Sefa Initium iCAP 2 User manual

INSTRUCTIONS MANUAL

iCAP 2 / iLOGO

BY SEFA

Distributors

SEFA

Z.I. Pastabrac 11260 Esperaza

Tel : +33(0)4 68 74 05 89

Fax : +33(0)4 68 74 24 08

www.sefa.fr

CHEMICA

8 rue Auguste Poncetton 42000 Saint Etienne

Tel : +33(0)4 77 49 20 90

Fax : +33(0)4 77 25 79 82

www.chemica.fr

V0414

Page 2

INDEX

INDEX ..........................................................................................................................................................2

I. CONDITIONS OF GUARANTEE ............................................................................................................3

II. ASSEMBLY DRAWING .........................................................................................................................4

III. Technical Parameters.....................................................................................................................5

IV. USING THE MACHINE .........................................................................................................................5

1. SAFETY .................................................................................................................................................. 6

2. INSTALLATION ....................................................................................................................................... 6

3. CAP HEATER AND PLAIN HEAT PLATEN EXCHANGE.................................................................................. 7

V. OPERATION PROCESS ........................................................................................................................8

1. SET TEMPERATURE REQUIRED ............................................................................................................... 8

2. SET TIME REQUIRED .............................................................................................................................. 8

3. SET PRESSURE REQUIRED ...................................................................................................................... 8

4. PRINTING METHODS .............................................................................................................................. 9

5. RECOMMENDATIONS .............................................................................................................................. 9

VI. CIRCUIT DIAGRAM ...........................................................................................................................10

VII. MAINTENANCE .............................................................................................................................11

1. SERVICING........................................................................................................................................... 11

2. QUICK REPAIR ADVICES ....................................................................................................................... 11

3. TROUBLE SHOOTING FOR TRANSFER PRINT QUALITY ........................................................................... 12

4. EXPLOSION VIEW ................................................................................................................................. 12

V0414

Page 3

I. CONDITIONS OF GUARANTEE

The guarantee period starts the day of putting the equipment into service at the user’s place, materialized by the

return of the guarantee bill for a duration of one year, 8h per day or 2000 hours.

The guarantee is strictly limited to our equipments, against the defects of matter and execution, with the buyer’s

responsibility to prove the known defects.

Our responsibility is limited to the obligation to rectify or replace free of charge the parts acknowledged as faulty by

ourselves, and there will no claim for any indemnity whatever the reason given.

Parts replaced under the guarantee: remain our property are the subject of an invoicing of deposit

A credit of cancellation is activated as soon as the faulty parts are returned.

The return will have to occur ONE MONTH MAXIMUM after the intervention

THE GUARANTEE DOES NOT COVER :

The retail consumables such as:

- Fuses, bulbs, transformers, joint, flexible devices, covers, nozzles, filters.....

- The supplies, which are not our own manufacturing, undergo the guarantee of their manufacturer.

THE GUARANTEE DOES NOT APPLY :

To replacements, nor repairs which would result from normal wear and tear of apparatus and machines, of

deteriorations and accidents coming from negligence, defect of monitoring and maintenance, defective use or

modifications without our written agreement.

In case of vice coming from the material supplied by the buyer, or a design imposed by the latter.

To repairs which would result from deteriorations or accidents occurred during transport.

To operations of maintenance and adjustments inherent in the use of the machine, and indicated in the maintenance

manual, such as:

