5. OPERATION

STW291 Issue No.1 28/06/12

Original Language Version

© Jack Sealey Limited

NOTE: ENERGY SAVINGS FUNCTION:

If left on and unused, the torque adaptor will turn off

automatically after a period of 4 minutes.

5.1 PREPARATION:

5.1.1 Unscrew the battery cover and install the two batteries

supplied as shown below, ensuring the correct polarity

as indicated in g.1A. Rex the battery cover as shown

in g.1B.

5.4.1 This value can then be stored by pressing the “ M/u “

button. Once the value is stored, taking 2 to 3 secs, the

display will revert to “ 000.0 “.

5.4.2 If you attempt to store a torque value that is below the

minimum value or above the maximum value dened in

the specication, the abbreviation “Erro” will be shown

on the display. After 1 second, the torque adaptor will

revert to torque measuring mode. The preset value will

not have been stored, and the warning indicators will

not work until a valid value has been stored.

5.5 (b) ANGLE setting mode:

NOTE: Before setting the angle, the adaptor (with

wrench and socket attached) should be positioned onto

the tting to be tightened so that the adaptor has a

datum starting point against which to set the angle.

5.5.1 To set the angle value, press the “ “ button for 2

seconds. (NOTE: If no buttons are then pressed, the

display will revert to zero after 6 seconds).

5.5.2 The display will initially show “ SET “ for 1 second and

then revert to the last saved angle or “ 0° “. ( To zero

the last saved angle setting press the “ “ button).

By repeatedly pressing the “ “ button, the angle

value will be progressively increased until the required

angle value is reached.

5.5.3 This value can then be stored by pressing the “ M/u “

button. Once the value is stored, taking 2 to 3 secs, the

display will revert to “ 0° “.

5.5.4 When in ANGLE measuring mode the direction of

rotation of the adaptor can be changed from clockwise

(CW) to counterclockwise (CCW) and back again by

pressing the “ M/u “ button

5.6 Mode Select:

5.6.1 The “TRACK” mode is the default when the torque

adaptor is switched on. In “TRACK” mode the display

shows the reading in real time during the torque

process both when the pressure is increased or

released. When the programmed value is reached the

unit signals both audibly and visually whilst the adaptor

is under pressure. As soon as the pressure is released

the display reverts to zero

5.6.2 Press the “M/u” button to shift into “PEAK” mode. The

display shows “peak” in the top left of the display.

5.6.3 In “PEAK” mode the display will always hold the current

value reached, even if the pressure is slightly released.

When the programmed value is achieved, the unit

signals both audibly and visually and the value shown

on the display will begin to ash after approx. one

second. If further pressure is applied after the

programmed value has been reached the unit assumes

that further torque is to be applied up to the current

programmed value and the display again shows torque

ascending from zero. Alternatively, you can zero the

display and apply the programmed torque to another

xing.

5.7 Turning the display illumination on/off.

The display illumination can be turned on prior to or

after programming the torque. In order to do this, press

and hold the “ “ button for 2 Secs.

5.8 OPERATION:

5.8.1 When you approach within +/- 5 Nm of the programmed

torque value the unit will beep intermittently.

5.8.2 When you approach within +/- 2 Nm of the programmed

value the unit will emit a quicker sound sequence.

