turned

work

pieces

of

various

diameters

present

dif-

ficulties

when

an

attempt

is

made

to

drill

through

or

into

their

centers

without

an

adequate

stabilizing

device.

The

drill

vise

or

a V

block

should

always

be

used

for

work

of

this

type.

If

the

drill

is

long

enough

to

go

through

the

piece.

but

its

'penetration

is

limited

by

the

travel

or

feed

limit

of

the

chuck.

the

piece

may

be

set

up

on

a

block

after

the

first

cut

of

maximum

feed

depth

has

been

made.

thus

allowing

the

drill

to

penetrate

to

its

max-

imum

length.

Holes

through

a'

piece.

the

thickness

of

which

is

greater

than

the

drill

length

may

often

be

completed

by

first

establishing

the

location

of

the

piece

in

rela-

tion

to

the

drill

center.

then

after

drilling

as

far

as

possible

from

one

side

the

piece

may

be

reversed

and

the

hole

completed

from

the

other

side.

All

metal

work

should

be

clamped

securely

to

the

work

table

before

drilling

is

attempted.

Should

the

drill

lodge

in

a

piece

not

clamped.

it

could

easily

tear

the

piece

from

the

operator's

grip

resulting

in

injury

to

the

operator

as

well

as

mutilation

of

the

drill

press

and

work

piece.

A

punch

mark

on

the

metal

surface

at

the

center

of

the

proposed

hole

will

tend

to

keep

the

drill

on

center

until

the

drill-spot

is

established.

Always

reduce

the

feed

pressure

when

the

drill

is

breaking

through

the

surface

of

a

work

piece.

This

reduces

the

tendency

of

the

drill

to

bite

deeply

at

this

point

and

thereby

minimizes

drill

breakage.

Avoid

set-ups

which

will

allow

the

work

to

spring.

This

will

help

minimize

drill

breakage.

Lubricants

should

be

used

on

all

metals

except

cast

iron

which

is

drilled

dry.

For

most

metals.

lard

oil is a

suitable

lubricant.

for

the

harder

metals

a

solution

of

sal

soda

in

water

may

be

used.

This

drill

press

is

designed

to

give

maximum

pro-

tection

from

moving

parts

at

all

times.

Since

a

guard

on

the

chuck

and

drill

would

also

hide

the

work.

it

must

be

impressed

upon

the

operator

that

as

with

all

rotating

power

tools.

no

loose

clothing

should

be

worn

when

working

with

the

drill

press.

The

face

should

be

kept

away

from

the

drill

so

that

the

hair

does

not

become

entangled

with

moving

parts

or

that

flying

chips

do

not

injure

the

operator.

Accessories

are

available

with

which

further

opera-

tions

may

be

performed

on

your

drill

press

such

as

dovetailing.

shaping.

routing.

carving.

sanding.

spot

finish

or

engine

turn.

cutting

of

plugs

or

dowels.

flut-

ing

and

reeding

and

buffing.

An

interesting

booklet

covering

details

on

these

various

operations

is

avail-

able.

