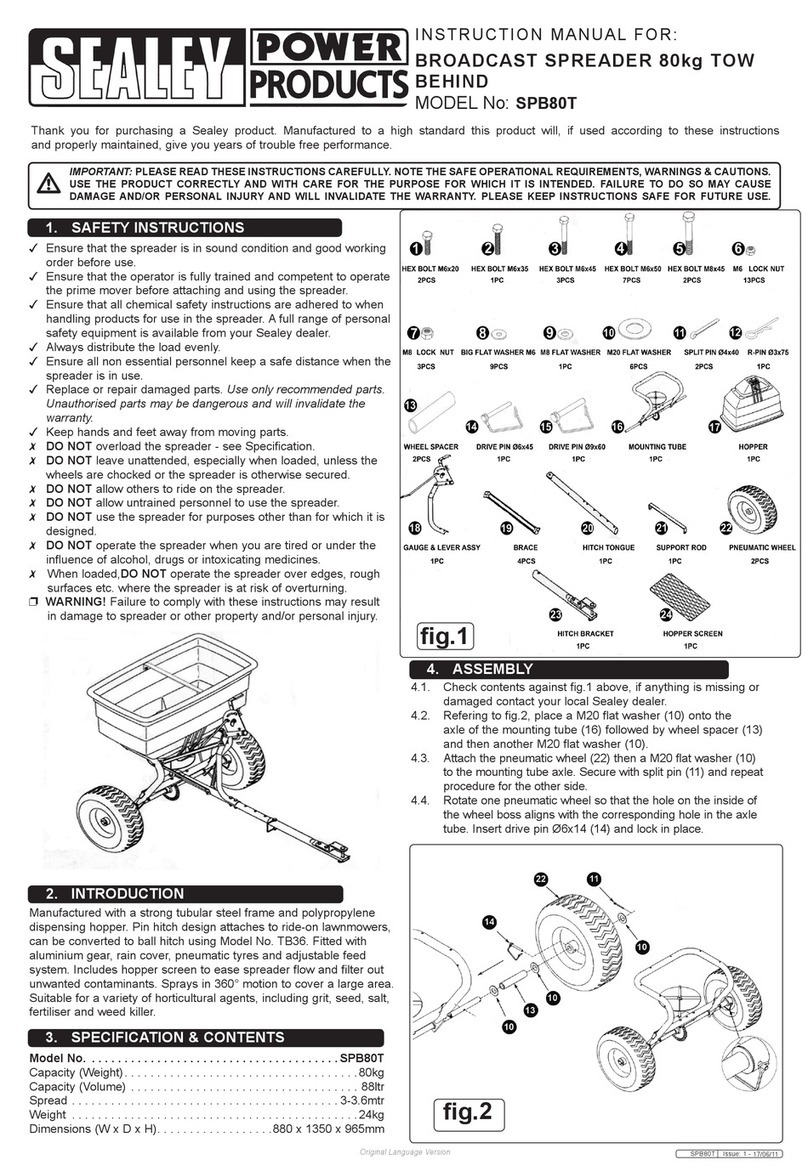

Original Language Version SPB57W Issue: 1 - 17/06/11

fig.5

5.1 USING THE SPREADER. (refer to fig.6)

WARNING! Do not use the spreader on windy days when

spreading grass seed or herbicides.

WARNING! Follow the fertiliser/material manufacturers

recommended coverage for each product. Over coverage

could result in damage to lawns etc. and contamination of

the area.

