Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND

CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY

CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

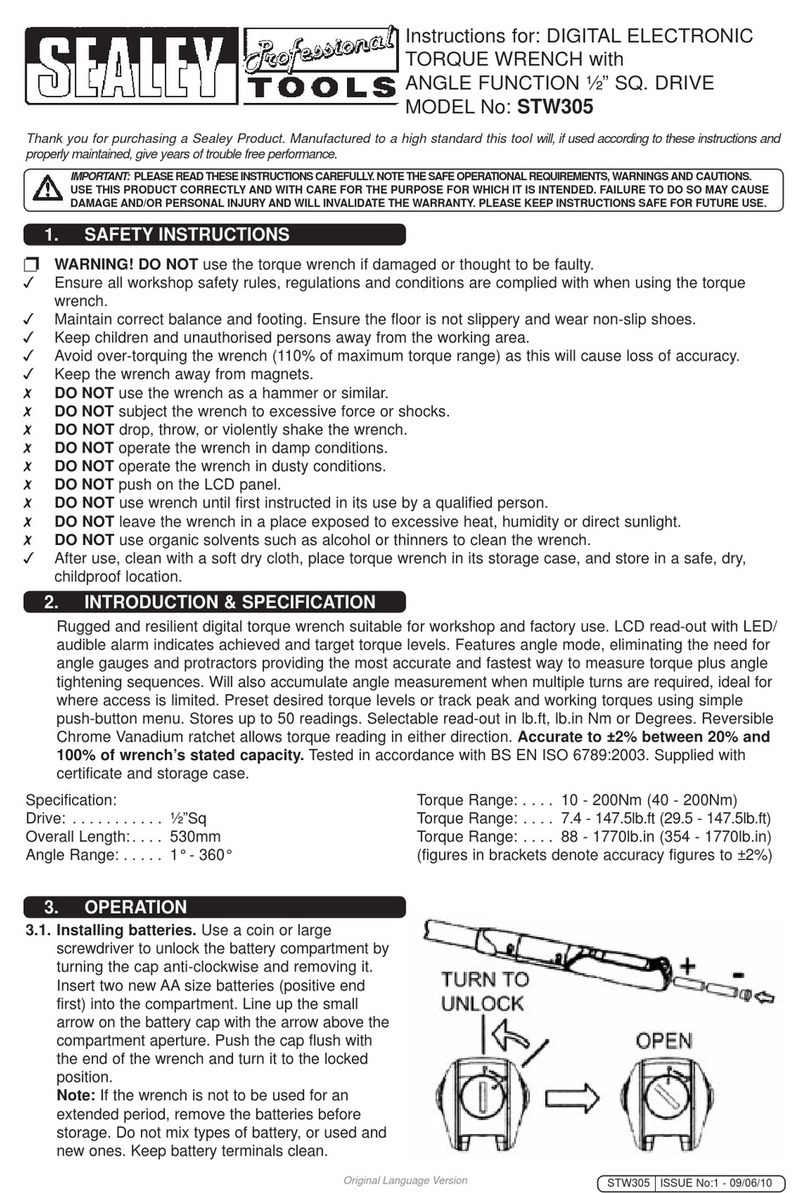

2. INTRODUCTION & SPECIFICATION

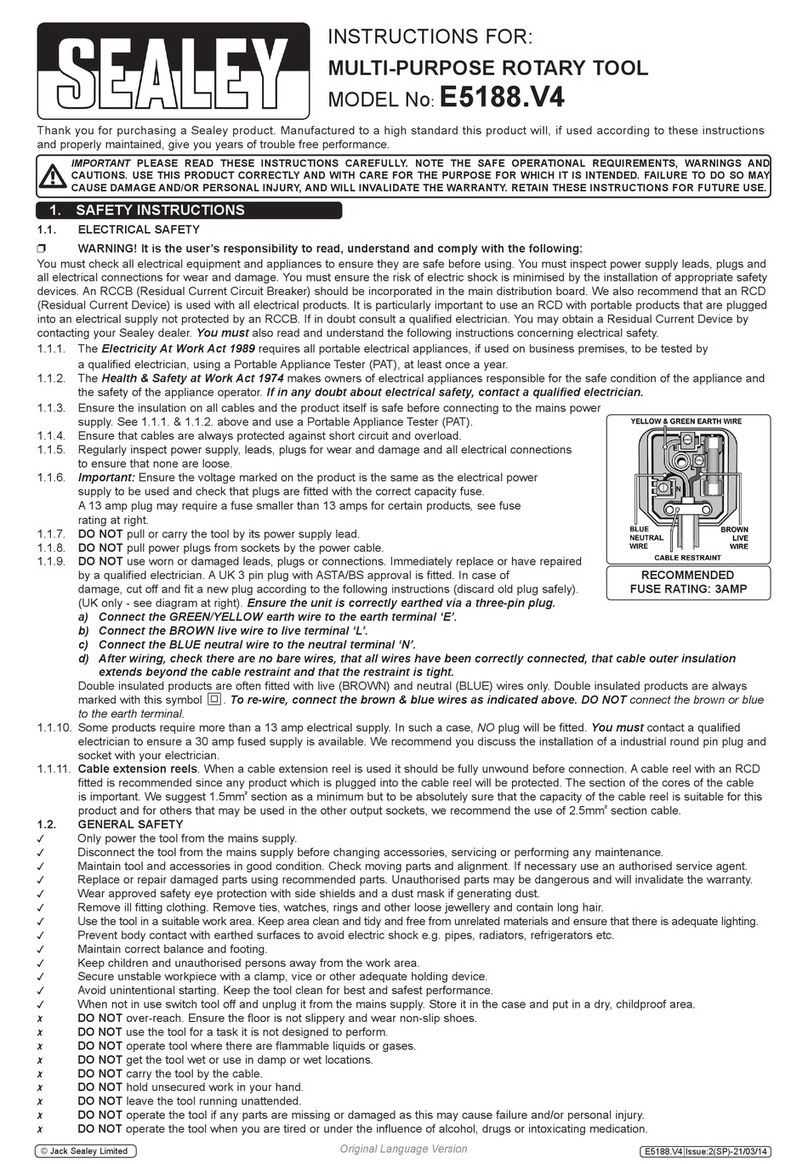

1. SAFETY INSTRUCTIONS !

! DANGER! For safety reasons, always ensure the workpiece and

press tools are secured on the table and will not flex or suddenly

“give way” causing danger to operator or the component.

2.2. SPECIFICATION

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30ton

Ram stroke. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150mm

Max height - ram to table . . . . . . . . . . . . . . . . . . . . . . . . . . 965mm

Min height - ram to table . . . . . . . . . . . . . . . . . . . . . . . . . . . 110mm

