Seco EASYSHRINK EVO User manual

EASYSHRINK®EVO

USER INSTRUCTIONS

TOOLING

SYSTEMS

2

3

We thank you for purchasing an Easyshrink Evo device.

This induction shrinking device oers you a lot of benefits:

▪User-friendly: Automatic or manual heating cycles, simple interface,

ergonomic and easy to use control interface.

▪Quick shrinking and unshrinking of steel, high speed steel, heavy

metal and carbide tools*.

▪Localized and homogeneous heating of the clamping area

▪Minimal energy consumption

▪Fast cooling of the tool and the toolholder

This operating manual will give you all the necessary information to

use this device in the best way.

Our sales team is at your full disposal if you need further clarification.

Your Partner,

Seco Tools

* This device was optimized to be used with all standard Seco Tools

toolholders. Other branded toolholders need to be configured and validated.

DEAR CUSTOMER

PROVISIONS OF WARRANTY

If your product proves to be defective even if it has been used properly

(in accordance with the written operating instruction manual supplied

with it) within a period of 24 months from the date of invoicing, this

product will be repaired or replaced free of charge.

This warranty covers material defects. Any defect that occurs due

to mishandling that is not mentioned in the operating instruction

manual or is due to improper maintenance, etc. is not covered. Seco

Tools' sole liability is limited to repairing or replacing the product.

Any liability for indirect or consequential loss or damage of any

kind incurred or suered by the customer due to a product defect is

excluded.

4

IMPORTANT

CAUTIONS & WARNINGS

The Easyshrink Evo is built

with the latest technology and

it is extremely safe and easy to

operate.

However, there is still some

danger if this device is operated

incorrectly and/or by untrained

personnel.

Pay particular attention to the

following cautions and warnings

marked with the “Attention” and

“Danger” symbols.

Failure to follow safe operating

practices may cause injuries,

death or damage to the

device and may VOID your

manufacturer's warranties.

WARNING

▪Before attempting to use the

device, you must read and

fully understand this User

Guide. Keep this User Guide

within easy reach of operating

personnel.

▪Visually inspect the device,

power cord and accessory

items for any signs of wear or

damage before operating the

device. Do not use the device if

there is any sign of damage or

if the device is not performing

normally.

▪Never operate the device

without the correct induction

heat-focusing stopper in place

on the induction head. Do not

allow any part of the induction

head to contact the tool

holder or cutting tool during

operation or damage to the

device may occur.

▪The holder and the tool must

be clean, free from grease and

dry before being fitted to the

device.

▪Tool shank tolerance required:

Ø3 to 5 mm (Ø0.118” to

0.1968”) maximum h5.

Tool shank must be carbide or

heavy metal (e.g. Densimet).

Ø6 to Ø32 mm (Ø0.236” to Ø

1.25”) maximum h6.

Tool shank can be steel, HSS,

carbide or heavy metal.

Using h5 for Ø6 to Ø32

mm (Ø0.236” to Ø1.2598”)

provides a safer minimum

clamping torque.

▪Do not wear rings, bracelets

or other metallic objects

while operating the device.

Metallic objects may heat

up very quickly when near

the induction head during

operation.

▪ Use the provided heat-resistant

gloves and pliers whenever

handling tools or tool holders.

Never try to handle hot tools or

tool holders until the cooling

cycle is complete.

▪If the device is moved from a

cold environment to a warm

one, wait three hours before

operating to prevent build-up

of condensation and electronic

system errors.

▪Persons with pacemakers fitted

may not operate the device and

must maintain a minimum safe

distance of 2 meters (6 feet)

from the device at all times.

▪Cutting tools have sharp edges.

Handle with caution.

WARNING

Electric shock risk

▪The power cord provided

must be plugged into the

correct standard, three-phase

outlet for your country.

Operating the device while it

is improperly connected or at

the wrong voltage may damage

the device and could cause

death or injury.

▪Position the power cord so that

it cannot be damaged by fork

trucks or other equipment or

cause a tripping hazard for

personnel.

▪Do not operate the device

in a wet environment where

exposure to coolant or spills

are likely to occur. Electric

shocks or damage to the device

may occur.

