SECOP 105N4866 User manual

www.secop.com Sustainable Cooling Solutions

Operating Instructions

EXTENDED CONTROLLERS

FOR NLV-CN COMPRESSORS

105N4866 Multi Voltage · 100–240V|50/60Hz

Commercial

Applications

Premium

Controllers

Variable-Speed

Efficiency

Page 2 / 3

TABLE OF

CONTENTS

1. Introduction _________________________________________________ 4

1.1. Applications ____________________________________________ 5

1.2. Capabilities ____________________________________________ 5

1.3. Operating Conditions ____________________________________ 5

1.4. Programming Interface __________________________________ 5

1.5. Main Features __________________________________________ 6

2. Hardware Interface description_________________________________ 8

2.1. In General _____________________________________________ 9

2.2. Controller Connections___________________________________ 10

2.3. Earthing the Compressor and Controller ____________________ 11

2.4. Mounting the Airflow ____________________________________ 11

2.5. Brazing: Warning! _______________________________________ 12

2.6. Checklist ______________________________________________ 12

2.7. Electrical Ratings _______________________________________ 13

2.7.1. Temperature Sensors_____________________________ 14

2.7.2. Analog and Digital I/Os____________________________ 14

2.7.3. Modbus Connection ______________________________ 15

2.7.4. Power Connection _______________________________ 15

2.7.5. Connecting Power Outputs ________________________ 16

3. User Interfaces ______________________________________________ 18

3.1. Display ________________________________________________ 19

4. Functions ___________________________________________________ 22

4.1. Application Control ______________________________________ 23

4.2. Modbus Addressing _____________________________________ 24

4.3. Temperature Acquisition _________________________________ 24

4.4. Temperature Logger _____________________________________ 27

4.5. Reference for the Capacity Controller_______________________ 29

4.6. Compressor Capacity Control _____________________________ 30

4.7. Emergency Cooling Function ______________________________ 34

4.8. Evaporator Fan Control___________________________________ 35

4.9. Condenser Fan Control___________________________________ 36

4.10. Defrost Control _________________________________________ 37

4.10.1. Defrost Execution Details _________________________ 38

4.10.2. Defrost Scheduling_______________________________ 39

4.11. Melt Function___________________________________________ 40

4.12. Case Cleaning Function __________________________________ 41

4.13. Night Operation _________________________________________ 42

4.14. Blind Control ___________________________________________ 42

XT Controllers for NLV-CN Compressors

4.15. Light Control ___________________________________________ 43

4.16. Real Time Clock and Control Timer ________________________ 44

4.17. Alarm Handler__________________________________________ 45

4.17.1. Application Related Alarms________________________ 45

4.17.2. Alarm Acknowledgement _________________________ 47

4.18. Safety Function _________________________________________ 47

4.19. Event Logging __________________________________________ 47

4.19.1. List of Possible Events ____________________________ 48

4.20. Service Mode ___________________________________________ 49

4.21. Rail Heater Control ______________________________________ 51

4.22. Gearbox _______________________________________________ 52

4.23. Storing and Restoring to Factory Settings ___________________ 56

5. Analog and Digital Inputs and Outputs ___________________________ 58

6. Configuring Relays ___________________________________________ 60

7. Modbus _____________________________________________________ 64

7.1. Short Description of All Bus Parts _________________________ 65

7.2. Installation _____________________________________________ 66

8. Technical Data _______________________________________________ 70

8.1. Controller Connection ___________________________________ 71

8.1.1 Input Power_____________________________________ 72

8.1.2. Relays _________________________________________ 72

8.1.3. Modbus ________________________________________ 72

8.1.4. Temperature Sensors_____________________________ 73

8.1.5. Analog and Digital I/Os____________________________ 73

8.2. Controller Data _________________________________________ 74

8.3. Compressor Data _______________________________________ 74

8.4. Capacity and Performance Data NLV12.6CN _________________ 75

8.5. Capacity and Performance Data NLV10CN___________________ 76

8.6. Capacity and Performance Data NLV8.0CN __________________ 77

9. Dimensions__________________________________________________ 78

10. Ordering ____________________________________________________ 80

10.1. Secop Orders ___________________________________________ 81

10.2. Third-Party Orders ______________________________________ 82

NLV with Intelligent Multi Voltage Controller _________________________ 84

Secop Group: Around the World ____________________________________ 86

Page 4 / 5

1

INTRODUCTION

The 105N4866 controller regulates temperatures in refrigeration appliances, including supermarket

refrigeration, freezer cabinet systems, and industrial kitchens.

The controller is a complete case controller with integrated inverter for variable speed compressors.

The controller is fully functional in every operation required for modern refrigeration control. The

controller connects to a range of interfaces such as potentiometers, LED displays, PC software, and bus

monitoring systems. The controller features an internal temperature and event logging system as well as

general-purpose interface for broad and flexible application.

The compressor should be operated under the following conditions:

>Line voltage: Multi-Voltage (100–127V + 220–240V) operation 50/60 Hz

>Ambient temperature: 0 to 43°C

The controller should not be used in ambient air containing acids or alkalies. To ensure an optimal service

life, the ambient temperature should be kept as low as possible (ambient temperature range for operation:

0 to 50°C compartment temperature, humidity 30–90%). The heat sink on the control units should not be

covered, and no objects should be lent up against the enclosure.

The control system should not be exposed to dust and water above the IP43 requirements.

Ambient temperature range for storage: -20°C to 70°C

The controller can be accessed via:

> The local display CRA 162, 172, and 200

> The Secop PC Service tool Tool4Cool®together with a RS485 gateway

> A custom interface – please contact Secop for further information regarding custom interfaces.

1.1.

Applications

1.2.

Capabilities

1.3.

Operating

Conditions

1.4.

Programming

Interface

XT Controllers for NLV-CN Compressors Page 6 / 7

>IP43 housing for maximum environmental protection

>8 relay outputs for controlling fans, heaters, light, valves, and alarm output

>4 temperature sensors with weighting for temperature control, defrosting,

condenser sensing, and HACCP

>4 digital inputs for door sensors, blind curtain, coordinated defrosting, light

control, and main switch

>2 analog inputs for pressure transducers

>2 analog outputs for expansion valve control or light intensity

>5 application sets of parameters for multi-function cabinets

>Motor control for variable speed brushless motors

>PID capacity control for precise cooling capacity control

>Management of minimum and maximum run times

>Alarm indication on the display, buzzer, via the Modbus interface, or via

relay

>Display control (optional)

>Data logging system to save events in the memory of the control unit

>Hot gas defrost system with algorithms to reduce risk of liquid return to

compressor

>Speed control evaporator and condenser fans

>Modbus communication for supermarket monitoring systems

>HACCP temperature reporting (not approved yet)

>Supported by Tool4Cool®

>Firmware upgrading through Modbus

>Power-factor corrector to comply with EU regulations

>Available for multi-voltage (100–127 V + 220–240 V) operation

>Backwards compatible connection to 105N46xx series controllers

>CCC-, UL-, VDE-approved with annex AA

The controller also features integrated monitoring of the operating conditions

and takes corrective action to prevent any damage to the electronics, which

1.5.

