Maintenance and careFilling the containers

Never clean chrome-plated soap dispensers with aggressive clea-

ning agents containing acid or chlorine.

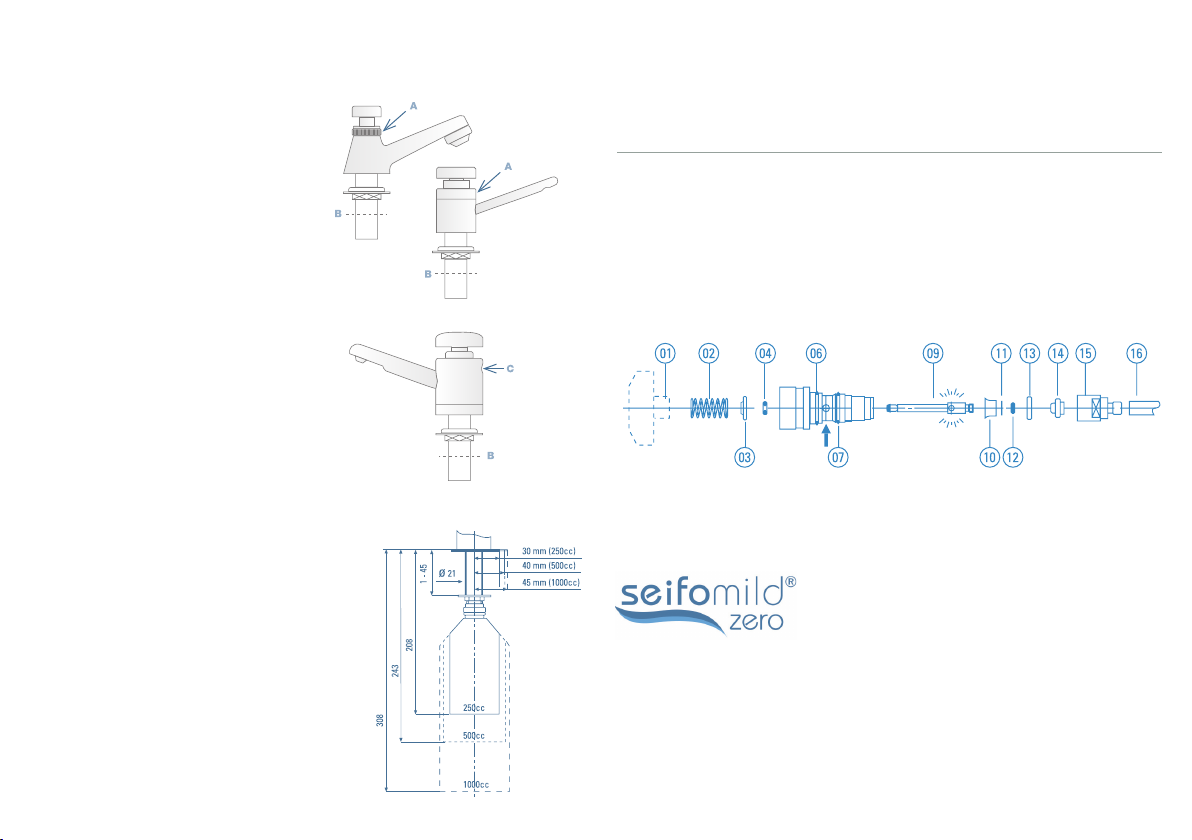

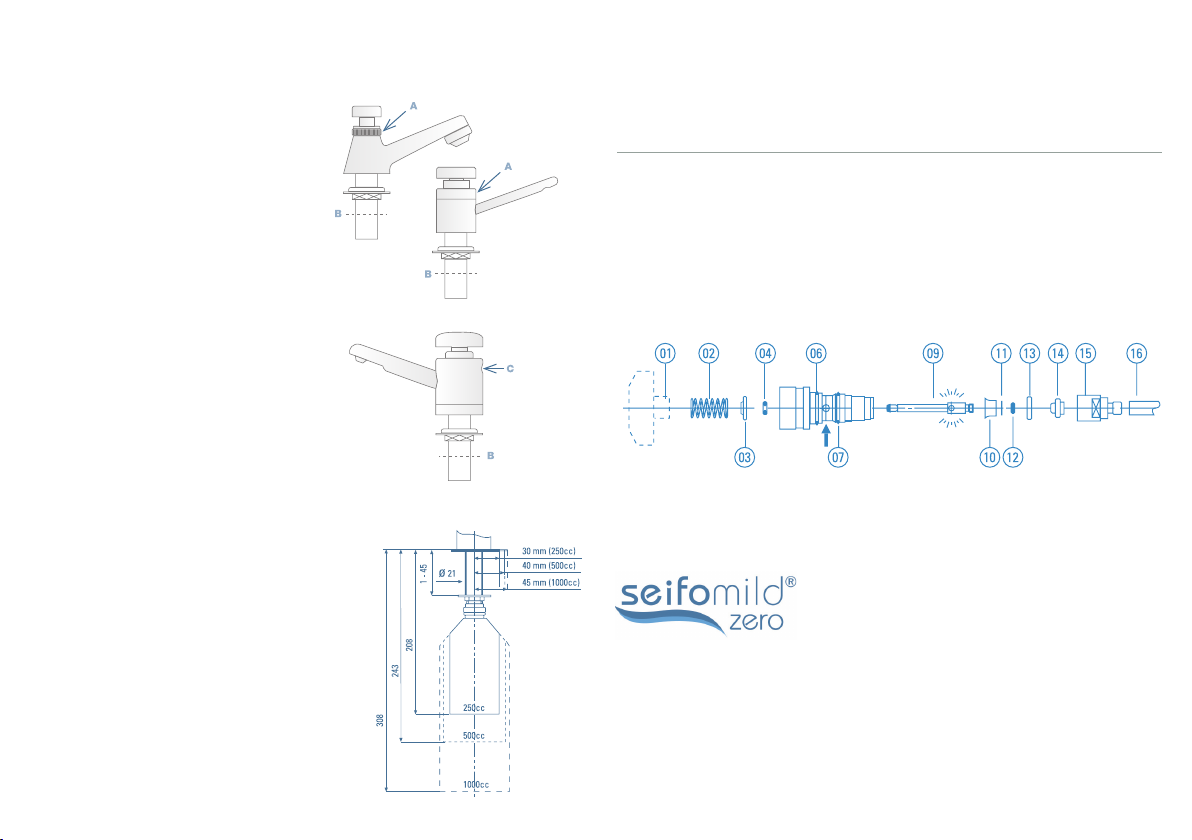

The pump cylinder can be completely dismantled for possible replacement

of components:

- Dismantle the hose connector (pos. 15).

- Block the axle: Through one of the holes in the pump cylinder

(s. arrow) a pin or something similar (ø max. 3 mm) into the hole

in the axle (pos. 09).

- Then unscrew the push button (pos. 01).

- The axle can now be removed from the pump cylinder.

- A revision kit is available.

