Sefa ROTEX AIR PRO User manual

English version

V0916

Page 1

INSTRUCTION MANUAL

ROTEX AIR PRO

S.E.F.A

®

Z.I PASTABRAC

11260 ESPERAZA

FRANCE

Tel: +33 (0)4.68.74.05.89 - Fax: +33 (0)4.68.74.24.08

E-ma l: contact sefa.fr

English version

V0916

Page 2

INDEX

I.

WARRANTY TERMS ........................................................................................................................ 3

II.

TECHNICAL DATA .......................................................................................................................... 4

III.

WEAR PARTS ............................................................................................................................. 4

IV.

USING THE PRESS ......................................................................................................................... 5

A.

SETTING UP THE MACHINE ................................................................................................................ 6

1.

Unpacking ................................................................................................................................................... 6

B.

TRANSFER CYCLE ............................................................................................................................... 6

C.

CONTROL PANEL ................................................................................................................................ 7

D.

OPERATION ....................................................................................................................................... 8

Presets ................................................................................................................................................................. 8

Settings menus ...................................................................................................................................................... 9

Sleep mode ........................................................................................................................................................... 9

Machine settings .................................................................................................................................................. 10

User comfort settings ........................................................................................................................................... 10

Energy saving mode ............................................................................................................................................. 10

E.

AUTO-SWING ................................................................................................................................... 11

F.

MAINTENANCE ................................................................................................................................. 12

V.

TROUBLESHOOTING TIPS ........................................................................................................... 13

VI.

WIRING and PNEUMATIC DIAGRAMS ......................................................................................... 14

VII.

MAINTENANCE LOG ................................................................................................................ 16

English version

V0916

Page 3

I. WARRANTY TERMS

•The warranty period shall come into effect on the day on which the equipment is brought into service at the

user's premises, as attested on the returned warranty certificate and the delivery note, and shall run for two

years, based on a standard equipment operating schedule of 8 hours per day, i.e. 3,000 hours.

•The warranty is strictly limited to our equipment, and covers faulty materials and workmanship, which the

purchaser shall be required to substantiate.

•Our liability shall be limited to making good or replacing free of charge parts that are acknowledged by us to

be defective, and no claims for damages for any reason may be made against us.

•Parts replaced under warranty shall:

-remain our property

-be invoiced on consignment

•A credit note will be issued upon return of the faulty parts.

Returns must be made NO LATER THAN ONE MONTH after the work is performed under warranty.

THIS WARRANTY DOES NOT COVER:

•Commercially sourced wearing parts, material and equipment such as:

-- Fuses, bulbs, seals, hoses, nozzles, filters, etc.

-Material and equipment not manufactured wholly by us, which are covered by the warranty of the

manufacturer thereof.

THIS WARRANTY DOES NOT EXTEND TO:

•Replacements or repairs arising from fair wear and tear of the appliances or machines, damage or accidents

arising from negligence, lack of supervision or maintenance, improper use or alterations made without our

written consent.

•Defects arising from material provided by the purchaser or mandatory design requirements issued by the

purchaser.

•Repairs made necessary by damage or accidents arising during carriage.

•Normal maintenance and adjustment procedures required during use of the machine, as set out in the

maintenance instructions, such as:

-adjustment of intermediate components

-tightening of pipes, hoses, etc. …

-

Any traces of detergent o l n the a r system of pneumat c mach nes shall nval date the

aforement oned warranty terms.

Quote the mach ne reference and ser al number when mak ng techn cal enqu r es or order ng spare

parts.

English version

V0916

Page 4

II. TECHNICAL DATA

Non-contractual document: we reserve the right to alter our product specifications in line with advances in technology.

III. WEAR PARTS

When order ng:

