C/L

Trailing

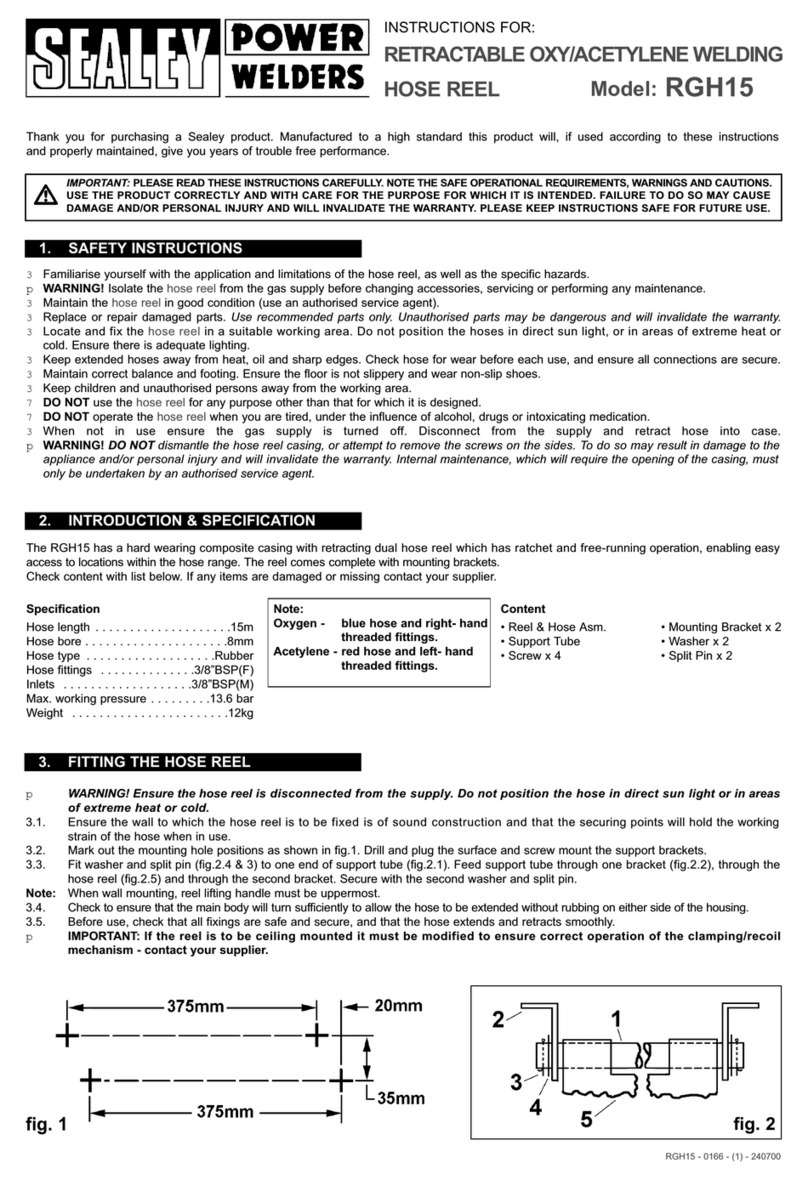

Arm (Fig.1)