Main Features

could potentially occur in the event of an overload.

The following monitoring functions ensure that operating conditions remain

within the acceptable range:

>Temperature sensor on the printed circuit boards to monitor the

temperature of the electronics in the enclosure

>Temperature sensor to monitor temperature in the motor inverter

>Monitoring for correct motor speed; motor speeds outside the permitted

range can damage the valves and bearings

>Inadequate line voltage due to fluctuations in the line supply

>Locked rotor caused by excessive pressure

>Defrost valve and temperature sensor defects

Other advantages:

>Minimal start current required due to soft start of compressor

>Controlled restart

>Control of the pressure equalization time

Page 8 / 9

2

HARDWARE

INTERFACE

DESCRIPTION

>The connections are divided into different areas:

• a “hot area”which is connected to line voltage;

• a “cold area”which is separated from line voltage and safe to touch.

This includes all sensors, display, and low-voltage signals; and

a barrier in the housing, makes it possible to route low voltage cables

and keep power cables separated.

>Signal lines must be separated from power lines

>Relay RL8 can both be used as a signal relay or power-relay. In case it is

used for power, the cable must be routed together with the power-cables.

>Maximum cable length for signal and sensor cables is 3 meters. A cable

length of more than 3 m could alter the EMI performance.

>All protective earth lines, PE, in the application must be connected to one

star point.

The star-point is normally a screwed terminal on the chassis This prevents

loop currents which could cause problems concerning the electronic

components, communication lines and sensors.

>RCCBs (Residual Current Circuit Breakers) is recommended for safe

installation.

>The controller must be protected by a circuit breaker, type C, 16-20A.

>L and N connection must be respected for polarized power-cords.

>Connecting the Modbus communication line between two devices when

the cable is installed outside the building or between two buildings is not

allowed. This prevents potential induction problems, in case of lightning.

>The display connection is used to connect the Secop display CRA 162, 172,

and 200. Please refer to the hardware specifications for approved operating

conditions.

>Installation may only be done by trained personal.

>Do not remove the cover of the inverter when the unit is powered.

>Disconnect from power and wait 30 seconds before accessing terminals.

2.1

In General

XT Controllers for NLV-CN Compressors Page 10 / 11

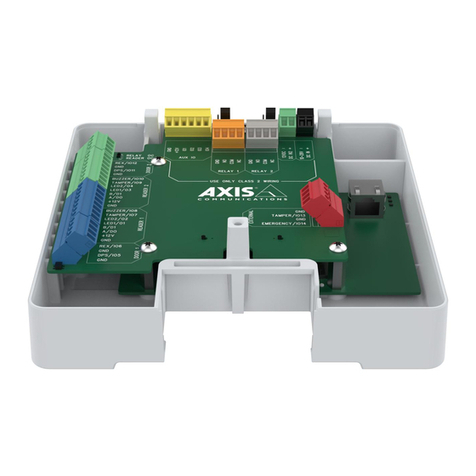

2.2.

Controller

Connections

8936-5

Spade connectors 6.3 x 0.8

RAST 2.5

RAST 5 RJ45 connector

L

L

N

PE

PE

N

RL2

N

RL1

N

RL3

N

N

RL5

RL6

RL7

RL4

N

S

NO

NC

RL8 Modbus DIO1 DIO2 Displa y

AIO

S4

S3

S1 S2

GND

GND

GND

GND

GND

GND

GND

12V

I/O

12V

I/O

12V

open

open

open

Aout 1

Aout 2

Ain2

Ain1

Inp.

Inp.

Inp.

Inp.

GND

12V

I/O

RAST 5

Sensors

Relays Display

DIO1/2

AIO

Modbus

Mains

100-240 V

50/60 Hz

NL

Supply Relays

L

L

N

PE

PE

N

RL2

N

RL1

N

RL3

N

N

RL5

RL6

RL7

RL4

N

S

NO

NC

RL8 Modbus DIO1 DIO2 Displa y

AIO

S4

S3

S1 S2

GND

GND

GND

GND

GND

GND

GND

12V

I/O

12V

I/O

12V

open

open

open

Aout 1

Aout 2

Ain2

Ain1

Inp.

Inp.

Inp.

Inp.

GND

12V

I/O

>Ensure proper airflow of 3 m/sec. at both compressor and heat sink of electronic unit..

>Ensure that the controller doesn’t block for the airflow to the compressor..

2.4

Mounting:

Airflow

2.3.

Earthing the

Compressor and

Controller

>For optimum EMC performance, the copper shield on the controller cable must be fastened properly in

the clip at the compressor.

>Compressor and controller must be connected to PE (Protective Earth) to avoid risk of electrical

hazard.

>All protective earth lines, PE, in the application must be collected to one star point. This prevents loop

currents which could cause problems concerning the electronic components, communication lines,

and sensors. The star point is normally a screwed terminal on the chassis.

XT Controllers for NLV-CN Compressors Page 12 / 13

2.5

Brazing:

Warning!

Brazing on Suction Connectors

(Direct Intake)

Refer to Product Bulletin:

Brazing on Suction Connectors

(Compressors with Direct Suction Intake)

R290

!

To remove a compressor

from a system, the tubes

must be cut.

Never use a torch to

remove brazed tubes.

2.6.

Checklist

Software Download

Tool4Cool®Flexible Control Settings

www.secop.com/tool4cool

32

4 5

Secop 105N4866

controller

Service product

key for controller:

- On request -

NTC temperature

sensor

(color-coded)

Display

CRA 200, 172

or 162 cable

must be ordered

separately)

RS485 to USB

gateway

>Gateway

>USB power

supply

>DSUB-9/RJ45

adaptor

>RJ45 Ethernet

patch cable

Tool4Cool®

LabEdition

software

1

!

2

3

4

5

1

2.7.

Electrical Ratings Electronic unit 105N4866

Power supply

Nominal voltage 100–240 V AC

Minimum operating voltage 80 V AC

Minimum starting voltage 180 V AC

Maximum voltage 270 V AC

Frequency 50–60 Hz

Max power input 1,000 W

Power factor corrector Yes, active, PF ≥ 0.95

Motor cable length 680±20 mm / 26.0–27.6 in.

