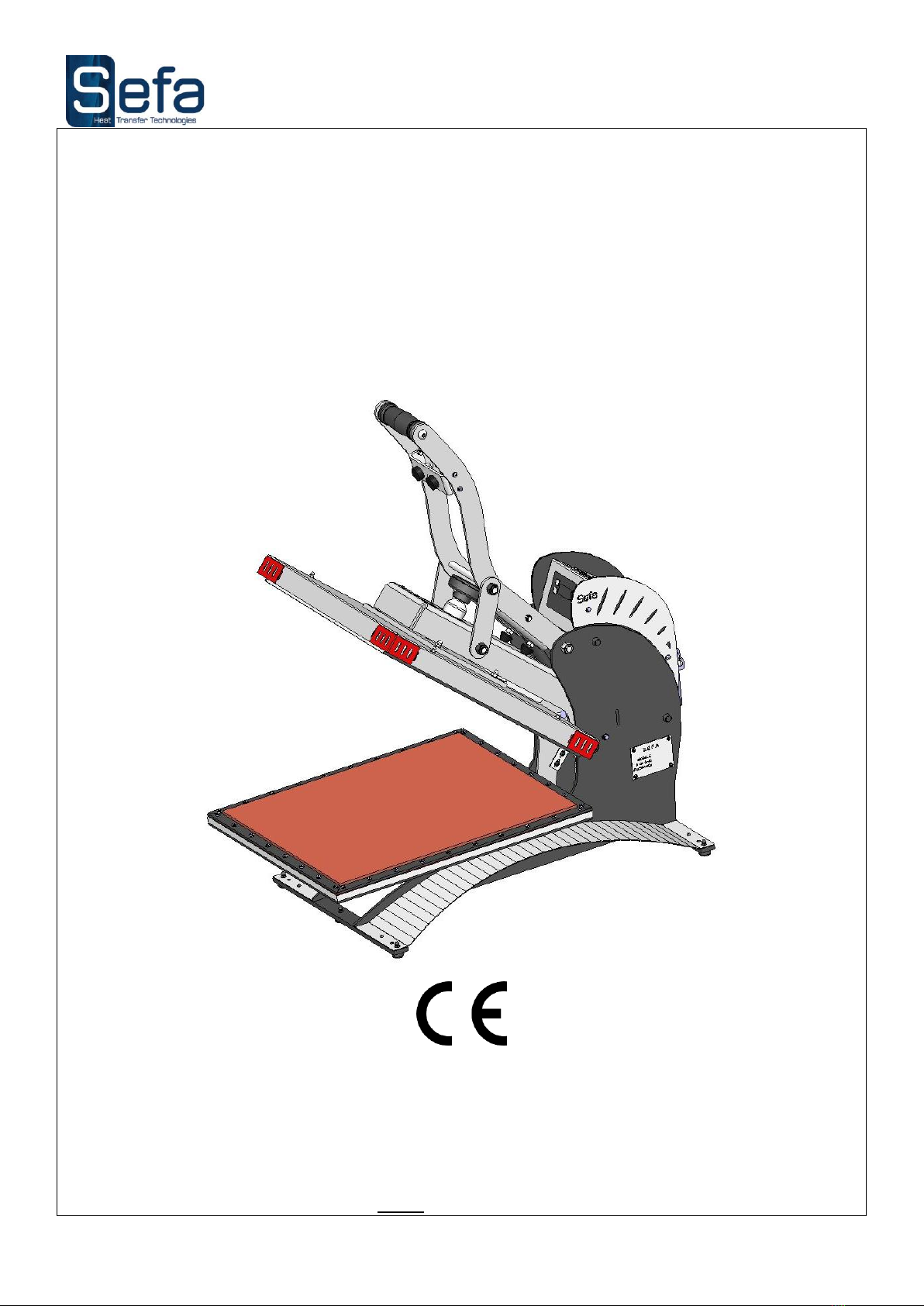

Sefa AIR CLAM X User manual

INSTRUCTION MANUAL

AIR CLAM X

S.E.F.A®

Z.I PASTABRAC

11260 ESPERAZA

FRANCE

Tel :33 (0)4.68.74.05.89 -Fax :33.(0)4.68.74.24.08

E Mail : contact@sefa.fr

V0412

Page N° 1

CONDITIONS OF GUARANTEE

The guarantee period starts the day of putting the equipment into service at the user’s place, materialized

by the return of the guarantee bill for a duration of two years, 8h per day meaning about 3000 hours.

