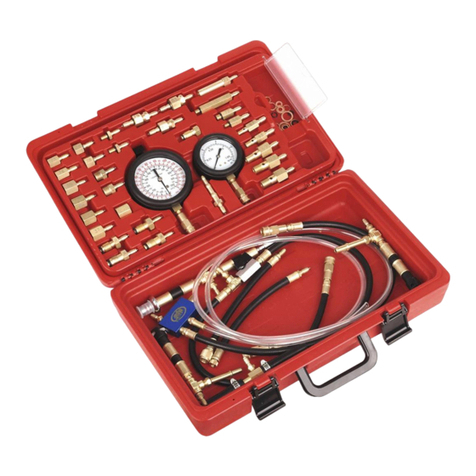

PETROL ENGINE COMPRESSION TEST KIT

3PC

MODEL NO: CT951.V4

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGEAND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure all Health & Safety, local authority and general workshop practice regulations are strictly adhered to when using

tools.

8DO NOT use tester if damaged.

8DO NOT use the tester for a task it is not designed to perform.

9Maintain the tester in good and clean condition for best and safest performance. Use an authorised service agent.

9Wear approved eye protection. A full range of personal safety equipment is available from your Sealey stockist.

9Wear suitable clothing to avoid snagging. Remove ties, watches, rings and other loose jewellery and contain long hair.

9 Maintaincorrectbalanceandfooting.Ensuretheoorisnotslipperyandwearnon-skidshoes.

9Account for all tools and equipment being used and do not leave them in, on or near engine.

9Keep the work area clean, uncluttered and ensure that there is adequate lighting.

8DO NOToperatethetoolwhenyouaretiredorundertheinuenceofalcohol,drugsorintoxicatingmedication.

9When not in use, place in original protective case and store in a safe, dry, childproof location.

9Always refer to the vehicle manufacturer’s service instructions or a proprietary manual, to establish the current procedure and data.