il

II

PARTS LIST

il

I

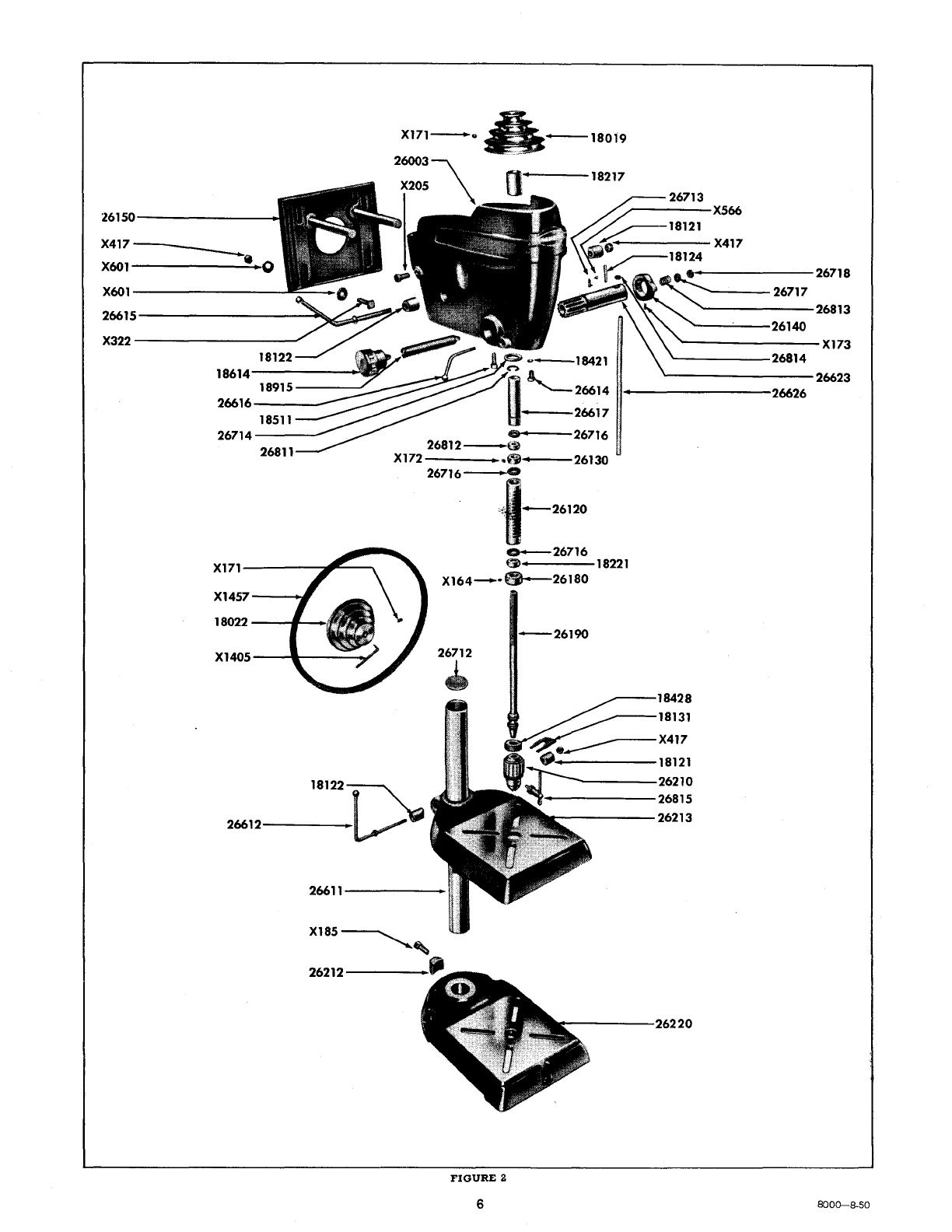

Part

No.

18019

18022

18121

18122

18124

1813 I

18217

18221

18421

18428

1851 I

18614

18915

26003

26120

26130

26140

26150

26180

26190

26210

26212

26213

NAME

OF

PART

Prepaid

Selling

Price

(Each)

Pulley

(Spindle)

........

_

...........

..

Pulley

(Motor)

............••...•.....

Headstock

and

Table

Lock

..••••••......

Headstock

and

Table

Lock

Sleeve

........•

Pin

..............................

..

Chuck

Release

Wedge

...............

,

..

Headstock

Bushing

••.•..•..•..........

Ball

Bearing

••.••.••..••..•..........

Washer

•.•..••.••.•••.•..•..••.••..•

Thrust

Collar

Nut

..•...........•......

Adj.

