4. INSTRUCTIONS

VS311.V2 Issue No: 1 - 04/11/13

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

NOTE: To minimise the possibility of damage to the engine, it is

advisable to remove the cylinder head from the engine prior to

commencing work of this nature. The tap guide system

includedwiththissetwillsignicantlyreducetheingressof

swarf/debris into the combustion chamber and cylinder.

Always wear eye and hand protection when cleaning any

swarf/debris from the engine. A full range of personal safety

equipment is available from your Sealey Dealer.

4.1. Repairing a damaged thread using a tap

WARNING! Ensure you have read, understood and apply

Section 1 safety instructions.

4.1.1. Determine the size of the thread to be repaired. This can be

done by carefully using the insert drivers to compare with the

thread of an undamaged glow plug aperture.

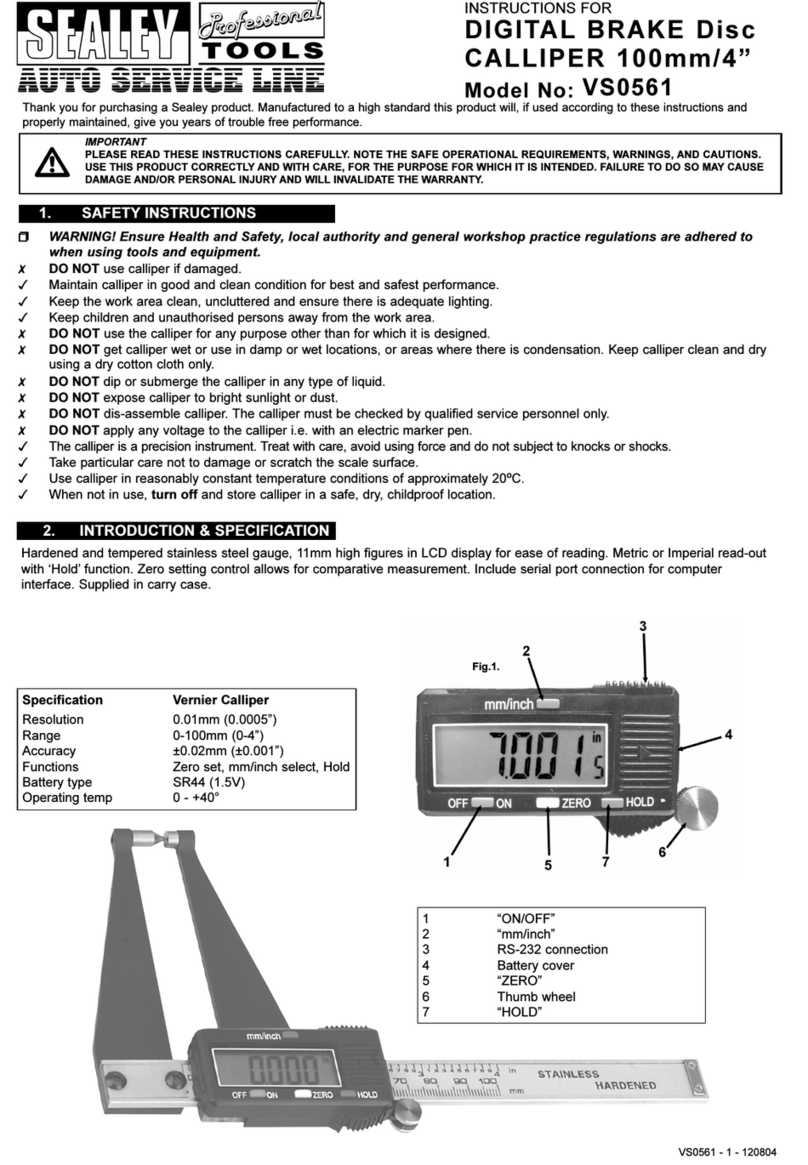

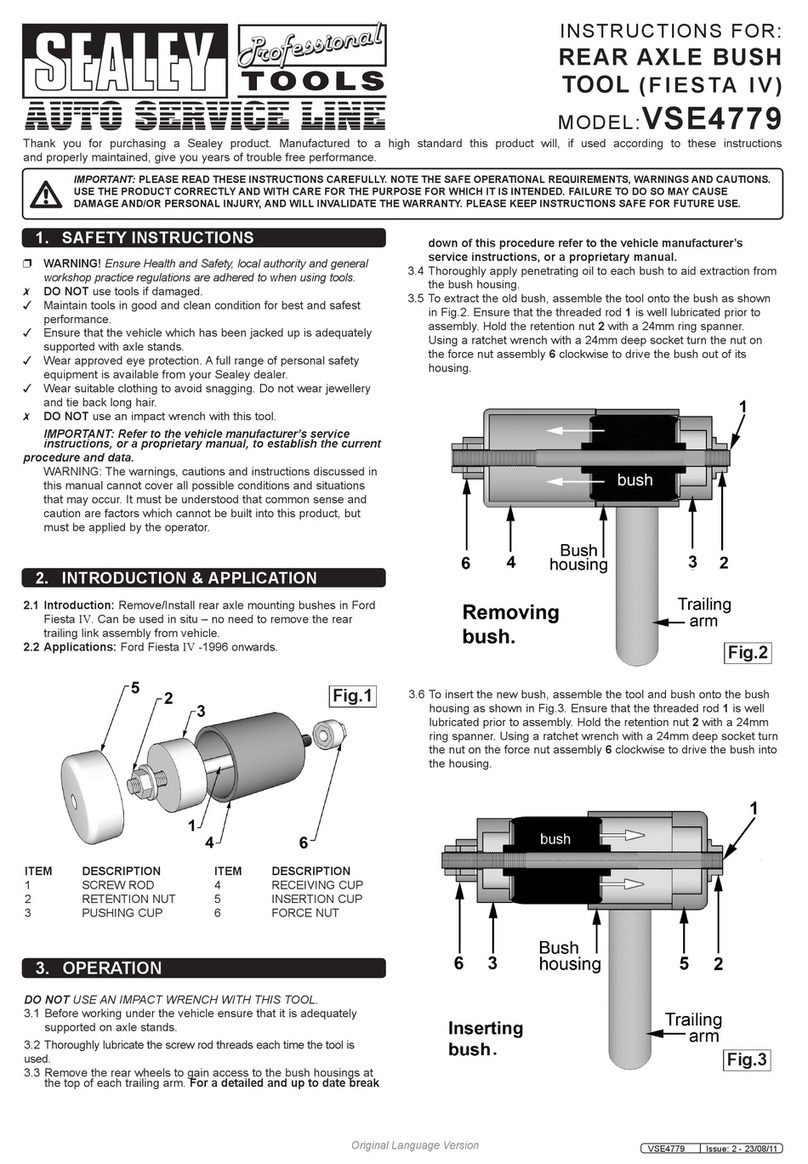

4.1.2. Using the correct size of tap and insert guide, assemble the

setasshowning.2andg.3.

4.1.3. If a ring spanner is to be used, position on the tap before

inserting the insert guide pin into the glow plug aperture. Apply

a layer of general purpose grease to the insert guide to help

prevent swarf/debris from entering the engine and place into

the glow plug aperture.

4.1.4. Hold the knurled head (17) and position the guide rod (16)

so that the insert guide pin is squarely positioned in the glow

plug aperture.

4.1.5. Using a spanner with adequate downward pressure, carefully

run the tap down the damaged thread 1/2 of a turn forward

then 1/4 of a turn back to repair the damaged thread. Always

useasuitablecuttinguid.Periodicallyremovethetapand

insert guide to clean away the swarf/debris. Apply a layer

of general purpose grease to the insert guide before

re-inserting into the glow plug aperture. Continue until the full

length of the thread has been repaired.

