CORDLESS SCREWDRIVER SET

26PC 3.7V LITHIUM-ION

MODEL NO: CP36B

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. GENERAL SAFETY

9Maintain the screwdriver in good condition. Check moving parts alignment on a regular basis.

9Keep the screwdriver and charger clean for best and safest performance.

9Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery and contain long hair.

9Secure loose workpieces with a clamp, vice or other adequate holding device.

9Avoid unintentional starting.

9Wear approved safety eye protection.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9Keep children and unauthorised persons away from the working area.

8888 DO NOT allow children to operate the screwdriver.

8888 DO NOT hold unsecured workpiece in your hand.

8888 DO NOT carry the screwdriver with your finger on the trigger.

8888 DO NOT use the screwdriver for a task it is not designed for.

8888 DO NOT operate the screwdriver when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8888 DO NOT get the screwdriver or battery charger wet or use in damp or wet locations.

8988 Keep screwdriver and charger in a safe, dry, child proof area where the temperature will not exceed 104°F (40°C).

1.2. ELECTRICAL SAFETY FOR USE OF CHARGER

USE ONLY THE SUPPLIED CHARGER PLUG FOR CONNECTING SCREWDRIVER TO THE POWER SUPPLY.

WARNING! It is the user’s responsibility to read, understand and comply with the following electrical instructions:

You must ensure the risk of electric shock is minimised by the installation of appropriate safety devices. An RCCB (Residual Current

Circuit Breaker) should be incorporated in the main distribution board. We also recommend that an RCD (Residual Current Device)

is used with all electrical products, particularly portable equipment which is plugged into an electrical supply not protected by an

RCCB. You must also read and understand the following instructions concerning electrical safety.

1.2.1. The Electricity At Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by a

qualified electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.2.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of the

appliance and the safety of the appliance operator. If in any doubt about electrical safety, contact a qualified electrician.

1.2.3. You must ensure that you:

8988 Inspect the charger plug, cable and connector for wear and damage to ensure items are safe before connecting to the mains power

supply. If worn or damaged DO NOT use.

88 IMPORTANT: Check that the voltage marked on the charger plug is the same as the power supply to be used.

8888 DO NOT pull the charger plug from the mains socket by the lead.

8888 DO NOT use any other type of charger with this product.

8888 DO NOT try to take the charger plug apart.

8888 DO NOT use the charger plug to charge or power any other electrical item.

8888 DO NOT get the charger wet, or use in wet, damp conditions (for indoor use only).

888 WARNING!8NEVER substitute a standard 13amp 3 pin plug, or any other type of plug, for the charger plug.

1.3. BATTERY SAFETY

888 WARNING! To reduce the risk of burns or fire:

8888 DO NOT attempt to open, dismantle, modify or service the battery.

8888 DO NOT crush, puncture, short external contacts or dispose of in fire or water.DO NOT expose to temperatures above 60°C (140°).

