3.2. Installation

3.2.1. You will require an air pressure of between 60-80psi, and an air volume of 15cfm for operating the unit.

WARNING! Ensure air supply does not exceed 100psi. Too high an air pressure and/or unclean air will shorten the cabinet

life due to excessive wear, and may be dangerous causing possible damage and personal injury.

3.2.2. The air supply must be clean and dry. Drain the air supply tank daily. Water in the air line will damage the item being blasted and will

invalidate the cleaning tank warranty.

3.2.3. Clean the compressor air inlet filter screen weekly. For recommended hook-up, see diagram below.

3.2.4. Line pressure should be increased to compensate for

unusually long air hoses (over 8 metres). The minimum

hose diameter should be 10mm I.D. and fittings must

have the same inside dimensions.

3.2.5. Keep hose away from heat, oil and sharp edges. Check

hoses for wear. Make certain all connections are secure.

Capacity . . . . . . . . . . . . . . . . . . . 0.33m3

Max Air Pressure ........... 40-80psi

Max Air Flow................. 15cfm

Extraction Port Ø:.............64mm

Air Inlet ......................1/4”BSP

Width/Depth/Height ... 960x720x1500mm

Viewing Area: . . . . . . . . . . . . 580 x 270mm

Doors ............................ 2

3. ASSEMBLY & INSTALLATION

4. OPERATING INSTRUCTIONS

WARNING! Ensure you have read, understood and apply safety instructions in Section 1 before using the unit.

4.1. A Ceramic Nozzle must be fitted to the gun output head.

Different Ceramic Nozzle sizes will increase or decrease shot blast flow.

The Ceramic Nozzle is fixed to the gun head by loosening the head screw, inserting the Ceramic Nozzle and re-tightening the screw.

4.2. There is a small metal nozzle located within the gun head. This is the Air Jet. The Air Jet may need to be replaced due to general

wear and tear. To fit a replacement Air Jet you will need to remove the Ceramic Nozzle first, and then use a 1/4" Drive 10mm Socket

to remove the old Air Jet and fit a replacement. Air Jet Part No.SB974/23-1.

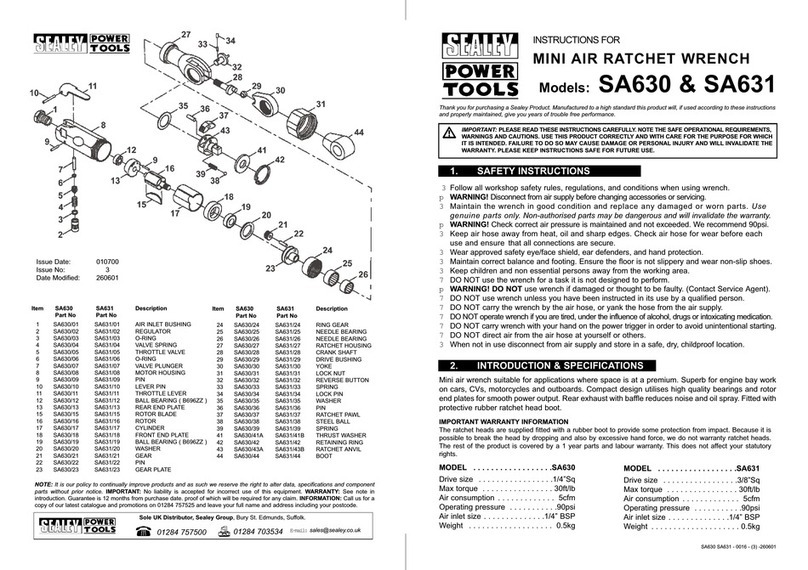

3.1. Assembly (This cabinet should be assembled by two people).

3.1.1. Unpack the product and check contents. Should there be any damaged or missing

parts contact your supplier immediately.

3.1.2. Connect the leg ends to legs (fig 1.1 & 2.) by passing screws from the outside and

tightening with nuts and washers on the inside of the leg.

3.1.3. Attach the four legs to cabinet frame (3) with screws, washers and nuts.

3.1.4. Fasten shelf (4) to holes in the middle of the four legs.

3.1.5. Carefully peel backing paper from the foam sealing strip and lay the exposed sticky

surface on the upper edge of frame (3). Trim as required, and make screw holes in

foam (in some cases the foam may already be attached).

3.1.6. Site funnel (5) so that it passes through the hole in shelf (4) and sits on frame (3)

with the funnel outlet locking lever (A) facing to the front of the cabinet.

3.1.7. Sit the wire mesh shelf (6) in the top of funnel (5).

3.1.8. Stick further sealing strip all around the edge of the funnel.

3.1.9. Sit cabinet (7) on top of funnel, ensuring that all the sealing strips are intact and fix

the cabinet and funnel to frame (3) with screws, washers and nuts.

3.1.10. If not already attached, connect gun (8) to hose (9) at the nozzle outlet end of gun (B).

3.1.11. Push other end of hose (9) onto the shot media input pipe inside the funnel (10).

2. DESCRIPTION & SPECIFICATION

Heavy-duty steel cabinet with toughened glass viewing screen and integral low voltage

illumination. Double side doors on Model No. SB974 provide easy access for bulkier items.