NOTE: It is very important to clean away as much swarf/debris

as possible during the thread cutting process to avoid any

ingress into the engine.

4.1.6. Once the thread has been repaired, ensure that all swarf/

debrishasbeencompletelyremovedandcarefullytthe

glow plug.

4.1.7. Ensure all tools are removed from the engine bay and stored

away. Store in a safe, dry, childproof location.

01284 757500

sales@sealey.co.uk

www.sealey.co.uk

01284 703534

Web

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk

IP32 7AR

Original Language Version

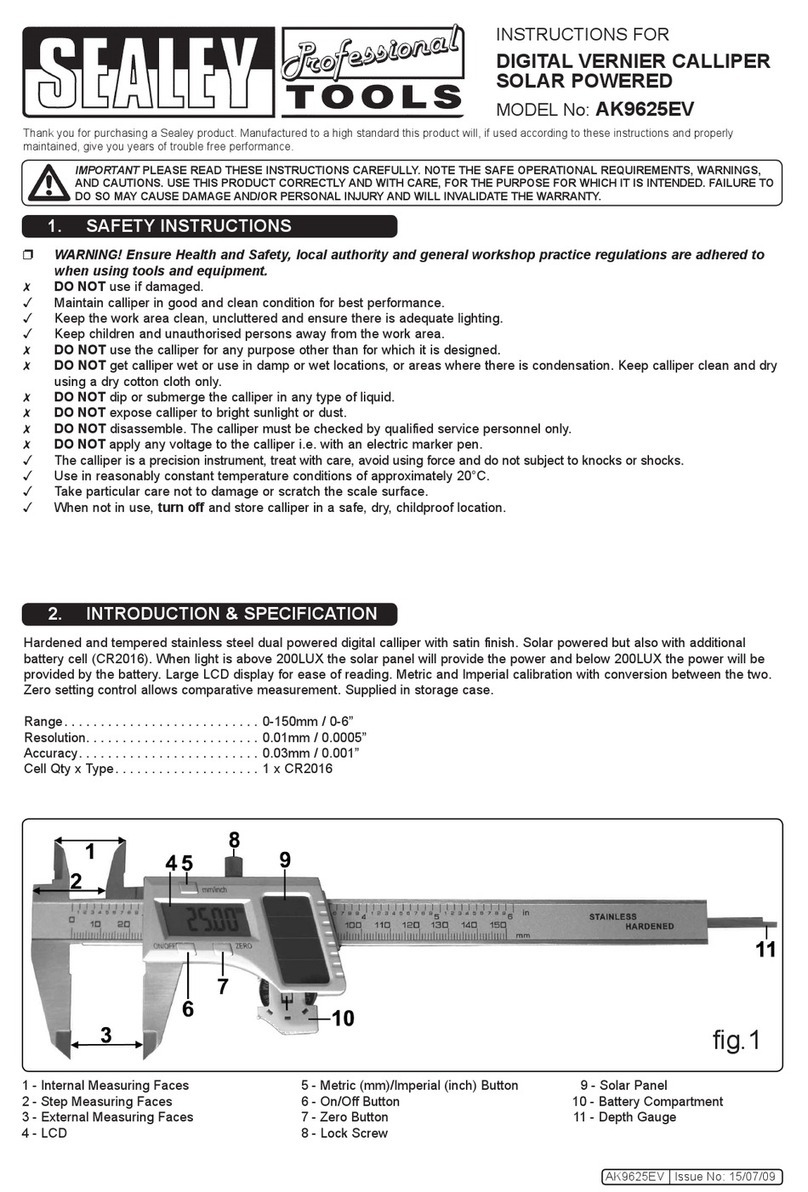

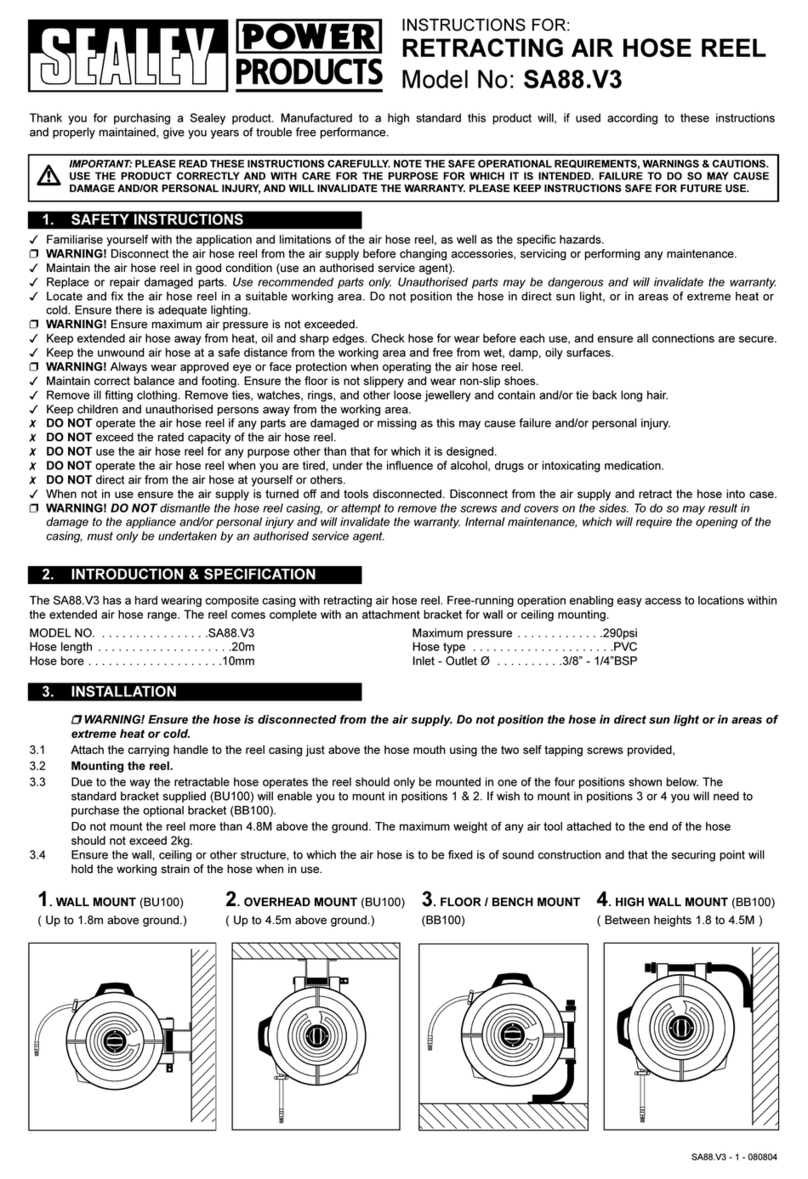

Insert/Tap/Guide Congurations (Refer to g.1 & g.2)

Insert Size: Tap Size: Guide Size:

M8x1.0 (1) M10x1.0 (6) M8 (13)

M10x1.0 (2) M12x1.0 (8) M10 (14)

M10x1.25 (3) M12x1.25 (9) M10 (14)

M12x1.25 (4) M14x1.25 (10) M12 (15)

4.2. Repairing a damaged thread using an insert

WARNING! Ensure you have read, understood and apply

Section 1 safety instructions.

4.2.1. Determine the size of the thread to be repaired. This can be

done by carefully using the insert drives to compare with the

thread of an undamaged glow plug aperture.

4.2.2. Usingthetableabove,assembletheset,asshowning.2and

g.3withthecorrecttapandinsertguidecongurationforthe

size of insert required.

4.2.3. If a ring spanner is to be used, position on the tap before

inserting the insert guide into the glow plug aperture. Apply

a layer of general purpose grease to the insert guide to help

prevent swarf/debris from entering the engine and place into

the glow plug aperture.