always quote the description, reference and quantity

Reference

Descr pt on

Quant ty

AFF-EL3’’5 HMI TOUCH SCREEN 1

CAR-EL I POWER BOARD

RES-CI1 GAS-OPERATED AUTO-SWING SPRING 1

RES-500X400-

3200W MICA HEATING ELEMENT 400x500 3200 W 1

SON-PT100 PT100 TEMPERATURE PROBE 1

TOI-4050 PROTECTIVE TEFLON SHEET FOR HEAT-PLATEN 1

MOU-540 SILICONE FOAM 400X500 mm 1

VER-SM21 COMPACT JACK Ø 140 mm 1

ELE-SM8 SOLENOID CONTROL VALVE 24V 1

DET-SM1 MAGNETIC REED SWITCH FOR ACTUATING JACK

ROTEX AIR PRO

We ght n work ng order

97kg

41kg

Height

681 mm

Depth 940 mm

Width 624 mm

Platen s ze 400 x 500 mm

Power supply

230 V S ngle phase + Earth 50/60 Hz

Power consumption

3200 W

Amp rating

14 A

Electron c temperature controller

Accuracy

+/- 1%

Setting range

0 to 220 °C

Electron c t mer

Accuracy

+/- 1%

Setting range

0 s to 9 min 30 s

Adjustable pressure

430 g/cm² at 6 bars and 560 g/cm² at 8 bars

English version

V0916

Page 5

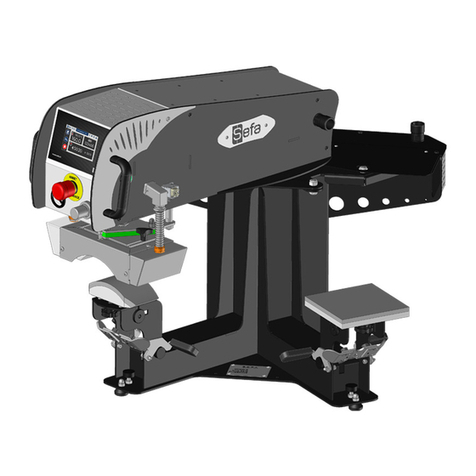

IV. USING THE PRESS

This heat press has been designed for small production runs without risk to operator safety in accordance with

article L 233-5 of the French labour code.

This press has been designed for use by a single operator working from the front.

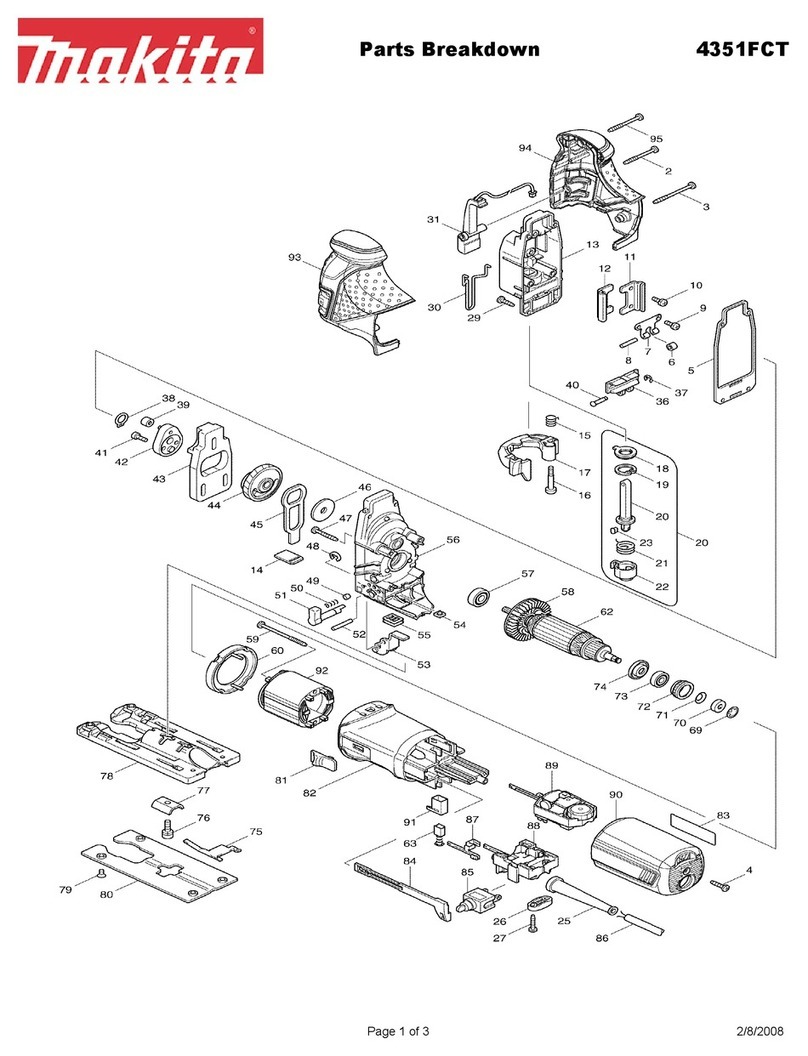

Air pressure

adjustment

wheel

Platen lowering

handle

Silicone pad

Filter

TOUCH SCREEN

control panel

Electronic board and

pneumatic components

Main switch

Detachable cold

lower platen

Dual-handed press

operating buttons

Heat platen

Emergency stop

button

Pressure gauge

English version

V0916

Page 6

A. SETTING UP THE MACHINE

1. Unpack ng

1. Remove the packing case from the machine.

2. Set up and secure the machine on its work table.

3. Make sure the press is cold before picking it up. Carry the press holding both platens (upper and lower),

which should be in the closed position.