Bush

steel

sleeve

Fig.7

Handbrake

cable bracket

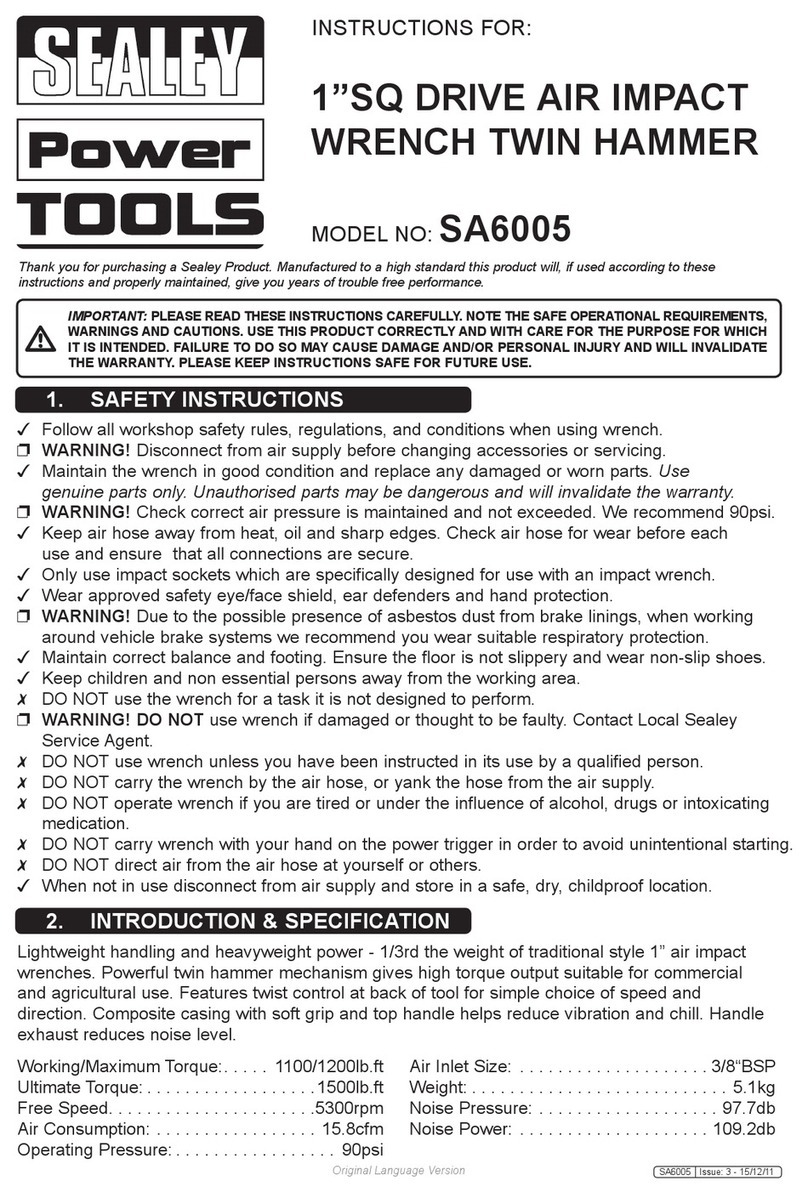

15mm 'C' ring Fig.8

15mm 'C' ring

registers in

c'bore

Cylindrical ram

concentric and

square with

bush sleeve.

