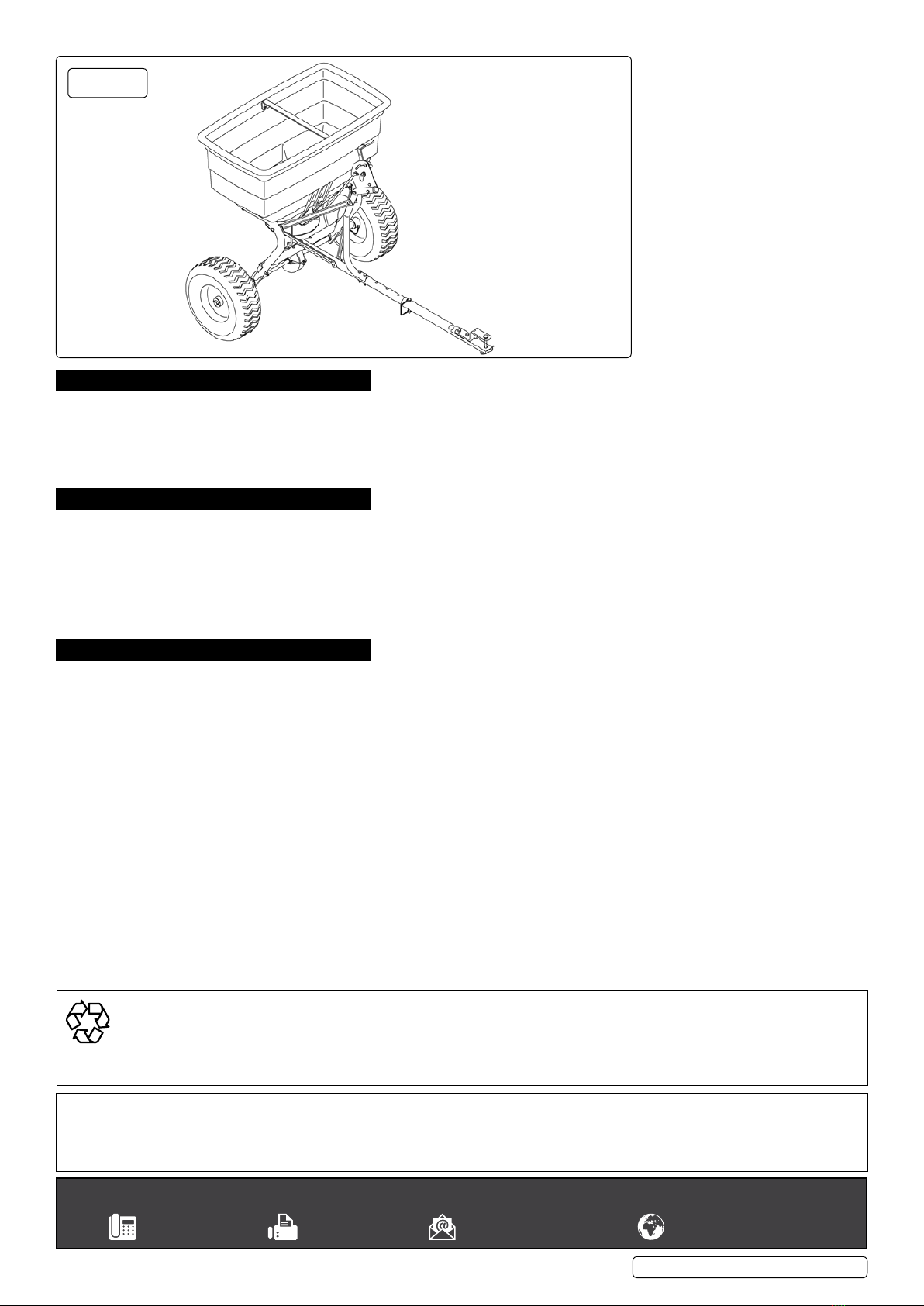

80KG TOW BEHIND BROADCAST SPREADER

MODEL NO: SPB80T.V2

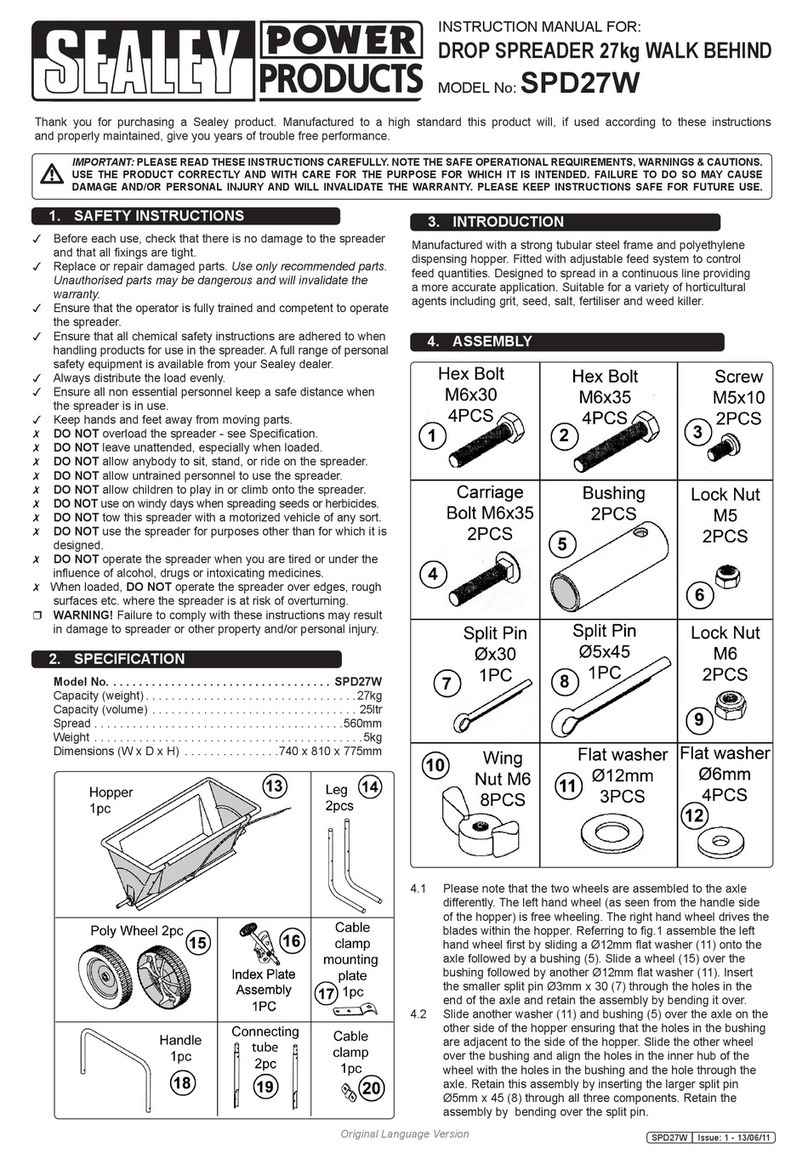

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

9Ensure that the spreader is in sound condition and good working order before use.

9Ensure that the operator is fully trained and competent to operate the prime mover before attaching and using the spreader.

9Ensure that all chemical safety instructions are adhered to when handling products for use in the spreader. A full range of personal safety

equipment is available from your Sealey stockist.

9Always distribute the load evenly.

9Ensure all non essential personnel keep a safe distance when the spreader is in use.

9Replace or repair damaged parts. Use only recommended parts. Unauthorised parts may be dangerous and will invalidate the warranty.

9Keep hands and feet away from moving parts.

8DO NOT overload the spreader - see Specification.

8DO NOT leave unattended, especially when loaded, unless the wheels are chocked or the spreader is otherwise secured.

8DO NOT allow anyone to ride on the spreader.

8DO NOT allow untrained personnel to use the spreader. DO NOT allow children to use the spreader.

8DO NOT use the spreader for purposes other than for which it is designed.

8DO NOT operate the spreader when you are tired or under the influence of alcohol, drugs or intoxicating medicines.

9When loaded, DO NOT operate the spreader over edges, rough surfaces etc. where the spreader is at risk of overturning.

WARNING! Failure to comply with these instructions may result in damage to spreader or other property and/or personal injury.

2. INTRODUCTION

Manufactured with a strong tubular steel frame and polypropylene dispensing hopper. Pin hitch design attaches to ride-on lawnmowers, can be

converted to ball hitch using Model No. TB36*. Fitted with aluminium gear, rain cover, pneumatic tyres and adjustable feed system. Includes

hopper screen to ease spreader ow and lter out unwanted contaminants. Sprays in 360° motion to cover a large area. Suitable for a variety of

horticultural agents including grit, seed, salt, fertilizer and weed killer.

* Some modication may be required

3. SPECIFICATION

Model no ..............................................................SPB80T.V2

Capacity (volume) ............................................................ 88L

Dimensions (W x D x H)........................880 x 1350 x 965mm

Spread ........................................................................3-3.6m