4. Remove the transport safety screws before opening the press.

5. Plug in the press (230 Volt + Earth / 50 or 60 Hz).

B. TRANSFER CYCLE

1. Press the main switch at the back of the machine to turn the power on.

2. Set the temperature.

3. Set the pressing duration.

4. Set the pre-heat duration if necessary.

5. Adjust the pressure (to suit the type of transfer).

6. Place the T-shirt on the lower platen.

7. Position the transfer sheet correctly.

8. When the heat platen is at the correct temperature, press the dual-operated buttons to lower it into

position.

9. The timer will start when the platen is pressed against the T-shirt.

10. The press will open automatically when the timer has finished.

11. The cycle can be stopped early by pressing the stop button on the control panel. The press will open

automatically.

12. If the auto-swing is engaged, the machine will also swing open to the side automatically.

English version

V0916

Page 7

C. CONTROL PANEL

Current

temperature

reading and

temperature

adjustment field

Heating indicator

Date

Settings menu key

Increment-up, open next

menu, browse presetting

sub-menus

Increment-down, open

previous menu, browse

presetting sub-menus

Time

Main timer

Resettable counter

Presets

English version

V0916

Page 8

D. OPERATION

Presets

This menu contains nine pre-saved operating programs; up to five presets can be assigned to each program by

entering the required setpoints.

The operating programs must be suited to the processes you use. The temperature adjustment system is fine-

tuned for each program.

Available programs:

Customised: the system applies the user-defined settings keyed in at the control panel

Flex: for placing flex and flock

DTG 1: for drying pre-treated materials

DTG 2: for pressing pre-treated materials

SUBLI T: for sublimation printing on textiles

SUBLI R: for sublimation printing on rigid materials

SCREEN: for placing screen transfers

LASER: for placing laser transfers

QUICKFLEX: for placing flex in under 5 seconds

Browse between

programs

Browse between

program presets

English version

V0916

Page 9

Sett ngs menus

Press the green key in the centre of the screen to open the settings.

Click to access the required menu.

Press the arrow in the bottom centre of the screen to exit.

Sleep mode

Sleep mode keeps the machine temperature at a certain level for a certain length of time

Internal menu code

Error log (last 10 errors)

Counters

To previous screen

Machine settings

Energy saving mode

User comfort settings

Sleep mode

Diagnostic mode

End-of-cycle beeper time

setting

To next screen

To previous screen

Temperature in sleep mode

Start of sleep m

ode

End of sleep mode

O

N/OFF

English version

V0916

Page 10

Mach ne sett ngs

User comfort sett ngs

Energy sav ng mode

Energy saving mode reduces the machine temperature to the set temperature when the defined idle time has

elapsed.

Enable drying mode

The drying time is set at the

control panel with the

pressing time setpoint

Enable/disable buzzer

°C/°F

Machine operating

temperature range

On/Off

Temperature

Time

English version

V0916

Page 11

E. AUTO-SWING

When the cycle ends, the heat platen will lift up and the auto-swing system will rotate the press away to the side,

free of the heat platen.

You can disable this feature if you wish.

To enable this feature, first make sure the press is in the open position, then turn and push the thumbwheel down

as shown on the diagram below.

English version

V0916

Page 12

F. MAINTENANCE

•Daily:

Clean the heat platen with a dry cloth.

•According to use:

Replace the silicone foam pad at the first sign of damage or deterioration in quality.

English version

V0916

Page 13

V. TROUBLESHOOTING TIPS

The machine’s electrical power must be switched off and locked and tagged prior to any service repair

work.

The heat platen can cause burns. Check that the platen temperature reading on the display panel is below

25° C before handling.

PROBLEM POSSIBLE CAUSES SOLUTION

The platen does not heat up Faulty electronic board

Temperature probe not

working

Check and if necessary replace

Replace the temperature probe

The platen overheats The relay is stuck

The electronic board is

damaged

Replace the electronic board

Replace the electronic board

The timer does not count

down

The sensor is not being tripped

Check whether the sensor is tripped as the

descending heat platen moves past

English version

V0916

Page 14

VI. WIRING and PNEUMATIC DIAGRAMS

English version

V0916

Page 15

English version

V0916

Page 16

VII. MAINTENANCE LOG

The following checks and maintenance procedures should be performed at regular intervals to ensure that your

press remains in good working order and continues to provide reliable service.