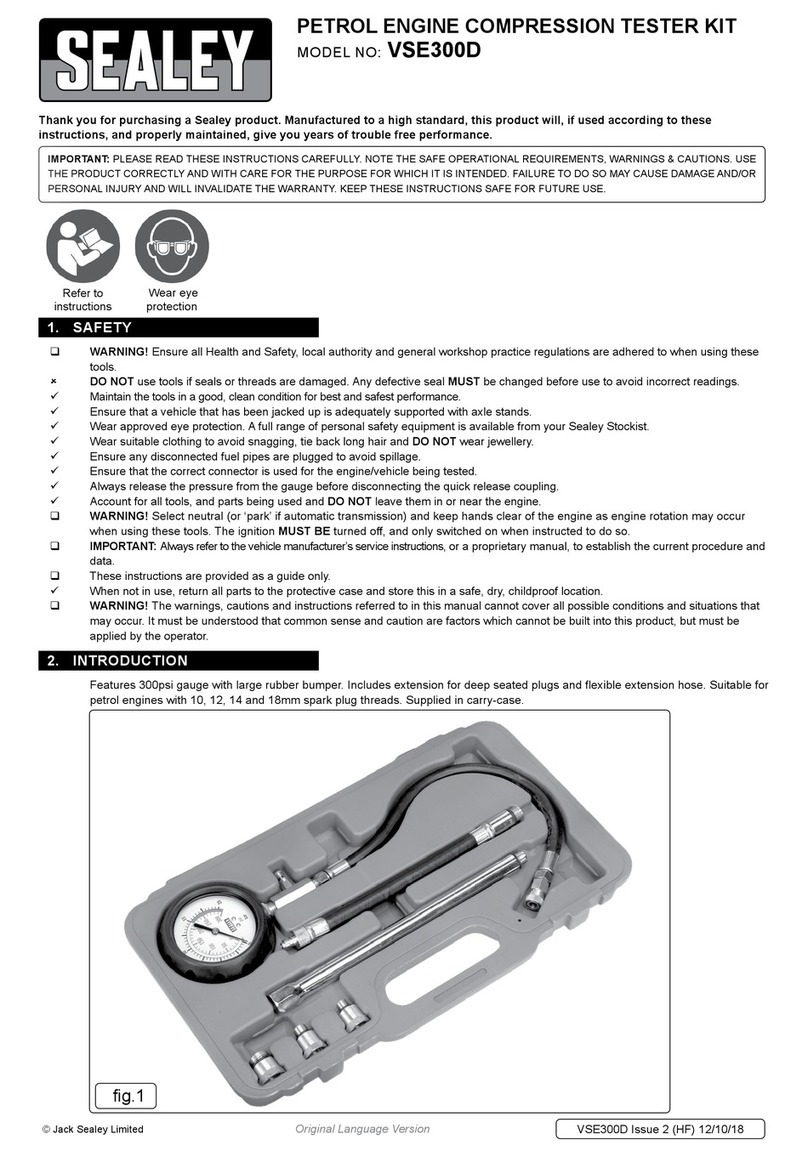

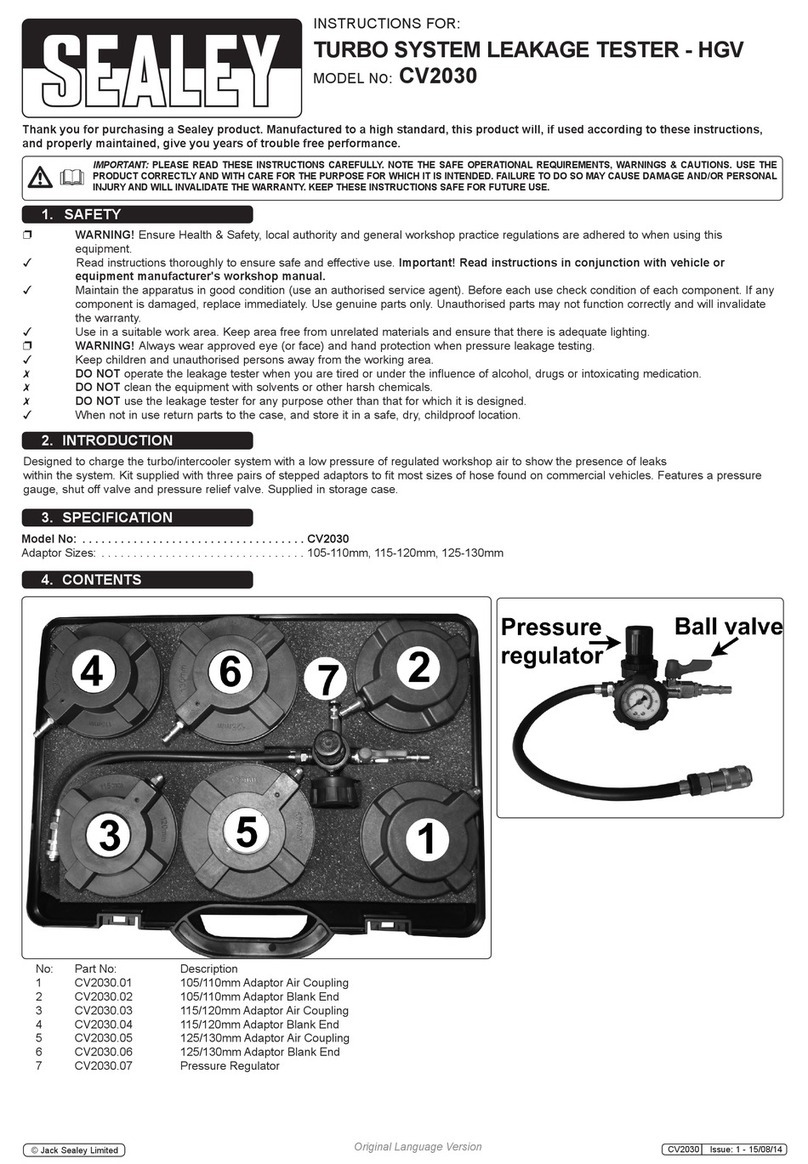

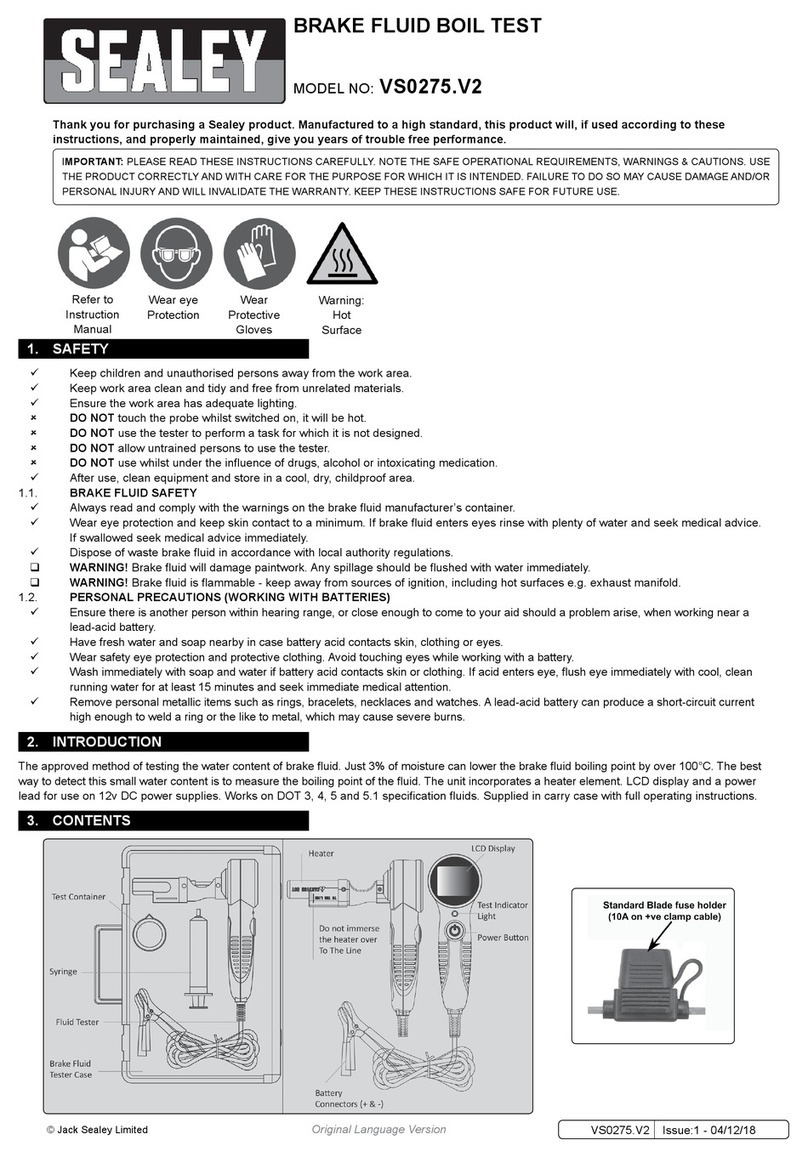

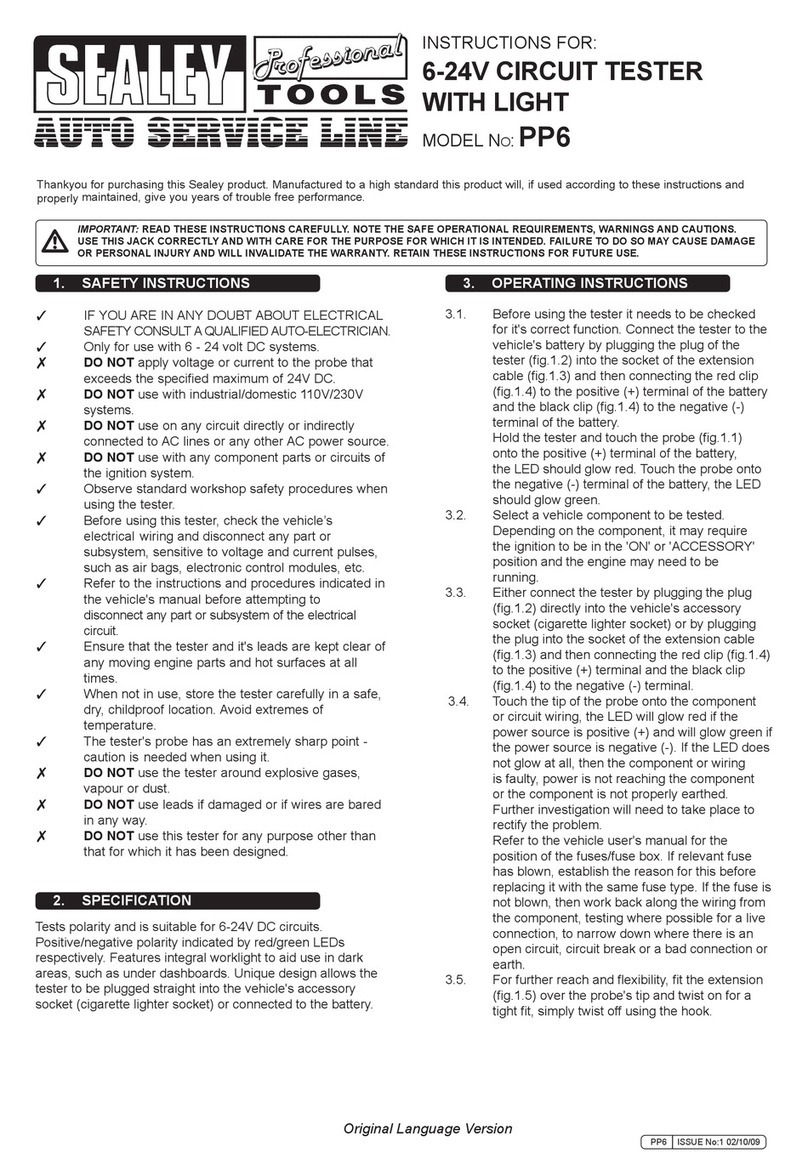

2. INTRODUCTION

Largeeasytoreadgaugewithimperialandmetricreadings.Sidereleasevalveand12”exiblehoseforeasyreach.Pressurerange

0-300psi/0-2000kpa.Screwin14and18mmadaptorsand150mmrigidstemconeadaptortsmostsparkplugholes.Suppliedinstorage

case.

3. OPERATION

3.1. PREPARATION

3.1.1. Run engine until normal operating temperature is achieved.

3.1.2. Stop engine, loosen spark plugs one turn, with an air hose, blow dirt and debris from the spark plug wells.

3.1.3. Remove all spark plugs.

3.1.4. Ifttedwithacarburettorsetthethrottlevalvewideopen.

WARNING! The ignition system MUST be disabled. Failure to disable could result in damage to the ignition system or ECU.

3.1.5. Unplug the low tension connections to the coil. If you aren’t sure how to disable the vehicle ignition system then consult the