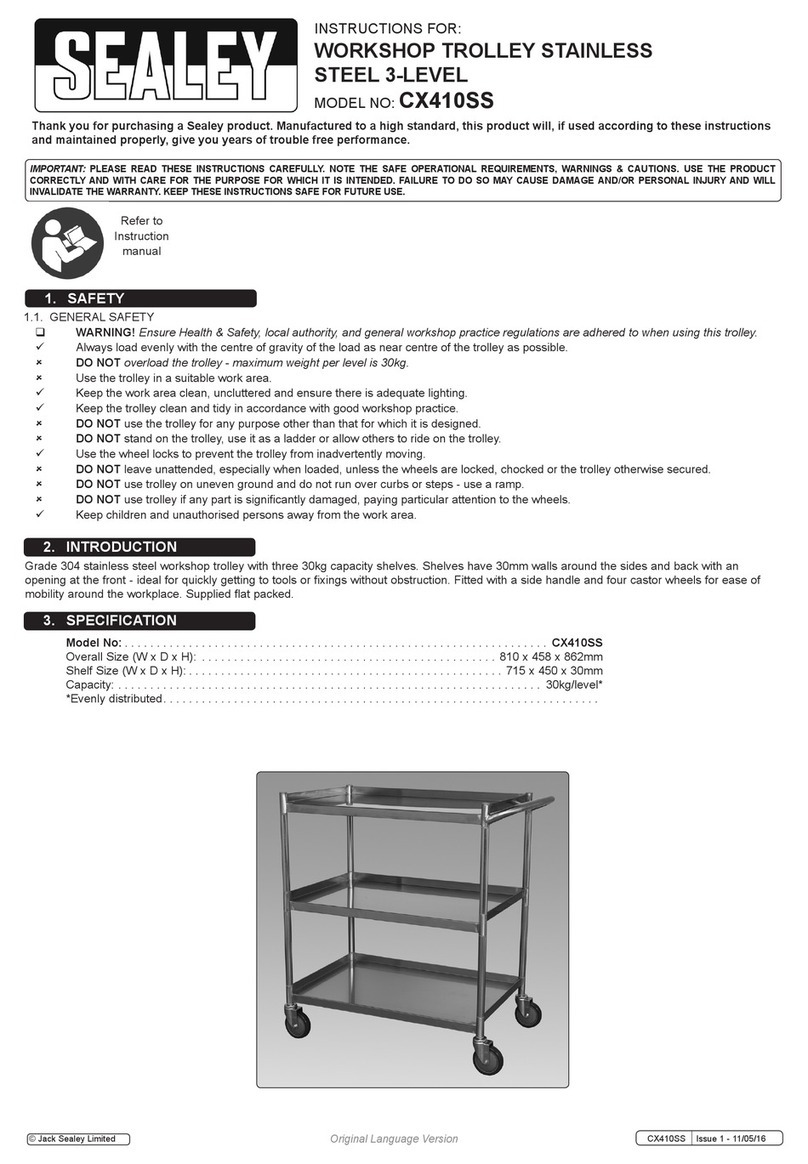

Press Frame Studs Fig.12

NOTE! It may be necessary to disassemble and reassemble

the press frame insitu when access is limited. A 17mm

spanner only required, the clear opening height is

governed by the studs.