▪Never operate the device

around flammable materials or

fumes. Do not use flam-

mable liquids or aerosols to

clean the tool holders. Never

expose the device or hot tools

to combustible materials.

▪Never open the device or

attempt repairs or you will

VOID the manufacturer’s

warranty. There is dangerous

residual voltage inside that

may cause death or injury.

▪Unauthorized modifications

or changes to the Shrinkfit

Evo device will VOID your

manufacturer’s warranty. Do

not try and service your device

yourself. After-sales techni-

cians can provide any

necessary repairs or

maintenance. Do not modify

or disable the built-in safety

features of the device.

▪Turn o the power switch

and disconnect the power

cord from the outlet before

cleaning, servicing or storing

the device.

5

CONTENT

Device general overview .................6

Accessories and spare parts ............7

Easyshrink Evo features ..................8

Range overview................................9

Refrigeration unit ...........................9

Refrigerated water-cooling bells

unit............................................10-13

Shrinking principle.......................14

Taking delivery ..............................15

Working environment of the

device.............................................15

Keypad and display presentation .16

Starting the device ........................16

Starting to shrink and unshrink...17

Shrinking depths to be respected 17

Stop rod selection .........................18

Mode selection..............................19

Shrinkfit.........................................20

Shrink release................................22

Audible feedback ..........................22

Boost mode....................................22

Shrinkfit of special tool holders...23

Shrink release of special tool

holders...........................................25

Shrinking capability......................26

Maintenance frequency................27

Safety precautions.........................28

Annexes .........................................28

Technical features .........................29

Compliance statements ..........30-31

6

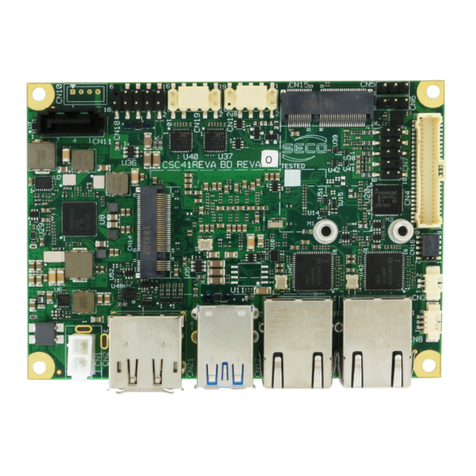

GENERAL OVERVIEW

PNEUMATIC

BUTTON

COLUMN

INTERFACE KEYPAD

STORAGE

FOR STOP

RODS

STORAGE FOR HEAT-

FOCUSING STOPPER

MAIN

SWITCH

FINNED

SUPPORT

CONTACT BUSHING

FOR COOLING BELLS

ROTARY

PLATE

COOLING BELL

DEPTH SETTING

WHEEL

INDUCTOR HOUSING

TOOL COOLING

SUPPORT

HANDLE REFRIGERATION UNIT

COOLING

CONE

7

ACCESSORIES AND SPARE PARTS

Important: These accessories related to the Shrinkfit tool holders must be

ordered separately in order to use the Easyshrink EVO.

REQUIRED AS A MINIMUM FOR SHRINK GRIP AND SHRINK RELEASE

OPERATIONS

▪Finned supports for each type of machine side taper used on Shrinkfit

tool holders. Available for all types of tool holder (HSK / DIN & DIN TF

/ BT & BT TF / CAT & CAT TF / Capto).

Provides positioning of the tool holder onto the support module.

REQUIRED AS A MINIMUM FOR THE WATER COOLER

▪Contact bushing for each type and size of Shrinkfit tool holder used.

Available for all types of Shrinkfit holders and diameters (DIN type /

Reinforced / Mold and Die / MQL)

Required to extract heat from the front end of the holder towards

the liquid cooling bell.

SPARE PARTS

▪Set of standard and thin stop rods.

4 stop rods with 2.5 mm (0.098") front end and 4 stop rods with 5 mm

(0.197") front end covering a shrink depth capacity of 0 to 240 mm (0 to

9.45"):

0-60 mm (0-2.36") / 60-120 mm (2.36-4.72")/ 120-180 mm (4.72-7.09") /

180-240 mm (7.09-9.45").

Enables the tool shrinking depth setting and ejection of broken tools.

▪Air cooling cones.

