TB MRU3-1 12.00 E 7

4 Working principle

4.1 Analog circuits

The input voltages are galvanically insulated by the in-

put transformers. The noise signals caused by inductive

and capacitive coupling are supressed by an analog

R-C filter circuit.

The analog voltage signals are fed to the A/D-

converter of the microprocessor and transformed to

digital signals through Sample- and Hold- circuits. The

analog signals are sampled with a sampling frequency

of 16 x fN, namely, a sampling rate of 1.25 ms for

every measuring quantity, at 50 Hz.

4.2 Digital circuits

The essential part of the MRU3-1 relay is a powerful

microcontroller. All of the operations, from the analog

digital conversion to the relay trip decision, are carried

out by the microcontroller digitally. The relay program

is located in an EPROM (Electrically-Programmable-

Read-Only-Memory). With this program the CPU of the

microcontroller calculates the three phase voltage in

order to detect a possible fault situation in the pro-

tected object.

For the calculation of the voltage value an efficient

digital filter based on the Fourier Transformation (DFFT -

Discrete Fast Fourier Transformation) is applied to sup-

press high frequency harmonics and d.c. components

caused by fault-induced transients or other system dis-

turbances. The microprocessor continuously compares

the measured values with the preset thresholds stored

in the parameter memory (EEPROM). If a fault occures

an alarm is given and after the set tripping delay has

elapsed, the corresponding trip relay is activated.

The relay setting values for all parameters are stored in

a parameter memory (EEPROM - Electrically Erasable

Programmable Read Only Memory), so that the actual

relay settings cannot be lost, even if the power supply

is interrupted.

The microprocessor is supervised by a built-in "watch-

dog" timer. In case of a failure the watchdog timer re-

sets the microprocessor and gives an alarm signal via

the output relay "self supervision".

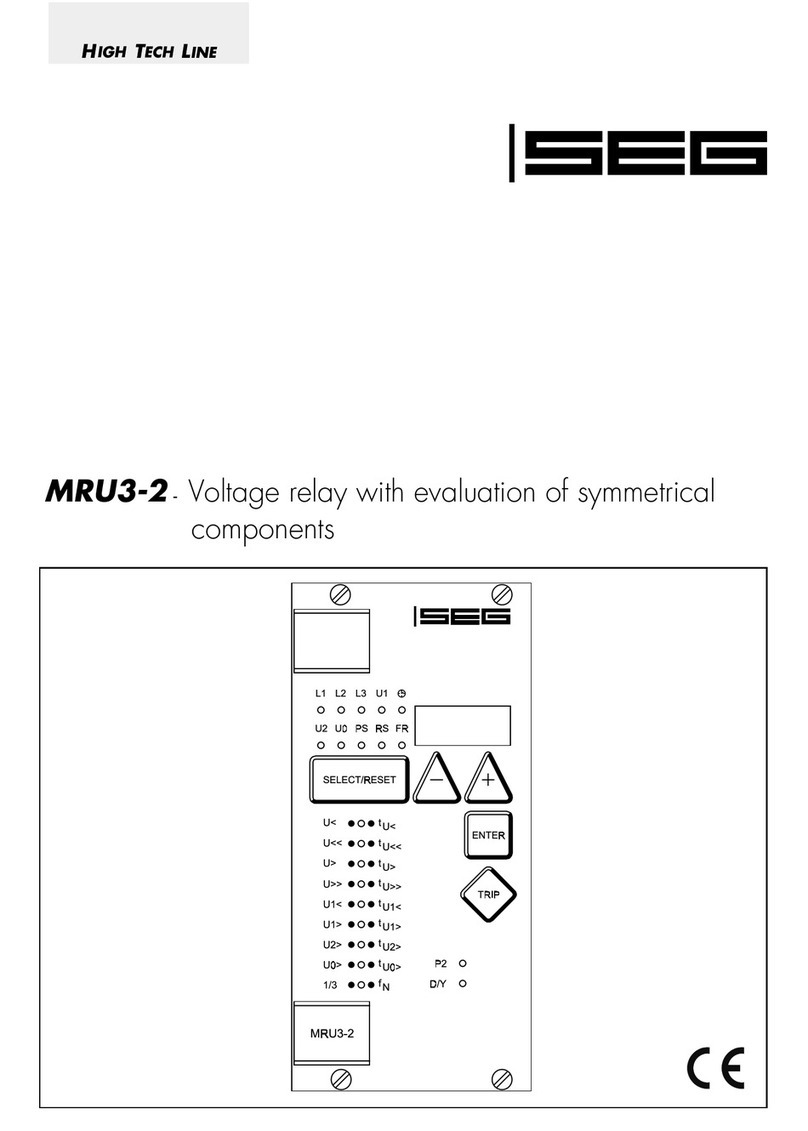

4.3 Voltage supervision

The voltage relay MRU3-1 protects electrical genera-

tion systems, consumers and appliances in general

against over- and/or undervoltage. The relay is

equipped with an independent, 2-step over- (U>, U>>)

and undervoltage supervision (U<, U<<) with sepa-

rately adjustable tripping values and delay times. Volt-

age measuring is 3-phase. In this process there is a

continuous comparison of the line conductor voltages

in case of a delta connection and of the phase volt-

ages in case of a star connection with the preset limit

values.

With the MRU3-1 the highest voltage is always evalu-

ated for overvoltage supervision and the lowest volt-

age for undervoltage supervision.

A distinction is made between 1-phase and 3-phase

tripping. (1/3 – Parameter)

With 1-phase tripping the voltages are evaluated as

follows:

U</U<</U</U>>: Activation or tripping takes place

if at least one phase has fallen short of the tripping

value.

With 3-phase tripping the voltages are evaluated as

follows:

U<: Activation or tripping takes place if all three

phases have fallen short of the tripping value.

U<<: Activation or tripping takes place if one phase

has fallen short of the tripping value.

U>: Activation or tripping takes place if all three

phases have exceeded the tripping value.

U>> Activation or tripping takes place if one phase

has exceeded the tripping value.