VSE4784 Issue No.2 - 07/11/16

Original Language Version

©Jack Sealey Limited

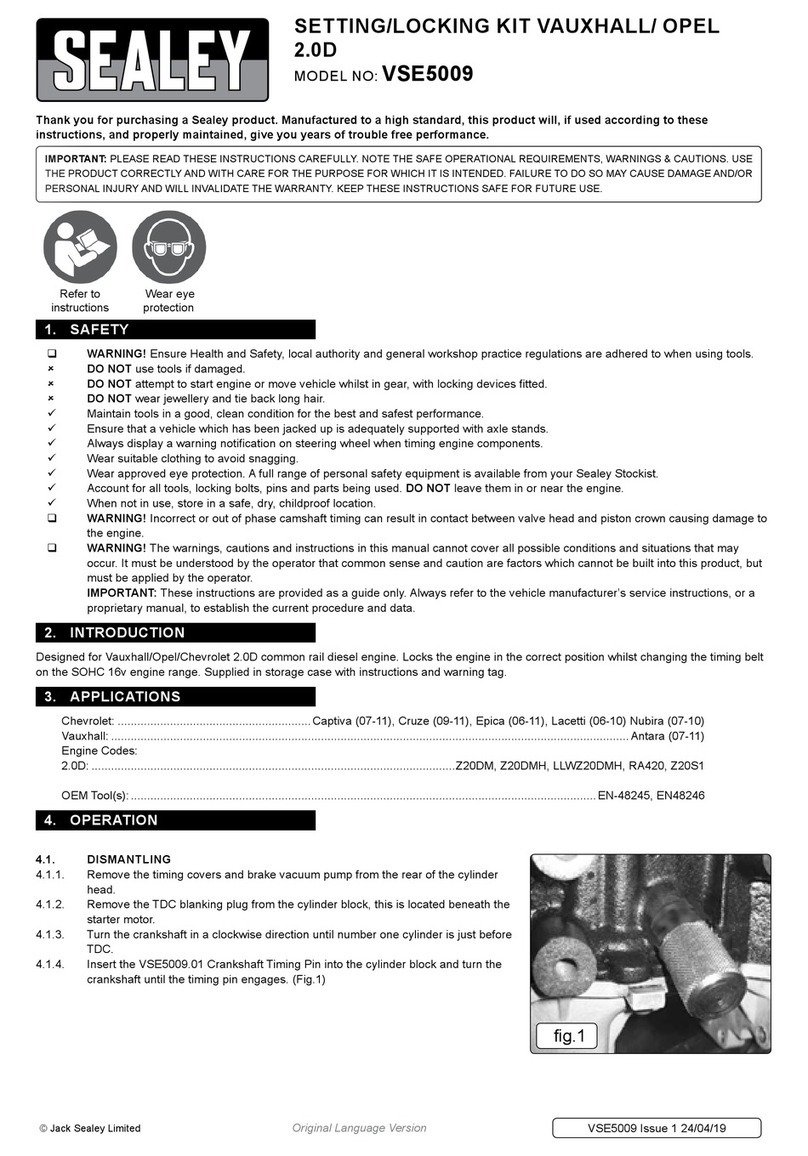

5.1 NOTE! Illustrations hereafter are with a section of the trailing arm removed

from the vehicle and are all "R" (offside) assembly. Refer to manufacturer's

service manual, or proprietary manual when using these instructions.

5.1.1 Jack up the vehicle, placing the jack clear of the rear suspension allowing it

to swing down.

5.1.2 Support the rear suspension whilst removing the trailing arm bush mounting

nuts,boltsandwashers.Unclipthehandbrakehoseandassociatedxings.

It may be necessary to remove further fastenings to allow the trailing arm

to fully sweep beneath the vehicle, enabling maximum access and

clearance for the bush extraction tool. Continue supporting the trailing arm

and controlling during lowering.

5.1.3 With the area around the suspension now clear we suggest a thorough

cleantoavoidaccumulateddebrisinterferringwithprecisiontting

processes.Sprayingaproprietory'freerelease'uidontothebushsleeve

and housing may assist with removal in 5.1.7.

5.1.4 Note the orientation of the existing bush before removal. The method of

marking is best decided by the engineer. A scribed line on the bush

sleeve><and a mirrored orientation mark on the housing would give an

accurate orientation, for example see Fig.7. See also the manufacturer's

instructions.

5.1.5 Offer the 15mm 'C' ring on to the pressed steel housing, aligning the gap

with the handbrake cable bracket. This will be held in place (Fig.8) by the

three permanent magnets inserted in the ring. Ensure it is seated correctly

on a grit free face.

5.1.6 Access and adequate clearance is essential for offering the bush press

assembly over the trailing arm and bush housing. Weave the bottom plate

end over the "Tee" plate (Fig.9) and locate the counterbore with the 'C' ring

(Fig.10). Continue to support the opposite end with your hand (Fig.11).

It may be necessary to disassemble and reassemble the press

frame insitu when access is limited.

5.1.7 Two people are now recommended, with one continuing to support the

press frame and the other positioning the adaptor (Fig.12), stepped end

inside the bush sleeve. The shoulder of the stepped end will offer thrust

to the steel bush sleeve. Please note for the removal of the bush, 360°

orientation of the adaptor is not important and the side 'depth control legs'

arenottted.Thesecondpersoncannowwindinthethrustscrew

ensuring concentricity and squareness of both the press frame and the

cylindrical adaptor. With a 16mm socket increase the torque and observe

the bush sleeve projection from the housing, through to removal. Excessive

torque, above 180NM, is not envisaged, but if this occurs, stop and check

alignments. There may be some resistance initially. Continued support to

the press is required throughout, especially when the bush is removed

from the housing as the bush is then free to fall. Remove the old bush, the

press frame and prepare details for insertion of a new bush assembly. An

"exploded" view (Fig.13) supports actions shown in (Fig.8) through (Fig.12)

Old Bush Assembly Removal Details

Fig.10 Fig.11

Fig.13

Thrust Screw

Cylindrical Adaptor

15mm "C" Ring

Bottom Plate

Fig.9

Trailing

Arm (Fig.1)

Orientation marks

Locate 'C' ring

in counterbore