Directs the air stream against the front end of the holder for cooling

▪Heat-focusing stoppers.

Available for shrinking and unshrinking tool holders Ø3 to Ø32 mm

(Ø0.118" to Ø1.26").

Magnetic insulator that allows the magnetic field to be concentrated on

the front part of the tool holder and to achieve optimised heating.

▪Split heat-focusing stoppers.

For the split heat-focusing stopper, a locking ring must be ordered.

Split magnetic insulator that allows the magnetic field to be concentrated

on the front part of the tool holder and to achieve optimised heating of

tools with a front end that is larger than shank.

Finned support

Contact bushing

Set of stop rods

Air cooling cone

Standard heat-focusing

stopper

Pair of split heat-focusing

stopper and ring

LOCKING

RING

HALF HEAT-

FOCUSING

STOPPER

8

EASYSHRINK EVO FEATURES

COLUMN

Enables the shrinking and

unshrinking of tool holders

with a maximum length of:

▪480 mm (18.897") with

HSK-32 finned support

▪430 mm (16.930") with

SA50 finned support

▪490 mm (19.290") with

other finned support

540 mm

SMART

▪Small computer that

enables a smart web

interface through a Wi-Fi

connection or by RJ45

▪TDM Systems compatible

▪Special program is easily

programmable

▪Global view of the system

status

HEAT-FOCUSING STOPPERS

Enable the shrinking or

unshrinking of carbide or

HSS tools Ø3 to Ø32 mm

(0.118" to 1.260").

NB: Split heat-focusing

stoppers available as

accessories for larger head

tools.

STOP RODS

Different size stop rods are

available to easily adjust the

depth of your tool in your

tool holder

INDUCTOR

Fast and optimized cycle for

shrinking and unshrinking

steel, HSS, heavy metal or

carbide tools with Seco Tools

holders

INTERFACE

- Simple control panel with

LED indicator

▪3 standard programs for all

Seco Tools holders

▪1 programmable mode for

other tool holders (specific

shape or competitors)

▪1 manual mode

ROTARY PLATE WITH SHRINK

DEPTH SETTING

▪Allows the operator to

switch the hot tool holder

from the heating position

to the cooling position

without any contact with

the hot tool holder

▪Allows the operator to

adjust the depth of your

cutting tool using a height-

adjusting knob that moves

the stop rods

9

RANGE OVERVIEW

EASYSHRINK EVO

OPTIONAL PRODUCT

REFRIGERATION UNIT

FEATURES

Power: 20 kW allows the shrinking and unshrinking of tools Ø3 to Ø32 mm

(Ø0.118" to Ø1.26")

Max. tool length: 430 to 490mm

Max. machine interface: HSK-A125

Dimensions (W x D x H): 317 x 955 x 920 mm / 12.5" x 38" x 36"

Cooling time: ± 7 minutes with cooling cones

Weight: 46.2 kg (102 lbs)

DELIVERY CONTENT

▪5 standard heat-focusing stoppers for Ø3 to Ø32 mm (Ø0.118" to Ø1.26")

▪8 stop rods

▪2 cooling cones

▪1 pair of gloves

▪1 operating instructions

CONNECTIONS

The device only accepts the voltage AC 3 x 400 V (+/-10%) + PE/28 A/50 Hz

For other voltages the use of a ZFM30IN30 transformer is required,

which needs to be bought separately (CSA approved transformer needed for

Canadian market):

- Input voltages: 3 x 208 / 240 / 480 / 600 VAC + GND/28 amp/50-60 Hz

- Output voltages: AC 3 x 400 V + PE/28 A/50 Hz

- 3 meters (10 ft) cable is supplied

- Incoming air supply 3 to 6 bars (43 to 87 psi)/pipe Ø10 mm (Ø 0.393") required

FEATURES

Cooling time: ± 1 minutes

Extension table: Allow storage of 5 contact bushing and 1 cooling bell

Weight: 39.8 kg (88 lbs)

DELIVERY CONTENT

- Refrigeration unit

- Tube support

- 2 bells

- Extension table

EASYSHRINK EVO

920 mm / 36"

955 mm / 38"

317 mm / 12.5"

EASYSHRINK EVO &

TOOL COOLING SUPPORT

920 mm / 36"

1060.5 mm / 42"

317 mm / 12.5"

COOLING UNIT

285 mm / 11"

630 mm / 24"

314 mm / 12"

10

REFRIGERATED WATER COOLING BELLS UNIT

WATER LEVEL

FLEXIBLE PIPESCOLUMN WATER TANK COVER

TEMPERATURE

CONTROL

VENTILATION

COOLING BELLS SUPPORT FOR

CONTACT BUSHING

FOR COOLING BELLS

The water cooler must be positioned on a stable

working platform with a clearance of 50 cm (19.7")

on both sides in order to allow air flow.