Date Number

of hours

Pressure

check Air filter

check Cylinder

check

Condition

of foam

pad

Heating

element

check

Replaced

parts Observations

Tip - use the following abbreviations to help complete the log more quickly:

C: Checked W: Washed/Cleaned R: Replaced

Table of contents

Other Sefa Power Tools manuals

Sefa

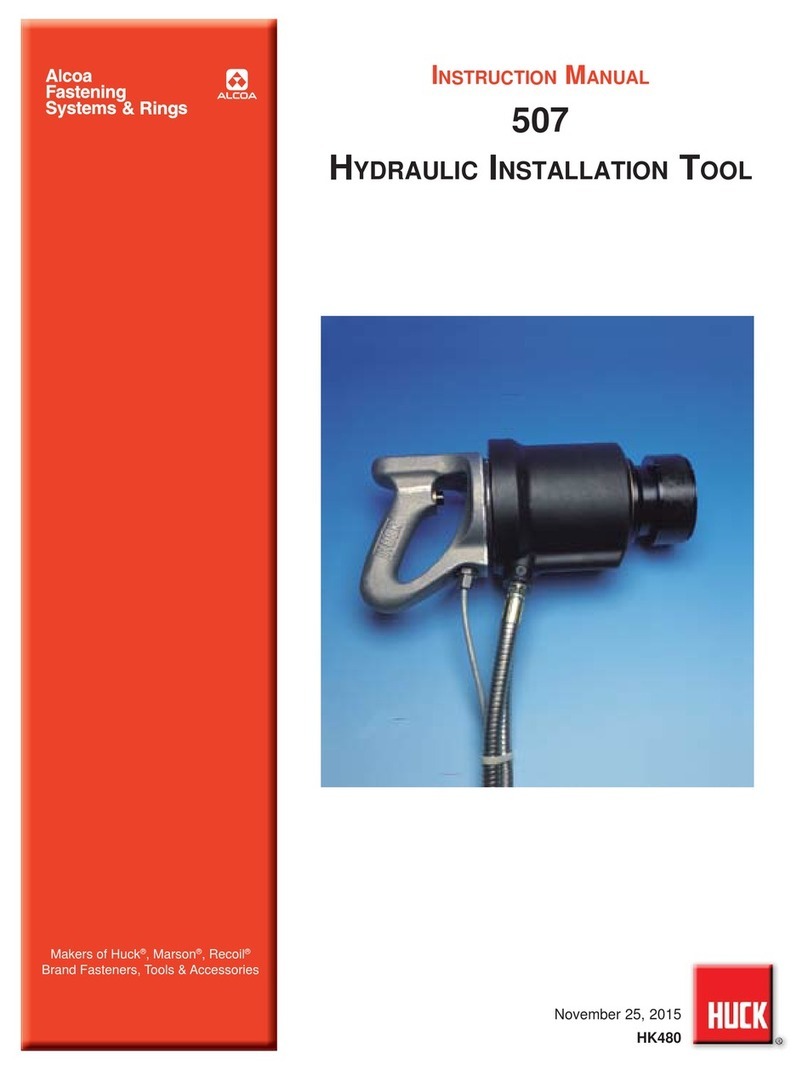

Sefa AIR CLAM X User manual

Sefa

Sefa DUPLEX PRO User manual

Sefa

Sefa LM V3 Series User manual

Sefa

Sefa ROTEX AIR V3 Series User manual

Sefa

Sefa INiTiUM User manual

Sefa

Sefa BR 180 PCAS User manual

Sefa

Sefa LP 130 V3 User manual

Sefa

Sefa Initium iCAP 2 User manual

Sefa

Sefa CLAM 45M User manual

Sefa

Sefa DUPLEX MINI PRO User manual

Popular Power Tools manuals by other brands

Sparx

Sparx PS100 operating manual

Yokota

Yokota YLA140E-JQ manual

EINHELL

EINHELL BT-BJ 900 Original operating instructions

Clarke

Clarke CCT48 Operation & maintenance instructions

Baileigh Industrial

Baileigh Industrial DP-1850G Operator's manual

Sioux Tools

Sioux Tools IW100AI-8H Instructions and parts list