Knob

Lock

Screw

..••..••.•....•..•

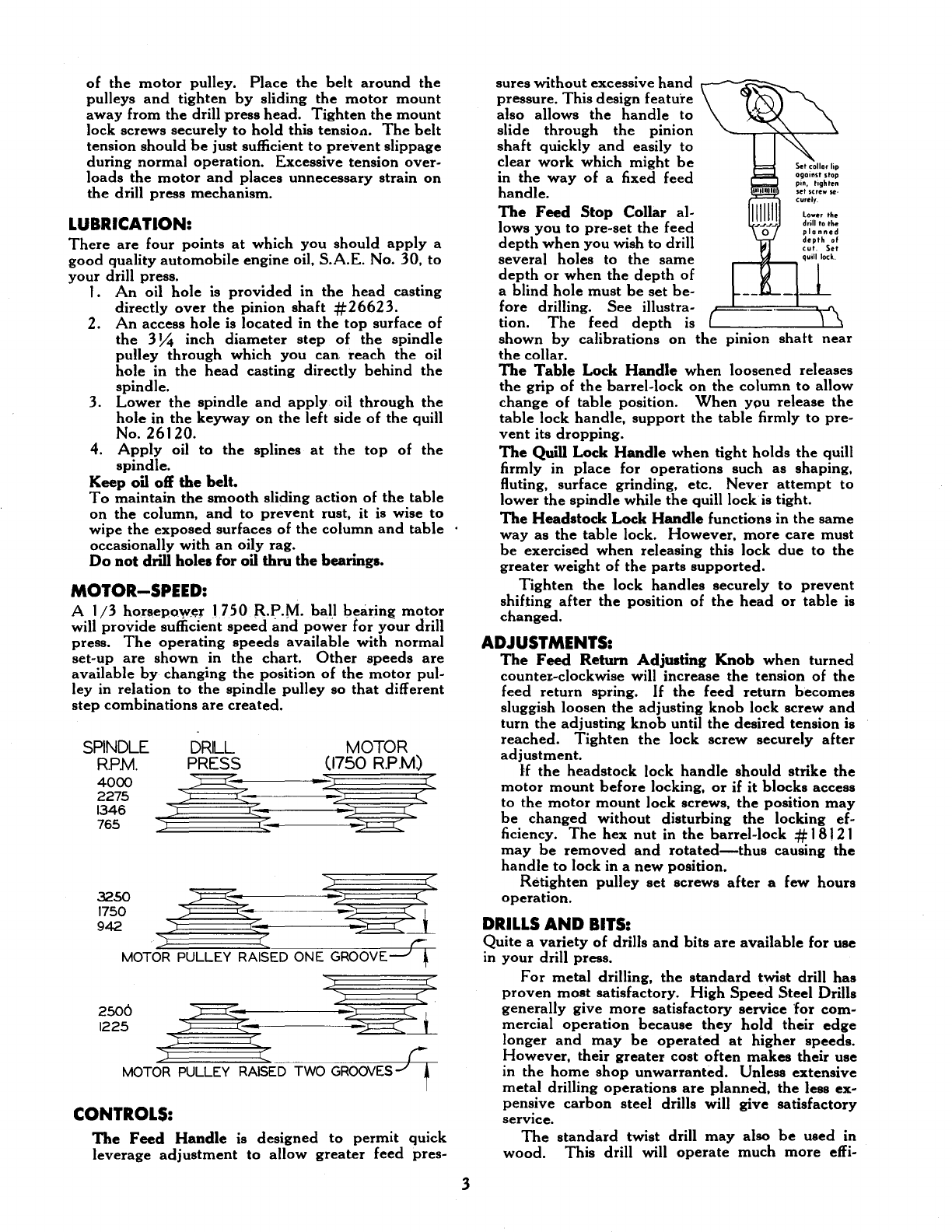

Feed

Return

Adj.

Knob

...•........•....

Feed

Return

Spring

•.•..•...........•..

Head

Frame

Aaay

.••.••..•..•.......•.

Quill

Assy

.•.•.••••••••............••

Upper

Spindle

Collar

&

Set

Screw

.......•

Feed

Stop

Collar

&

Set

Screw

.••.........

Motor

Mount

•.....•..............•..

