4 TB MRIK3 12.00 E

1Introduction and application

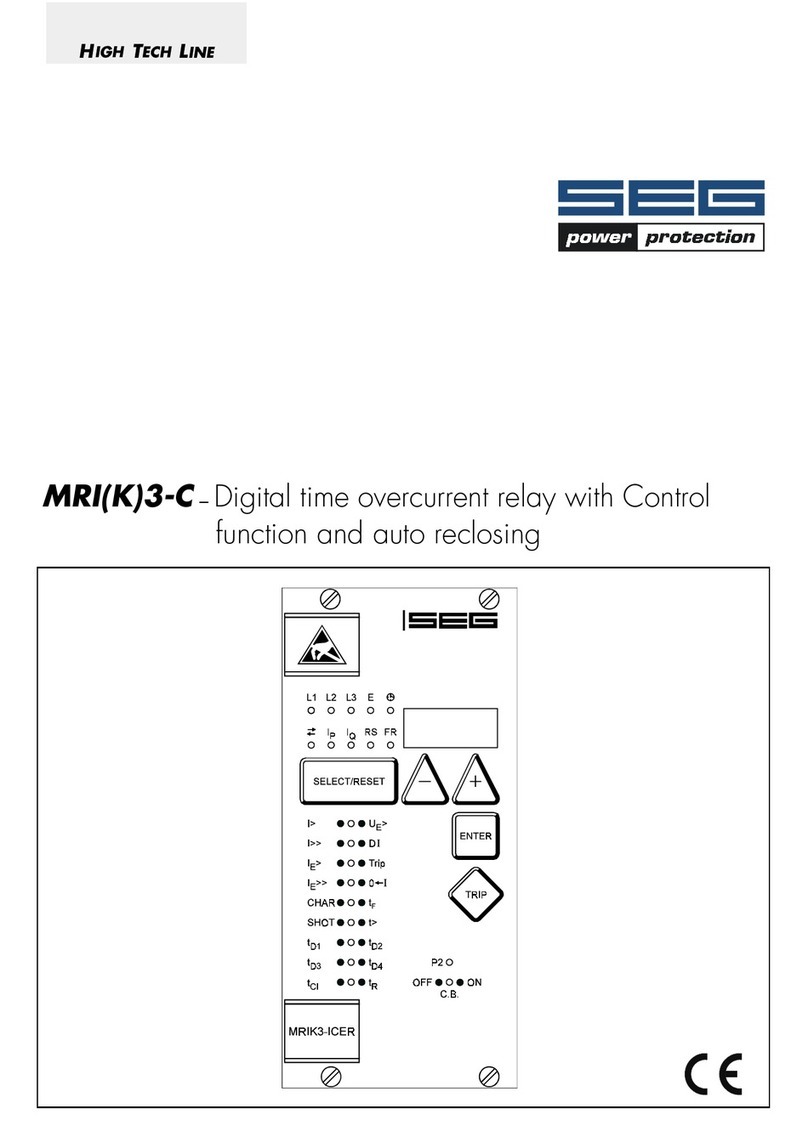

The MRlK1 digital multifunctional relay is a universal

time overcurrent and earth fault protection device with

integrated auto reclosing relay intended for use in me-

dium-voltage systems, either with an isolated/com-

pensated neutral point or for networks with a solidly

earthed/resistance-earthed neutral point.

In transmission line networks more than 70% of the oc-

curring faults are transient (electric arcs extinguish,

branches are falling on the overhead lines etc.)

With the application of the automatic reclosing (AR) to-

gether with protection relays, many electric arcs are ex-

tinguished through temporary interruption of the energy

supply.

Without utilizing the automatic reclosing (AR) power

supply interruptions would occur quite frequently.

Statistics have shown that yet part of the faults remain

after the first fast AR can be cleared with a longer 2nd

AR interval.

The digital multi-shot, three phase auto reclosing relay

MRIK3 fulfills these requirements for use on medium

voltage transmission or distribution systems, by

4-element AR with variable adjustable dead times.

Important:

For additional common data of all MR-relays please re-

fer to manual "MR - Digital Multifunctional relays".

2Features and characteristics

•Digital filtering of the measured values by using dis-

crete Fourier analysis to suppress the high frequence

harmonics and DC components induced by faults or

system operations,

•two parameter sets,

•selectable protective functions between:

definite time overcurrent relay or

inverse time overcurrent relay,

•selectable inverse time characteristics according to

IEC 255-4:

Normal Inverse (Type A)

Very Inverse (Type B)

Extremely Inverse (Type C

Special characteristics,

•reset setting for inverse time characteristics selectable,

•high set overcurrent unit with instantaneous or de-finite

time function,

•two-element (low and high set) overcurrent relay for

both phase and earth faults independent from each

other,

•circuit breaker failure protection,

•4-element AR with Fast-Trip Mode,

•adjustable timer for fault time, dead time, close im-

pulse time and reclaim time,

•external blocking and blocking release of AR,

•optical indications of the AR functional sequence and

the AR results,

•external control through optically isolated inputs,

•number of auto reclosings, adjustable from 1 to 4,

•display of measuring values as primary quantities,

•blocking e.g. of high set element (e.g. for selective

fault detection through minor overcurrent protection

units after unsuccessful AR),

•free assignment of output relays,

•free assignment of protective function for every reclos-

ing separately adjustable,

•blocking the protection function or Fast-Trip-tripping for

a selective switch off before and after each AR sepa-

rately adjustable,

•suppression of indication after an activation

(LED flash),

•storage of trip values and switching-off time (tCBFP) of 5

fault occurences (fail-safe of voltage),

•recording of up to eight fault occurences with time

stamp,

•serial data exchange via RS485 interface possible;

alternatively with SEG RS485 Pro-Open Data Protocol

or Modbus Protocol,

•display of date and time