- adjustments of intermediaries

- screwing of piping, etc…

For any technical information or spare parts orders, please give the reference number of the

machine as well as its serial number

V0414

Page 4

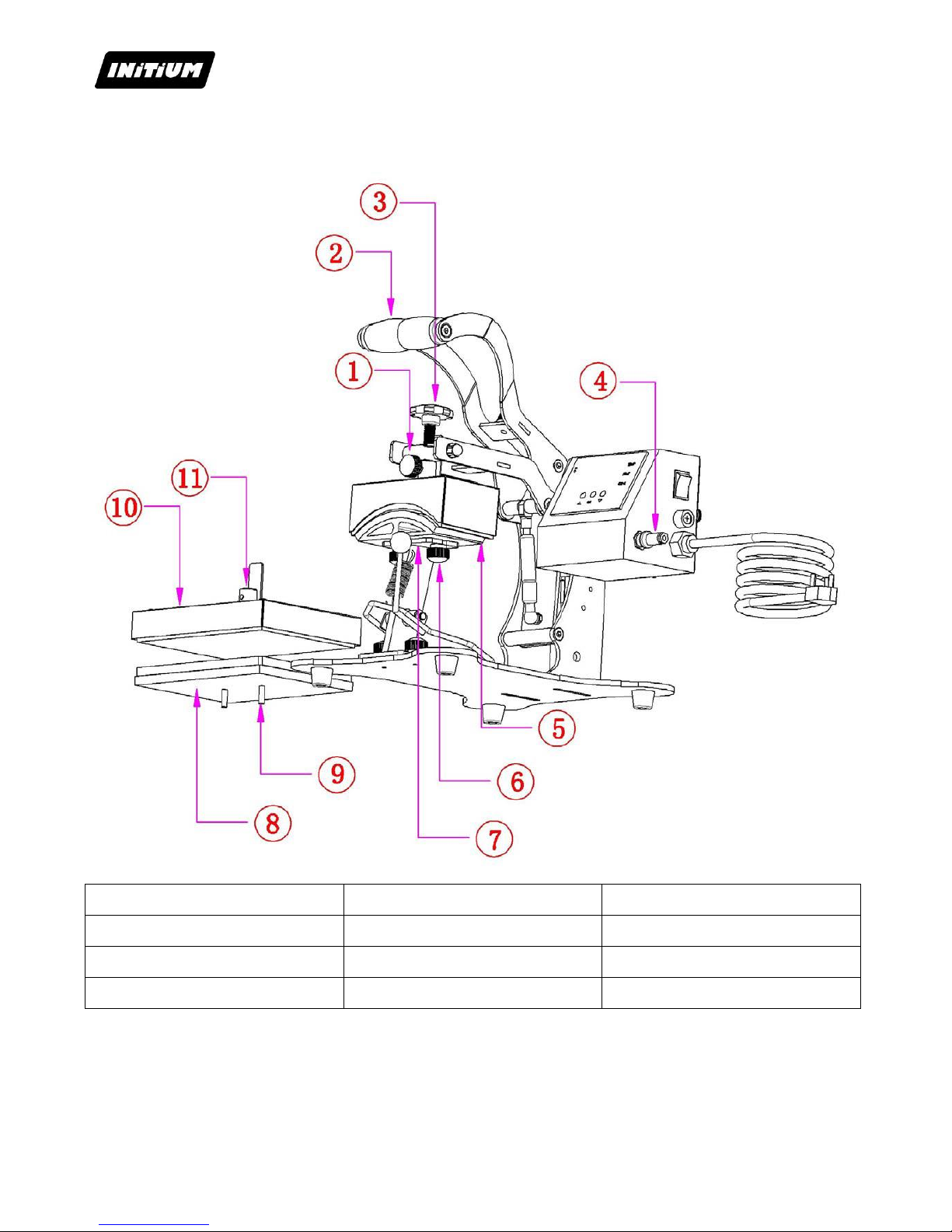

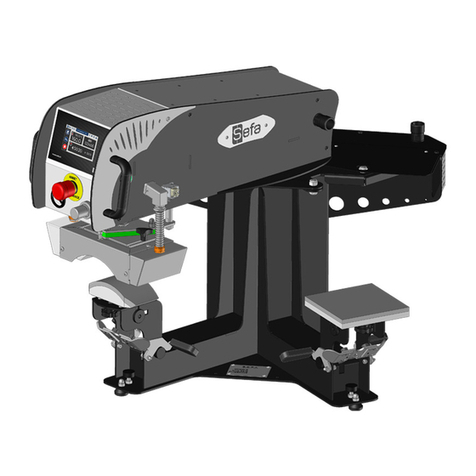

II. ASSEMBLY DRAWING

1Upper Hand Wheel Screw

2Handle Bar Grip

3Adjusting Screw

4 Power Cord

5Cap Heater

6Under Hand Wheel Screw

7Supporting Holder

8Plain Under Plate

9Fasten Screw

10 Plain Heat Platen

11 Fixing Fittings

V0414

Page 5

III. Technical Parameters

Model No.

