© Jack Sealey Limited Original Language Version

INSTRUCTIONS FOR:

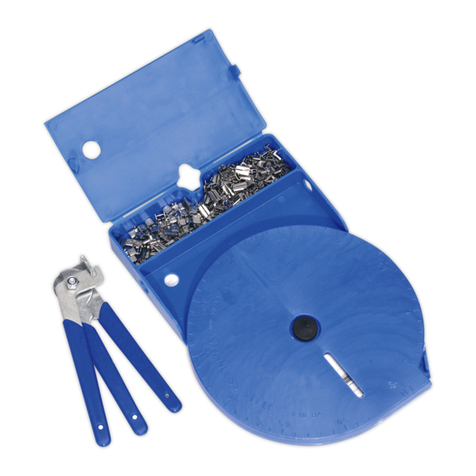

BRAKE AND CLUTCH BLEEDER

MODEL No: VS1205

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions

and maintained properly, give you years of trouble free performance.

Refer to Instruction

Manual

1. SAFETY

Keep this product in good working order and condition, take immediate action to repair or replace damaged parts.

Use approved parts only. Unapproved parts may be dangerous and will invalidate the warranty.

Keep children and unauthorised persons away from the work area.

Keep work area clean and tidy and free from unrelated materials.

Ensure the work area has adequate lighting.

DO NOT use the kit to perform a task for which it is not designed.

DO NOT allow untrained persons to use the kit.

DO NOT use when tired or under the influence of drugs, alcohol or intoxicating medication.

After use, clean equipment and store in a cool, dry, childproof area.

Dispose of waste liquids in accordance with local authority regulations.

Always read and comply with the warnings on the brake fluid container.

Wear eye protection and keep skin contact to a minimum. If brake fluid enters eyes rinse with plenty of water and seek medical advice.

If swallowed seek medical advice immediately.

WARNING! Only use new Brake Fluid, used Brake Fluid or other fluids will contaminate the system and possible brake system failure may

result.

WARNING! DO NOT pollute the environment by allowing uncontrolled discharge of fluids.

WARNING!Brake fluid is flammable - keep away from sources of ignition, including hot surfaces e.g. exhaust manifold.

WARNING!Brake fluid will damage paintwork. Any spillage should be flushed with water immediately.

2. INTRODUCTION

One-man brake and clutch bleeder. Bleeding requires no external power source - simply fill and pump. Bottle holds 400ml of hydraulic fluid.

Design incorporates pressure control valve set at 20psi. Pressure range makes unit suitable for use with ABS systems. Fitted with Ø42mm cap

which is suitable for most European models.

3. SPECIFICATION

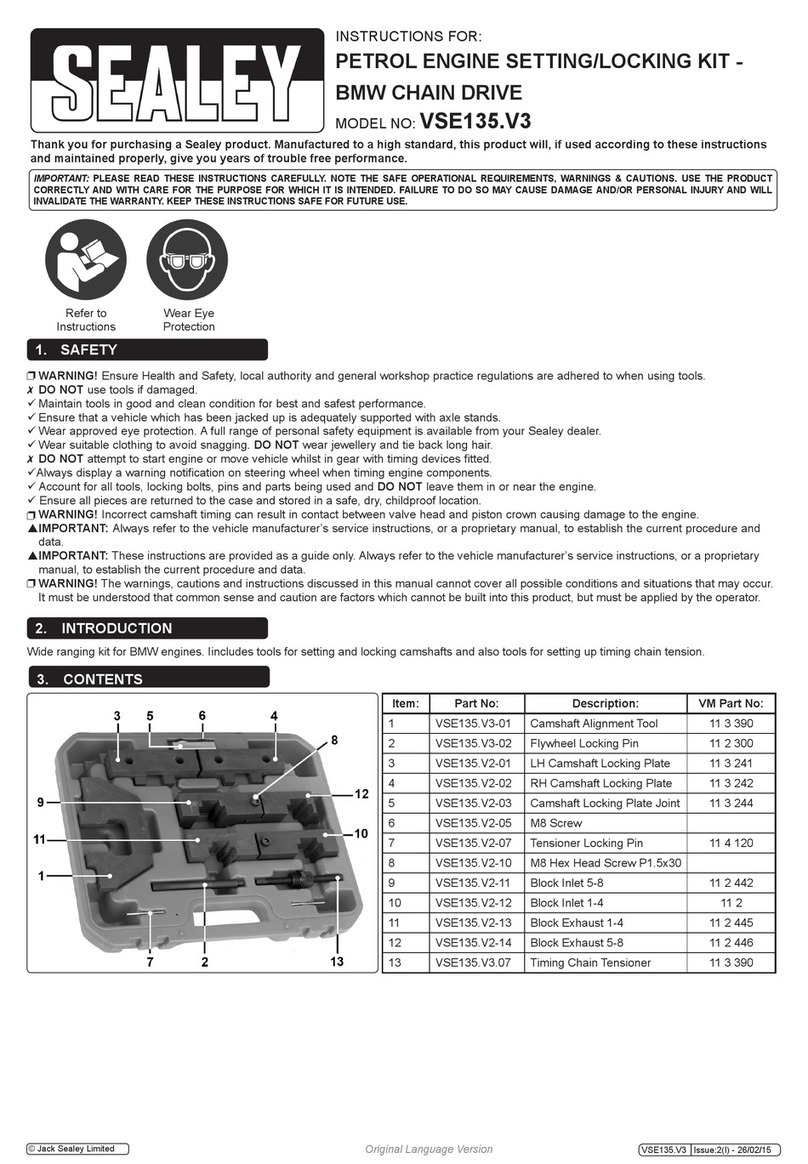

Model No: ..........................................................VS0205

Capacity..............................................................400ml

Maximum Pressure:.............................................. 1.4bar (20psi)

g.1

VS1205 Issue: 1 - 31/05/16