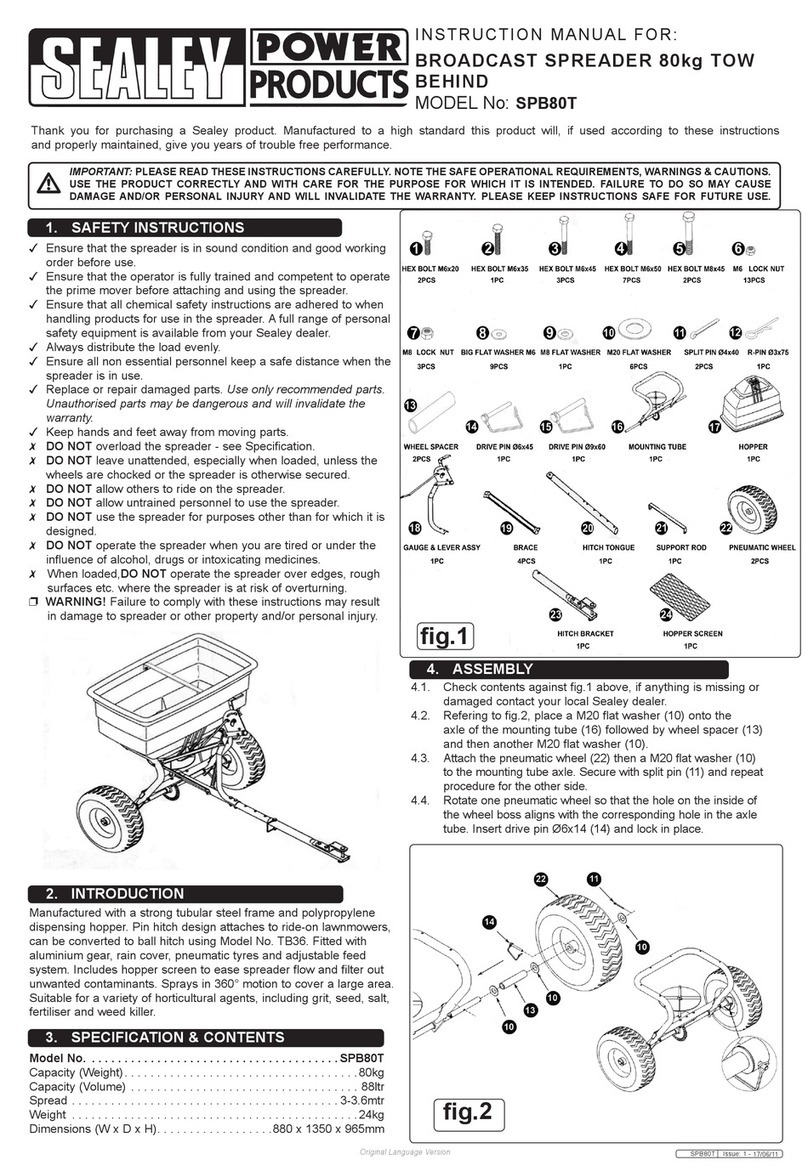

4. CONTENTS

Original Language Version

© Jack Sealey Limited

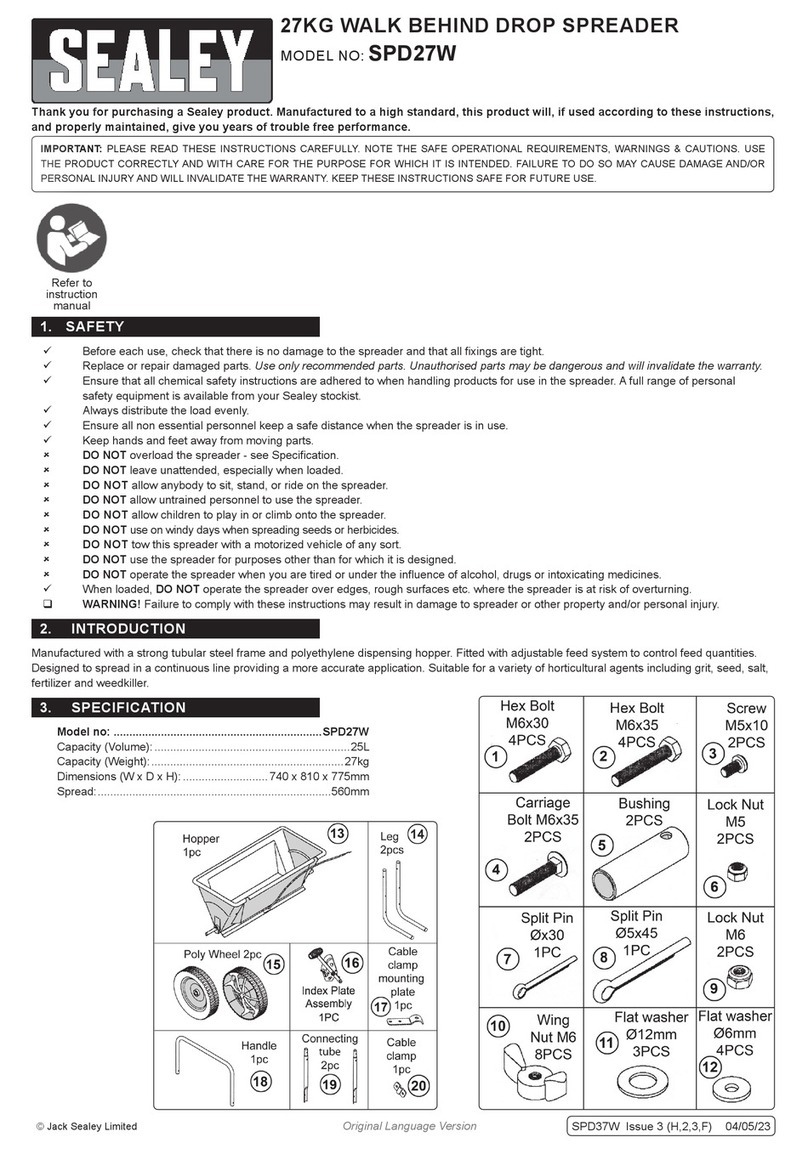

Refer to

instruction

manual

SPB80T.V2 | Issue:1 11/11/19