The guarantee is strictly limited to our equipments, against the defects of matter and execution, with the

buyer’s responsibility to prove the known defects.

Our responsibility is limited to the obligation to rectify or replace free of charge the parts acknowledged as

faulty by ourselves, and there will no claim for any indemnity whatever the reason given.

Parts replaced under the guarantee:

remain our property

are the subject of an invoicing of deposit

A credit of cancellation is activated as soon as the faulty parts are returned.

The return will have to occur ONE MONTH MAXIMUM after the intervention

THE GUARANTEE DOES NOT COVER :

The retail consumables such as:

- Fuses, bulbs, joints, flexible devices, covers, nozzles, filters.....

- The supplies, which are not our own manufacturing, undergo the guarantee of their manufacturer.

THE GUARANTEE DOES NOT APPLY :

To replacements, nor repairs which would result from normal wear and tear of apparatus and machines, of

deteriorations and accidents coming from negligence, defect of monitoring and maintenance, defective use

or modifications without our written agreement.

In case of vice coming from the material supplied by the buyer, or a design imposed by the latter.

To repairs which would result from deteriorations or accidents occurred during transport.

To operations of maintenance and adjustments inherent in the use of the machine, and indicated in the

maintenance manual, such as:

- adjustments of intermediaries

- screwing of piping, etc…

For the pneumatic machines, any trace of detergent oil in the pneumatic circuit inhibits

the conditions of guarantee previously mentioned.

For any technical information or spare parts orders,

please give the reference number of the machine as well as its serial number

V0412

Page N° 2

SUMMARY

CONDITIONS OF GUARANTEE.............................................................................................................................................1

SUMMARY ..................................................................................................................................................................................2

SPECIFICATIONS......................................................................................................................................................................3

INSTALLATION OF THE MACHINE.....................................................................................................................................3

PARTS SUBJECTED TO WEAR AND TEAR.........................................................................................................................4

GENERAL POINTS ....................................................................................................................................................................5

ELECTRONIC BOX ...................................................................................................................................................................6

USAGE..........................................................................................................................................................................................7

1. CONTROL PANEL ...........................................................................................................................................................7

2. POWER ON .......................................................................................................................................................................7

3. SETTINGS.........................................................................................................................................................................8

a) TEMPERATURE ........................................................................................................................................................8

b) TIME...........................................................................................................................................................................8

4. HEIGHT ADJUSTMENT..................................................................................................................................................8

5. MAINTENANCE...............................................................................................................................................................8

CYCLE DESCRIPTION:............................................................................................................................................................9

QUICK REPAIR ADVICES.....................................................................................................................................................10

DIAGRAM..................................................................................................................................................................................11

NOTEMAKER...........................................................................................................................................................................12

