TB XRI1-IR 02.00 E 9

4Working principle

4.1Analog circuits

The incoming currents from the main current transform-

ers on the protected object are converted to voltage

signals in proportion to the currents via the input trans-

formers and burden. The noise signals caused by in-

ductive and capacitive coupling are supressed by an

analog R-C filter circuit.

The analog voltage signals are fed to the A/D-

converter of the microprocessor and transformed to

digital signals through Sample- and Hold-circuits. The

analog signals are sampled at 50 Hz (60 Hz) with a

sampling frequency of 800 Hz (960 Hz), namely, a

sampling rate of 1.25 ms (1.04 ms) for every measur-

ing quantity. (16 scans per periode).

4.2Digital circuits

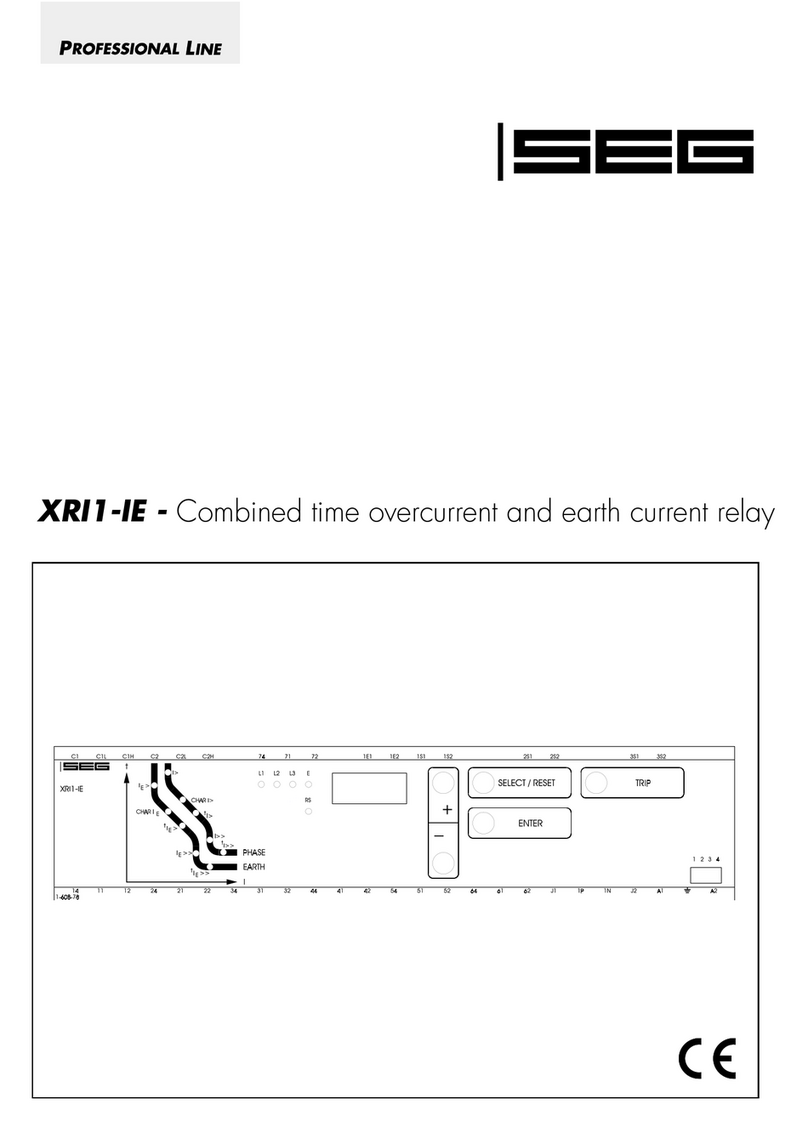

The essential part of the XRI1-IR relay is a powerful

microcontroller. All of the operations, from the analog

digital conversion to the relay trip decision, are carried

out by the microcontroller digitally. The relay program

is located in an EPROM (Electrically-Programmable-

Read-Only-Memory). With this program the CPU of the

microcontroller calculates the three phase currents and

ground current in order to detect a possible fault situa-

tion in the protected object.

For the calculation of the current value an efficient digi-

tal filter based on the Fourier Transformation (DFFT -

Discrete Fast Fourier Transformation) is applied to sup-

press high frequency harmonics and DC components

caused by fault-induced transients or other system dis-

turbances.

The calculated actual current values are compared

with the relay settings. If a phase current exceeds the

pickup value, an alarm is given and after the set trip

delay has elapsed, the corresponding trip relay is acti-

vated.

The relay setting values for all parameters are stored in

a parameter memory (EEPROM - Electrically Erasable

Programmable Read-only Memory), so that the actual

relay settings cannot be lost, even if the power supply

is interrupted.

The microprocessor is supervised by a built-in "watch-

dog" timer. In case of a failure the watchdog timer re-

sets the microprocessor and gives an alarm signal, via

the output relay "self supervision".

4.3Directional feature

A built-in directional element in XRI1-IR is available for

application to doubly infeeded lines or to ring net-

works.

The measuring principle for determining the direction is

based on phase angle measurement and therefore

also on coincidence time measurement between cur-

rent and voltage. Since the necessary phase voltage

for determining the direction is frequently not available

in the event of a fault, whichever line-to-line voltage fol-

lows the faulty phase by 90° is used as the reference

voltage for the phase current. The characteristic angle

at which the greatest measuring sensitivity is achieved

can be set to precede the reference voltage in the

range from 15° to 83°.

Figure 4.1: Relay characteristic angle

The TRIP region of the directional element is deter-

mined by rotating the phasor on the maximum sensitiv-

ity angle for ±90°, so that a reliable direction deci-

sion can be achieved in all faulty cases.

Figure 4.2: TRIP/NO-TRIP region for directional element in

XRI1-IR. In this case the advance direction is

defined as TRIP region and the reverse direction

as NO-TRIP region.