8988 Recycle or dispose of used battery as stipulated by local regulation.

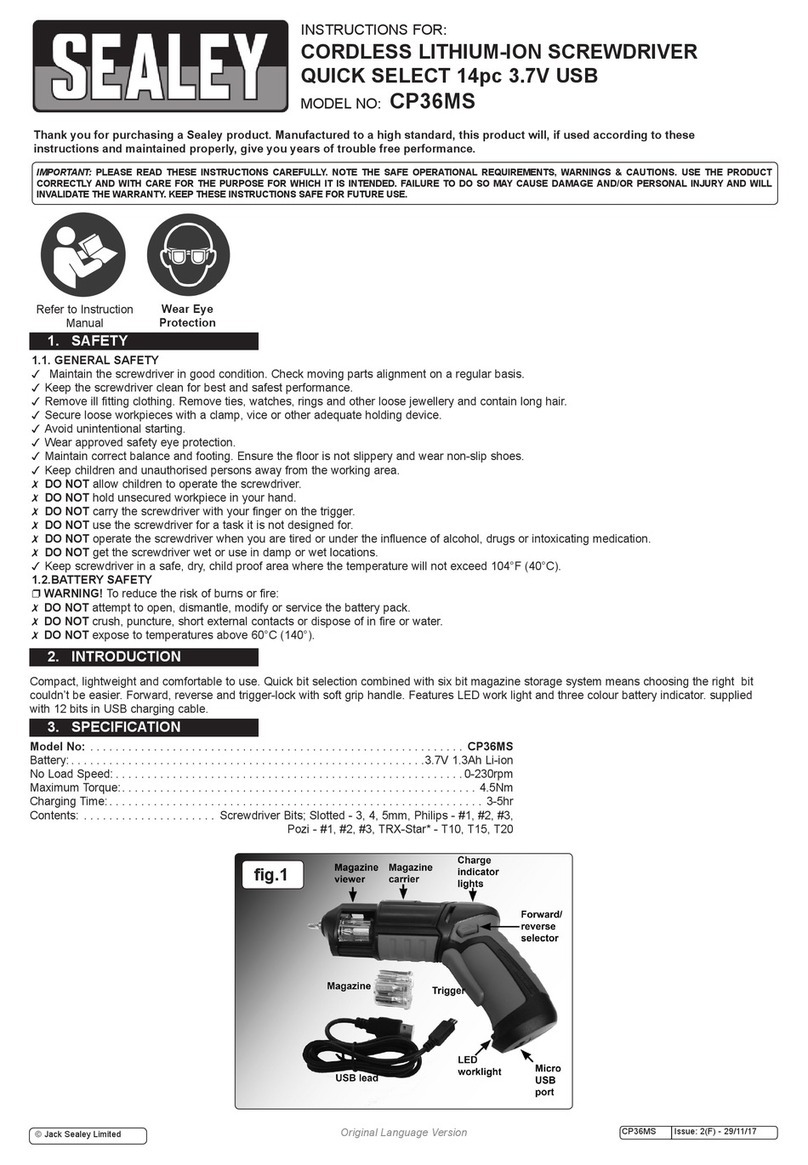

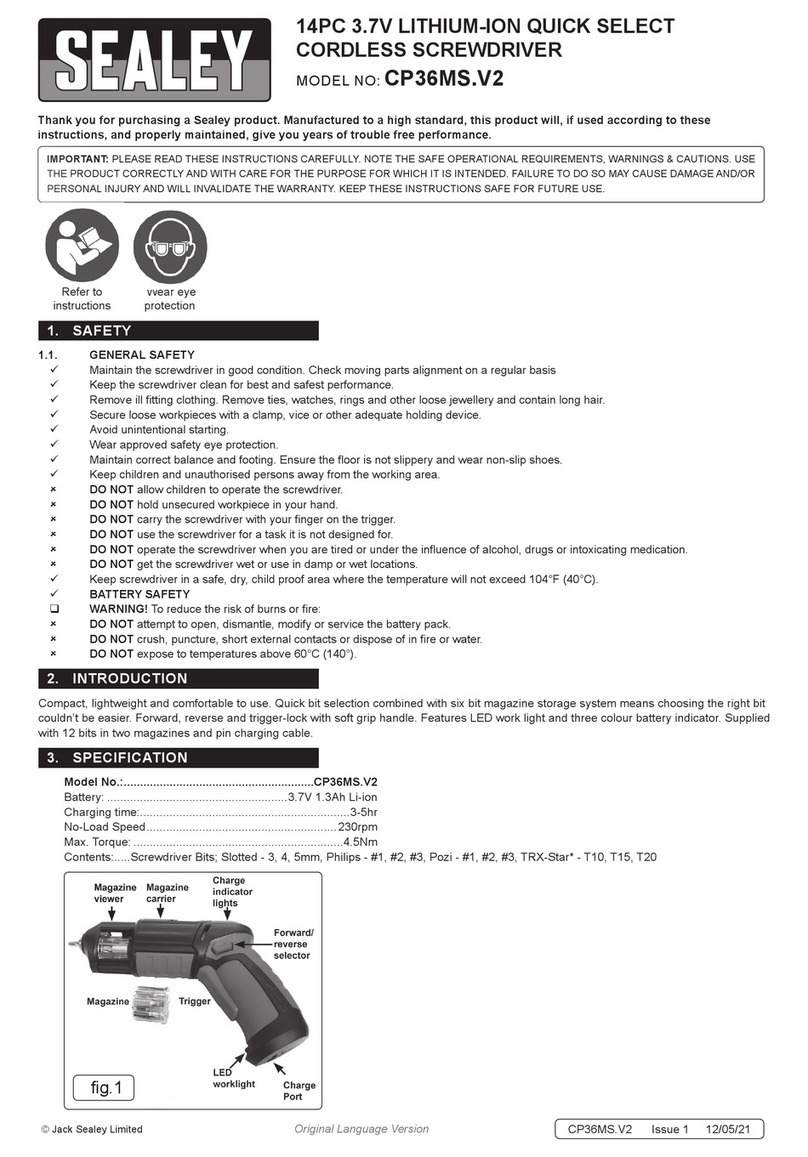

2. INTRODUCTION

Compact, lightweight and comfortable to use. Features locking swivel adjustment from pistol to straight grip. Forward, reverse and trigger-lock

with soft grip handle. Features LED work light and three colour battery indicator. Eight adjustable torque settings coupled with a quick release

bit holder. Supplied with 24 assorted bits and mains charging cable.

CP36B | Issue 2 (3) 22/08/2019

Original Language Version

© Jack Sealey Limited

Refer to

instructions

Wear eye

protection