Environment

IP class IP43

Humidity 30–90% rH

Maximum operating temperature 50°C / 120°F

Minimum operating temperature 0°C / 32°F

Storage temperature -30 to 70°C / -22°F to 158°F

Approvals/Safety

Compressor protection Software protection + internal in compressor

Safety Approval

UL60335-2-34 with Annex AA

EN60335-2-34 with Annex AA

CB, CCC

EMC conformity According to 2014/35/EC

RoHs conformity 2011/65/EU

Speed control

Frequency input 5–12 V, max. 8 mA, 0–200 Hz

Galvanic isolated, short and reverse protected

AEO thermostat input (Lsw) 80–264 VAC, non-isolated

AEO defrost input (Def) 80–264 VAC, non-isolated

RX/TX interface (DWI) 5–12 V, max. 8 mA, 600 baud galvanic isolated

Single wire interface (SWI) Modbus communication port, 9600 baud galvanic isolated

Relays

Max. individual load RL1–RL7 8A resistive. 30,000 cycles

Max. total load RL1–RL7 16A resistive

Max. load RL8 3A resistive

XT Controllers for NLV-CN Compressors Page 14 / 15

2.7.3.

Modbus

Connection

Name Pin Signal Type Specification

MODBUS

RTU

4 D1

TOP

Common

D0

D1

1

8

Standard: IEA485

Maximum nodes:

With RC termination: 100

With resistor termination: up to 32

Cable max. length: 1000 m

Maximum stub No. and length: 30/1 m

Termination: Resistor 150 Ω (30 nodes)

Recommended RC series: 120 Ω, 1nF

Installation must be in accordance to “standard

modbus.org” with RJ45 plugs and CAT5

5 D0

8 Common

System Stop No Operation Nominal 100–127 VAC No Operation Nominal 220–240 VAC No Operation

<50 V <80 V 80–90 V 90–150 V 150–155 V 155–160 V 160–180 V 180–270 V 270–280 V >280 V

>The dark green area shows “Continuous Run”

• Within this range, the compressor can run, start, and stop without any restrictions.

>The light green range shows where the compressor will continue to run, yet restarts are not possible

>As soon as you enter the “No Operation” area, the controller will show a voltage failure. It will stop and

only start again within “Continuous Run” area (dark green)

>In the red area (below 50 V), the controller will switch off and can no longer send any alarm, etc.

Power connection can be done by:

>2-pole Rast5 connector

>Standard 6.3 × 8 mm faston connectors

Note:

Maximum current rating for the chosen connector system and proper wiring must be considered in the

application.

Name Type Coding of external connector

Protective earth (PE) 2 pcs. tab 6.3 ×0.8 mm No coding

Power supply

2 pole RAST 5

or

2 pcs. tab 6.3 × 0.8 mm

(Black means pin is present)

P

1

K

2

1a 1b 2a 2b

1c 2d

2.7.4.

Power

Connection

The controller operates in two voltage bands.

>At startup, the controller will detect the connected voltage and set the minimum and maximum limits

for the detected band accordingly.

>If the controller operates in the low voltage band and detect a voltage higher than 150 VAC but lower

than 160 VAC, it will close and disconnect all outputs.

>If the voltage is above 180 VAC it will switch to the high band after a short interruption.

>The disconnection of the relays and compressor is to protect both compressor and auxiliary devices

such as fans and valves.

2.7.1.

Temperature

Sensors

Name Pin Type Specification

S1

1 GND

Measurement range: -55 to 85°C

Sensor characteristics:

Nominal resistance at 0°C: 16.3kΩ

Nominal resistance at 25°C: 5.0kΩ

Nominal resistance tolerance: ±2%

B value: 3980 K

B value condition: B25/100

B value tolerance: ±1.5%

2 Not connected

3 Analog input

S2

1 GND

2 Not connected

3 Analogue input

S3 1 GND

2 Analogue input

S4

1 GND

2 Not connected

3 Analog input

The controller provides the option to connect up to 4 temperature sensors.

The general sensor setting is:

>Sensor S1 and S2 are used to measure the cabinet temperature.

>Sensor S3 is used for product temperature (HACCP) or condenser fan control.

>Sensor S4 is used for controlling defrost.

2.7.2.

Analog and

Digital I/Os

Name Pin Type Specification

DIO1

1 GND 10–12 V DC

2 V supply

3 Digital I/O

Digital output: “open collector”

Internal pull-up resistor to V supply: 10 kΩ

Signal voltage range (low/high): 0/5–12 Vpp

DIO2

1 GND 10–12 V DC

2 V supply

3 Digital I/O

Digital output “open collector”

Internal pull-up resistor to V supply 10 kΩ

Signal voltage range (low/high): 0/5–12 Vpp

Display

(DIO3)

1 GND 10-12V DC

2 V supply

3Single wire interface signal

(SWI)

Internal pull-up resistor to V supply 10 kΩ

Signal voltage range: 5–12 Vpp

Max current sourcing: 20 mA

Half-duplex single wire, baud rate: 1200–9600

AIO1

1 GND 10–12 V DC

2 Vsupply

3 Analog/digital input Analog signal range: 0–5 V

Input impedance >10 kΩ

4 Analog/digital input

5 Analog output Currently not enabled

6 Analog output

The controller provides 2 analog I/Os and 4 digital I/Os.

The digital I/Os can be used to connect the auxiliary contact device, door sensor, buzzer, and light switch.

The controlling function can be selected by the software parameters.

The analog I/Os can be used for customized use such as pressure transducers, light control, and fan

speed control. The analog inputs can be configured as digital inputs too.

XT Controllers for NLV-CN Compressors Page 16 / 17

2.7.5.

Connection of

Power Outputs

>All connector outputs on the power board are pre-wired with neutral and live switched over the relay.

>The connector outputs are mechanically coded to prevent wiring errors in production and service.

>Connectors 1 to 4 are compatible with 105N46xx series controllers.

>The coding scheme shows the position of keying and locking latches. Black means the key is present.

>Max. load for individual relays: RL1–RL7:

• 8 A res., 30,000 cycles

• 2(2)A, 100,000 cycles

• 12 RLA, 2 FLA, 100,000 cycles

>Max. total load for RL1–RL7 depends on compressor status:

• max when compressor is stopped: 16A (electrical defrost)

• Max when compressor is running: 6A

>Max load: RL8: 2A res, 100.000 cycles

Name Connector Pin Type Connector

RL 1 1

1 Live switched, N.O. P

1

K

2

1a 1b 2a 2b

1c 2d

2 Neutral

RL 2 2

1 Live switched, N.O. P

1

K

2

1a 1b 2a 2b

1c 2d

2 Neutral

RL 3 3

1 Live switched, N.O. P

1

K

2

1a 1b 2a 2b

1c 2d

2 Neutral

RL 4

RL 5 4

1 RL4 output, live switched, N.O. P

1

K

2 3

1a 1b 2a 2b 3a 3b

1c 2d 3a 3b

2 RL5 output, live switched, N.O.

3 Neutral

RL 6

RL 7 5

1 RL6 output, live switched, N.O. P

1

K

2 3

1a 1b 2a 2b 3a 3b

1c 2d 3a 3b

2 RL7 output, live switched, N.O.

3 Neutral

RL 8 6

1 N.C.

1

K

P

2 3

1a 1b 2a 2b 3a 3b

1c 2d 3a 3b

2 N.O.

3 Base pin

Page 18 / 19

3

USER

INTERFACES

The different parameters of the controller

can be accessed via the local display or via

the Modbus. In this section, only the local

display interface will be described.