V0412

Page N° 3

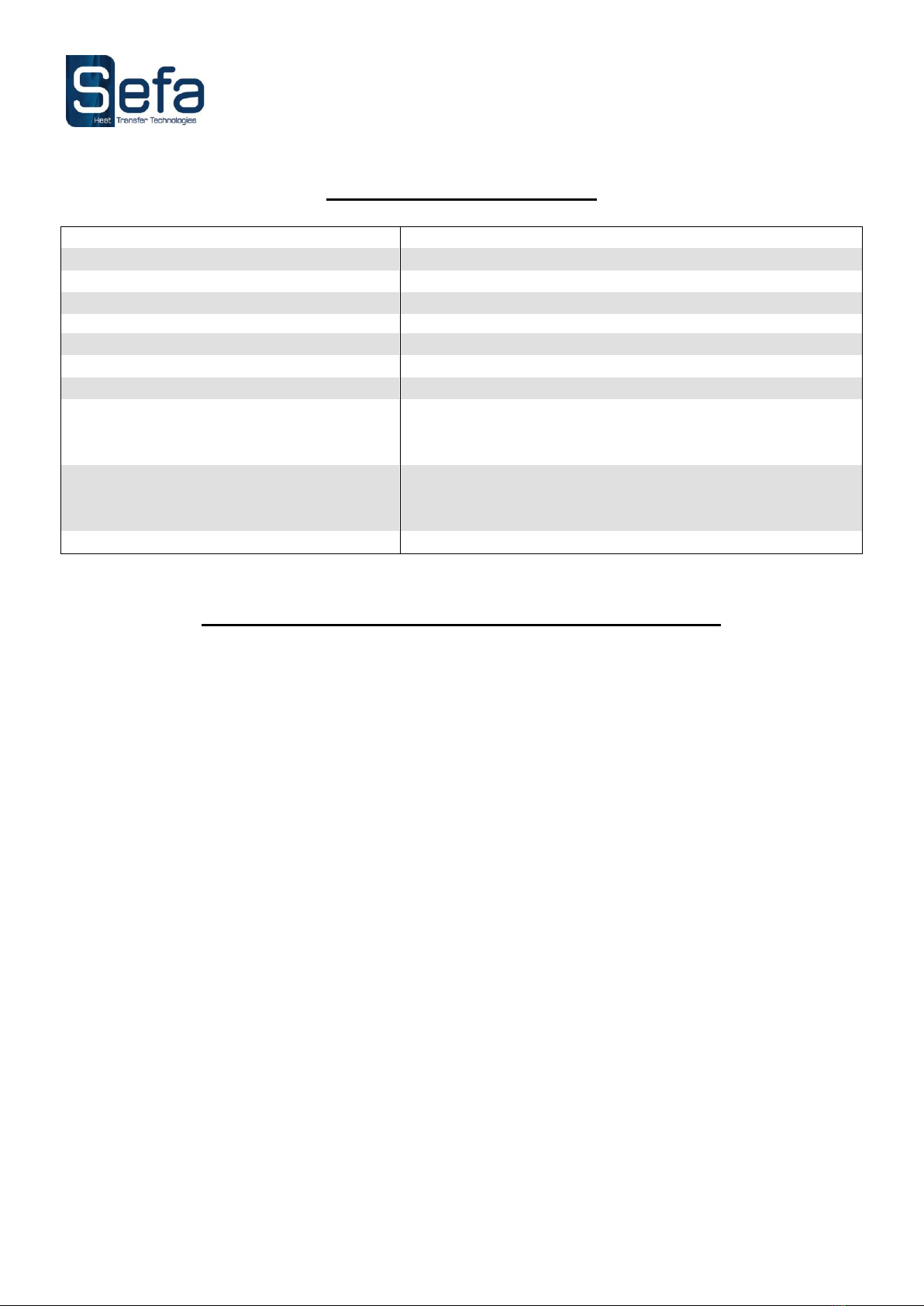

SPECIFICATIONS

Non contractual document : according to the technical progress, we reserve the right to modify the characteristics of our products.

INSTALLATION OF THE MACHINE

Unpack the machine from the box.

Install it on a safe table.

To move the press, make sure it is cold and handle it by grabbing both plates (upper and lower) at the same time

(machine closed).

Remove the screw labelled « Transport security » before opening the press.

Plug the machine electrically (230 Volt + Ground / 50 or 60 Hertz)

Plug the machine to a compressed air network (2 bar mini, 10 bar maxi).