iCAP 2 / iLOGO

Machine Dimension

380*360*340mm

Heating Elements Size

one normal cap heater & one 15x 20cm heat platen

Printable Articles Max Size

150 x 80mm&150 x 20mm

Voltage

220V/1Phase

Power

0.5KW for cap press; 0.6KW for heat platen

Recommend Setting

180~190C°; 30~40s.

Time Range

0~999s

Maximum Temp

225 C°

Packing Size

48*32*39cm

Gross Weight

19.5kg

IV. USING THE MACHINE

iCAP 2/iLOGO press was designed for the application of transfers of all grades.

This equipment has been tested in our workshops to get a one year warranty against manufacturing

defects.

Power settings, mechanical and pneumatic submitted by our technicians in the workshop as well as the

security established on the machine should never be changed. Otherwise, INITIUM company will deny

all responsibility on potential problems associated with said machine.

Before starting any pressing operation, it is recommended that you read the safety instructions and the

instructions for use.

The press should be used by an authorized person and having been informed of the risks that may be

caused by improper use of the equipment.

V0414

Page 6

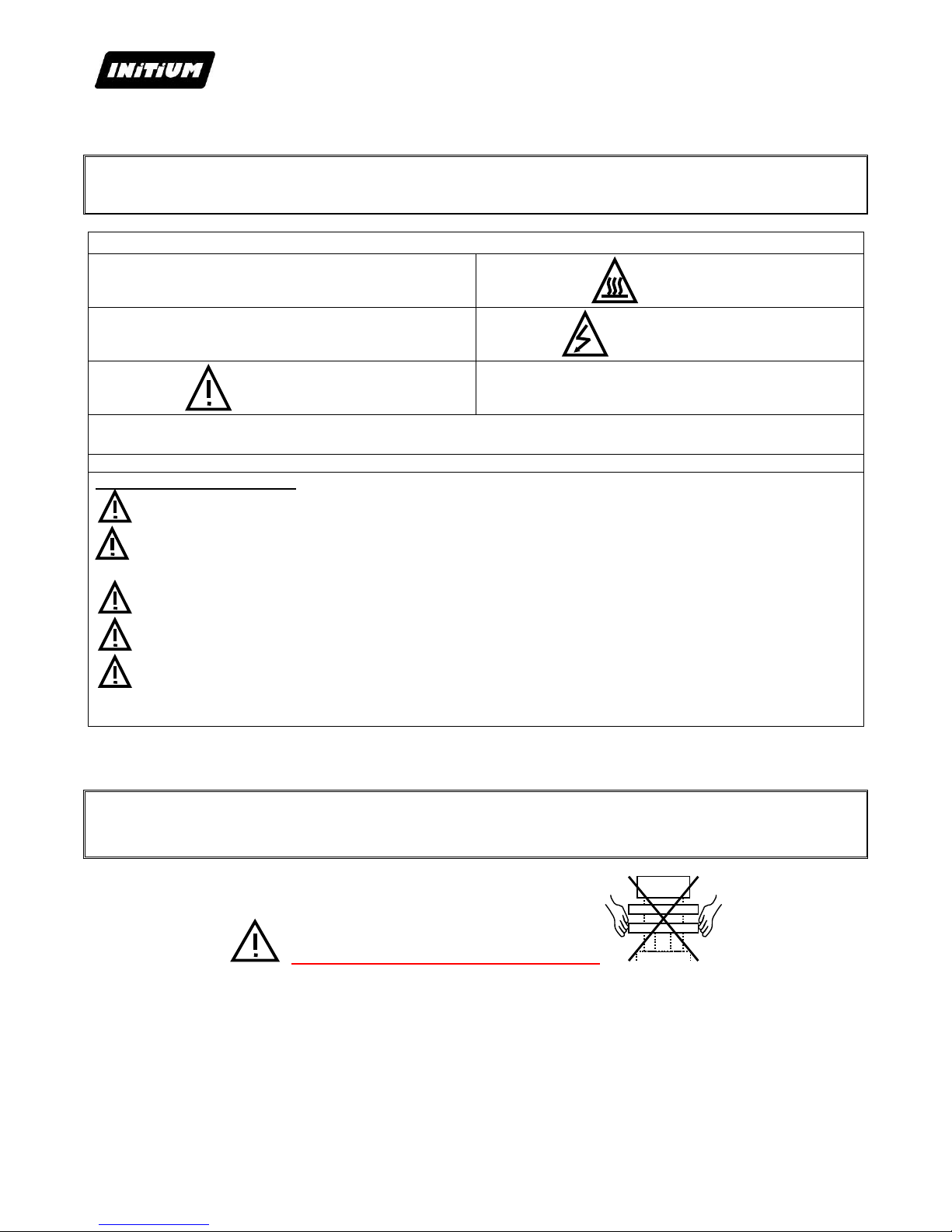

1. SAFETY

THIS EQUIPMENT IS DESIGNED FOR SINGLE USE ONLY

USE BY QUALIFIED STAFF ONLY

International Symbols

O OFF

HOT SURFACE

I ON

ELECTROCUTION RISK

DANGER, WARNING

You will find most of these symbols on the INITIUM equipment.

Important point for security :

Don’t touch the hot parts of the equipment while in use.

During handling action, ensure the operator does not take any risk in terms of burns, electrocution or

other.

Proceed with a daily inspection of the machine before starting the production .

Make sure nobody is around or near the machine before you start it up.

