3/4”SQ DRIVE BREAKBACK TORQUE WRENCH

300-1000NM

MODEL NO:STW501

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURYAND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Refer to

instruction

manual

Original Language Version

© Jack Sealey Limited

Wear eye

protection

1. SAFETY

9Ensure all workshop safety rules, regulations, and conditions are complied with when using the torque wrench.

9Maintain the wrench in good condition and replace any damaged or worn parts. Use genuine parts only. Unauthorised parts may be

dangerous and will invalidate the warranty.

9The wrench is a precision tool, handle with care.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9If it is suspect that the wrench is damaged or faulty, have it checked by Sealey or one of our Service Agents.

8DO NOT use wrench unless you have been instructed in its use by a qualified person.

8DO NOT use any cleaner which might affect the high pressure grease with which the wrench is packed.

8DO NOT use torque wrench as a lever bar.

8Use of damaged hand tools, sockets, extensions and accessories may result in injury.

8DO NOT use torque wrench as a hammer.

8Torque wrenches not in calibration may cause damage to parts or tools.

8DO NOT use extensions on handle as damage to torque wrench will result and will invalidate the Warranty.

8Over tightening of fasteners may result in breakage.

8Handle is not insulated, do not use on live electrical or high voltage circuits.

2. INSTRUCTIONS

Range 300-1000Nm (200-750 lbf.ft). Scales graduated in both lb.ft and Nm giving accurate results to ±4%. Calibration

tolerance in accordance with BS EN ISO 6789:2017. Every wrench is tested and supplied with an individually numbered test

certicate.Breakbackdesignsignicantlyreducestheriskofovertorquing.Ratchetheadfeaturespush-throughdrivetoallow

torquing either clockwise or anti-clockwise. Comfortable soft grip handle. Supplied with additional tool to drive the external nut at

base of grip clockwise/anti-clockwise for easy torque adjustment/setting. Supplied in storage case.

3. SPECIFICATION

Model No:........................................................ STW501

Drive ................................................................... 3/4”Sq

Length..............................................................1550mm

Range .................................. 300-1000Nm(200-750lb.ft)

4. ASSEMBLY

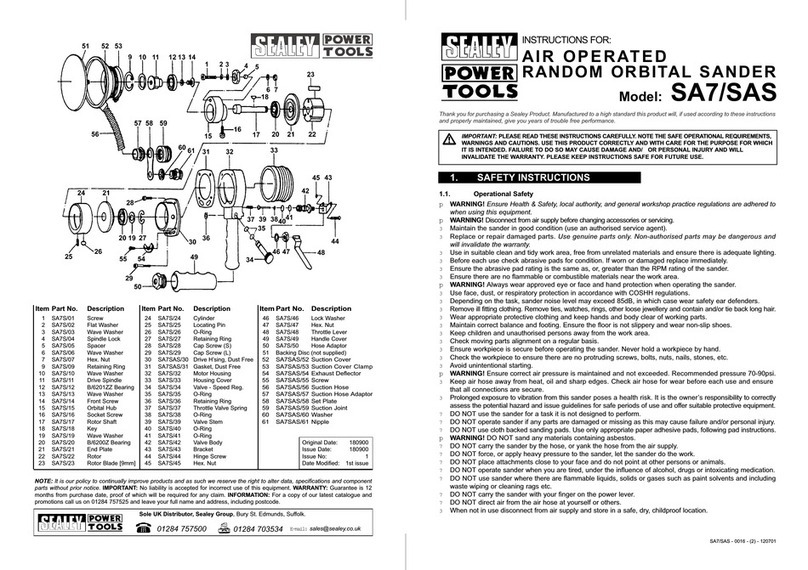

Push in Pin locator (Fig1.1) and push bar (Fig1.2) into ratchet head (Fig1.3) making sure that the pin clicks into place. The assembled bar

willlookasin(g2).

g.2

g.1

13

2

STW501 Issue:3 (2,5) 19/01/23