Weight in running order

61 kg

40 kg

Height

534 mm

Depth

878 mm

Width

443 mm

Plate size

400 x 500 mm

Power supply

230 V Single phase + Ground 50/60 Hz

Power

2500 W

Amperage

11 A

Thermo regulator

Accurate to

+/- 2%

Range of control

0 à 250 °C

Timer

Accurate to

+/- 1%

Range of control

0s à 9min59s

Pressure

0.5 kg/cm²

V0412

Page N° 4

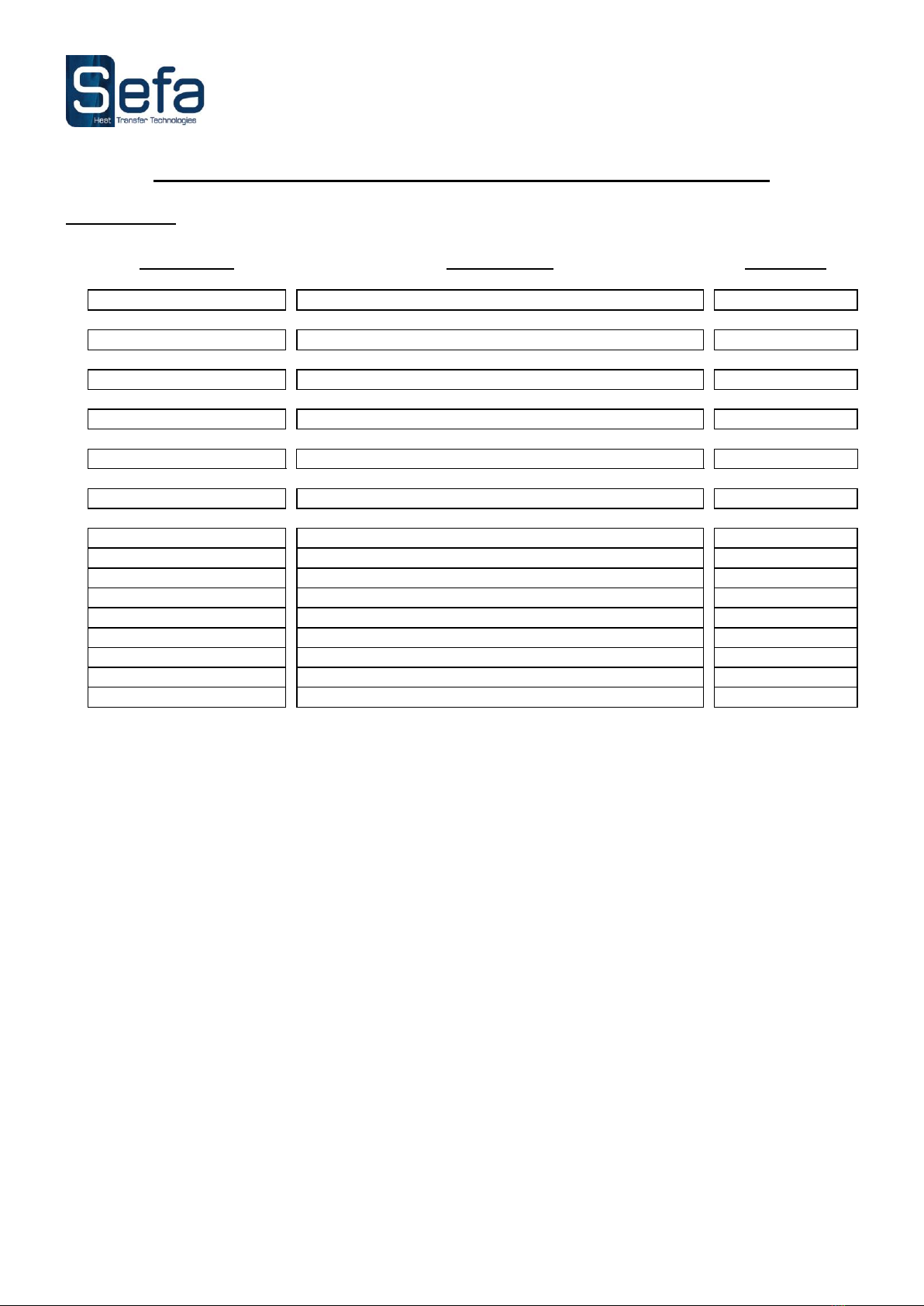

PARTS SUBJECTED TO WEAR AND TEAR

For any order:

precise the description, la reference and the quantity

Reference

Description

Quantity

CAR-CO1-EV0

ELECTRONIC CARD

1

REL-OM5

HEAT RELAY

1

RES-682

HEAT ELEMENT MICA 400x500 2500W

1

SON-189

SENSOR

1

FIN-231

MICROSWITCH WITH TONGUE

1

MOU-540

SILICONE RUBBER 400x500 mm

1

RES-BI2

GAS SPRING

1

RES-172

MECHANICAL SPRING

2

PLA-MEMBRANE

INFLATABLE MEMBRANE

1

FUS-153

FUSE 16 A

1

HOU-50

NOMEX COVER 400x500

1

V0412

Page N° 5

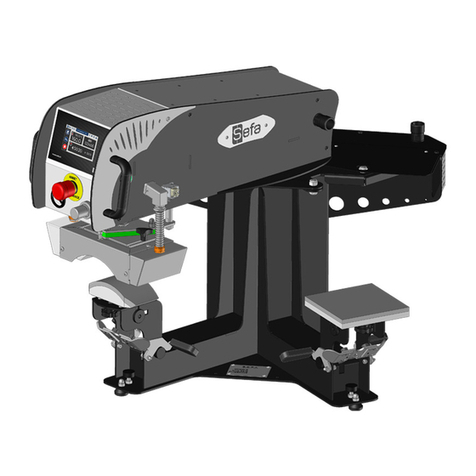

GENERAL POINTS

This heat seal press machine is standard to the labour laws to ensure the security of the user.

