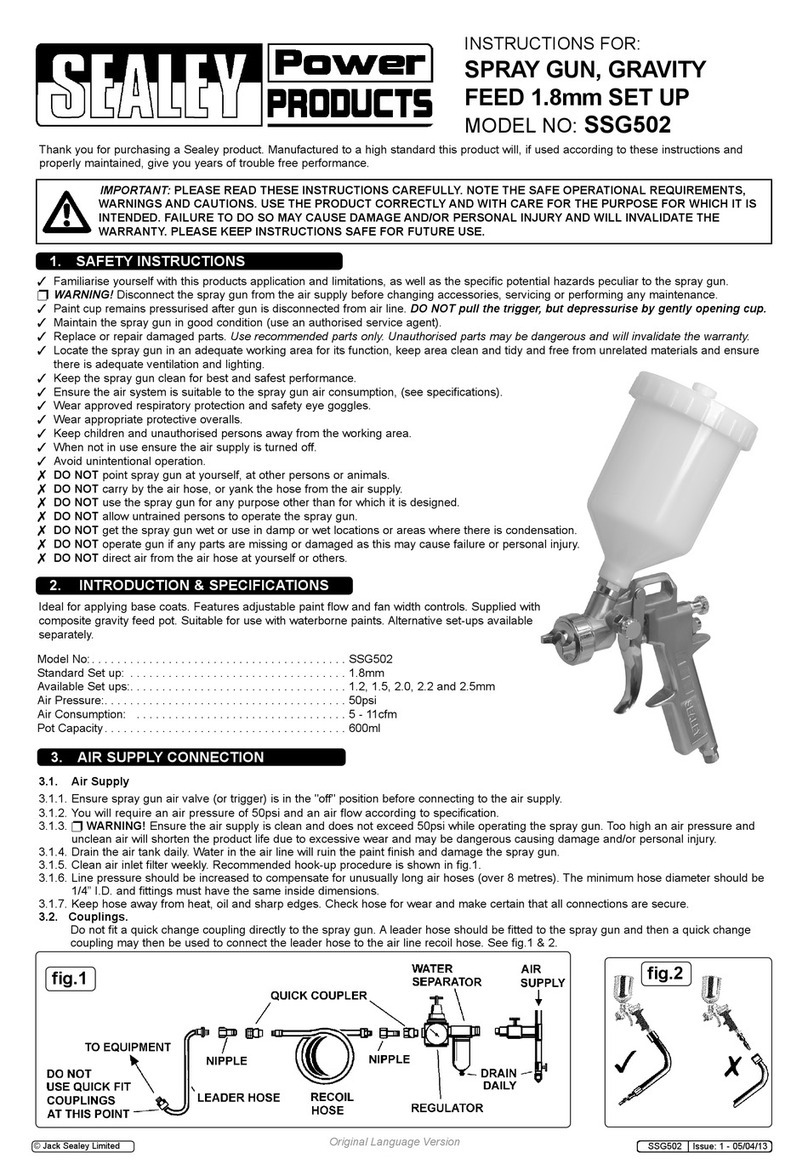

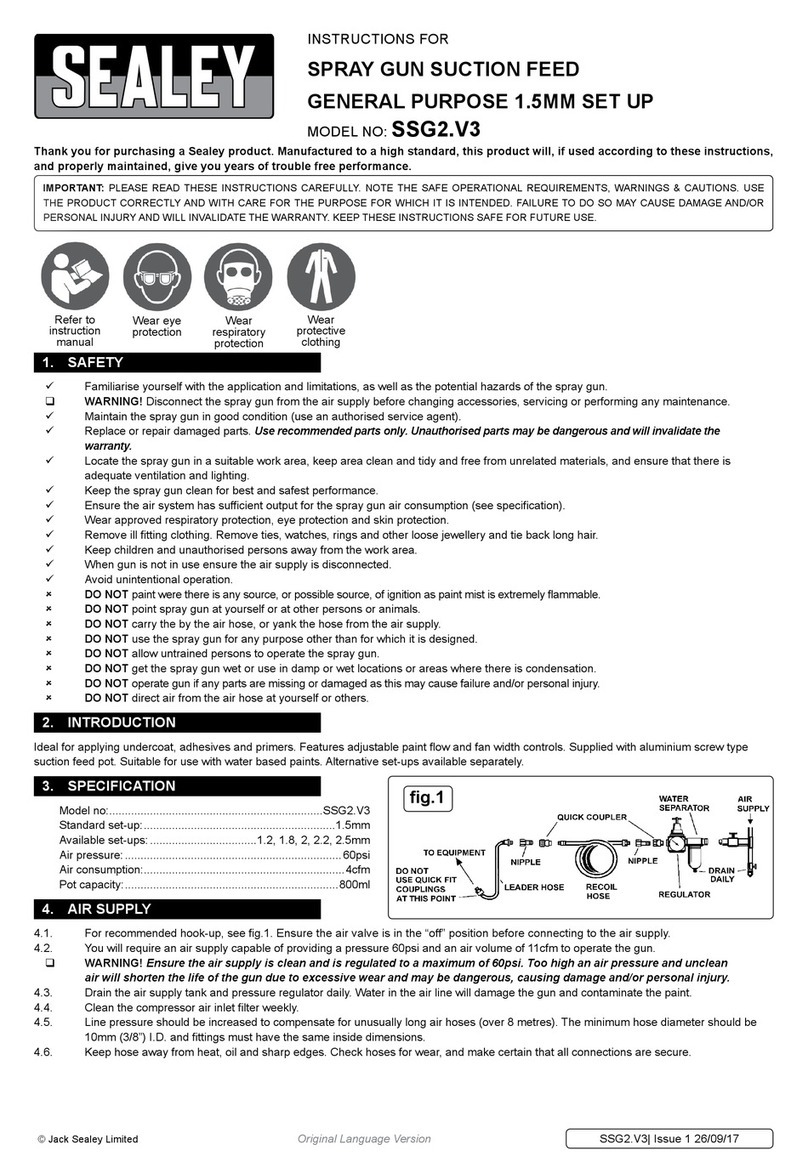

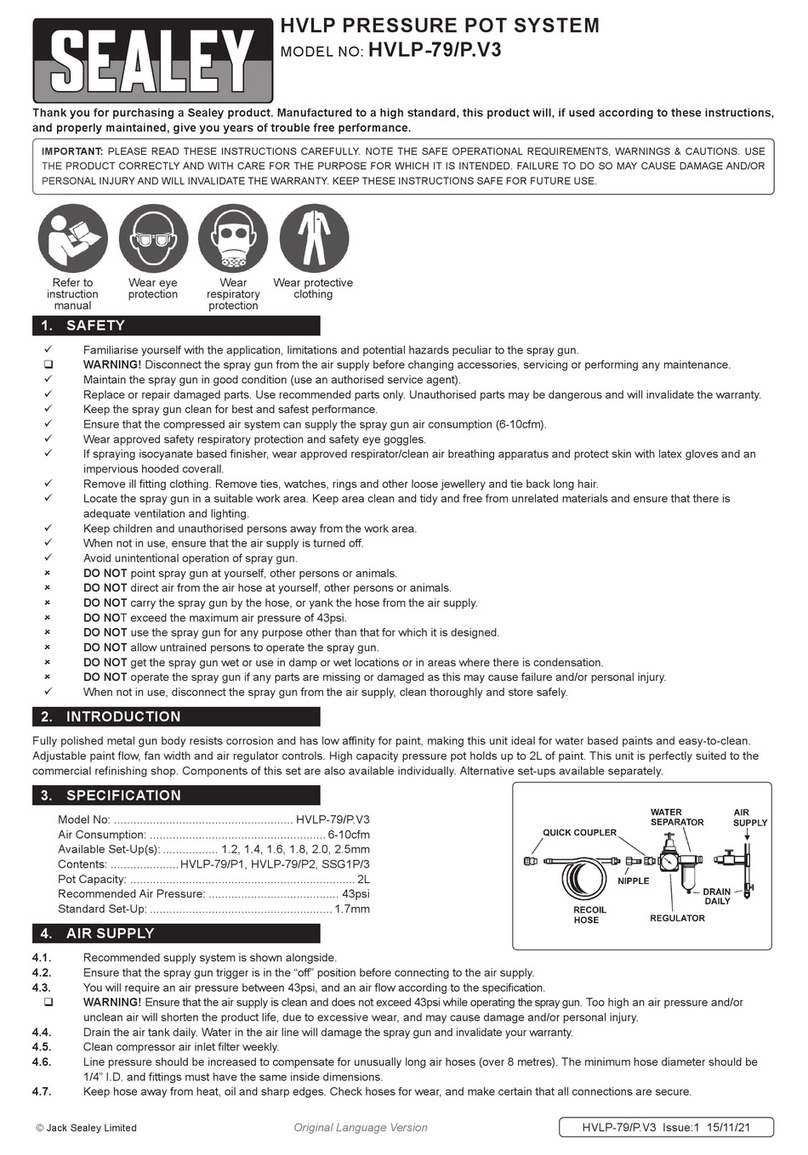

14.1. Recommended hook-up g.8.

14.1.1. Ensure tool’s air valve (or trigger) is in the off position before connecting to the air supply.

WARNING! Ensure the air supply is clean and does not exceed specication (above) while operating the tool. Too high an air pressure