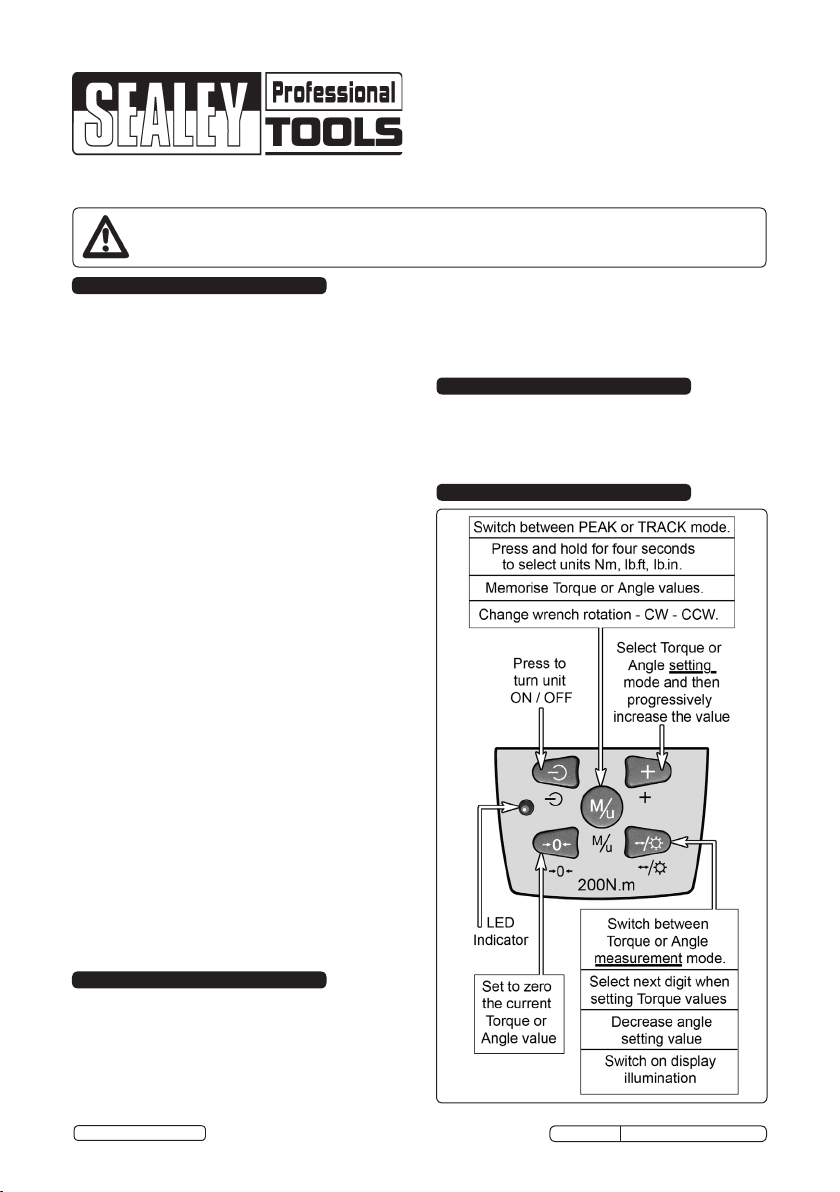

g.1

5.1.2 Press the ON/OFF button once to turn the meter on.

The display will initially show four zeros (“0000”) before

reverting to a “0.0” torque reading.

5.1.3 To select the required unit of measurement, press and

hold the “M/u” button for 4 seconds. As soon as the

display jumps to the next unit of measurement let go of

the button. Repeat this process until the display shows

the unit you require. ( Nm / lb.ft / lb.in ).

5.1.4 Ascertain the correct size and type of socket for the

xing to be tightened and attach it to the square drive

connection (1/2” ) at the base of the adaptor.

5.1.5 Insert the required ratchet wrench/drive bar into the

socket at the top of the adaptor. Do not use a tool that

will allow you to apply excessive force through the

adaptor.

5.2 SELECTING THE TORQUE OR ANGLE

MEASUREMENT MODE:

5.2.1 By default, the adaptor switches on in Torque

Measurement Mode. Press “ “ button to switch

to Angle Measurement Mode or back into Torque

Measurement Mode when required.

5.3 SETTING THE TORQUE OR ANGLE VALUE:

5.3.1 In order to set the torque or angle value, press the

“ “ button for 2 seconds. NOTE: If no buttons are

then pressed, the display will revert to zero after 6

seconds.

5.4 (a) TORQUE setting mode: The display will initially

show “ SET “ for 1 second and then revert to the last

saved torque or “ 000.0 “. The rst digit of this value

( “000.0“ ) will be ashing, indicating that the value can

now be set/altered. ( To zero the last saved torque

setting press the “ “ button ). By repeatedly

pressing the “ “ button, the value of the ashing

digit will be progressively increased. When the

required value is reached, press the “ “ button to

move to the next digit. Repeat this process for all digits

(ones, tens, hundreds etc) until the desired value has

been set.