Seeing Machines Guardian Gen 2 Installation instructions

FIELD SUPPORT MANUAL

Guardian - Generation 2 (Gen2)

PURPOSE

The purpose of this manual is to describe the process for the installation, fault finding

and maintenance of Guardian - Generation 2 (Gen 2). Please refer to the Guardian Field

Installation Manual (June 2016) for installations of the previous generation of Guardian.

All Guardian Gen 2 installations must be completed in accordance with this manual.

This document is the standard for Guardian Gen 2 installations.

Deviation from the process described in this manual may void the warranty of the

product and lead to the suspension of an individual’s certification.

SECTIONS

SECTION

TITLE

0.

Preface

1.

Introduction to Guardian Gen 2

2.

Installation of Guardian Gen 2

3.

Service & Maintenance of Guardian Gen 2

REFERENCE DOCUMENTS

The below referenced documents can be downloaded from the Technical

Communication Portal (TCP) at tcp.seeingmachines.com if you require access to the

TCP, please make a request via the ‘Apply Here’ button on the TCP website.

ITEM

TITLE

1.

Knowledgebase

2.

Installation Checklist

3.

Tutorial videos

4.

Technical Support Bulletins

FCC COMPLIANCY

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation. This product does not contain any user serviceable components. Any

unauthorized product changes or modifications will invalidate warranty and all

applicable regulatory certifications and approvals, including authority to operate this

device.

FCC Part 15 Digital Emissions Compliance

We, Seeing Machines, Level 1, 11 Lonsdale St, Braddon, ACT, 2612, Australia, +61 2 6103

4700, declare under our sole responsibility that the product Guardian complies with

Part 15 of the FCC Rules.

15.19

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

15.105

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

•Reorient or relocate the receiving antenna.

•Increase the separation between the equipment and receiver.

•Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

•Consult the dealer or an experienced radio/TV technician for help.

15.21

Any changes or modifications not expressly approved by the party responsible for

compliance could void the authority to operate equipment.

This device and its antenna must not be co-located or operating in conjunction with any

other antenna or transmitter.

End-users and installers must be provided with antenna installation instructions and

transmitter operating conditions for satisfying RF exposure compliance.

FCC RF Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance

20cm between the radiator & your body.

FIELD SUPPORT MANUAL

Section 1 –Introduction to Guardian Gen 2-2

Table of Contents

1. OVERVIEW.....................................................................................................................................3

2. ABBREVIATIONS ..........................................................................................................................4

3. TERMS............................................................................................................................................7

4. SAFETY ...........................................................................................................................................9

5. PACKAGING ................................................................................................................................10

6. STANDARD COMPONENTS .....................................................................................................11

7. OPTIONAL COMPONENTS.......................................................................................................19

8. INSTALLATION TOOL KIT (Provided by Trainer) .................................................................20

9. REQUIRED TOOLS FOR INSTALLATION.................................................................................21

10. ROLES AND RESPONSIBILITIES...........................................................................................24

1. OVERVIEW

The aim of this section is to introduce the acronyms, components anof Guardian Gen 2

Section 1 A certified Guardian Technician must read and understand this section before

commencing a physical installation of the System.

2. ABBREVIATIONS

ABBREVIATION

MEANING

APN

Access Point Name-Relates to SIM Card

CELL

Cellular

-Wireless communications via a communications network

DC

Direct Current

Demo

Demonstration

DSSi

Driver Safety System interface

EMC

Electromagnetic Compatibility

FFC

Forward Facing Camera

FOV

Field Of View

GPS

Global Positioning System

HSE

Health, Safety and the Environment

ICS

In Cab Sensor (also known as the Driver Facing Camera)

IP

Ingress Protection Marking (for use with connectors)

Internet Protocol (for use with computers)

IR

Infra-Red

IVS

In-Vehicle System

JHA

Job Hazard Assessment

LAN

Local Area Network

LED

Light Emitting Diode

OJT

On Job Training

PC

Personal Computer

PCB

Printed Circuit Board

PIN

Personal Identification Number

PPE

Personal Protective Equipment (e.g. safety glasses, gloves)

PSU

Power Supply Unit

RMA

Return Materials Authorization

URL

Uniform Resource Locator

-Refers to a webpage link

SD

Secure Digital

-Refers to the SD memory card

SIM

Subscriber Identity Module

-As in SIM Card for a communications device

SM

Seeing Machines

TCP

Technical Communications Portal

USB

Universal Serial Bus

HDMI

High-Definition Multimedia Interface

-Refers to video output

Wi-Fi

Refers to a local area wireless network

MEASUREMENTS

MEANING

A

Ampere

C

Celsius

cm

Centimeter

DC

Direct Current

ft.