50 cm

19.7"

50 cm

19.7"

INSTALLATION OF THE REFRIGERATION UNIT

11

MOUNTING THE EXTENSION TABLE

(AVAILABLE AS AN ACCESSORY OR DELIVERED WITH THE WATER-COOLING OPTION)

Tighten the 2 screws 1.

MOUNTING THE COLUMN FOR THE WATER-COOLING TUBES

(DELIVERED WITH THE WATER-COOLING OPTION)

Tighten the 4 screws 2.

Connect the 2 tubes 3of the water-cooling system to the connectors of the

column.

FILLING THE COOLER

Open the cover on the top of the cooler (4 screws to release) 4.

Fill in the tank with pure water until the indicator shows you

that the tank is full.

Tap water: 7.5 < pH < 9 / 7°C (44.6°F) < TH < 15°C (59°F)

Note: change the water approx. every 6 months.

1

2

3

4

12

WATER TEMPERATURE SETTING

When the power is turned on, the water cooler displays « -88 » for 3 seconds

and then displays the temperature of the water.

The water temperature is preset in our plant at +20°C (68°F).

It is adjustable from 10°C to 25°C (50°F to 77°F) 6.

In the case of noticeable condensation, it is recommended to

set the water temperature higher.

To see the preset temperature, press the SET button 7.

To modify the preset temperature, simultaneously press SET and « up arrow »

or « down arrow » 8.

As soon as the SET button is released, the water temperature is displayed.

The temperature varies between « preset temperature » and « preset tempera-

ture + 2° C (35.6°F)».

USE

Install the corresponding contact bushing 9for the cooling bells (Ø and holder type-depending) onto the top of the

holder, and slip over the cooling bell 10 .

CONNECT THE REFRIGERATED UNIT TO THE EASYSHRINK EVO

Plug the cable from the refrigerated unit into the outlet 5.

Never turn on the power without having filled the cooler first.

After first use, it might be necessary to add more water to the

tank (check the level).

Afterwards, a regular check of the water level and quality is

recommended.

WARNING

5

WARNING

10

7 8

6

10

9

13

WATER COOLER MAINTENANCE

FREQUENCY OBSERVATION

WATER LEVEL CHECK 1 month

WATER TANK CHECK 6 months Water (7.5 < pH < 9 and 7°C (44.6°F) < TH < 15°C (59°F)

RADIATOR CLEANING 2 months Do not use an air blower

REMARKS

▪The tank must only be filled up with pure water (tap water, please refer to recommendations in the table above) and any

other product is forbidden (distilled water, demineralised water, glycol etc.).

▪If the water cooler will be idle for a long period, the device must be stored in an area at an ambient temperature to avoid

any risk of frost.

▪Repairs to the refrigeration unit must only be carried out by qualified heating and cooling expert.

▪The water cooler must not run with an empty tank.

14

The Shrinkfit holder’s internal diameter 1is designed to be slightly smaller than the shank diameter 2of the

cutting tool. When placed into the induction heating system, the inside bore is heated and expands. The tool

shank can then be slipped easily into the holder. As the holder cools down, the resulting thermal contraction

exerts a tremendous, uniform pressure around the entire surface of the tool shank.

INDUCTION

The induction heating allows tools to be clamped in a few seconds.

A high magnetic field flux is created and remains concentrated on

the clamping area. This means that less energy remains in the holder

and the cooling time is reduced. This allows the HSS tools to be

unshrinked with the same thermal expansion coecients as the steel

used for the holders.

SHRINKING PRINCIPLE

21

15

TAKING DELIVERY

The device you have received has been controlled and tested in our plant according to ISO9001 specifications.

