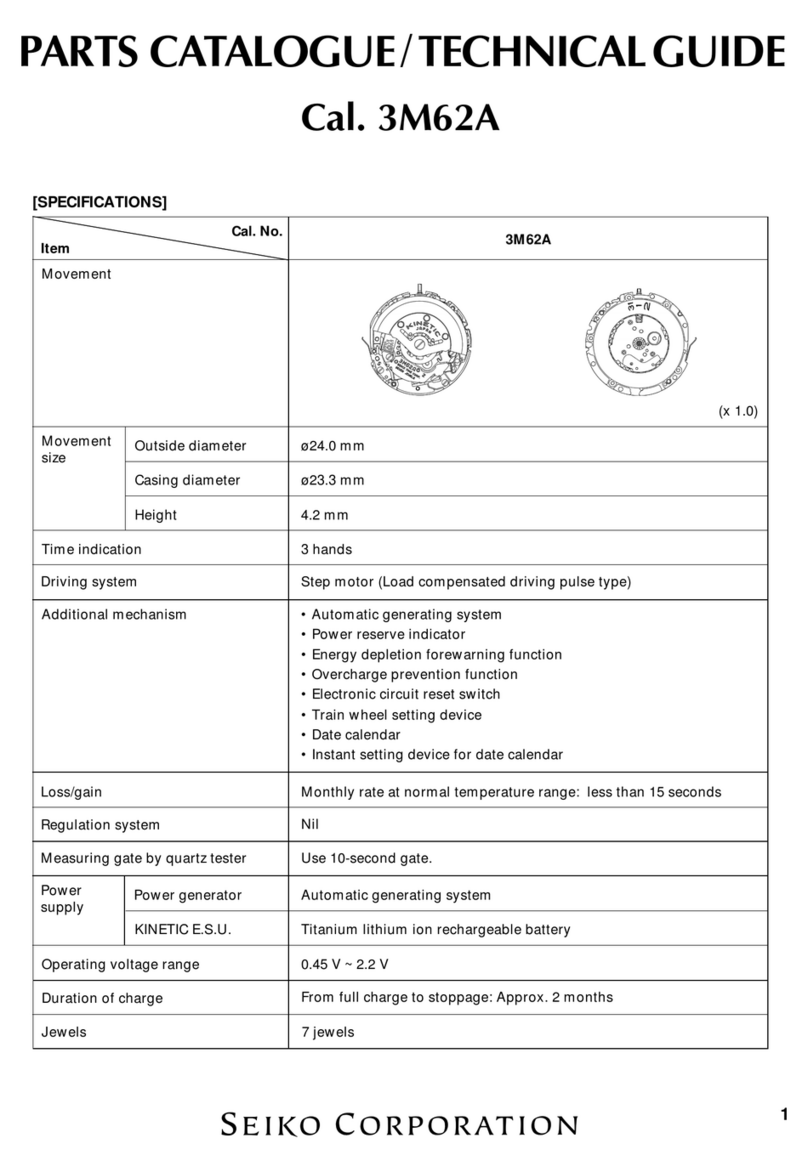

SPECIFICATIONS

2/19

Cal. 6T63A

Cal. 6T63A has a new structure employing one crown and two buttons. The construction of chronograph

mechanism is based on Cal. 8R28 mechanical chronograph watch by using the one-piece 3 pointed reset

hammer. While other Swiss-made watches are using separate hammers which require an assembly and

adjustment of the hammers, the one-piece hammer design realizes maximum durability and stability of

the component and easier maintenance. It is also equipped with the self-alignment function for all counting

hands to return to zero positions instantaneously.

This is the multi-display analogue watch featuring a stopwatch function.

●The time is indicated by the 24-hour, hour and minute hands, and a small second hand.

●The stop watch can measure up to 60 minutes in one second increments. After 60 minutes,

it will stop automatically.

●Measurement performance

Displays the elapsed time with the 2 designated STOPWATCH hands.

Measures up to 60 minutes in one second increments.