If the machine does not work properly, shut down immediately all energy supplies and search for the

cause by using the book’s « Maintenance » chapter.

2. INSTALLATION

USE BY QUALIFIED STAFF ONLY

Do not handle the machine by its plates !

Unpack the machine from the box.

Remove all packaging specific items: paper, cardboard, plastic film, wood, etc. ...

Put the machine level (if necessary) by acting on the feet of height adjustment.

Plug the machine electrically

V0414

Page 7

3. CAP HEATER AND PLAIN HEAT PLATEN EXCHANGE

1. Unplug the power socket ④, press down the handle bar grip ②with left hand and release

screw bolt ①with right hand.

2. Leave the left hand and the cap platen is now lying on the cap under plate ⑤.

Release screw nut ⑥to take out the cap press parts.

3. Fix two screws ⑨in the flat under plate ⑧and mount it to the support arm ⑦, fasten screw

nut ⑥to fix the flat under plate ⑧.

4. Place flat heat platen ⑩above the flat under plate ⑧, use left hand to press down the handle

bar grip ②, and adjust the heat platen mounts and adjustment bolt with right hand, then

tighten the screw ①.

5. Use left hand press down the handle bar grip ②again to make sure the flat heat platen ⑩is

aligned with flat under plate⑧. Fasten the screw bolt ①and screw nut ⑥tightly and plug the

power socket ④.

The exchange process is done.

V0414

Page 8

V. OPERATION PROCESS

1. SET TEMPERATURE REQUIRED

Turn on power switch.

The digital display shows

Press button “OK” , the light is

on (C denotes Celsius). Press

arrows ۸or ۷to select “C” or

“F” (F denotes Fahrenheit)

according to your habits

Press button “OK”, the temp light

is on. Select with arrows the

temperature according to different

transfer material (Normally

180.~200° C.)

