TS1098 - 0016 - (2) - 140700

2. INTRODUCTION & DESCRIPTION

The TS10/98 Professional quality table top

saw is fully approved to CE regulations and

backed by independent laboratory

certification. Compound angle cutting

permitted by full tilt and height adjustment

of up to 450of cutting arbor. The unit is fitted

with a No-Volt safety switch and approved

splitter for added user safety.

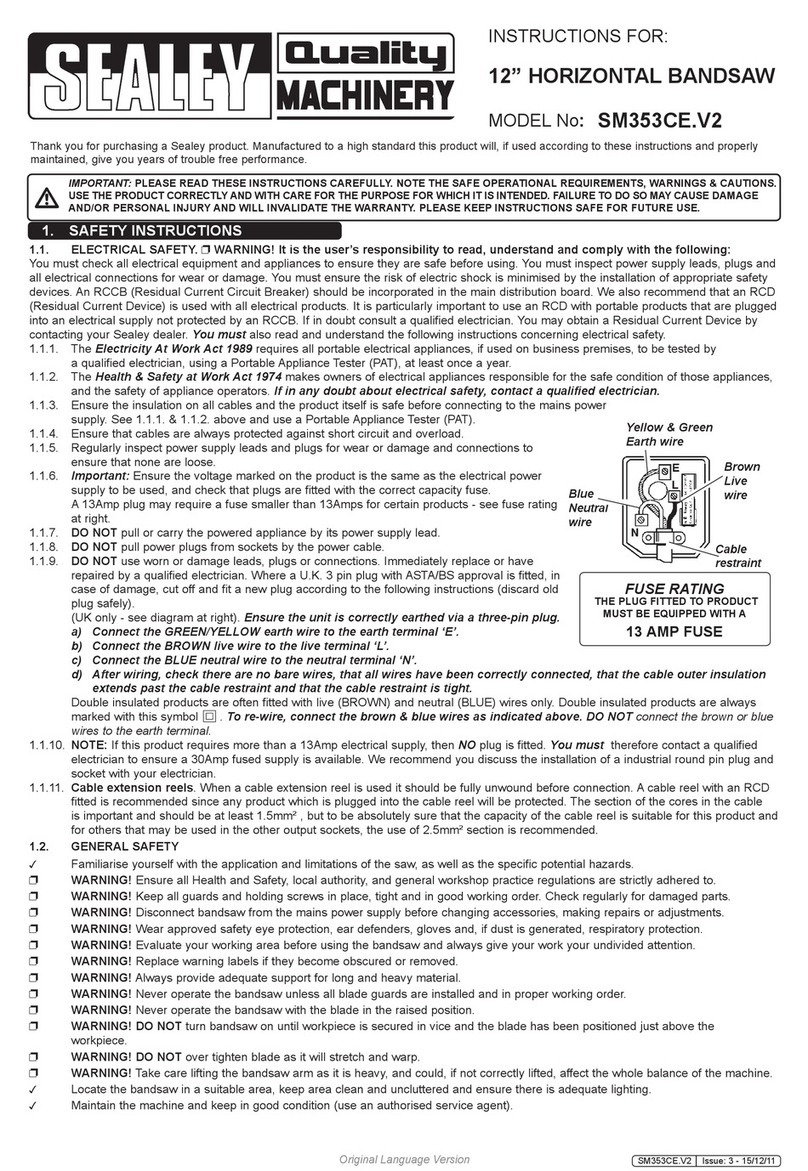

1. Support table.

2. Blade guard with splitter.

3. Mitre gauge.

4. Self-aligning fence with lock.

5. Mounting base holes.

6. Blade tilt & height handle.

7. On/Off switch.

8. Base cover (on the underside of unit).

9. Mitre slot (left, the right slot is obscured by the fence).

10. Tilt locking knob.

3Replace or repair damaged parts. Use recommended parts only. Non authorised parts may be dangerous and will invalidate the warranty.

pWARNING! Keep all guards and holding screws in place, tight and in good working order. Check regularly for damaged parts.

A guard or any other part that is damaged should be checked to ensure that it will operate properly and perform its intended function

before the tool is used. The safety guard is a mandatory fitting where saw is used in premises covered by the Health & Safety at Work Act.