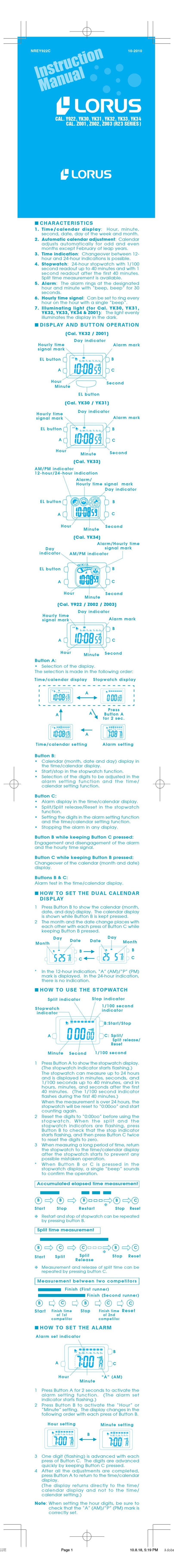

●Button operation (Crown position: Normal position)

Button A: START/STOP

Button B: RESET

1. STOPWATCH FUNCTION

Cal. 6T63A

a b c

Hour hand

Minute hand

STOPWATCH 1/5-second hand

STOPWATCH minute

hand

Small second hand

a: Normal position

b: First click

c: Second click

24-hour hand

A

B

CROWN

When pushing the reset button

the HAMMER OPERATING LEVER

B moves automatically to

keep appropriate balance of the

HAMMER position.

CHRONOGRAPH

COUPLING LEVER

HAMMER OPERATING

LEVER A

HAMMER OPERATING

LEVER B

HAMMER HAMMER HAMMER OPERATING

LEVER B

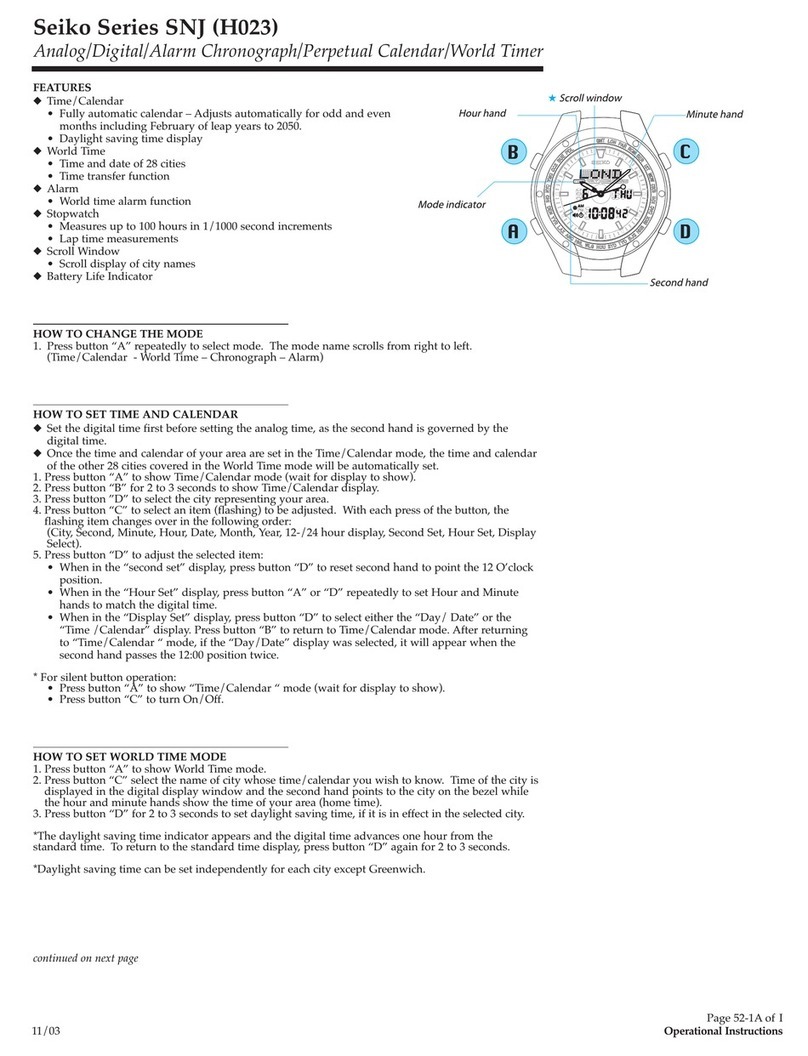

FEATURES

START RESET