2. SET TIME REQUIRED

Press button after temperature

setting and the time light is

on. Select with arrows the time

according to different transfer

material

Press button after time setting;

the display shows the temperature

starts to rise. “CD-L” shows the

time counting down during your

transfer.

Note: There are two small port in

front side of the digital display.

If the real temperature is lower

than digital controller shown, you

can adjust the “hot port”; Clockwise

to raise temperature; anticlockwise

to reduce temperature.

3. SET PRESSURE REQUIRED

1) Gently lower the handle (without closing it) to put the heating element in contact with the lower plate tray,

2) Loosen the screws on the front ①,

3) Increase the pressure by turning in the direction of clockwise,

4) Decrease the pressure by turning anticlockwise

5) Tighten the screws on the front ①.

Hot Port

Cold Port

V0414

Page 9

4. PRINTING METHODS

Step 1:

Make sure the cord is connected well to the wall socket. Place the cap in the cap heater, and transfer paper with

images facing down the cap, adjust moderate pressure, and power on.

P.S: use heat resistant tape to fix the transfer paper, make sure transfer paper is exactly attached to cap heater;

Step 2:

Set the temperature and time required, then temperature starts to rise.

Step 3:

When the temperature rises to the setting temperature, the buzzer sends out sounds; then press down the cap

heater, (meantime the sounds stop) and starts to transfer.

Step 4:

Then the time counter is on, once time is up, take out the caps. Transfer work finished.

Note: use the similar way when you need to transfer other substrates by using the plain heat platen.

But the printing parameters are different from different items. You can refer to below.

5. RECOMMENDATIONS

1) Cap transfer:

Set temperature: 180°C

Set time: 60 seconds

2) Ceramic Tile transfer:

Set temperature: 210°C

Set time: 240seconds

3) Key Chains & Pearlite Plate transfer:

Set temperature:180°C

Set time: 100~120seconds

4) Mirror (Pearlite plate) and Jigsaw Puzzle transfer:

Set temperature:180°C

Set time: 60~80seconds

5) Wallet (Waist pack) transfer:

Set temperature:180°C

Set time: 120~140seconds

NOTE:

1) Please switch off the machine and unplug the power cord when the machine is not in use.

2) The heater or heat platen will cool down to the room temperature, if heat press stays un-use for more than 30

minutes.

3) For better maintenance of heat press, the maximum setting temperature is 210 degrees C (410 degrees F).

4) To avoid re-heating the first transfer when printing double sided substrates, insert a sheet of cardboard in

between the item, adjust the height to less pressure, then press.

5) Heat platen may pivot slightly back and forth rotationally. This is due to movement allowance within the clamp

assembly, and is normal.