4.2.4. Hold the knurled handle and position the guide rod so that the

insert guide is squarely positioned in the glow plug aperture.

4.2.5. Using a spanner with adequate downward pressure, carefully

run the tap down through glow plug aperture 1/2 of a turn

forward then 1/4 of a turn back to cut a thread for the insert.

Alwaysuseasuitablecuttinguid.Periodicallyremove

the tap and insert guide to clean away the swarf and debris.

Apply a layer of general purpose grease to the insert guide

to assist with the removal of swarf/debris before re-inserting

into the glow plug aperture. Continue until the length of thread

cutissufcienttoaccommodatetheinsert.Ensurethatall

swarf/debris is completely removed from the glow plug

aperture.

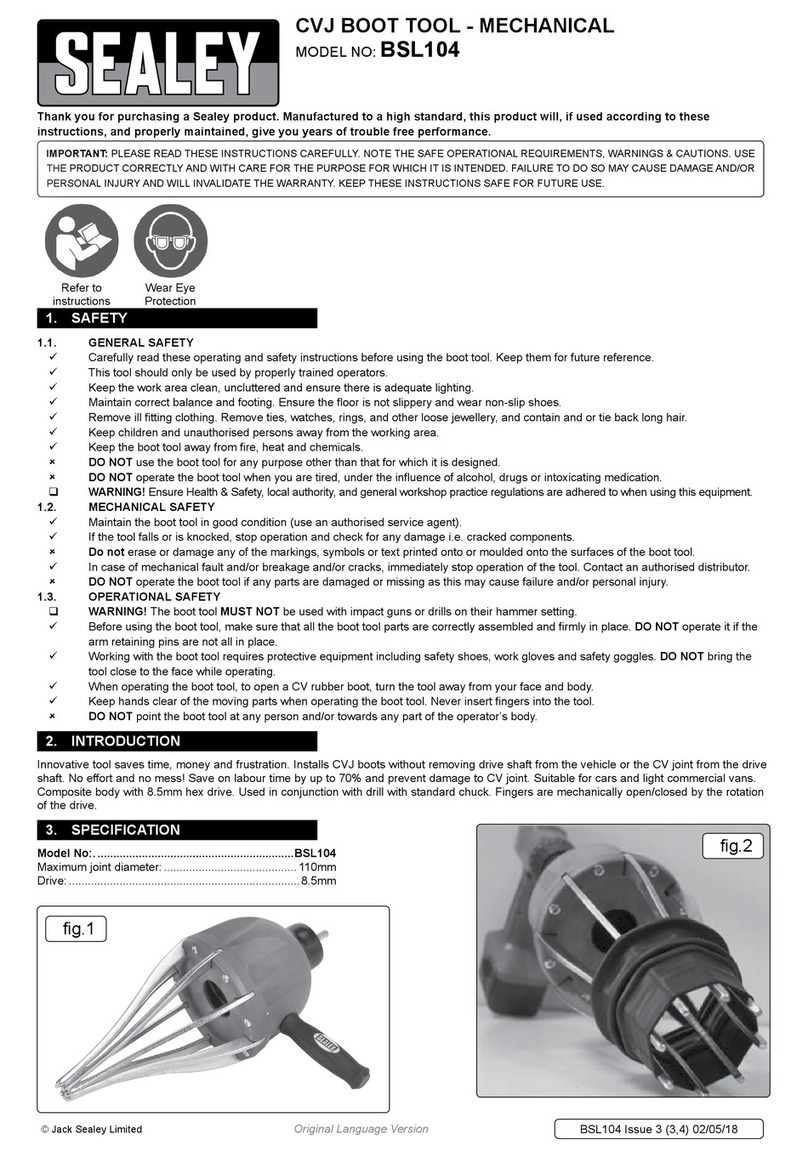

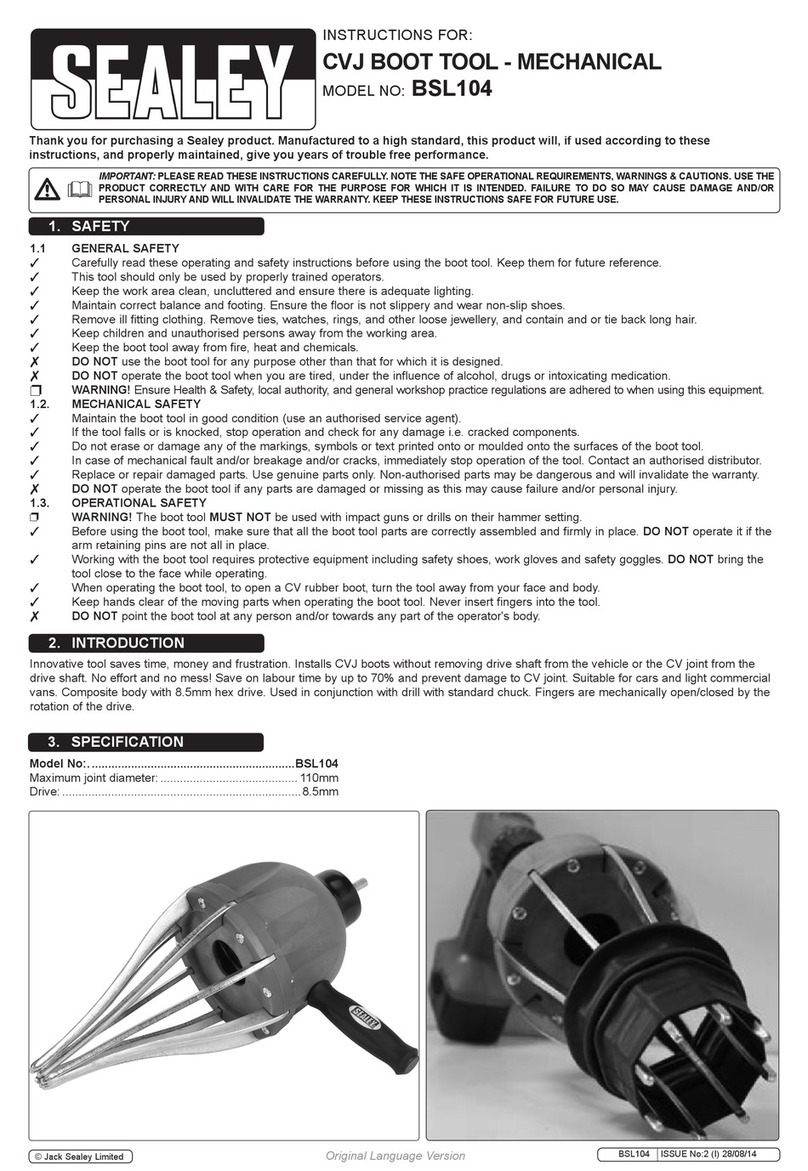

4.2.6. Screwtheinsertontotherelevantinsertdrive(g.4).

4.2.7. Apply a suitable thread locking solution to the exterior thread

of the insert. Screw the insert into the prepared glow plug

apertureuntiltheangeatthetopoftheinsertlocatesatthe

top of the aperture thread and tighten using a suitable

spanner.

4.2.8. Remove the insert driver, taking care not to dislodge the insert.

4.2.9. Allow the thread locking solution to completely cure before

ttingtheglowplug.

4.2.10. Ensure all tools are removed from the engine bay and stored

away. Store in a safe, dry, childproof location.

fig.4

Parts support is available for this product. Please log on to www.sealey.co.uk, email sales@sealey.co.uk or phone 01284 757500

©Jack Sealey Limited

fig.3

13 14 15

16

17

10

5 6 789

Environmental Protection.

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken

to a recycle centre and disposed of in a manner which is compatible with the environment. When the product is no longer

required' it must be diposed of in an environmentally protective way