Sefa DUPLEX PRO User manual

English version

INSTRUCTION MANUAL

DUPLEX PRO

S.E.F.A

®

Z.I PASTABRAC

11260 ESPERAZA

FRANCE

Tel: 33 (0)4.68.74.05.89 - Fax: 33.(0)4.68.74.24.08

E Ma l: conta[email protected]

English version

V0516

Page no. 1

WARRANTY TERMS

The warranty eriod shall come into effect on the day on which the equi ment is brought into service at the

user's remises, as attested on the returned warranty certificate and the delivery note, and shall run for

two years, based on a standard equi ment o erating schedule of 8 hours er day, i.e. 3,000 hours.

The warranty is strictly limited to our equi ment, and covers faulty materials and workmanshi , which the

urchaser shall be required to substantiate.

Our liability shall be limited to making good or re lacing free of charge arts that are acknowledged by us to

be defective, and no claims for damages for any reason may be made against us.

Parts re laced under warranty shall:

remain our ro erty

be invoiced on consignment

A credit note will be issued u on return of the faulty arts.

Returns must be made NO LATER THAN ONE MONTH after the work is erformed under warranty.

THIS WARRANTY DOES NOT COVER:

Commercially sourced wearing arts, material and equi ment such as:

- Fuses, bulbs, seals, hoses, nozzles, filters, etc.

- Material and equi ment not manufactured wholly by us, which are covered by the warranty of the

manufacturer thereof.

THIS WARRANTY DOES NOT EXTEND TO:

Re lacements or re airs arising from fair wear and tear of the a liances or machines, damage or accidents

arising from negligence, lack of su ervision or maintenance, im ro er use or alterations made without our

written consent.

Defects arising from material rovided by the urchaser or mandatory design requirements issued by the

urchaser.

Re airs made necessary by damage or accidents arising during carriage.

Normal maintenance and adjustment rocedures required during use of the machine, as set out in the

maintenance instructions, such as:

- adjustment of intermediate com onents

- tightening of i es, hoses, etc.

Any traces of detergent o l n the a r system of pneumat c mach nes shall nval date the

aforement oned warranty terms.

Quote the mach ne reference and ser al number when mak ng techn cal enqu r es or

order ng spare parts.

English version

V0516

Page no. 2

INDEX

WARRANTY TERMS .................................................................................................................................................................1

INDEX ..........................................................................................................................................................................................2

TECHNICAL DATA ....................................................................................................................................................................3

SETTING UP THE MACHINE..................................................................................................................................................3

OVERVIEW .................................................................................................................................................................................4

OPERATION ...............................................................................................................................................................................4

1.

SAFETY..................................................................................................................................................................................5

a) International symbols.........................................................................................................................................................5

b) Important safety precautions..............................................................................................................................................5

c) Safety features....................................................................................................................................................................5

Safety system checks...............................................................................................................................................................6

After an emergency stop.........................................................................................................................................................6

Instructions and manuals .......................................................................................................................................................6

2.

SWITCHING

ON ...................................................................................................................................................................7

3.

CONTROL

PANEL .................................................................................................................................................................7

4.

SETTINGS .............................................................................................................................................................................8

a) Temperature.......................................................................................................................................................................8

b) Timer..................................................................................................................................................................................8

c) Pressure .............................................................................................................................................................................8

d) Swing-away speed..............................................................................................................................................................8

5

.OPERATING

CYCLE..............................................................................................................................................................8

6.

ELECTRONIC

BOARD

SETTINGS........................................................................................................................................9

a) Presets................................................................................................................................................................................9

b) Settings menus....................................................................................................................................................................9

c) Sleep mode .......................................................................................................................................................................10

d) Machine settings ..............................................................................................................................................................10

e) User comfort settings .......................................................................................................................................................11

f) Energy saving mode..........................................................................................................................................................11

7.

FULL-AUTO

MODE

(OPTIONAL).......................................................................................................................................12

a) Cycle options: "foot pedal", "single workstation" and "full auto"..................................................................................12

b) Selecting a work mode:....................................................................................................................................................12

c) Setting the "post-press timer" (in automatic mode only): ................................................................................................12

PARTS LAYOUT .......................................................................................................................................................................13

WIRING AND PNEUMATIC DIAGRAM ............................................................................................................................14

SERVICING...............................................................................................................................................................................16

1.

REPLACING

WORN

PARTS................................................................................................................................................16

a) Silicone foam pads...........................................................................................................................................................16

b) Other parts.......................................................................................................................................................................16

2.

M

AINTENANCE

........................................................................................................................................................................16

3.

ELECTRONIC

BOARD

MESSAGES.....................................................................................................................................17

WEAR PARTS ...........................................................................................................................................................................17

TROUBLESHOOTING TIPS ..................................................................................................................................................18

MAINTENANCE LOG ..............................................................................................................................................................19

English version

V0516

Page no. 3

TECHNICAL DATA

Non-contractual document: we reserve the right to alter our roduct s ecifications in line with advances in technology.

SETTING UP THE MACHINE

TO BE PERFORMED BY QUALIFIED PERSONNEL

Do not hold the mach ne by the platens!

Remove the machine from its ackaging. The machine is secured to a allet.

Place the machine on a stable, level table using the carry bars.

Secure the machine to the table.

Place the foot edal on the floor.

Plug in the ress using the lug rovided (230 Volt + Earth / 50 or 60 Hz).

Connect the ress to your com ressed air su ly (min. 3.5 bar, max. 10 bar).