manufacturer’s service instructions or a proprietary manual before you start. It is also good practice to unplug the fuel injectors or

disablethefuelpump,especiallyoncarsttedwithacatalyticconverter.Thispreventsunburnedfuelgettingintotheexhaustsystem

during the test.

3.2. COMPRESSION TEST

3.2.1. Usingtheappropriatethreadedadaptor,screwthetester(g1),intoasparkplughole(nger-tight-donotuseawrench)orusing

thepushtting(g2),holdthecompressiontesterrmlyagainstthesparkplugaperture.

3.2.2. Cranktheengineuntilnoincreaseinpressureisnotedonthegaugereading;usually3or4revolutionsissucient.Takeanoteofthe

pressure reading.

3.2.3. Decompresstesterbypressingreleasevalve(g1)removethecompressiontesterfromthesparkplugholeandproceedtothenext

cylinder. Note pressure reading for each cylinder.

NOTE: Theactualgureinpsiisnotimportant.Itisimportantthatallcylindershaveapproximatelythesamecompressionpressures.

Onhighcompressionengines(150psiandhigher)thepressureshouldnotvarymorethan15psifromthehighesttothelowest

cylinder reading.

Onlowcompressionengines(under150psi)thepressureshouldnotvarymorethan10psifromthehighesttothelowestcylinder

reading.

NOTE: Compression readings are unbalanced when one or two cylinders are considerably higher or lower than the others.

3.3. CAUSES OF UNBALANCE

3.3.1. Low cylinder compression is caused by leakage from:

A.HeadGasket-explosivesoundwhenrunningengine.

B.HeadGasketbetweencylinders-compressionwillbelowintwoadjacentcylindersandwatermayappearincylindersor

crankcase.

C. Valves that are not seating properly.

D.Pistonringsthatareworn.Pourateaspoonofoilintothesparkplugholetosealtherings.Repeattest.

CT951.V4Issue111/03/22

Original Language Version

© Jack Sealey Limited

Refer to

instructions Wear eye

protection Wear protective

gloves Wear safety

footwear Wear protective

clothing