3.1.

Display

The display performs the following functions:

>Daily operation of the cooling appliance

>Readout of measurements and status of the refrigeration system, actual temperature, alarms

>Defrost activation

>Start and stop of appliance

>Setting of parameters

>Reset of alarms

The display has the following layout:

Left are 4 status LEDs with the following functions (from top down):

1) LED 1: Compressor Run Status (unless defrost)

2) LED 2: Defrost, Melt, Case Cleaning

3) LED 3: Alarm

4) LED 4: Editing Mode

>One minus sign

>3 seven segment LEDs (1,2,3) with one decimal dot between LED segment 2 and 3

>3 push buttons with the following names (from top down):

top button, middle button, bottom button

Display CR-172

XT Controllers for NLV-CN Compressors

Menu structure for the display:

The maneuvering through the local display menu structure is based on different activations of the buttons

on the right side of the front.

There are 3 different ways of activating the buttons:

>single short activation

>single long activation

>triple short activation

Event Action

Top button short Application change over if more than one application is enabled. Repeated

activation toggles between the enabled applications.

Top button triple Change Modbus address (only when stopped)

Top button long No action

Middle button short Start/Stop defrost depending on d90 and d61

Middle button triple Change to Code/-> (Edit Set point)

Middle button long No action

Bottom button short Acknowledge alarm/Inspect alarm list

Bottom button triple No action

Bottom button long Stopped / Running

By entering the correct access code, it’s also possible to access the service level of the controller. In

addition to the numeric display, there are 4 additional LED’s which show the status of Alarm, Defrosting,

Service, and Cooling.

To access the different parameters of the controller for the local display interface, there are three different

access levels.

Each level can be protected with an individual access code, defined by the manufacturer of the cooling

appliance. If a level is protected with an access code, this code must be entered first. If the controller is

accessed via both the CRA 162/172/200 and the Modbus at the same time, the latest modified value for a

setting will be stored as the final.

The access code can be adapted in the Service Mode structure in Tool4Cool®

Parameter Function Code Min. Max. Default

Setting

Access code Daily User o05 0 999 0

Access code Ice o06 0 999 0

Access code Bottle o07 0 999 0

Access code OEM o08 0 999 0

Page 20 / 21

Page 22 / 23

4

FUNCTIONS

4.1.

Application

Control

The controller is designed for multi-application cabinets. For instance, universal cabinets where the

user can change the unit from freezer to cooler mode just by pressing a button or by changing a single

parameter.

Up to 5 applications can be defined. Each application contains basically any setting for a specific

application, such as freezer, cooler, dairy products, meat, or night operation. Applications can be changed

via the local display, Modbus, external switch, or internal timer.

The following parameters can be set:

>Temperature settings: set points, offsets, time constants, sensor weighting

>Alarms: Which alarms should be reported and were, limits, delay of alarms

>Defrost control, defrost scheduling

>Relay usage

>Sensors, time constants, offsets

>User interface: resolution of temperature, temperature unit, definition of buttons

>Peripherals, fans, light, heaters

How to manage applications:

1. Enable the number of applications you need. If only 2 are needed, then enable 2 and disable the

remaining

2. Name the applications to get a better overview in Tool4Cool®

3. Select the application to edit the parameters

4. Go through the settings one by one

5. When finished, switch to the next application and repeat (4) until all (enabled) applications have been set

Parameter Function Code Min. Max. Default

Setting

Application selection via MMI and remote

0: Application 1

1: Application 2

2: Application 3

3: Application 4

4: Application 5

P10 0 4 0

Application 1 selectable P01 0 1 1

Application 2 selectable P02 0 1 0

Application 3 selectable P03 0 1 0

Application 4 selectable P04 0 1 0

Application 5 selectable P05 0 1 0

Selected application (Read only)

0: Application 1

1: Application 2

2: Application 3

P20 0 4 RO

Application selection via DIO P27 0 5 0

Application 1 nighttime P21 0 (none) 5 0

Application 2 nighttime P22 0 (none) 5 0

Application 3 nighttime P23 0 (none) 5 0

Application 4 nighttime P24 0 (none) 5 0

Application 5 nighttime P25 0 (none) 5 0

Application active timer P28 0 5 0

XT Controllers for NLV-CN Compressors Page 24 / 25

4.2.

Modbus

Addressing

The controller can be mounted in a Modbus network of up to 99 controllers. To recognize the different

controllers on the network, each controller must have its own, unique address.

Functional description:

The Modbus address can be set either via the Tool4Cool®service tool or the local display. If the controller

has a password, this must be entered first.

The address range can be set in the range from 1 to 99. Parameter “Modbus address” (o03).

Restrictions:

If the Modbus address is modified via the Tool4Cool®, the user must ensure that the new address is within

the setting range of the Tool4Cool®, otherwise communication to the controller will be lost, until the

correct address range has been selected on Tool4Cool®, and the network has been scanned again.

Parameter Function Code Min. Max. Default

Setting

Modbus address o03 0 99 1

Modbus baud rate

1 = 9600

2 = 19200

o04 1 2 2

4.3.

Temperature

Acquisition

The temperature acquisition system handles all the temperature measuring related issues, such as

sensor selection, weighting of sensors, and sensor error detection.

The NLV controller has 4 sensor inputs. The S1, S2, S3, and S4 sensors are compatible with the 5K NTC

sensors. All sensors are NTC sensors. Please refer to the chapter Temperature Sensors.

Sensor configuration:

The sensors are configured by software parameters in the function where it is used.

For instance, the defrost sensor is configured in the defrost control menu. Temperature control sensors

are configured for several functions, such as capacity control, alarms, display, Modbus reading, or

temperature logging.

Generally, the S1 and S2 sensors are used to measure the cabinet temperature, S4 for controlling defrost,

and S3 for product temperature or condenser fan control.

Offset adjustment of temperature measurements:

To compensate for measuring errors or wrong placement of the sensor, all sensors include an offset

adjustment. With the parameter “Fx temperature offset” (r09), (r10), (r55), and (r57) it is possible to adjust

the respective temperature measurements from -10 to 10 K.

Filtering of temperature measurements:

Furthermore all temperature measurements can be filtered with the parameter “Filter constant for Txx”

(o90 to o96), which can be used for very unstable or fluctuating temperatures.

>0: no damping, (fastest updating of the read out)

>10: 0.01 K/sec (slowest updating of the read out)

Weighting of sensors:

In some cases, it might be necessary to use 2 sensors at different locations, to achieve the correct

temperature measurement. For instance, top-bottom, left-right, or evaporator inlet – outlet.

Different weighting (balancing) can be set for sensor S1 and S2 at day and night, for alarms, temperature

control, and display.

Weighting is done by setting a parameter between 0 to 100%, depending on how much influence the

sensors should have on the temperature measurement.