If the equipment is being stored or transported under unacceptable conditions it may be permanently damaged.

In this case the manufacturer will exclude all warranty claims and obligations.

Unpacking must be carried out carefully to avoid any damage.

A tilt-watch indicator is positioned on the packaging to guaranty the pallet has not been tipped over.

WORKING ENVIRONMENT OF THE DEVICE

The Easyshrink Evo device needs to be positioned in a dry and clean working area on a stable and rigid surface

that is resistant to hot tool holders (+/-100°C (212°F)).

CONNECTIONS

Remark: The transformer for voltages in the USA or Canada is available as an optional accessory.

▪Power supply:

The device only accepts the voltage AC 3 x 400 V (+/-10) + PE/28 A/50 Hz

For other voltages the use of a ZFM30IN30 transformer is required, which needs to be bought separately

(CSA approved transformer needed for Canadian market):

- Input voltages: 3 x 208 / 240 / 480 / 600 VAC + GND/28 amp/50-60 Hz

- Output voltages: AC 3 x 400 V + PE/28 A/50 Hz

▪Air supply:

- 3 to 6 bar (43 to 87 psi)/pipe external Ø10 mm (Ø0.393") (pipe not supplied)

- 3 meters (10 foot) cable is supplied

16

KEYPAD AND DISPLAY PRESENTATION

STARTING THE DEVICE

12Switch ON the main interrupter of the Shrinkfit device.

3The Power LED turn ON.

4After 10 seconds, the Power Led and Mode 1 LED are activited

and show that the device is ready to be operated.

HEATING CYCLE LED INDICATOR POWER LED INDICATOR

HEATING CYCLE

BUTTON

BUTTON FOR MODE

SELECTION

MODE LED INDICATOR

LED BLINKING = BOOST OF THE MODE CURRENTLY SELECTED

3

4

1 2

17

STARTING TO SHRINK AND UNSHRINK

Always wear protective gloves while handling

Shrinkfit holders, tools, accessories and spare

parts.

Electrical hazard when dismounting module

parts

Persons with medical implants are not per-

mitted to use or work with this device. Persons

with a pacemaker must refer to the guidelines

for their pacemaker established on the basis

of: NF EN 60601-1-2 (September 2017)

Do not use hydraulic tool holders on this

device as there is a risk of explosion and

third-degree burns.

Please notify and provide training to

operators who may use this device.

SHRINKFIT TOOL HOLDER & CUTTING TOOLS

The Easyshrink Evo device makes it easy and safe to perform Shrinkfit tool changes without causing damage

to the toolholder or cutting tool, as long as the device is correctly installed and the operating procedures are

followed.

Easyshrink Evo is designed to work best with all standard SECO Shrinkfit toolholders and eciently with tools

made from steel, HSS, heavy metal or carbide.

Tool shank diameter tolerance is critical.

Tool shank tolerance required:

Ø3 to Ø 5 mm (Ø0.11” to Ø0.19”) maximum h5, tool shank must be carbide or heavy metal (e.g. Densimet).

Ø6 to Ø32 mm (Ø0.23” to Ø1.25”) maximum h6, tool shank can be steel, HSS, carbide or heavy metal.

Using h5 for Ø6 to Ø32 mm (Ø0.23” to Ø1.25”) provides a safer minimum clamping torque.

Make sure the minimum shrinking depth LSC shown in the Product pages for each holder is respected when

fitting the tool shank into the holder.

Make sure that the toolholders and the tools are clean, free from grease and dry before being fitted in the

device.

SHRINKING DEPTHS TO BE RESPECTED

We recommend the following shrinking depth in order to guarantee

the minimum transmittable torque and lifetime of the tool.

EXAMPLE FOR A TYPE SFD 5403 SECO TOOL HOLDER:

The diameter DCBX (tool-fitting size) is indicated in the toolholder

specification.

The shrinking depth (depending on the position of the stop end

screw) must be set to LSC as a minimum.

In this case, the chart indicates LSC = 39 mm (1.54")

18

STOP ROD SELECTION

The stop rods enable:

▪The depth of the tool inside a tool holder without back-up screw to be set

▪The depth of the tool for twin tool holders for multi-spindle machines to be set

▪Broken tools stuck inside a tool holder to be pulled out

NOTE

The stop rod is chosen by the LFNLF (= LPR - LSC) result and your value will correspond to a specific S Group.