Table aperture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140mm

Work table width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540mm

Overall height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1920mm

Gauge included . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Yes

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128kg

3. ASSEMBLY

Unpack the product and check contents. If there are any damaged or

missing parts contact your supplier immediately. Take care to ensure

safety when removing main frame parts from packing as the unit is

very heavy. We recommend that the press should be assembled by

two people.

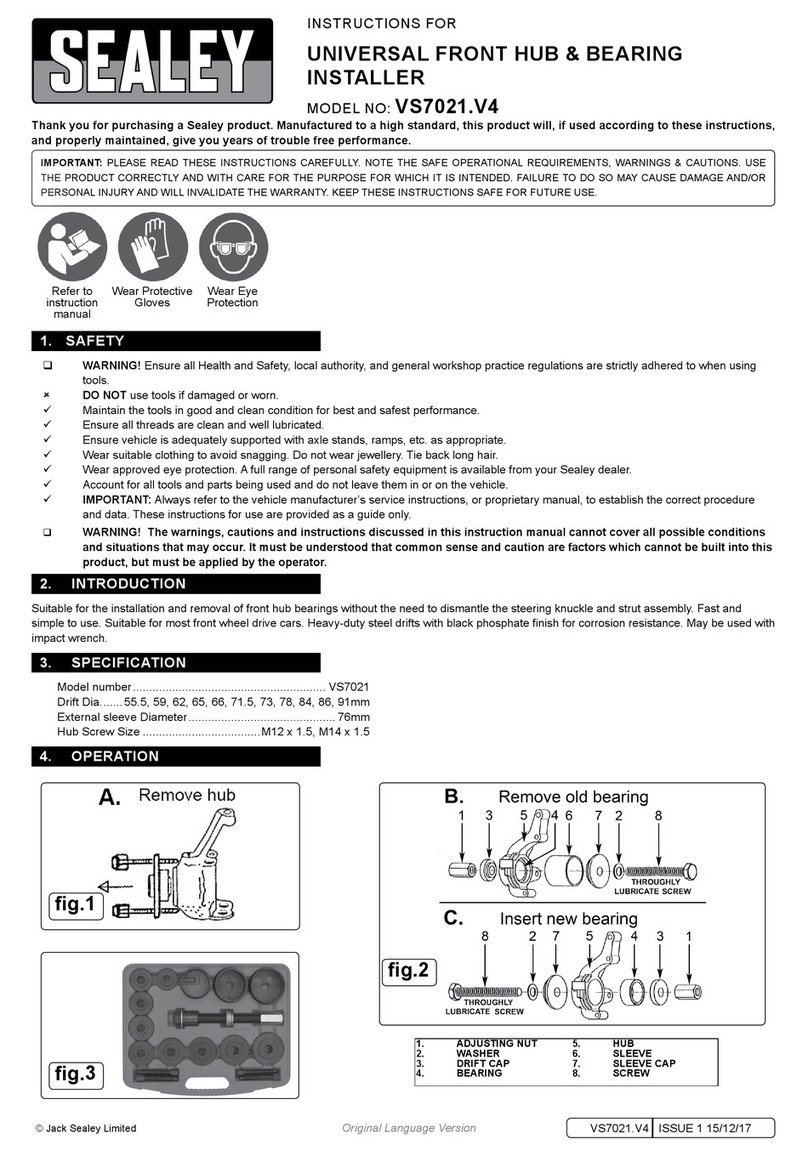

3.1. Use the assembly diagram overleaf as your guide. Lay all

parts and assemblies out before beginning. The following

procedure is recommended:

3.2. Attach one base leg (01) and lower cross member (08) to left

post (09) using bolts (03), washers (04), lock washers (05)

and nuts (06) to secure, then repeat with the other base

leg (01), attaching it to right post (09) and the lower cross

member (08). Make sure that the joining plates on the two

posts are facing outwards.

3.3 Place the assembly in an upright position and attach two

diagonal braces (02) to each base leg and post using bolts

(03), washers (04), lock washers (05) and nuts (06).

3.4. Attach the upper cross beam (20) to the left and right posts

(09) using bolts (16), washers (17), lock washers (18) and

nuts (19). Place the bolt heads on the inside of the frame.

3.5. Bolt the ram (15) to the underside of the plate welded into the

centre of the cross beam using four M10 hex socket cap

bolts with washers (04), lock washers (05) and nuts (06).

Ensure that the ram goes on the right way round so that the

pressure gauge mounting tube protrudes through the hole in

the plate.

3.6. Insert the nylon sealing ring (22) into the internal thread of

the fitting on the mounting tube and screw the pressure

gauge (23) into the fitting. Before tightening the fitting make

sure that the gauge is facing in the best direction for viewing

during operation.

3.7. Take note of which side the ram inlet port is facing and mount

the pump assembly (26) onto the adjacent post using the

upper two joining plates. Fix in position using four M10 x 20

bolts (25) washers (04) and lock washers (05). The pumping

handle should be at the base of the pump.

3.8. Connect the hydraulic hose (24) to the ram inlet port.

3.9. To mount the work table first slide a frame pin (10) through

each post ensuring they are both at the same height.

#Familiarise yourself with the applications, limitations and hazards

of the press.

#Maintain the press in good condition (use an authorised service

agent).

#Replace or repair damaged parts. Use recommended parts only.

Unauthorised parts may be dangerous and will invalidate the

warranty.

#Keep the press clean for best and safest performance.

#Locate the press in a suitable work area, on a surface that is

stable, level, dry, not slippery, and capable of sustaining the load.

Keep area clean and tidy and free from unrelated materials, and

ensure there is adequate lighting.

$WARNING! Always wear approved eye or face protection when

operating the press.

#Remove ill fitting clothing. Remove ties, watches, rings and other

loose jewellery, and contain long hair.

#Keep hands and body clear of the work table when operating the press.

#Maintain correct balance and footing. Do not over reach. Ensure

the floor is not slippery and wear non-slip shoes.

#Keep children and unauthorised persons away from the working area.

%DO NOT use the press for a task it is not designed to perform.

%DO NOT adjust or tamper with the safety valve, or make any

modifications to the press.

%DO NOT exceed the rated capacity of the press. Avoid applying

excessive force, use the pressure gauge to determine the

applied load.

%DO NOT apply off-centre loads. Ensure that workpiece is centrally

loaded and correctly secured before operating the press.

%DO NOT allow the workpiece or the arbor plates to fall from the

press work bench.

%DO NOT get the press wet or use in damp or wet locations or

areas where there is condensation.

%DO NOT operate the press when you are tired or under the

influence of alcohol, drugs or intoxicating medication.

%DO NOT climb upon the press.

%DO NOT use if bent, broken, cracked, leaking or otherwise

damaged, or if press has been subjected to a shock load.

%DO NOT operate the press if any parts are missing as this may

cause failure and/or possible personal injury.

%DO NOT use the press to compress a spring or any other item

that could disengage and cause a hazard.

%DO NOT stand directly in front of loaded press and never leave

loaded press unattended.

%DO NOT allow untrained persons to operate the press.

$WARNING: DO NOT use brake fluid, or any fluid other than

a good quality jack oil, such as SEALEY HYDRAULIC JACK

OIL, as this may cause serious damage to the press and

will invalidate the warranty!

#When not in use, release pressure from the pump and clean the

press. Stand or store the support blocks in a safe location.

INSTRUCTIONS FOR :

30 TON HYDRAULIC FLOOR PRESS

MODEL :YK30F

YK30F.- 1 - 140607

2.1. GENERAL INFORMATION

Sealey heavy-duty floor hydraulic presses are ideal for a variety

of workshop applications and are particularly suited to

agricultural or industrial use. Jobs such as straightening,

bending, folding, punching, pressing etc. are some of the tasks

that may be accomplished with this press. Fitted with a pressure

gauge and supplied with work table arbors. Detachable pump

and ram allowing hydraulics to be used for other purposes when

press is not in use.