Spindle

Collar

and

Set

Screw

............

.

Spindle

............................•

Chuck

and

Key

.............•.........

Lock

Shoe

.•.•.•..•.......•.•..•...••

$1.80

1.70

.30

.30

· I5

.20

.40

.25

.15

.35

•I5

.65

.25

16.00

2.00

.30

.50

2.50

.35

3.75

10.00

.25

Table

. • . . . • . . . • . . . . . . . . . . . . . . • . . • .

.•

10.00

26220

Base

••••....

,........................

I 1.00

266 I I

Column...

• • • • • • . • • • • . . • . . • . . . . . . •

.•

3.00

26612

Table

Lock

Handle....................

.35

26614

26615

26616

Pinion

Retaining

Screw

•••••.••...•..••

Headstock

Lock

Handle

'"

..••••.•.••.•

Quill

Lock

Handle

•••••••••••••••..•.•

·I5

.35

.

20

Prepaid

Part

No.

NAME

OF

PART

Price

Selling

'.j

(Each)

I

26617.

-Splined

Sleeve

..•.

--~.

,

••.

~~----

•

$2.D.O..

--')11

26623

Pinion

............................

2.75 I

26626

Feed

Handle

•.••...•...•••••...••••

.50

26712

Column

Plug.......................

.15

267

I3

Pointer............

• • . . • • • . . • . • • . • • •I5

II

267

I4

Steel

Washer

•.....••..•••.•••••

,...

•I5

;!

26716

Fibre

Washer

.......................

.15 .

267 I7

Steel

Disc

.•.

. . . . • . . • . • • • • . . • • • • . • • • •I5

,"

267

I8

Leather

Disc.

. • . . . • • • . . . . • • • . . • . • • . . •

15

268

I I

Snap

Ring.

. • • • . . . • . . • . . . . . . • . • • • • • . . I 5

268

I2

Rubber

Washer

•••...••.•••••••.••.•

•I 5

268

I3

Feed

Handle

Thrust

Spring

. . . . . . . • • • . • •I5

268

I4

Feed

Handle

Snap

Ring

..............

•I 5

26815

Chuck

Key

........................•

.80

X-164

Set

Screw

No.

6-32

x

3/16

Slotted

Hd.

X-I71

X-I72

X-I73

X-I85

·X-205

·X-322

X-417

·X-566

X-601

·X-1405

X-I457

Round

Point

......................

.

Set

Screw

!4-20

x

Ys

Socket

Hd.

Cup

Pt.

Set

Screw

];4-20

x

5/16

Socket

Hd.

Cone

Point

..•.•...•.........•.•........

Set

Screw

!4-20

x

5/16

Socket

Hd.

Cup

Point

.................•..•.......•

Set

Screw

Y2-"-

I3 x

1!4

Square

Hd.

Cup

Point

..•....••........

,

........••..•

Cap

Screw

5/

16-

18

x

~

Hex

Hd

.•••.•

Mach.

Bolt

5/16-18

x 2

Sq.

Hd

...•...•

Hex

Nut

5/1

6-18

Am.

Std.

Reg.

Full

..•

Mach.

Screw

No.

6-32

x

3/1

6

Round

Hd

..

Plain

Washer

11/32

•.•.••.••••••.•..

Allen

Wrench

Vs

Std.

•

..•.••..•...•••

V-Belt.

purchase

from

your

nearest

Sears

retail

store

or

mail

order

house.

Ask

for

Catalog

No. 9- I637

•....••••..•..•.•

.10

.10

.10

.10

.10

.10

.10

.10

.10

.10

•I5

·Part.

marked

in

this

manner

may

be

purchased

locally.

This

sheet

is

intended

for

instruction

and

repair

parts

only

and

is

not

a

packing

slip.

The

parts

shown

and

listed

may

include

accessories

not

necessarily

part

of

this

tool.

All

parts

are

shipped

prepaid.

All

prices

are

subject

to

change

without

notice

.

• 5