Feet

g

gram

GB

Gigabyte

F

Fahrenheit

in.

Inch

kg

Kilogram

lb.

Pound

m

Meter

mm

Millimeter

nm

Nanometer

oz

Ounce

RPM

Revolutions per minute

V

Volt

3. TERMS

TERM

DEFINITION

Black Box

Guardian Gen 2-2 has an inbuilt function to record all footage for a set period

of time. This is known as the Black Box Recorder which is similar to a Flight

Information Recorder - “Black Box”.

Certified

Technician

A Certified Technician is a person who has completed the Seeing Machines

training program and has been assessed in the installation and maintenance of

a system in a vehicle. A Certified Technician can complete installations and

conduct maintenance tasks on Guardian.

Configuration

File

The configuration (config) file contains all the details required for the System to

function as per the client’s requirements

FOV

A Field of View (FOV) event is an event where the driver has not been tracked

by the Guardian System for a configurable duration of time whilst travelling at

or above the configured speed limit. You may be asked to rectify FOV’s by a

client or in response to a support ticket.

Isolation

The removal of all electrical energy to the vehicles, providing a safe

environment for workers

Isolation could be achieved by, but is not limited to:

•Switching the main power supply isolation switch to the off position

(where provided)

•Removing the Positive wire from the battery

Non-

Standard

Installation

A Non-Standard Install may be conducted by using non-permanent measures –

Velcro, cable-ties, double-sided tape or magnets. Drilling and cutting are

normally not allowed during a non-standard install.

May also be referred to as a ‘soft’ install.

Operator

The person in control of the vehicle. Can also be called the Driver.

Pitch

The angle in degrees, of the Driver Facing Sensor position up and down.

Value range between 10 to 30 degrees.

(usually mounted on the dashboard is 10 degrees)

RMA

Return Merchandise Authorization (RMA) is the SM mechanism to investigate a

warranty claim.

Soft Install

See ‘Non-Standard Install’

System

Refers to the Guardian Gen 2-2 System but predominately relates to the

hardware.

Yaw

The angle in degrees, the In-Cab Driver Facing Sensor is mounted left or

right in relation to the driver’s head.

Value range between -20 to 20 degrees.

(- equals left of the driver, + equals right of the driver)

4. SAFETY

Safety must be considered prior to installing Guardian.

You must comply with the client’s site safety policies, processes, arrangements and

requirements in place at the site where you will install or maintain the System.

If such policies do not exist it is a requirement to follow the SAFE WORK practices

detailed below.

For additional Safety related information, contact the local Occupational Health & Safety

authority in your country

SAFE WORK means:

LOOK –for the hazards that may be present during the job

ASSESS –the hazards and associated risk involved with the job

MANAGE –the hazards involved with the job with controls

EVALUATE –the effectiveness of the controls

When conducting your Safe Work Analysis, also called a Job Hazard Analysis (JHA), you

must plan for how you will manage the risks and hazards you have identified using the

“Hierarchy of Controls”, where Elimination is the most effective control measure and

Personal Protective Equipment (PPE) is the least effective control measure:

Elimination Completely eliminate or remove the hazard from the job

Substitution Change the task or tool to one with lower risks

Engineering Isolation from the hazard (e.g. machine guards)

Administration Training, policies and procedures

PPE Use of protective equipment such as gloves, safety glasses

5. PACKAGING

ITEM

QTY

DESCRIPTION

IMAGE

Box

1

Packaging: Brown Carton

Size: 280x270x560mm

Weight: 4.7kg

Markings:

Inner

Cartons

2

Contents: 2 layers of shaped

cardboard protecting components

Paperwork

1

Documentation: Installation

Checklist

6. STANDARD COMPONENTS

ITEM

QTY

DESCRIPTION

IMAGE

Controller Unit

1

Controller Unit Hardware:

Input voltage: 10 to 30V DC

Size: 182x124x43mm

Function: This is the Processor of the system

which runs the entire system

Connection:

Size:

Adjustment:

Function:

1

Controller Mounting Pan:

Comes in 2 parts

Connection:

Size: 218x146x54mm (Controller inside)

Adjustment:

Function:

4

Fastener M6x30 5mm cap head with side

hole:

Connection:

Size:

Adjustment:

Function:

4

Fastener M6 SS Nut:

Connection:

Size:

Adjustment:

Function:

4

M6 OD 11.8 SS Split Washer:

Connection:

Size:

Adjustment:

Function:

4

Fastener M6 OD 20 SS Flat Washer:

Connection:

Size:

Adjustment:

Function:

In-Cab Sensor (ICS)

1

ICS Module Hardware:

Connection: To the ICS Cable

Sensor viewing angle: ???

Function: This is the In-Cab Sensor, Audio and

IR Illumination of the system that alerts and

detects fatigue and distraction for the driver

Size: ??x??x??mm

Connection:

Size:

Adjustment:

Function:

1

ICS Cable

Connection: To the ICS Controller Unit

Connection:

Size:

Adjustment:

Function:

1

Mounting Arm Assembly:

Connection:

Size:

Adjustment:

Function:

1

Screw in dash mount

Connection:

Size:

Adjustment:

Function:

3

Fastener 10 Gauge x 25mm black self-

tapping screw CSK

Used with Screw in dash mount

Connection:

Size:

Adjustment:

Function:

1

Adhesive dash mount

Connection:

Size:

Adjustment:

Function:

4

Alcohol wipe

For adhesive dash mount to clean off dust or grease

Connection:

Size:

Adjustment:

Function:

1

Primer pen for VHB tape

For adhesive dash mount (warning could damage

dashboard on removal of this mount)

Connection:

Size:

Adjustment:

Function:

Forward Facing Camera (FFC)

1

FFC Hardware:

Connection: To the Controller Unit

Cable: 7m long cable

Adjustment: 1.5mm Allen key for pitch control

(supplied by installer)

Size: 72 x 41 x 40 mm

Field of View: H105.5°xV63.4°

Function: To provide footage of what the

drivers sees ahead when an event is triggered

Connection:

Size:

Adjustment:

Function:

Vibration Motor

1

Vibration Motor Hardware:

Connection: To the MFC

Cable Length: 4m + MFC 1m

Size: ???

Function: Alerts the driver with Vibration

when the system detects an event

Connection:

Size:

Adjustment:

Function:

Table of contents

Popular Security Sensor manuals by other brands

Oliver IGD

Oliver IGD TOCSIN 102 SERIES Operation manual

Online Electronics

Online Electronics ID5000A operating manual

BeaconMedaes

BeaconMedaes DiamondCare installation instructions

ESYLUX

ESYLUX MD-C 180i/16 Touch Detailed operating instructions

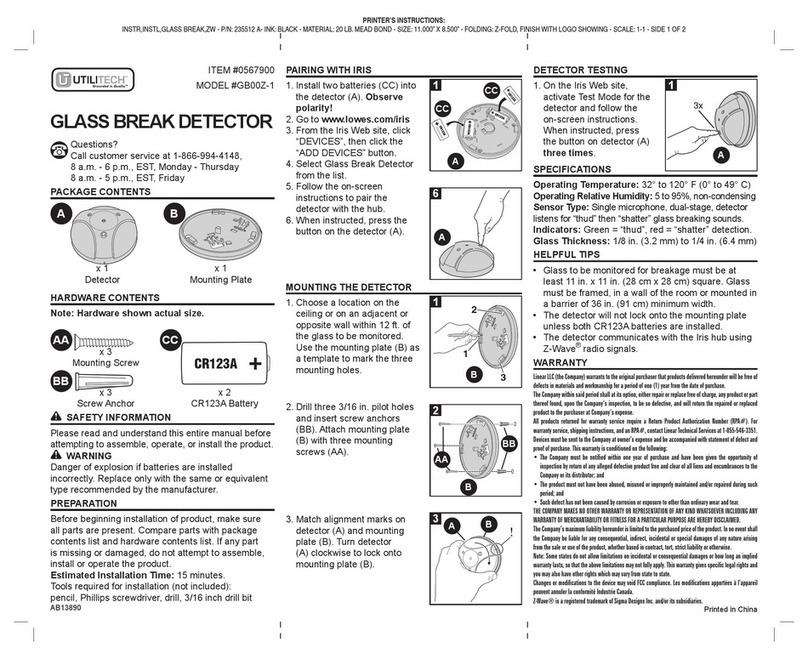

Utilitech

Utilitech GB00Z-1 instructions

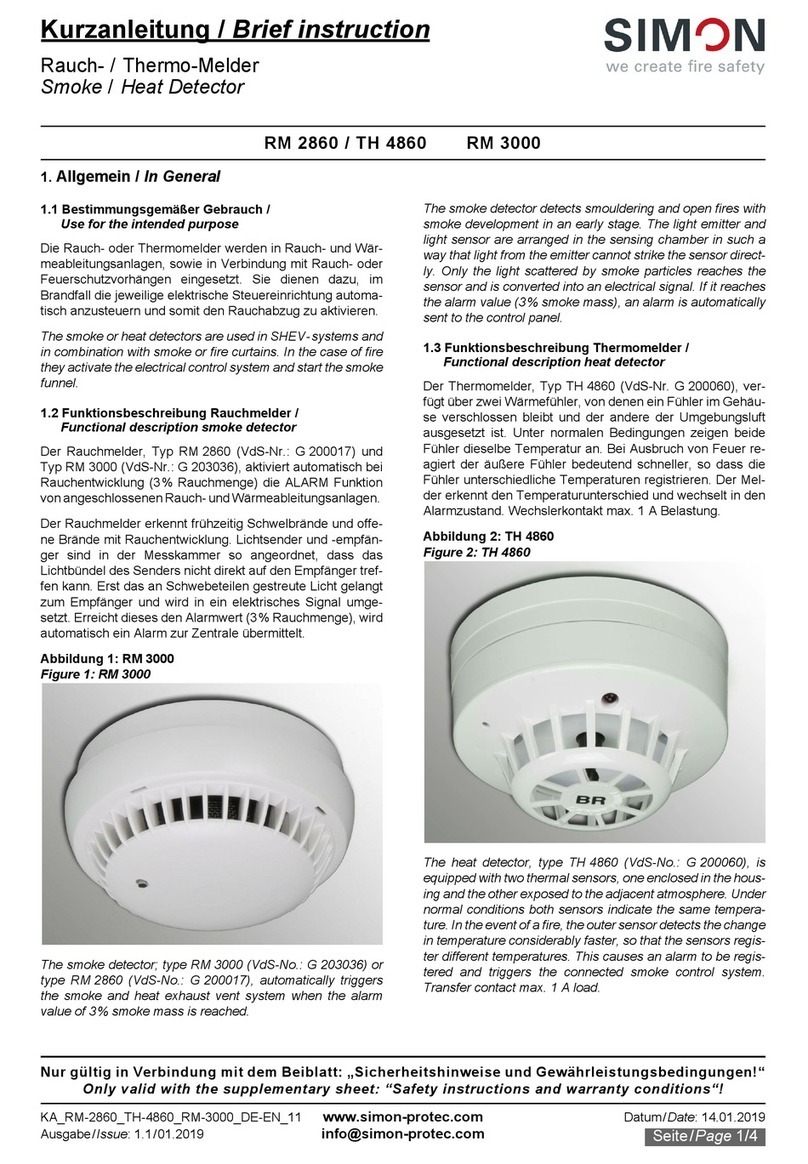

Simon

Simon RM 2860 Brief Instruction