If the parameter is set to 0%, only S1 is used, if set to 100%, only S2 is used.

If 50%, both S1 and S2 will have the same influence.

Example: S1 is -22°C and S2 is -18°C. If weighting (w) set to 25%, the resulting temperature is -21°C.

Parameter Function Code Multiple

Apps Min. Max. Default

Setting Unit

S1 temperature offset r10 x -10 10 0 °K

S2 temperature offset r09 x -10 10 0 °K

S4 temperature offset r57 x -10 10 0 °K

S3 temperature offset r55 x -10 10 0 °K

S1/S2 temperature offset r04 x -10 10 0 °K

Filter constant for Tact o90 x 0 (none) 0.10 0.01 K/sec.

Filter constant for Talarm o91 x 0 (none) 0.10 0.01 K/sec.

Filter constant for S1/S2 o92 x 0 (none) 0.10 0.01 K/sec.

Filter constant for S4 o94 x 0 (none) 0.10 0.01 K/sec.

Filter constant for S3 o96 x 0 (none) 0.10 0.01 K/sec.

Parameter Function Code Multiple

Apps Min. Max. Default

Setting Unit

Definition and weighting, of sensors S1 and

S2 when daytime mode is present (100%=S2,

0%=S1)

r15 x 0 100 100 %

Definition and weighting, of sensors S1 and

S2 when nighttime mode is present (100%=S2,

0%=S1)

r61 x 0 100 100 %

Definition and weighting, of sensors S1 and S2

Talarm (100%=S2, 0%=S1) A36 x 0 100 100 %

Definition and weighting, of sensors S1 and S2

for S1/S2 (100%=S2, 0%=S1) o17 x 0 100 100 %

XT Controllers for NLV-CN Compressors Page 26 / 27

Read out on the display:

It’s possible to select between a variety of different parameters to be shown on the display, “Display

temperature” (099). With “Display minimum limit temperature” (r06) the minimum read out can be limited

downwards. Furthermore, it’s possible to select, whether the temperature read out on the display must be

in °C or °F. The parameter “Temperature unit” (r05) is set to °C as default.

Restrictions:

All sensor inputs include a detection of open or shorted sensors. A sensor alarm will only be reported

and sent out if the sensor is being used by a function. If a sensor fails the sensor readout will be set to

-300 °C for an open circuit and +300 °C for a shorted sensor. If the sensors S1/S2 are used in a weighted

combination and one of the sensors fails, the sensor with no failure will be used and weighting is disabled.

An alarm will be sent out for the defective sensor.

Dependencies:

The step resolution for the display will be defined by the parameter “Display temperature step resolution”

(o15). Please refer to chapter Display.

Parameter Function Code Multiple

Apps Min. Max. Default

Setting Unit

S1 temperature U12 -300 +300 RO °C

S2 temperature U16 -300 +300 RO °C

S3 temperature U76 -300 +300 RO °C

S4 temperature U09 -300 +300 RO °C

S1/S2 temperature U98 -300 +300 RO °C

Tact temperature U17 -300 +300 RO °C

Thaccp temperature U99 -300 +300 RO °C

Tdisp temperature (displayed on MMI) U56 -50.0

(see r06) +300 RO °C/°F

Talarm temperature U57 -300 +300 RO °C

Actual

Cabine

temperature

U12 r10

r09 r04

F

o91 o90

FF

o92

TS3/S4

o17

S3 offset

S4 weight TS3/S4 S4 weight Talarm S4 weight Tact

Tact

act

Night

Talarm

alarm

S3/S4 offset S3/S4

S4 offset

+

+

+

S3

U16

U98 A36 U57 U17

Secop

06.10

r61

r15

S4

Parameter Function Code Multiple

Apps Min. Max. Default

Setting Unit

Temperature unit (°C = 0/°F = 1) r05 0 1 0 °C/°F

Display minimum limit temperature

(-300 if used sensor value is faulty) r06 -50

(-300) 20 -50 °C

Display temperature step resolution

1 = 0.1°K

2 = 0.5°K

3 = 1.0°K

o15 x 1

(0.1)

3

(1.0)

2

(0.5)

-

(°K)

Display temperature

0 = S1/S2 (U98)

1 = Talarm (U57)

2 = Tact (U17, default)

3 = Thaccp (U99)

4 = S1 (U12)

5 = S3 (U76)

6 = S2 (U16)

7 = S4 (U09)

o99 x 0 7 2 -

Selection of sensor for the HACCP function.

0 = None

1 = None

2 = S2/S1

3 = Talarm

4 = Tact

5 = S4

6 = S3

Note: If “h11 = 0”: Thaccp (U99) = 300.00°C

h11 x 0 6 0

4.4.

Temperature

Logger

The NLV controller has an internal temperature logger that can log a predefined temperature directly

into the memory of the NLV controller. It is possible to attach an alarm to the logger, which will indicate a

warning when the upper or lower alarm limits are exceeded, and when the alarm delay timer has elapsed.

Functional description:

Using the parameter “Selection of sensor for the logger function” (h11), it is possible to select a

temperature sensor or an internal temperature calculation for the temperature logger. If no sensor is

selected, the logger will not begin. Logging speed is determined by ”Log interval” (h01). The number of

logs is limited to 1,000. This means that the duration of the logging period depends on the number of logs.

For logging duration, please see the following table.

Logging Interval Maximum log duration in hours Maximum log duration in days

15 minutes 250 10 days

30 minutes 500 20 days

60 minutes 1000 40 days

XT Controllers for NLV-CN Compressors Page 28 / 29

As soon as the logger is full, the oldest logs will be

deleted and overwritten with a new log.

To limit at a certain number of logs, it is possible to

set up thresholds for the logging range.

Logging of temperatures outside a predefined

range:

As soon as the logger is full, the oldest logs will be

deleted and overwritten with a new log.

To limit at a certain number of logs, it is possible to

set up thresholds for the logging range.

Logging of temperatures outside a predefined

range:

Logging area

Logging area

Low Threshold" (h03)

High Threshold" (h03)

Logging area

Low Threshold" (h03)

High Threshold" (h03)

Parameter Function Code Multiple

Apps Min. Max. Default

Setting Unit

Log interval h01 x 15 240 30 Min.

High threshold for logging h02 x -50°C or

-58°F

50°C or

122°F -50 °C/°F

Low threshold for logging h03 x -50°C or

-58°F

50°C or

122°F 50 °C/°F

Selection of sensor for the logger function

0 = No logging function defined

1 = S1/S2 temperature

2 = Talarm temperature

3 = Tact temperature

4 = S4 temperature

5 = S3 temperature

h11 x 0(0.1) 3

(1.0) 1 -

Alarm limit for the logger function h12 x -50°C or

-58°F 7 60 °C/°F

Time delay for the alarm h13 x 1 6 60 Min.