Includes dust extraction port. Heavy gauntlets provide hand protection and each cabinet is

supplied with sand blasting gun and four ceramic nozzles. Suitable for proprietary brands of glass

beads, silicon carbide, aluminium oxide and silica sand only. Excellent for a wide variety of

workshop and bodyshop cleaning applications the cabinet requires a minimum 5hp compressor

with a DRY AIR SUPPLY.

3.2.6. Use an appropriate coupling suitable for your air system to

connect to the 1/4” inlet air coupling on the gun.

Pass the air line through the cabinet inlet hole (D).

3.2.7. Ensure the air gun (8) trigger is ‘Off’ before connecting to the air supply.

3.2.8. Check all fittings to ensure there are no leaks and check that the media supply hose is tightly attached to the underside of the gun.

3.2.9. Place abrasive into the centre of cabinet funnel, by pouring through the side door, until it is half full.

DO NOT exceed the stated amount. Excessive amounts of abrasive will impair visibility, create poor blasting performance and could

block the air exhaust at the rear of the cabinet.

3.2.10. Plug the transformer connector into the electrical inlet (E) at the rear of the blast cabinet. Plug the transformer into the mains socket.

3.3. Dust extraction: If not using an extraction system, remove the cover from air flow outlet (Z) at rear right hand side of the cabinet to

allow air flow.

3.3.1. We strongly recommend that a suitable dust extraction system is used with this unit.

The blast cabinet should be connected to a dust extraction unit. To do so, remove the plastic sealing plate (X) from the rear of the

cabinet and use the same screws to attach the plastic dust outlet. Fit a filter over the dust outlet to ensure that no abrasive is taken

into the extraction unit. Finally, connect the outlet to the extraction unit and use in accordance with the extractor instructions.

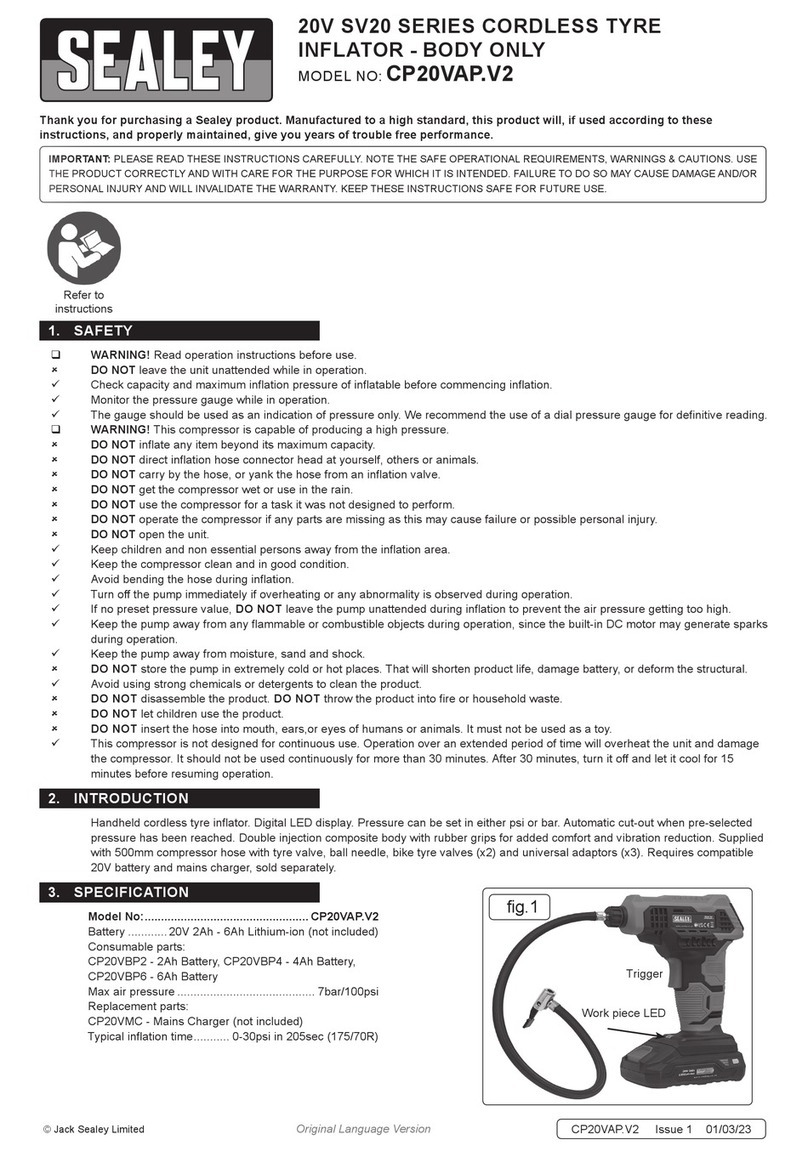

Fig.1

Original Language Version SB974.V3 Issue: 1 - 21/05/12

© Jack Sealey Limited