Its design allows it to ensure an intensive production while keeping a total reliability.

This press was designed for an operator working in front of the machine.

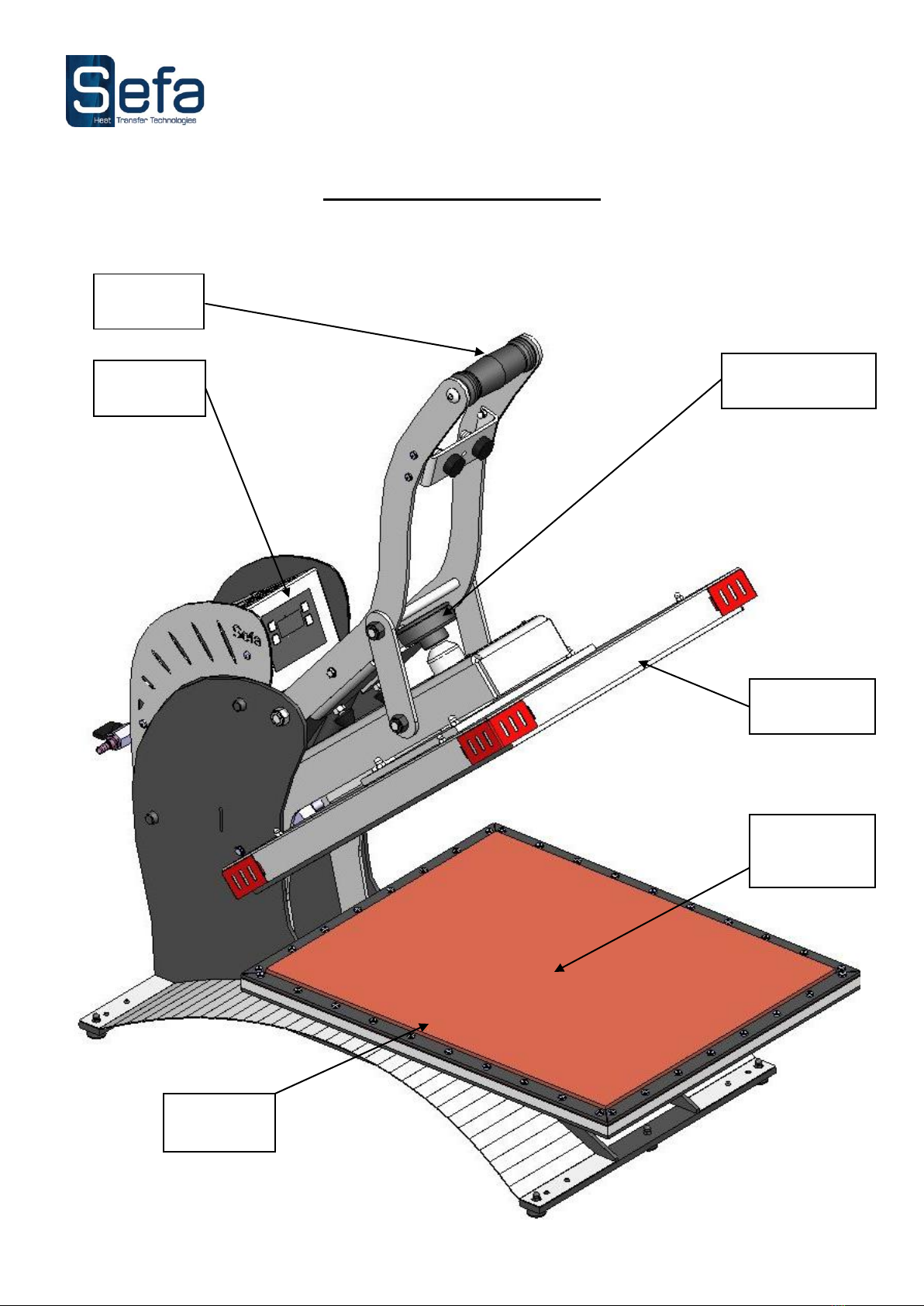

Control

panel

Heating plate

Silicon rubber

with inflatable

membrane

Handle

Height adjustment

wheel

Cold plate

V0412

Page N° 6

ELECTRONIC BOX

Relay

Filter

General

Switch and

fuse

Timer

Gate

Microswitch

Electro

distributor

Regulator

Electronic

card

Control

panel

V0412

Page N° 7

USAGE

It is recommended to read carefully the “instruction manual” before you start any pressing operation.