If the “Low Threshold” (h03) is set higher than the “High Threshold” (h02), only temperatures inside these

limits will be logged.

If the “Low Threshold for logging” and “High Threshold for logging” are set equal, no logging will be

performed.

Furthermore, the temperature logger contains a separate high alarm function (h12) with adjustable alarm

delay (h13).

Restrictions:

The maximum number of logs is limited to 1,000.

In the event of a sensor error on the selected temperature probe, there will be no logging. Instead, a

sensor error alarm will be generated.

4.5.

Reference for the

Capacity Controller

The purpose of the reference function is to generate a reference for the compressor capacity controller

and to create the limits for the temperature setting range during the day and nighttime. Based on the

deviation between the actual temperature Tact, compared to the temperature reference Tref, the capacity

controller will increase or decrease the requested compressor capacity. The bigger the deviation, the

faster the requested compressor capacity will be adapted.

Measurement and calculation of actual cabinet temperature Tact:

The cabinet temperature can be measured with either S1, S2 or in special applications as a weighted

combination of both. In the event of incorrect temperature measurements due to wrong placement of the

sensors, both temperature inputs include an offset adjustment possibility. “S1 temperature offset” (r10)

and “S2 temperature offset” (r09).

For the cabinet temperature measurement, with S1 and S2, a weighting of these 2 sensors is

implemented. Please refer to the chapter Temperature Acquisition.

Calculation of Tref

Tset r01

Tref

Max.

Secop

09.10

Max.

Min.

Min.

Night

Night offset

U28

r25

r03

r13

r02

r26

Tset

Limit Tref

Limit

Parameter Function Code Multiple

Apps Min. Max. Default

Setting Unit

Tset r01 x -49 Qqy -20 °C

Max. limitation of reference Tset r02 x -49 50 -15 °C

Min. limitation of reference Tset r03 x -50 49 -27 °C

Max. limitation of reference Tref r25 x -49 50 -15 °C

Min. limitation of reference Tref r26 x -50 49 -27 °C

Tset nighttime temperature offset r13 x -10 10 0 °K

Switch between sensor S2 and S4

Note: All parameter names are listed for value

0 (S2)

o18 x 0 = S2 1 = S4 1 -

The temperature reference Tref for calculating the reference for the PID controller is calculated as follows:

Tref = Tset + “Nighttime temperature offset” (r13)

The setting range of Tset can be limited with the 2 parameters “Tset max” (r02) and “Tset min” (r03).

To avoid a temperature reference too high or too low, the allowed temperature reference band is limited

with the following 2 set points: “Tref min” (r25) and “Tref max” (r26).

XT Controllers for NLV-CN Compressors Page 30 / 31

4.6.

Compressor

Capacity Control

The purpose of this function is to calculate the requested compressor capacity that is needed to cool down

or maintain the correct cabinet temperature during normal temperature control.

During the pull up/down of the cabinet, after the initial start or after a defrosting sequence, the capacity

controller will be overruled by predefined capacity requests.

Functional description:

The reference “Tref” for the controller is given by the reference function, based upon either the temperature

sensor S1, S2, or a mix of both.

The actual requested compressor capacity is determined based on a PI controller that compares the

actual temperature with the reference temperature. The greater the deviation in temperature, the faster

the adaptation of the compressor capacity is performed.

The compressor can be speed controlled in the range from 45% to 100%, corresponding to 2,000 to 4,500

revolutions per min. If the requested compressor capacity is less than 45%, the compressor will start and

stop at 2,000 RPM on a PWM basis. As default, the “Compressor Period Time” (g05) is set to 15 minutes.

This means that the compressor will be running for a shorter or longer time within this period.

The capacity controller contains compressor protection settings to prevent the start/stop of the

compressors from occurring too often (g03 and g04).

After initial start, the compressor capacity will be set to 100%, until the reference temperature Tref has

been reached. In some applications it might be an advantage to run the compressor at the pull-down

capacity for some extra time. Although the air temperature in the cabinet has reached the set point, the

goods will still be too warm. For that reason, the pull-down period can be extended, until the “Tact below

Tref to end Pull Down” (n48) has been reached. After this the PI controller will be preset to a default value,

depending on whether the controller is in day or night mode (n53 and n54).

Depending on the size of the deviation between the reference temperature Tref and the actual temperature,

the requested capacity will now be increased or decreased faster or slower. The speed of adapting the

requested capacity depends on the settings for the PI controller.

Requested Compressor Capacity Compressor Speed, Period Time = 15 minutes

0% Compressor constantly stopped

22%

Pulse width modulation, PWM

7,5 minutes ON (2000 RPM)

7,5 minutes OFF

45% Compressor constantly running 2,000 RPM

100% Compressor constantly running 4,500 RPM

Due to different load profiles for the different applications, the controller has a “smart setting for PI

control” (n30) application. The default setting is medium control, but if a faster adaptation of the requested

compressor capacity is needed, this can be changed to fast or even very fast control. On the other hand,

this can also be set to slow or very slow, if the cooling application requests this. In situations, where one

of these settings is not suitable for the application, the PI settings can be adjusted by the customer (n35

to n43). Contacting the supplier of the controller is recommended for optimal adjustment. Although, the

right smart setting or individual adaptation of the PI controller has been chosen, a cabinet temperature

exceeding a pre-defined minimum or maximum limit, compared to the temperature reference Tref could

occur.

As soon as the temperature reaches the limit of “Tact above c to start Pull Down limit” (n47) or the limit

of “Tact below Tref to start pull up limit” (n46), a timer “Temperature out of range timeout” (n50) begins.

After this timer has elapsed, a forced pull-up or pull-down starts. The timer will be reset as soon as the

temperature is back within the min. and max. limits.

If a pull down is requested, the compressor capacity will be preset to "Optimized pull down capacity" (n52).

This capacity will be applied, until the time "Optimized pull down time" (n51) has elapsed. Hereafter, the

compressor will run at 100%, until the set point has been reached.

If a forced pull-up has been initiated, the compressor will stop, until the temperature exceeds “Tact above

Tref to end pull-up” (n49).

If the digital input DI1 is defined to be used as a door switch, it is possible to stop the evaporator fan when

the doors are open. It is also possible to override the capacity controller at the same time. The compressor

can be stopped “Compressor capacity switching on door open” (n22) or the compressor capacity can

be preset by “Compressor capacity at door open” (n23). As soon as the door is shut again, the capacity

controller will resume with the same capacity as prior to the door opening.

Defrosting:

The PI controller is suspended during a defrosting sequence. Prior to defrosting, the actual requested

compressor capacity is stored in the memory. Once defrosting is complete and after pull-down of the

temperature to a set point, the normal capacity control is resumed, based upon the previous stored

capacity.

Emergency cooling:

In the event of sensor errors, the capacity controller stops and the compressor capacity is preset to a

customer specified value, “Emergency cooling capacity during S1/S2 error” (n21). For more information,

please refer to the chapter Emergency Cooling Function.