V0414

Page 10

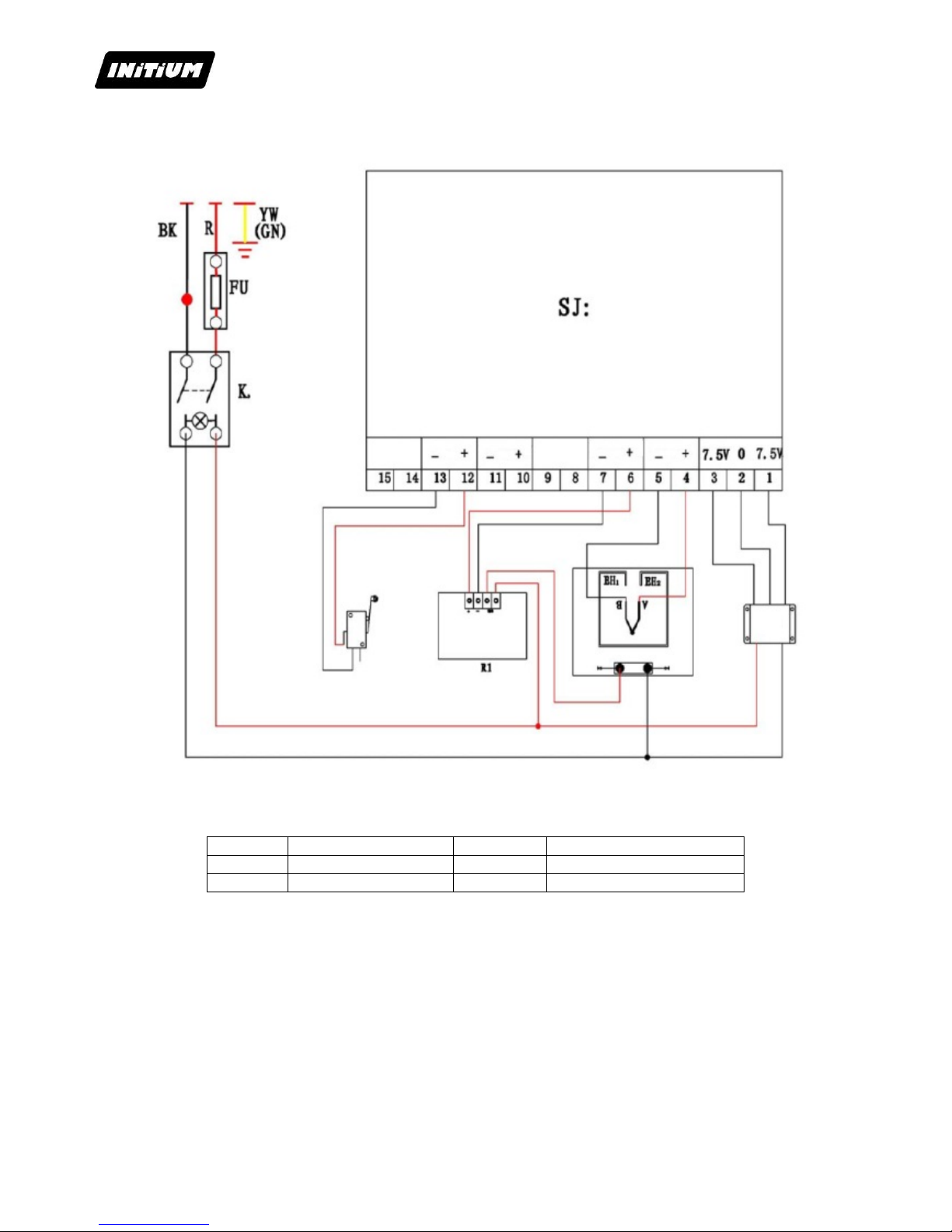

VI. CIRCUIT DIAGRAM

K0

Power Switch

EH1EH2

Heating Pipe

SJ

Digital Controller

T

Transformer

FU

Fuse

R1

Relay

V0414

Page 11

VII. MAINTENANCE

USE BY QUALIFIED STAFF ONLY

ANY SERVICING INTERVENTION MUST BE DONE WHEN THE MACHINE IS OFF AND LOCKED

(ELECTRIC AND PNEUMATIC ENERGIES UNPLUGGED)

1. SERVICING

Heat transfer press INITIUM ® require little maintenance. To ensure proper operation, follow the

preventive guidelines listed below.

Do not heat objects that could damage or even cut the silicon rubber or damaging the Teflon surface

DAILY :

CHECK that the heating element is clean.

EVERY 3 MONTHS :

Put a few drops of oil onto the various pivot pins and the pressure

adjusting screw

2. QUICK REPAIR ADVICES

SYMPTOMS

REPAIRS

No action after turn on the machine

1). Check the plug whether it connects well or whether it is broken.

2). Check the power switch or digital controller whether it is broken.

3). Check the fuse whether it has been burnt out.

4). Indicating light is on, but no display on screen, check the 5 cable of

Railway transformer. If it’s loosening, showing the problem is poor

connection. If they connects well, showing that the Transformer is faulty

The display screen is working well, but

no temperature increasing on the

heating element.

1). Check whether the thermocouple of the heating element touches well.