When using finned support for Shrinkfit holder taper SA50 (ZFAD05S50), add 60 mm to the LFNLF value

obtained.

Example: Seco Tools tool holder type SFD 5403

We have previously determined that the shrinking depth LSC = 39 mm (1.54").

The gauge length LPR can be found by reading the specification or by measuring.

LFN-LF = LPR – LSC = 120 (4.72") – 39 (1.54") = 81 mm (3.18")

In this case, the suitable stop rod is the one in front of the S2.

19

MODE SELECTION

Workpiece type Old

designation

New

designation

Symbol

Mode

Normal

5403

5603 SFD P1 1

5402

5602 SFD...-L1 P1 1

MQL 5403M

5403M1

5403M2

SFD...M

SFD...M1

SFD...M2

P1 1

SPECIAL SHORT* SPECIAL SHORT* PS 1

5600 SFR P2 2

5600P

Safe-Lock™ SFR P2 2

5801 SFS P2 2

5800 SFD...-F6 P3 3

Custom tool holders Special

program

Special

program /S

* Short tool holders for tools Ø3 to Ø8 mm, with V-ange surrounded by the inductor:

Use special heat focusing plate ZFAT30C06.

Immediately move up the inductor after each heating cycle.

HEATING MODE SELECTION

ACCORDING TO MARKING OF:

•Old designation

E=

Monobloc holder

Machine side

taper type Workpiece type

Tool tting

size Gauge

length

E 9304 5403 16 120

HSKA63 SFD

16 120

• New designation

• New tool holder P1

20

SHRINKING PROCESS

1Choose the tool holder finned support that corresponds to your

tool holder

2Select the corresponding heating mode to use with help of the

specification located on the flange and the table above

3Place the finned support on the rotary plate hole

4Take the heat-focusing stopper corresponding to your tool shank

diameter and place it in the inductor.

Secure the heat-focusing stopper by turning the heat-focusing stopper

a quarter turn into the inductor

NOTE

Only use ZFAT30C06 for special short tool holders. More details on

the "Heating Mode Selection" sticker.

