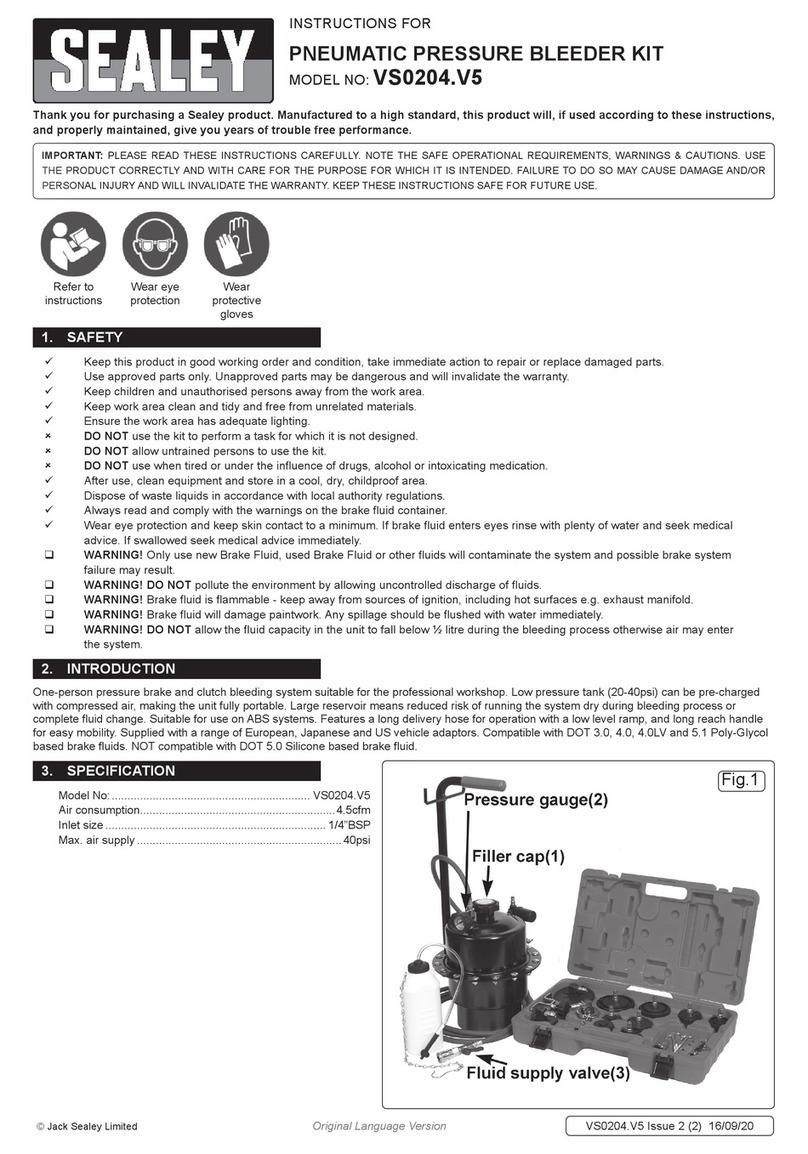

fig.1

fig.2fig.3

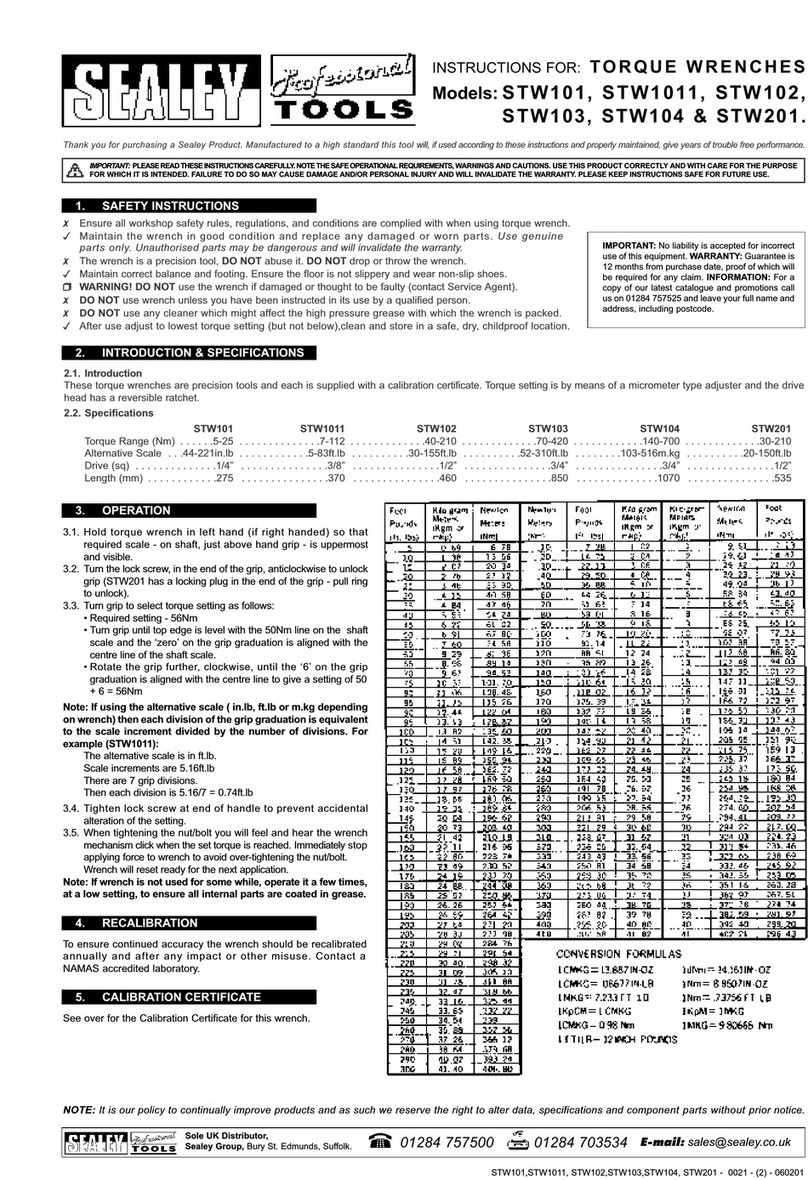

Original Language Version

© Jack Sealey Limited

5. OPERATION

5.1. BRAKE BLEEDING PROCEDURE

5.1.1. Refer to the vehicle manufacturer’s instructions for brake bleeding and wheel sequence before proceeding.

WARNING! Familiarise yourself with the hazards of brake uid - read manufacturers instructions on the container. DO NOT touch the

vehicle’s brake pedal whilst bleeding the brakes.

5.1.2. Remove the cap of the vehicle’s brake uid reservoir. If the uid level is not at maximum top it up.

5.1.3. Remove the cap assembly (g.1-A) from the replenishment bottle and invert it within the neck of the reservoir as shown in g.1. The

threaded outlet ‘B’ must be immersed in the brake uid. If it is not, rotate the three legged moulding ‘C’ clockwise towards the valve ‘D’

until sufcient thread is exposed to allow the outlet to be immersed in the brake uid.

5.1.4. Ensure the valve is closed as shown in g.1-D.

5.1.5. Fill the replenishment bottle just under half full with new brake uid and screw the cap assembly back down onto the bottle. Invert

the bottle over your container of new brake uid and open the valve so that the uid level begins to drop towards the level marked on

the bottle. As soon as the level mark is reached close the valve.

5.1.6. Place the bottle into the neck of the vehicle brake uid reservoir as shown in g.1. and open the valve. As the brakes are bled the uid