Pull up

n56 in range

Optimised pull down

Pull down

Initial pull down

after start up

n51 optimised

pull down time

n50 |Out

of range

timeout

n50 |Out

of range

timeout

n50 |Out

of range

timeout

Pull Down Cap

n52 Opt pull down Cap

Capacity after pull down

Tact

n47 Start pull down

n49 End pull up

Tref

n48 End pull down

n46 Start pull up

XT Controllers for NLV-CN Compressors Page 32 / 33

Parameter Function Code Min. Max. Default

Setting Unit

Number of compressors g01 1 3 1 -

Compressor minimum stop time g03 1 240 90 sec

Compressor minimum run time g04 1 240 30 sec

Compressor period time g05 5 30 15 min

Compressor swap time

0 = None g06 0 60 1 day

Compressor capacity for starting PWM control g07 1 100 1 %

Compressor capacity for starting speed control g08 20 100 45 %

CC Control Mode

0 = Internal temperature control (PID)

1 = External analog signal (AIO1)

2 = External analog signal (AIO2)

g09 0 2 0 -

Capacity compressor 1 g10 0 100 RO %

Capacity compressor 2 g11 0 100 RO %

Capacity compressor 3 g12 0 100 RO %

Actual main compressor/swapped g13 0 3 RO -

Compressor start delay g14 0 60 5 sec

Parameter Function Code Min. Max. Default

Setting Unit

Electronic power up delay n24 0 240 9 sec

Sensor failure capacity n21 0 100 60 %

Compressor capacity switching on door open

(n23)

0 = Off

1 = On

n22 0/no 1/yes 1 -

Capacity at door open n23 0 100 50 %

Capacity override select:

0 = Temperature Control

1 = Pause Temperature Control (external)

2 = Stop Temperature Control (external)

n28 0 2 RO -

Capacity override value (if n28=1) n29 0 100 RO %

Parameter Function Code Min. Max. Default

Setting Unit

Smart Set:

0 : User defined

1 : Very slow control

2 : Slow control

3 : Medium control (default)

4 : Fast control

5 : Very fast control

n30 0 5 3 -

PID polynomial R1 n35 -50 50.0 -1 -

PID polynomial R2 n36 -50 50.0 0 -

PID polynomial S0 n37 -50 50.0 -4 -

PID polynomial S1 n38 -50 50.0 3,9 -

PID polynomial S2 n39 -50 50.0 0 -

PID polynomial T0 n40 -50 50.0 -4 -

PID polynomial T1 n41 -50 50.0 3,9 -

PID polynomial T2 n42 -50 50.0 0 -

h sampling time n43 10 600 30 sec.

Umin minimum saturation value (high word) n44 0 100 0 -

Umax maximum saturation value (high word) n45 0 100 100 -

Tact below Tref to start pull up limit n46 -10 0 -3 K

Tact above Tref to start pull down limit n47 0 10 3 K

Tact below Tref to end pull down limit n48 -10 10 0 K

Tact above Tref to end pull up limit n49 -10 10 0 K

Temperature out of range timeout n50 0.0 30.0 4 min.

Optimized pull down time n51 0.0 30.0 10 min.

Optimized pull down capacity n52 20 100 60 %

Default capacity day n53 0 100 60 %

Default capacity night n54 0 100 55 %

Out requested capacity (RO) n55 0 100 RO %

Controller state:

0=Off,

1=Pull down

2=Pull up

3=In range

4=Out of range Up

5=Out of range down

6=Override

n56 0 6 RO -

XT Controllers for NLV-CN Compressors Page 34 / 35

4.7.

Emergency

Cooling Function

The purpose of this function is to ensure a reasonable level of refrigeration in case of an error in the

reference temperature sensor.

For low temperature applications, it is better to run at a high compressor capacity while high temperature

applications prefer a reduced capacity to prevent freezing of the chilled goods.

Functional description:

If the sensor required by the application input setup is in a sensor error state, an emergency cling function

takes over and presets the requested compressor capacity to “Emergency cooling capacity during S1/

S2 error” (n21). The emergency cling function takes over the normal capacity control while all remaining

functions will run unaffected.

When normal compressor capacity control resumes, the PI controller will be “released” from the

emergency cling level and the requested compressor capacity will adapt to the actual needed capacity.

Restrictions:

The function is overruled by the main switch off, service mode, case clean mode, loading of cabinet,

drain function cut out or the defrost mode which do not contribute to the calculation of the requested

compressor capacity.

Dependencies:

If a weighting of S1 and S2 is to be used for the input to the temperature reference, the emergency cooling

function will only be enabled when both sensors are detected to be defective. If only 1 sensor is defective,

the calculation of the cabinet temperature will be based upon the remaining sensor.

Parameter Function Code Multiple

Apps Min. Max. Default

Setting Unit

Emergency cooling capacity during S1/S2 error n21 x 0 100 60 %

4.8.

Evaporator

Fan Control

The evaporator fan can be controlled separately during normal operation, defrost, nighttime operation,

and by opening the door opening.

To avoid circulation of warm air in the cabinet, the fan can be stopped when the evaporator temperature is

too high.

To reduce noise and power consumption, the controller supports AC fans with 2-wire speed control.

Speed control can be done either by compressor speed or nighttime operation.

To configure the speed control, both parameters for fan control and relays must be set.

Parameter Function Code

Mul-

tiple

Apps

Min. Max. Default

Setting Unit Details

Evaporator fan mode:

0=Off

1=Enabled

2=Enabled and fan stop check on Tdefr

F01 x 0 2 1 -

If fan mode is 2, the

Tdefr temperature

is checked accord-

ing to F04. When

exceeding this value,

the fan stops. The

fan starts again if

the temperature

at Tdefr gets below

F04–2 K.

Evaporator fan stop on open door

0 = No

1 = Yes

F03 x 0 1 1 -

If set, the fan stops

when the door is

opened.

Evaporator fan stop temperature (Tdefr) F04 X -50 50 10 °C

If the evaporator

temperature is

higher than F04, the

evaporator fan is

stopped.

Evaporator fan speed operation:

0 = No speed control

1 = Low speed at compressor cut out

2 = Fan stop during nighttime operation

3 = Low speed during nighttime operation

4 = Low speed at low compressor speed

5 = (4) + fan stop at compressor stop

F05 X 0 5 0 -

Compressor speed for low Evap

fan speed F06 x 0 4500 0 rpm

If the compressor

speed is below F06,

the fan is set to low

speed.

When the speed of

the compressor has

increased by 200

rpm over F06, the

fan returns to high

speed.