1

2

3

4

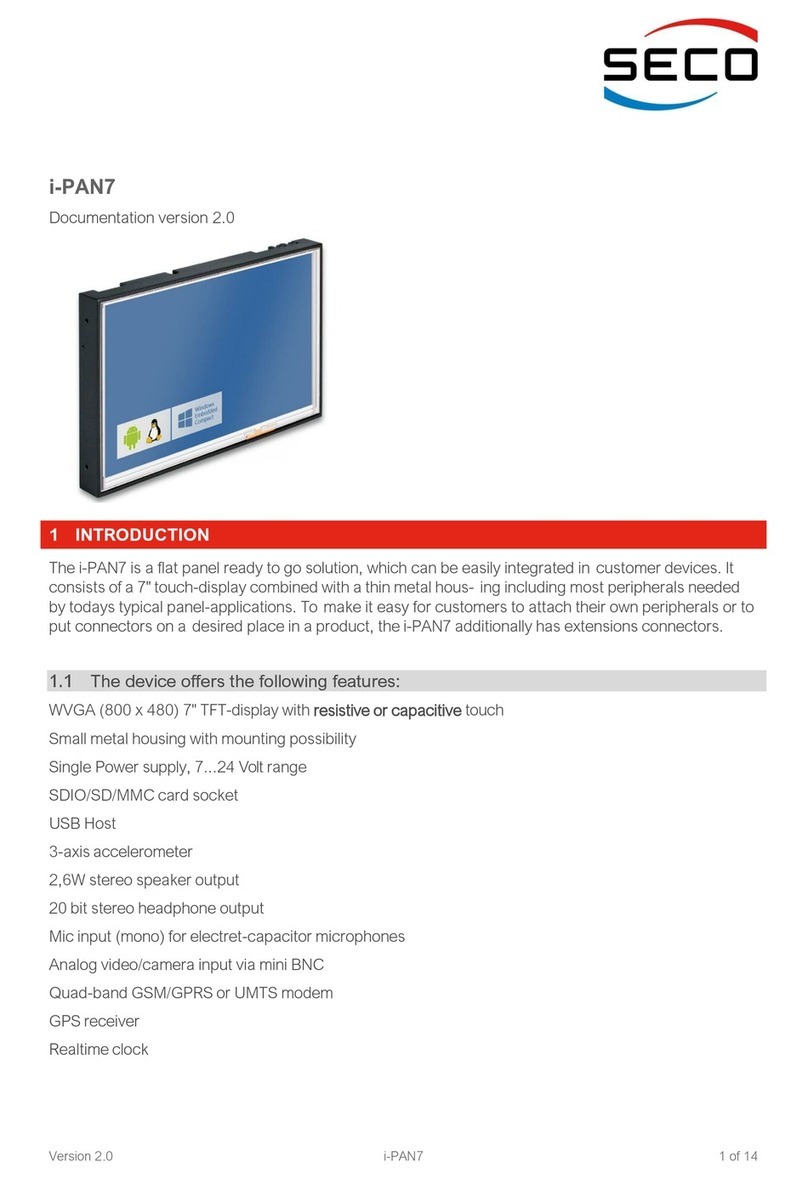

Table of contents

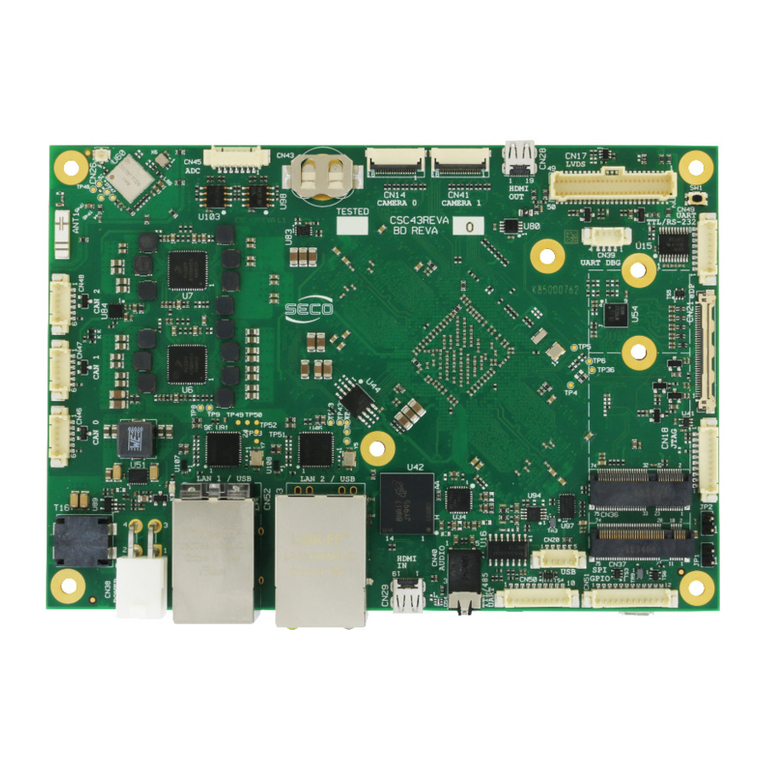

Other Seco Single Board Computer manuals

Seco

Seco SANTINO LT core User manual

Seco

Seco i-PAN7 User manual

Seco

Seco SBC-C43 User manual

Seco

Seco SBC-984 User manual

Seco

Seco SBC-C20 User manual

Seco

Seco SYS-B68-IGW Quick start guide

Seco

Seco TANARO User manual

Seco

Seco SECOnITX-ION User manual

Seco

Seco SYS-B68-IPC Quick start guide

Seco

Seco SBC-C31 User manual

Popular Single Board Computer manuals by other brands

Avermedia

Avermedia AVerAI EN713-AAE9 manual

Atmark Techno

Atmark Techno Armadillo-9 AN010 Hardware manual

Motorola

Motorola CompactPCI CPN5365 Installation and use guide

VersaLogic

VersaLogic EBX-22 Reference manual

Lanner electronics

Lanner electronics IAC-H668 Series user manual

Batocera

Batocera Radxa Zero manual