and/or unclean air will shorten the product life due to excessive wear, and may be dangerous causing damage and/or personal

injury.

14.1.2. Drain the air tank daily. Water in the air line will ruin the paint nish and damage the tool.

14.1.3. Clean air inlet lter weekly.

14.1.4. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should be

1/4” I.D. and ttings must have the same inside dimensions.

14.1.5. Keep hose away from heat, oil and sharp edges. Check hose for wear, and make certain that all connections are secure.

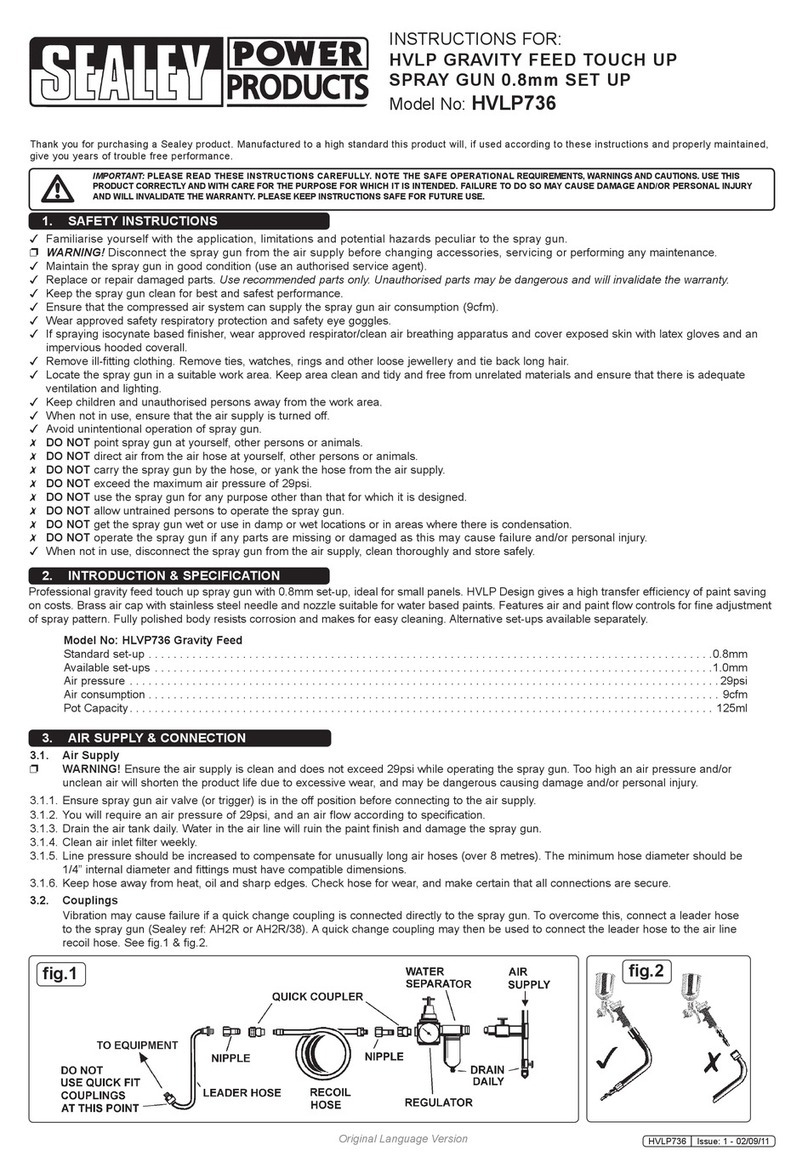

14.2. COUPLINGS

Vibration may cause failure if a quick change coupling is connected directly to the tool. To overcome this, connect

a leader hose. A quick change coupling may then be used to connect the leader hose to the air line recoil hose (g.8).

fig.8

Original Language Version

© Jack Sealey Limited SAC2420E.V3, SAC2420EPK.V2 Issue 1 13/06/19