XT Controllers for NLV-CN Compressors Page 36 / 37

Parameter Function Code Multiple

Apps Min. Max. Default

Setting Unit

Condenser fan mode:

0 = Off

1 = Run with compressor

2 = Speed controlled by sensor S3

3 = Always run unless stopped

4 = Run at low speed when compressor stopped

F11 x 0 4 1 -

Condenser fan high speed temperature (S3) F12 x -50 85 35 °C

Condenser fan low speed temperature (S3) F13 x -50 85 30 °C

Condenser fan alarm temperature (S3)

Set to zero the function is disabled F14 x 0 85 0 °C

Condenser fan low speed as function

of compressor speed

0 = constant high speed

4500 = constant low speed

F15 x 0 4500 2500 rpm

Condenser fan speed during defrost

0= Off

1= Low speed

2= High speed

F16 x 0 2 0 -

4.9.

Condenser

Fan Control

The condenser fan can be controlled separately during normal operation and defrosting. To reduce noise

and power consumption, the controller supports AC fans with 2-wire speed control.

Speed control can be done either by compressor speed or by a temperature sensor (S3) placed at the

condenser. The sensor can also be used for issuing a warning or alarm in case of blocked condenser or

defect condenser fan.

To configure the speed control, both parameters for fan control and relays must be set.

1. If F11 is set to 1, the fan speed is determined by the speed of the compressor.

a. If the compressor speed is below F15, the fan will run at low speed.

b. When the speed of the compressor has increased by 200 rpm over F15, the fan returns to high speed.

2. If F11 is set to 2, the fan follows the compressor, but the speed of the fan depends on the S3

temperature. When S3 is above or equal to F12 it runs at high speed. When below F13, it will run at low

speed. If sensor S3 has a failure the fan will run at full speed.

3. Defrost control:

The condenser fan can be stopped during hot gas defrost to optimize the power for defrosting. If the

controller becomes too hot, the condenser fan will be started and run until defrosting has finished.

4.10.

Defrost Control

The defrost control can handle systems with hot gas, natural, and electric defrosting

Scheduling of defrost can be based on a timer counting of the elapsed time to next defrost or real time

clock controlled hours.

The defrost execution contains algorithms to minimize risk of liquid return to the compressor.

1. After defrost has started, the hot gas valve is activated.

2. The compressor is kept stopped for the time defined by parameter d43

3. The compressor runs at low speed for the time defined by parameter d44.

4. After d44, the compressor continues at high speed until end of defrost.

During the defrost, the condenser fan can be stopped to improve the defrosting. The fan will turn on in

case the electronic unit needs cooling.

Parameter Function Code Min. Max. Default

Setting Unit

Defrost temperature U37 -300.00 +300.00 RO °C

Defrost stop temperature d02 0 25 6 °C

Max. defrost duration d04 o/skip 240 45 min.

Drip off time d06 0/skip 60 0 min.

Delay for evap. fan start after defrost d07 0 60 0 min.

Evap. fan start temperature d08 -50 0 -5 °C

Evap. fan cut-in during defrosting d09 0/no 1/yes 1/yes -

Defrost sensor:

0 = Stop on time

1 = S4

2 = S2

3 = S1

d10 0 3 0 -

Heat in drip tray. Time from defrosting stops to

heating in the drip tray is switched off. d20 0 240 30 min.

Drain preheat. Time to heat up the drain be-

fore starting defrosting. d40 0/skip 240 0 min.

Pull-down time. The maximum time that the

system is doing pull-down after defrosting. d41 0 240 0 min.

Hot-gas capacity. The capacity that is used for

hot gas defrosting. Capacity after d44. d42 0 100 0 %

Compressor time at 0 speed after hot gas start d43 0 60 0 min.

Compressor time at low speed after d43 d44 0 60 0 min.

Max hold time after coordinated defrost o16 0/skip 240 20 min.

Capacity during drip off time L95 0 100 0 %

Capacity during drain preheat L96 0 100 0 %

XT Controllers for NLV-CN Compressors Page 38 / 39

4.10.1.

Defrost Execution

Details

Hot gas defrost sequence if defrost temperature sensor is used:

Hot gas defrost sequence if no defrost temperature sensor is used:

For electrical or passive defrost, set the parameter L95, L96, and d42 to 0%.

States

Idle Drain Heat Drip off Pulldown Idle

Cap Rel

Heater / Valve

Drain heater

Evap Fan

S defrost

Defrost

Hold

d41 Pull down time

d06 Drip off time

d42 HotGas capacity

d40 Drain preheat

d09 Evan Fan Stop

d20 Drain Post Heat

d07 Delay for fan

d08 Fan start temp

d02 Stop temperature

d04 Maxduration

States

Defrost

Cap Red

Heater / Valve

Drain beater

Evap Fan

Idle Drain Heat Drip off Pulldown Idle

Hold

d41 Pull down time

d04 Max duration

d42 HotGas capacity

d40 Drain preheat

d09 Evap Fan Stop

d20 Drain Post Heat

d07 Delay for fan

d06 Drip off time

4.10.2.

Defrost Scheduling

Defrost can be done by timer, real-time clock, or manually.

1. Timer initiated defrost:

The timer starts when the defrost has ended. The timer counts elapsed time, not taking compressor

stops into consideration.

2. Clock controlled defrosting:

Defrost is started by the internal real-time clock.

3. Manual defrost:

Defrost can be initiated by pressing a button on the display or by using an external push button,

connected to the DIO. The interval between manual defrosting can be limited by a parameter. Manual

defrosting can be used in combination with automatic defrosting.

Parameter Function Code Min. Max. Default

Setting Unit

Method:

0 = Never

1 = Once per day

2 = Multiple times per day fixed hour

3 = Multiple times per day timer based

4 = Not used

d90 0 4 0 -

Interval between defrost start (timer based) d03 1.0 168.0 4.0 hrs.

Allow remote start of defrost

0 = Disabled

1 = Enabled

d60 0 1 0 -

Enable start from local MMI

0 = Disabled

1 = Enabled

d61 0 1 0 -

MMI min. interval between manual defrost.

The time to disable defrost start after a de-

frost.

If set to zero: no limit is used

d62 0 168.0 21.0 hrs.

Hour to start defrosting or

Hour to start defrosting on Sundays d71 -1(skip) 23 -1 hrs.

Hour to start defrosting or

Hour to start defrosting on Monday d72 -1(skip) 23 -1 hrs.

Hour to start defrosting or

Hour to start defrosting on Tuesday d73 -1(skip) 23 -1 hrs.

Hour to start defrosting or

Hour to start defrosting on Wednesday d74 -1(skip) 23 -1 hrs.

Hour to start defrosting or

Hour to start defrosting on Thursday d75 -1(skip) 23 -1 hrs.

Hour to start defrosting or

Hour to start defrosting on Friday d76 -1(skip) 23 -1 hrs.

Hour to start defrosting or

Hour to start defrosting on Saterday d77 -1(skip) 23 -1 hrs.

Hour to start defrosting d78 -1(skip) 23 -1 hrs.

Start time for defrost in minutes

Days are equal to d7x values

D81 for Sunday, D82 for Monday, …

d81..88 0 59 0 min.

This manual suits for next models

10

Table of contents

Other SECOP Controllers manuals