3Before commencing work, ensure the saw blade is set to cut in the correct direction, securely fastened, sharp and is compatible with the

machine, spindle speed, and the material to be cut. Never use saw blade if damaged, bent or warped. Use only recommended saw blades.

3Remove adjusting keys and wrenches from the machine and its vicinity before turning it on.

3Machine operators must have received sufficient training and instructions as to the dangers arising in connection with the machine, the

precautions to be observed and the requirements of the Wood working Machines Regulations which apply, operators must under

the adequate supervision of a person who has a thorough knowledge and experience of the machine and the required guards.

pWARNING! Wear approved safety eye protection, ear defenders, and if dust is generated respiratory protection.

3Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery, and contain long hair.

3Keep hands and body clear of the work table when operating the saw.

3Maintain correct balance and footing. Ensure the floor is not slippery and wear non slip shoes.

3Keep children and unauthorised persons away from the working area.

3Avoid unintentional starting and never leave the saw operating whilst unattended.

7DO NOT force the saw to achieve a task it was not designed to perform, and ensure operators are trained to use the saw.

7DO NOT get the saw wet or use in damp or wet locations or areas where there is condensation.

7DO NOT use saw where there is flammable liquids, solids or gases such as paint solvents, including waste wiping or cleaning rags etc.

7DO NOT operate the saw if any parts are damaged or missing as this may cause failure or possible personal injury.

7DO NOT operate the saw when you are tired, under the influence of alcohol, drugs or intoxicating medication.

1.3. SPECIFIC SAW SAFETY RULES

3Remove sawdust frequently. Unplug from mains power. Clean out sawdust from interior of saw to prevent potential fire hazard.

3Keep splitter and anti-kickback fingers and guard in place and operational, and replace table insert when worn.

3Ensure you select the appropriate saw blade for the material to be cut.

pWARNING! Before each use, check that the saw blade is secure and not worn or damaged.

3Use the guard, splitter and anti-kickback fingers on all through-sawing operations. Through-sawing operations are those when the blade cuts

completely through the workpiece as in ripping or cross-cutting.

3Check workpiece to ensure there are no nails or other items which may foul on the saw blade.

3Hold the work firmly against the mitre gauge or fence.

3Only feed the workpiece into the blade against the rotation of the blade.

3When cutting moulding, never run the stock between the fence and the moulding cutter-head.

3Avoid subjecting the saw blade to excessive strain, never force a workpiece. Maintain a controlled adequate progression.

3Should a saw blade jam switch the power off immediately to prevent damage to the motor.

3TO AVOID WORKPIECE KICKBACK (When a workpiece is violently thrown back toward yourself).

a) Keep the blade sharp. b) Keep rip fence parallel to the saw blade. c) DO NOT release the workpiece before it is pushed all the way

past the saw blade. d) DO NOT rip work that is twisted or warped or does not have a straight edge to guide along the fence.

3Use a push stick for ripping narrow stock. refer to ripping applications and push stick patterns in manual relating to the use of push stick.

3Provide adequate support to the rear and sides of the saw table for wide or long workpieces.

7DO NOT use your hands (free-hand) to guide the workpiece. Hold work firmly against the mitre or fence to guide work through the saw.

7DO NOT place yourself in an awkward operating position where a sudden slip could cause your hand to move into the cutting blade.

7DO NOT stand or have any part of your body in line with the path of the saw blade, and keep your hands out of the line of the saw blade.

7DO NOT use the fence as a cut-off gauge when cross-cutting.

7DO NOT hold what will become the off-cut (the waste part of workpiece).

pWARNING! DO NOT reach behind or over the saw blade with your hand or arms.

pWARNING! DO NOT attempt to free a jammed saw blade without first switching off or removing the plug from the mains power supply.

7DO NOT cut metal materials, and substances that may produce toxic dust. Saw must only be used to cut wood or wood type substances.

7DO NOT use solvents to clean plastic parts which may damage them. Use a soft damp cloth only.

3Store blades in a safe, dry childproof location.

3When not in use switch the saw off, remove plug from the power supply. ,

9

10