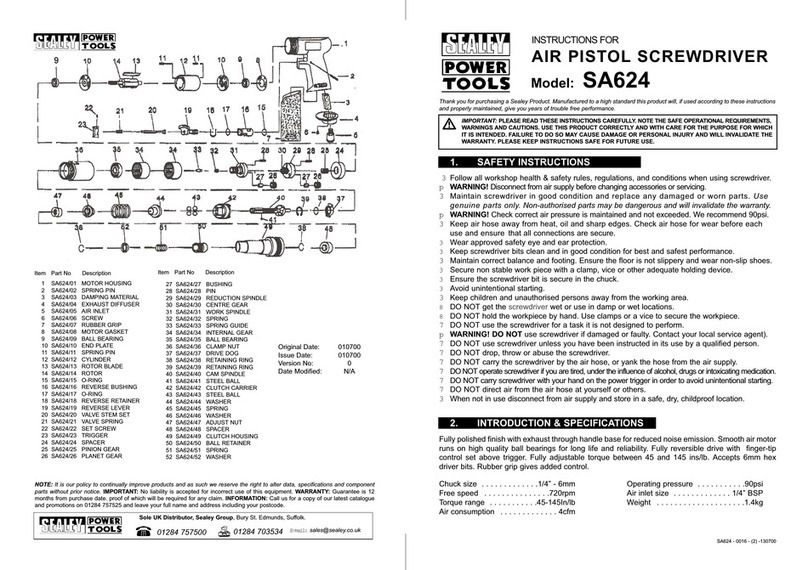

3.1. Air Supply.

Recommended hook-up procedure is shown in fig.1.

3.1.1. Ensure tool valve (or trigger) is in the "off" position before connecting to the air supply.

3.1.2. You will require an air pressure of 90psi, and an air flow according to specification.

3.1.3. WARNING! Ensure the air supply is clean and does not exceed 90psi while operating the

tool. Too high an air pressure and/or unclean air will shorten the product life due to

excessive wear, and may be dangerous causing damage and/or personal injury.

3.1.4. Drain the air tank daily. Water in the air line will damage the tool.

3.1.5. Clean air inlet filter weekly.

3.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8

meters). The minimum hose diameter should be 1/4” I.D. and fittings must have the same

inside dimensions.

3.1.7. Keep hose away from heat, oil and sharp edges. Check hose for wear, and make certain

that all connections are secure.

3.2. Couplings.

Vibration may cause failure if a quick change coupling is connected directly to the tool. To

overcome this, connect a leader hose to the tool. A quick change coupling may then be used to

connect the leader hose to the air line recoil hose. See fig.1 & 2.

!WARNING! Disconnect screwdriver from air supply before changing accessories, servicing

or performing maintenance. Replace or repair damaged parts. Use genuine parts only.

Unauthorised parts may be dangerous and will invalidate the warranty.

5.1. If the air system does not include an oiler, lubricate the air screwdriver daily with a few drops

of Sealey air tool oil dripped into the air inlet to prolong its life.

5.2. Clean the screwdriver after use.

5.3. Loss of power or erratic action may be due to the following:

a) Excessive drain on the air line. Moisture or restriction in the air pipe. Incorrect size or

type of hose connectors. To remedy check the air supply and follow instructions in

section 3.

b) Grit or gum deposits in the screwdriver may also reduce performance. If your model has

an air strainer (located in the area of the air inlet), remove the strainer and clean it. Flush

the screwdriver out with gum solvent oil or an equal mixture of SAE No 10 oil and

paraffin. Allow to dry before use.

5.4. When not in use, disconnect from air supply, clean screwdriver and store in a safe, dry,

childproof location.

3. PREPARING SCREWDRIVER FOR USE

4. OPERATING INSTRUCTIONS

5. MAINTENANCE

fig.1

We, the sole importer into the UK, declare that the product listed here is in conformity with the

following standards and directives. The construction file for this product is held by the Manufacturer

and may be inspected, by a national authority, upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Power Tools.

Air Straight Reversible Screwdriver

Model: SA57

98/37/EC Machinery Directive

93/68/EEC Marking Directive

24th July 2007

Declaration of Conformity

Signed by Tim Thompson

SA57 - (2) - 240707

SA57 - (2) - 240707

fig.2

Fig.3

A

B

C

!WARNING! Ensure you read, understand and apply safety instructions before use.

!WARNING! Disconnect screwdriver from air supply before changing accessories, servicing

or performing maintenance.

"DO NOT allow screwdriver to free run for an extended period of time as this will shorten its life.

4.1. Pull the chuck collar forward and push driver bit into self locking chuck (fig.3.A.), release

collar and ensure the bit is secure. To release bit, pull chuck collar forward and pull bit out.

4.2. Connect the screwdriver to the air hose as in Section 3.

4.3. Check that the screwdriver is set to operate in the required direction. The screwdriver

direction is changed by switching the reverse lever (fig.3.B).

4.4. Select from speeds 1, 2 or 3 using rotary switch (fig.3.C).

4.5. Depress the trigger to operate the screwdriver.

Risk of Hand Arm Vibration Injury.

The SA57, when operated in accordance with these instructions and tested in accordance with EN 28662-1: 1993 results in the

following vibration emission declared in accordance with BS EN12096: 1996.

Measured vibration emission value:......................2.54m/s2 Uncertainty: ............................................1.02m/s2

These values are suitable for comparison with emission levels of other tools that have been subject to the same test.

This tool may cause hand-arm vibration syndrome if its use is inadequately managed.

Recommended Measures to reduce risk of hand-arm vibration syndrome: This item represents a low Hand Arm Vibration risk

to users. The calculated maximum usage period exceeds 8 hours. We recommend appropriate safety equipment is utilised and

regular breaks for the operator are employed to reduce any residual risk of fatigue or repetitive strain injury.