level in the reservoir will begin to drop and expose the bottle outlet. Brake uid will begin to ow from the replenishment bottle. Once

the level in the reservoir has risen sufciently to cover the outlet the ow will automatically stop.

5.1.7. Connect the brake bleeder to a suitable compressed air supply.

5.1.8. Mount the black rubber pipe onto the brake nipple on the rst wheel and open the nipple about ¼ of a turn (g.2).

5.1.9. Activate the brake bleeder’s trigger. The vacuum created will draw the brake uid from the vehicle’s brake system.

5.1.10. Continue to bleed the system until there are no air bubbles visible in the clear tube (g.3).

5.1.11. Close the brake nipple (g.2).

5.1.12. Remove the rubber pipe from the brake nipple.

5.1.13. Depress the trigger to clear brake uid from the clear pipe.

5.1.14. Repeat the process at each wheel in turn.

5.2. CHANGING THE BRAKE FLUID

5.2.1. Repeat the brake bleeding procedure as described above. As the uid is being completely changed regularly check the level in the

replenishment bottle.

5.2.2. When new uid can be seen in the clear tube tighten the brake nipple.

5.2.3. Repeat this procedure at every wheel. When brake bleeding and/or uid changing is complete, test the action of the brake pedal to

ensure that the brakes are working correctly, before driving the vehicle on the road.

.

VS021.V3 | Issue:3 (H,F) 22/08/19

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.