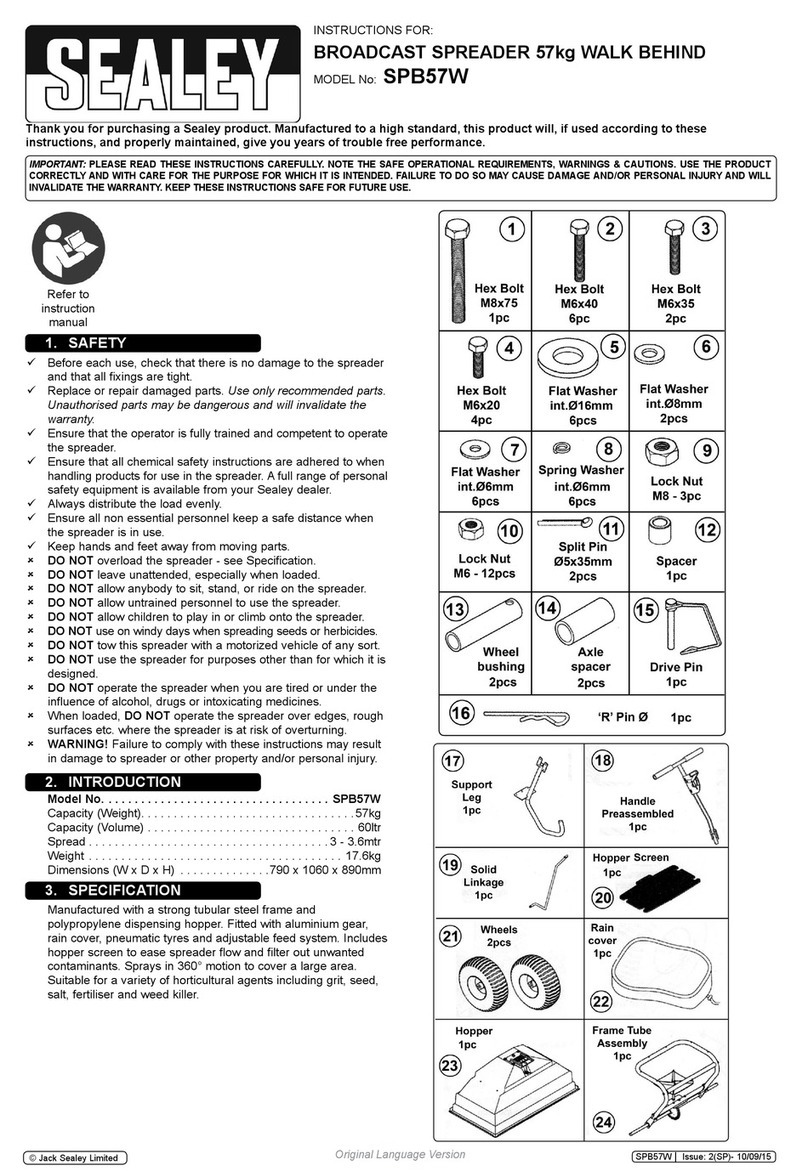

5.2 The spreader is designed for a variety of horticultural agents

including grit, seed, salt, and weed killer. Materials such as

powder, manure, top soil, gravel and mulch have the wrong

physical characteristics and should not be used with the

spreader.

5.3 Inspect the spreader before each use. Repair or replace any

damaged parts and check that the spreader is functioning

correctly.

5.4 Make sure the 'R' pin (16) is installed at the top of the gear

shaft within the hopper before using the spreader.

5.5 Before filling the hopper ensure that the flow control lever is in

the '0' position, i.e. the flow control plate must be closed.

5.6 Determine the approximate square footage of the area to be

covered and estimate the amount of material required by

referring to the manufacturers instructions. Break up any lumpy

fertiliser as you fill the hopper.

5.7 Always start walking prior to opening the flow control plate.

5.8 Every time you are ready to stop, or turn to make a new pass,

close the flow control plate to stop dispensing the material and

continue one more stride. This reduces waste and avoids

damaging a lawn with over saturated product coverage.

5.9 If spreading material is accidentally deposited too heavily in

a small area, soak the area with a garden hose or sprinkler to

prevent burning of the lawn.

5.10 To maintain the same coverage when walking at a different

speed, adjust the flow rate. Reduce the flow setting for slower

speeds and increase the flow setting for higher speeds.

5.11 Keep the impeller plate horizontal when operating the spreader.

Tilting the spreader will result in uneven coverage.

5.12 To ensure consistent coverage, make sure each broadcast

pattern slightly overlaps the previous one.

5.13 Make sure that any broadcast material does not come into

contact with trees, shrubs and flowers that could be harmed by

the material.

5.14 CALCULATING THE AMOUNT OF MATERIAL NEEDED.

(refer to Charts 'A' & 'B')

To calculate the amount of material needed e.g lawn fertiliser,

divide the coverage stated on the packaging by the weight of

the fertiliser bag. For example, a 10lb bag of fertiliser with a

coverage of 10,0000 sq. ft. will distribute 1lb of fertiliser every

1,000 sq.ft. at full rate or 1/2lb. of fertiliser every 1,000 sq. ft. at

half rate.

5.15 For pre-calculated rates see Chart 'A' (Example: A 25lb bag

with a 15,000 sq. ft. coverage requires 1.7lb of fertiliser per

1,000 sq.ft.

5.16 Use Chart 'B' to find the closest spreader setting. For example,

1.7lb per 1000 sq.ft. = spreader setting 8)

5. OPERATION

6. MAINTENANCE

6.1 After each use clean material out of hopper.

6.1.1 Rinse/dry inside and outside of spreader after each use.

6.1.2 Before operating make sure that the tyres are inflated to the

correct pressure i.e. 30psi.

6.1.3 Periodically check all fastenings are tight.

6.1.4 Annually clean and lightly lubricate parts.

6.1.5 Touch up all scratched or worn painted metal surfaces.

6.1.6 To avoid damaging the spreader never exceed the rated load

capacity of 57kg.

6.2 STORAGE.

6.2.1 Before storing ensure that the spreader is clean and dry.

6.2.2 Store indoors or in a protected area during severe weather and

in the winter months.

6.2.3 Never allow material to stay in the hopper for extended periods

of time.