The press will have to be used by a qualified person who will have been informed of the risks which can be

caused by misuse of the equipment.

1.

CONTROL PANEL

2.

POWER ON

When switching the machine on, the regulator displays the temperature.

Selection

key

Down

Up

.

.

LED Indicator for

T° display

LED Indicator

for time display

Stop

button

V0412

Page N° 8

3.

SETTINGS

a) TEMPERATURE

Push twice the selection key (The T° LED indicator blinking)

Push the Up key to increase the temperature.

Push the Down key to decrease the temperature.

b) TIME

Push one on the selection key (The Time LED indicator blinking)

Push the Up key to increase the time.

Push the Down key to decrease de time.

4.

HEIGHT ADJUSTMENT

Turn the wheel on top of the heating plate:

clockwise to decrease the height of heating plate

anticlockwise to increase it

5.

MAINTENANCE

Every day:

Clean the heating plate with a dry cloth.

Depending on use:

Change the silicon rubber as soon as it is damaged or if it has lost its properties.

V0412

Page N° 9

CYCLE DESCRIPTION:

Turn on the machine by switching the power button.

Adjust the desired temperature at 180°C (or depending on the type of transfer) See SETTINGS § 3.a).

Adjust the time at 15 Sec (or depending on the type of transfer) See SETTINGS §3.b).

Adjust the height of the heating plate.

Install a T-shirt on the lower/cold plate.

Add your transfer material on top of it.

Wait until the plate reaches the setted temperature.

Lower the heating plate using the handle and hold it during 1 second.

When the plate is in contact with the T-shirt, the membrane inflates automatically.

At the end of the countdown, the membrane will deflate and the press will open automatically.

If you want to interrupt the cycle, you can do it by pushing the stop button located on the control panel:

the press will open automatically.

Nb : If the membrane is inflated, the press can not be locked. Hold the « STOP » button while lowering the handle

of the machine in order to deflate the membrane. When the membrane is deflated and the press locked, raise the

handle then release the “STOP” button.

