3/11

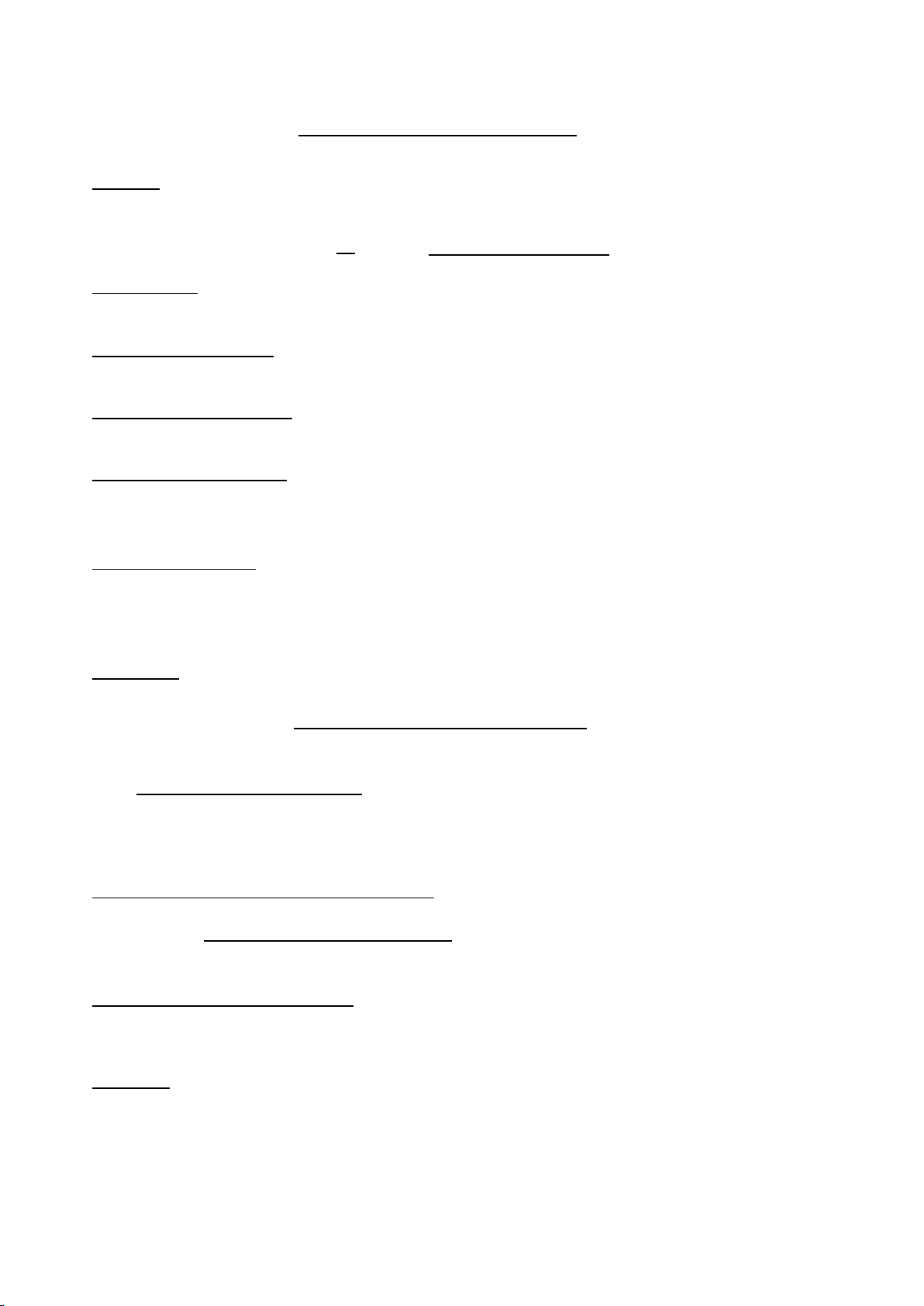

EnvironmentandMechanicalcharacteristics

Item Specifications Conditions

1 Hightemperaturestorage1 Δf/f0=±10×10-6 Afterstorageunder85℃for1000hours, *1

measureatroomtemperature. *3

Hightemperaturestorage2 Δf/f0=±15×10-6 Afterstorageunder125℃for1000hours, *1

measureatroomtemperature. *3

2 Lowtemperaturestorage Δf/f0=±10×10-6 Afterstorageunder-55℃for1000hours, *1

measureatroomtemperature. *3

3 Hightemperatureand Δf/f0=±10×10-6 Afterstorageunder+85±2℃, *1

highhumiditystorage 85%RHfor1000h,measureatroom *3

temperature.

4 Thermalshockresistance Δf/f0=±10×10-6 Measureatroomtemperatureafter *1

100cycles. *3

-55℃⇔+125℃for30minutes.

5 Mechanicalshock Δf/f0=±10×10-6 *2

resistance

6 Vibrationresistance Δf/f0=±10×10-6 Amplitude1.5mmand10〜500Hzwith *2

cycletime15minutesin3direction

(X,Y,andZaxis)eachfor2h.

7 IRReflow Δf/f0=±10×10-6 Measureafter2timereflowunder *1

reflowprofilespecifiedinpage10

8 Shearstrength Nopeeling-off Pressuringforce10N×10±1sec. *2

accordingtoIEC60068-2-21

9 Peelstrength Nopeeling-off Pressuringforce10N×10±1sec. *2

accordingtoIEC60068-2-21

10 Bendingtest Nopeeling-off Bending:3mm×5±1sec. *2

Thicknessofthetestingboard:1mm

Note:

1.Eachtestshallbedoneindependently.(notinseriestests)

2.*1:Measureafter24hoursleftatroomtemperature.

3.*2:Measureafter2hoursleftatroomtemperature.

4.*3:Preconditions

(1)IRReflow:2times

(2)Initialvaluesshallbemeasuredafter24hoursatroomtemperature.

5.Shiftinseriesresistanceaftertheabovetestsshallbelessthan±20%orlessthan±15kΩ.

IncaseofresistancetoIRreflow,shiftinseriesresistanceaftertheabovetestsshallbelessthan

±30%or±20kΩ.

Incaseofresistancetohightemperaturestorage(±125℃for1000hours),shiftinseriesresistance

aftertheabovetestsshallbelessthan±40%or±30kΩ.

Measureafter100g-dummy(SIIStandard)

dropfrom1500mmheightontheconcrete

3directions10times.