SPARE PARTS

14279957 Large revision set (02,03,04,06,07,09,10,11,12,13,14,15,16)

14279981 Revision set Kiga (02,03,04,06,07,09,10,11,12,13,14,15,16)

14279990 Revision set Steel (02,03,04,06,07,09,10,11,12,13,14,15,16)

14279968 Small revision set (03,04,06,07,10,11,12,13,14)*

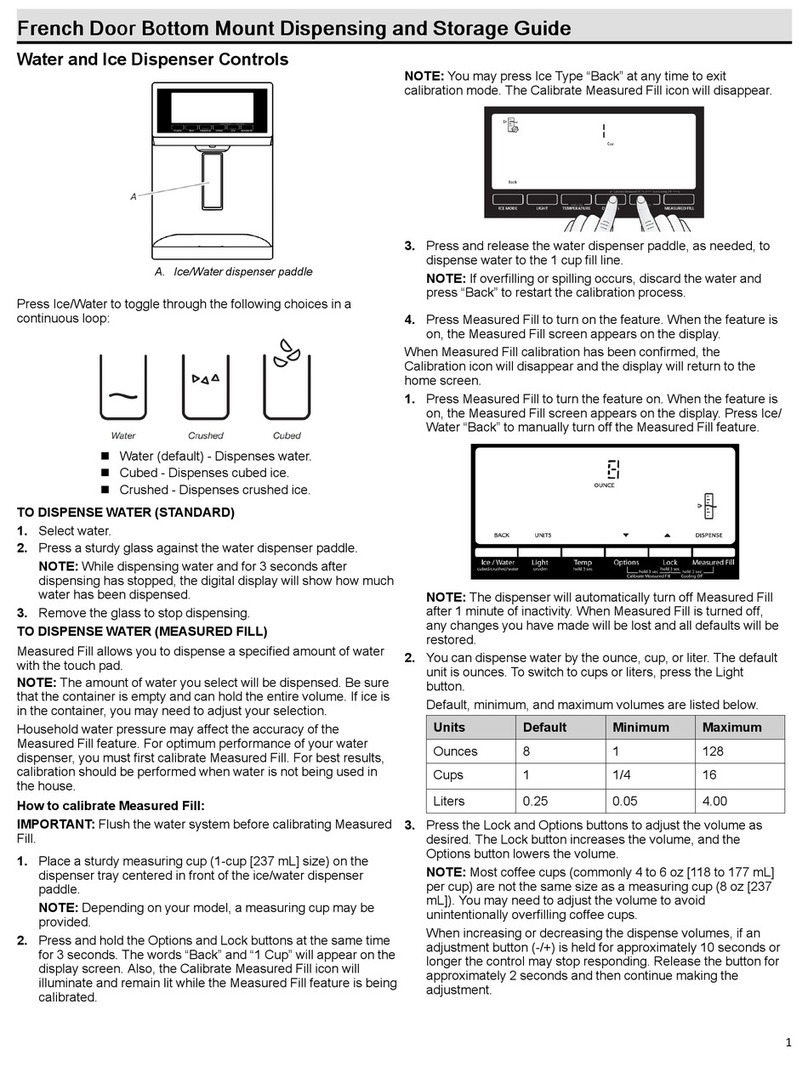

Soap: We recommend our soap cream

Seifomild Zero®. This soap cream was speci-

ally developed for use in soap dispensers. It is

discreetly scented with a pleasant fragrance, cosmetically mild to the skin,

dermatologically tested, free from environmentally harmful microplastic,

chloride-free, biodegradable and DIN-tested.

15999911 Soap for Seifomat soap dispenser 0,5 ltr. bottle SC050

15999901 Soap for Seifomat soap dispenser 1,0 ltr. bottle SC100

15999904 Soap for Seifomat soap dispenser 5,0 ltr. canister SC500

15999907 Soap for Seifomat soap dispenser 10,0 ltr. canister SC1000

Installation dimensions:

228

263

328

* From production date 19-1 and older (see hose connector no. 15), do not install item 11 as the

axle is too short

Modell „Nova“, „de Luxe“,

„Slim“ & „Air+Ship“ (Fig.1-2)

1. Loosen the pump cylinder by

turning the upper part (A).

2. Pull out the pump cylinder

by the push button.

3. Fill the container up to a

maximum of half of the

threaded shank fi ll (B).

4. After fi lling, screw the pump

cylinder back in.

Modell „Safe“, „Exquisit“, „Square“,

„Pure“, „Nova Steel“ & „Universal“ (Fig. 3)

1. Loosen the hexagon socket screw (C)

with the loosen the hexagonal spanner.

2. Pull out the pump cylinder by

the pull out.

3. Fill the container to a maximum

of half fi ll the threaded shaft (B).

4. Replace the pump cylinder and

keep it pressed.

5. Tighten the hexagon socket

screw again and then release

the pump cylinder.

For lling we recommend our special

funnel with venting ribs.