If the thermocouple is loose, the display will show 255℃.and machine

keeps beeping.

2). Check if the indicating light of solid-state relay is on, if not, check if

the relay or digital controller is broken.

3). If you already changed the new solid-state relay but the heating

element still can’t heating up, check if the heating element is faulty or the

heating element power cable is loose, need to change by new mug

heater.

The display screen show 255℃once

you power on

1). Check whether the thermocouple is loose or not.

2). If the thermocouple touches is not in loose state, but still show

255℃, then it is faulty.

The machine is heating during

0~180℃, but display number jumps to

above 200℃ or 300℃ suddenly, or the

numbers on display jumps irregularly

1). Check whether the thermocouple of the heating element touches well.

2). If the thermocouple is good, It shows that the program of digital

controller is broken, which namely IC or is broken, need to change by

new controller.

The temperature is out of control: Set

180℃,but the actual temperature is

above 200℃

1). It means the solid-state relay is broken, out of control, need to

change the relay.

2). Or the digital controller is faulty and it keeps conveying electric to

relay, need to change controller.

The setting temp and time becomes

abnormal after exchange the heating

element

1). Please reset the temp and time according the operation process

manual

Other notice

1). In order to prolong the machine service life, please add the

lubrication oil regularly on the joints.

2). In order to keep the heating element good transfer effect, please

protect it carefully whenever you are using or not.

3). Please keep the machine in dry place.

4). If you are not able to solve the electrical parts problem, please

contact the supplier

V0414

Page 12

3. TROUBLE SHOOTING FOR TRANSFER PRINT QUALITY

If the print color is pale: the temperature is too low / the pressure is not correct / or not pressed long enough.

If the print color is too brown or the transfer paper is almost burnt: reduce the setting temperature.

If the print is blurring: too much transfer time causes proliferation.

If print color is different/ partial transfer effect is not good enough: the pressure is not enough / or not pressed

long enough / or poor quality transfer paper.

If transfer paper stick to the object after transfer: the temperature is too high/ or poor quality printing ink.

4. EXPLOSION VIEW

For any order : specify designation and quantity

Item

Parts Name

Qty

1

Cap Heater

1 pc

2

Handle Shaft

1 pc

3

Cap Under Plate

1 pc

4

Cap Presser

1 pc

5

Screw

2 pc

6

Supporting Holder

1 pc

7

Anti-swing Part

1 pc

8

Adapter

1 pc

9

Flat Heat Platen

1 pc

10

Flat Under Plate

1 pc

Item

Parts Name

Qty

11

Screw

2 pc

12

Machine Base

1 pc

13

Supporting Plate

2 pc

14

Limit Switch

1 pc

15

Electrical Parts Bracket

1 pc

16

Electrical Case

1 pc

17

Power Cord

1 pc

18

Handle Bar Grip

1 pc

19

Pressure Adjusting Screw

1 pc

20

Screw

1 pc

This manual suits for next models

1

Table of contents

Other Sefa Power Tools manuals

Sefa

Sefa CLAM 45M User manual

Sefa

Sefa DUPLEX PRO User manual

Sefa

Sefa ROTEX V3 Series User manual

Sefa

Sefa DUPLEX PRO User manual

Sefa

Sefa DUPLEX MINI PRO User manual

Sefa

Sefa BR 180 PCAS User manual

Sefa

Sefa CLAM SPORT V3 User manual

Sefa

Sefa LM V3 Series User manual

Sefa

Sefa ROTEX AIR V3 Series User manual

Sefa

Sefa LP 130 V3 User manual

Popular Power Tools manuals by other brands

Omega Lift

Omega Lift 13120 Operating instructions & parts manual

Milwaukee

Milwaukee C18 PCG/600A-201B Original instructions

Arconic

Arconic 2580 instruction manual

Matco Tools

Matco Tools MTV5 manual

Hitachi

Hitachi CN 16SA Handling instructions

AL-KO

AL-KO MT 40 Translation of the original instructions for use