We ght n work ng order

150 kg

Height

713 mm

De th 1005 mm

Width 1071 mm

Platen size 400 x 500 mm

Power supply

220/240 V S ngle phase + Earth 50/60 Hz

Power consum tion

3200 W

Am rating

14A

Electron c temperature controller

Accuracy

+/- 1%

Setting range

0 to 255 °C

Electron c t mer

Accuracy

+/- 1%

Setting range

0 s to 11 min

Noise level Below 70 dB (A)

Max mum press ng force

925 daN

English version

V0516

Page no. 4

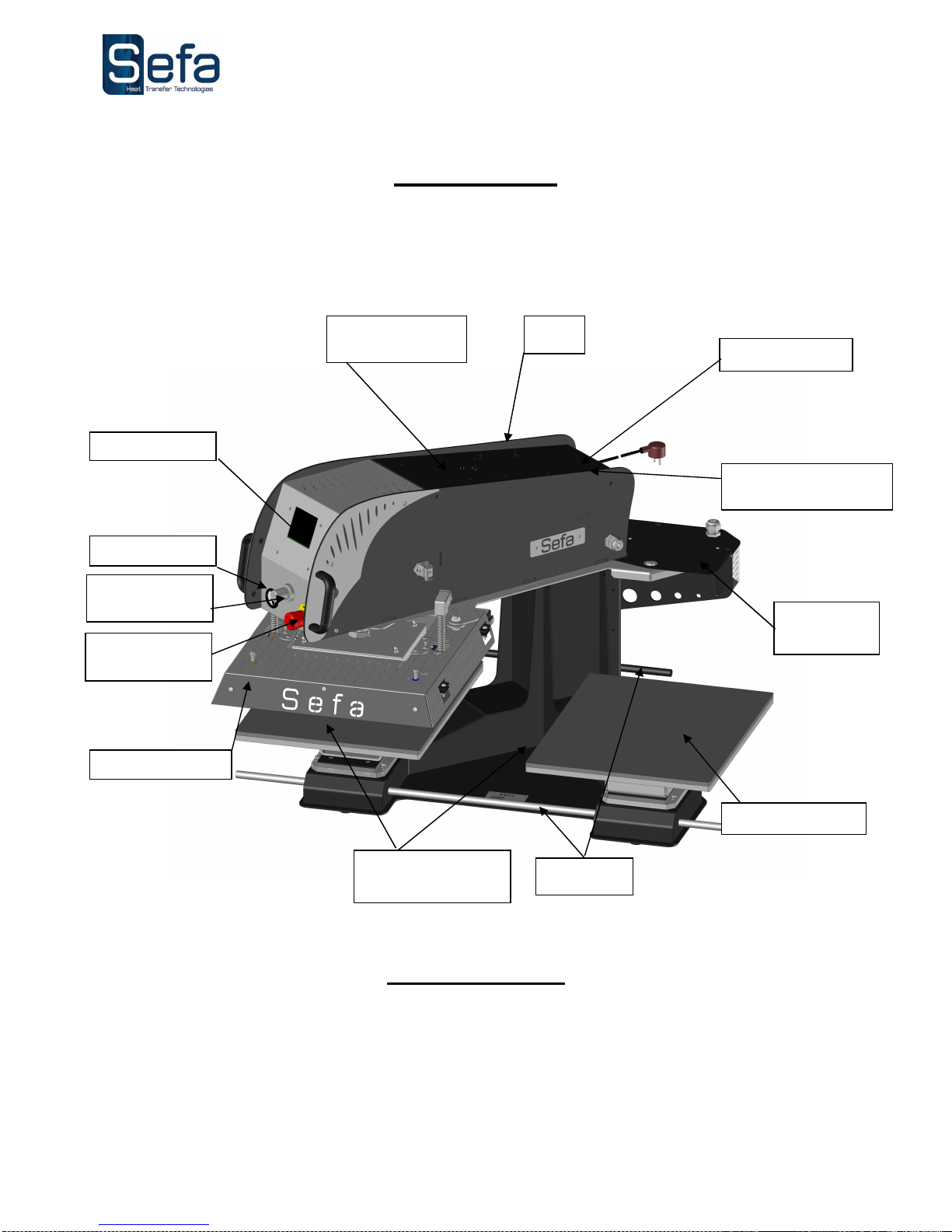

OVERVIEW

This heat ress has been designed to o erate at high out ut without risk to o erator safety in accordance with

article L 233-5 of the French labour code.

It has been designed for use by a single o erator ositioned in front of the machine.

OPERATION

Please read the O erating Manual carefully before o erating the ress.

The ress should be o erated by a qualified erson who is aware of the otential dangers arising from im ro er

use of the equi ment.

The factory-installed neumatic, electrical and mechanical settings rogrammed by our technicians and the safety

features must not be altered under any circumstances. SEFA acce ts no liability for roblems that may be caused

by the machine if such alterations are made.

Heat platen

Emergency

stop

Silicone foam pad

Detachable lower

platens

Filter

Touch screen

Cover +

electronic board Plug + fuse

Air inlet connection

Pressure gauge

Auto-swing

cylinder

Pressure

adjustment dial

Carry bars

Other manuals for DUPLEX PRO

1

Table of contents

Other Sefa Power Tools manuals

Sefa

Sefa DUPLEX MINI PRO User manual

Sefa

Sefa ROTEX AIR V3 Series User manual

Sefa

Sefa Initium iCAP 2 User manual

Sefa

Sefa INiTiUM User manual

Sefa

Sefa AIR CLAM X User manual

Sefa

Sefa LP 130 V3 User manual

Sefa

Sefa DUPLEX PRO User manual

Sefa

Sefa ROTEX AIR PRO User manual

Sefa

Sefa CLAM SPORT V3 User manual

Sefa

Sefa BR 180 PCAS User manual