V0412

Page N° 10

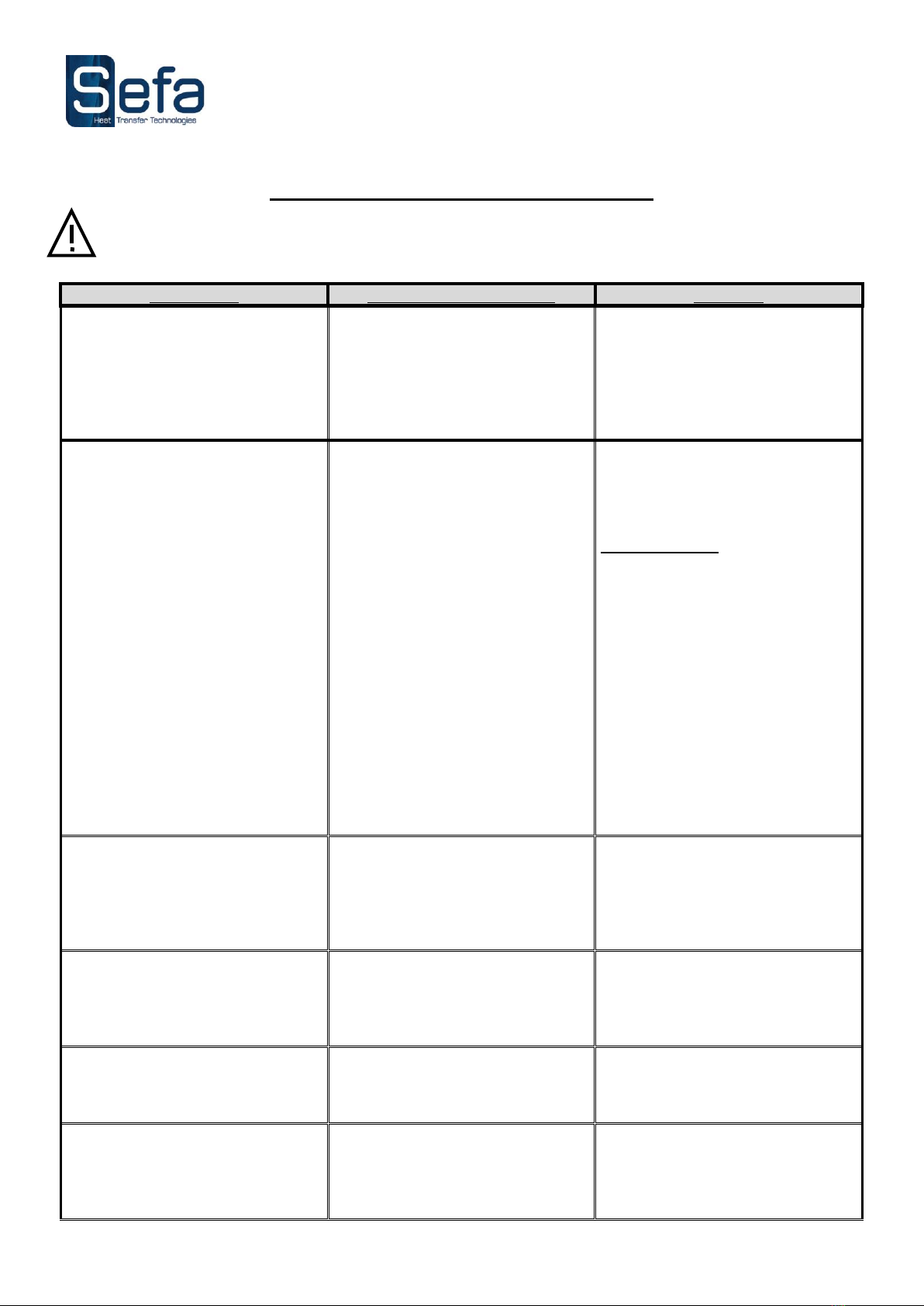

QUICK REPAIR ADVICES

All repair and maintenance operations should be done when the machine is turned off and unplugged from

the main electric power supply. The heating element can cause burns. The user must ensure the

temperature is below 25°C on the display, before any intervention.

SYMPTOMS

POSSIBLE BRAKDOWNS

REPAIRS

The press does not lock

The membrane is inflated

Hold the « STOP » button while

lowering the handle of the

machine in order to deflate the

membrane. When the membrane

is deflated and the press locked,

raise the handle then release the

“STOP” button

The plate will not heat

One of the fuses is out of order

The relay is damaged

Sensor out of order and/or

regulator displays ER1

If no light when the press goes

on, check the fuse, change it if

necessary.

GENERAL FUSE

located in a seating

next to the plug of the power supply

cable (16 A ). To access it, pull the

electrical cable off with the tip of a

pen or a screwdriver, lift the fuse

seating. You will find in a square

tube a spare fuse to replace the one

in the clip.

Check it out and change it if

necessary

Change the sensor

The plate overheats

The relay is stuck

The card is damaged

Change the relay.

Change the card

The timer doesn’t start

The microswitch isn’t activated

Make sure the Microswitch

tongue is touched by the

pressing arm of the machine.

The buzzer rings continuously

The Microswitch is stuck

Release the Microswitch tongue

or change it.

The press doesn’t stay closed

The Microswitch is stuck

Release the Microswitch tongue

or change it.

V0412

Page N° 11

DIAGRAM

V0412

Page N° 12

NOTEMAKER

------------------------------------------------------

------------------------------------------------------

------------------------------------------------------

------------------------------------------------------

------------------------------------------------------

------------------------------------------------------

------------------------------------------------------

------------------------------------------------------

------------------------------------------------------

------------------------------------------------------

Table of contents

Other Sefa Power Tools manuals

Sefa

Sefa ROTEX AIR V3 Series User manual

Sefa

Sefa DUPLEX PRO User manual

Sefa

Sefa DUPLEX PRO User manual

Sefa

Sefa INiTiUM User manual

Sefa

Sefa ROTEX V3 Series User manual

Sefa

Sefa LM V3 Series User manual

Sefa

Sefa LP 130 V3 User manual

Sefa

Sefa Initium iCAP 2 User manual

Sefa

Sefa DUPLEX MINI PRO User manual

Sefa

Sefa ROTEX AIR PRO User manual

Popular Power Tools manuals by other brands

Jet

Jet JDP-20MF Operating instructions and parts manual

Grizzly

Grizzly G0704 installation instructions

Kyocera

Kyocera Senco TN11G1 operating instructions

KRESS

KRESS 1-2+FIX instruction manual

Central Machinery

Central Machinery 42927 Assemble and operating instructions

Wacker Neuson

Wacker Neuson DPS 1850 Operator's manual