Seiko 4R Series User manual

Other Seiko Watch manuals

Seiko

Seiko Astron SSH109J User manual

Seiko

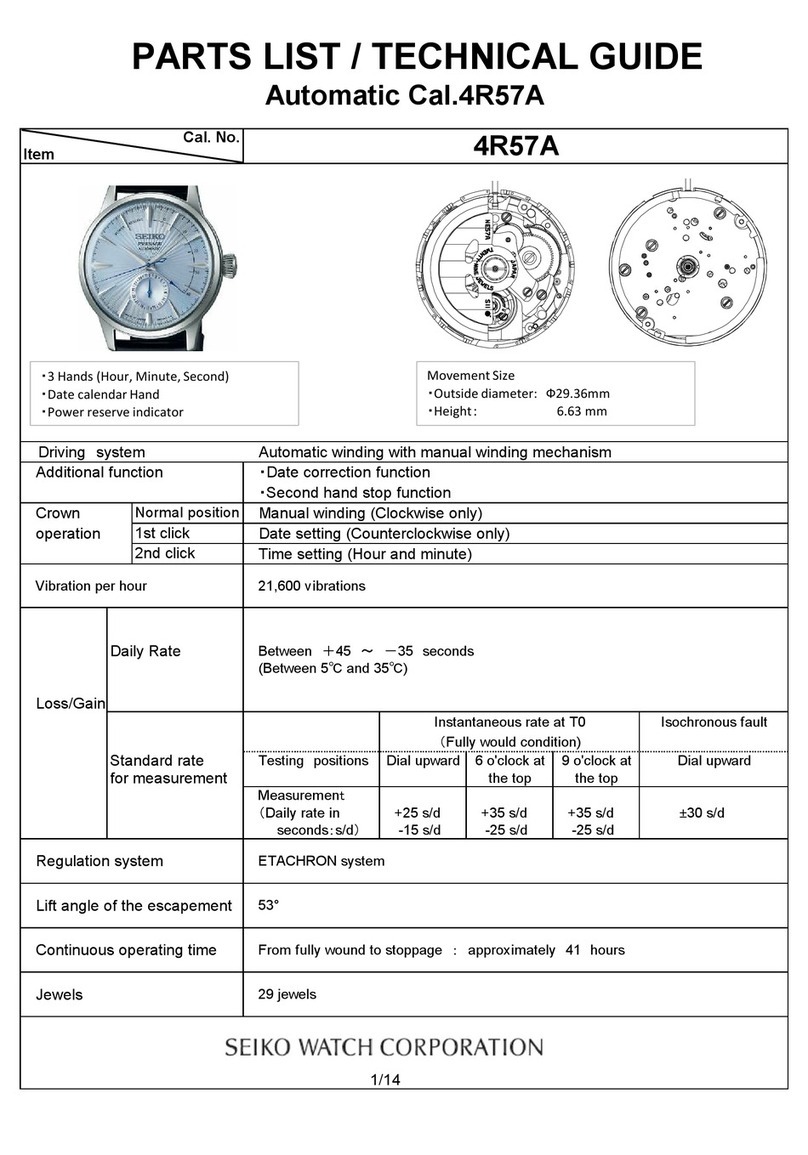

Seiko 4R57A Quick start guide

Seiko

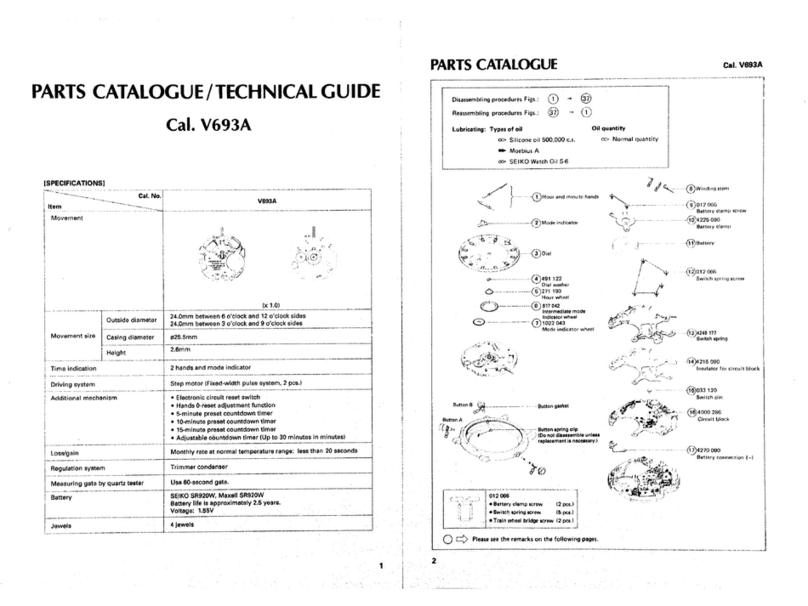

Seiko V693A Installer manual

Seiko

Seiko KINETIC 7D46 User manual

Seiko

Seiko 5M42A Quick start guide

Seiko

Seiko Credor 6870 User manual

Seiko

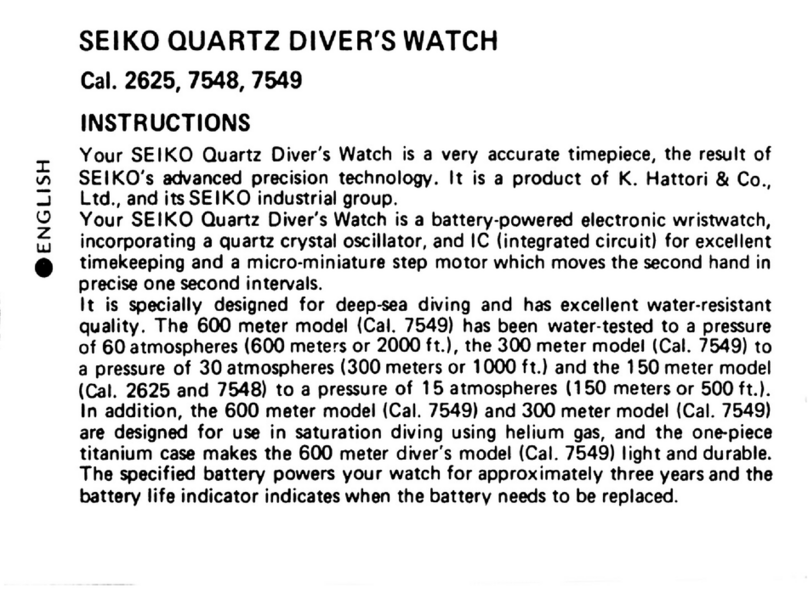

Seiko 2625 User manual

Seiko

Seiko V115A Quick start guide

Seiko

Seiko 4F56 User manual

Seiko

Seiko 8A50 User manual

Seiko

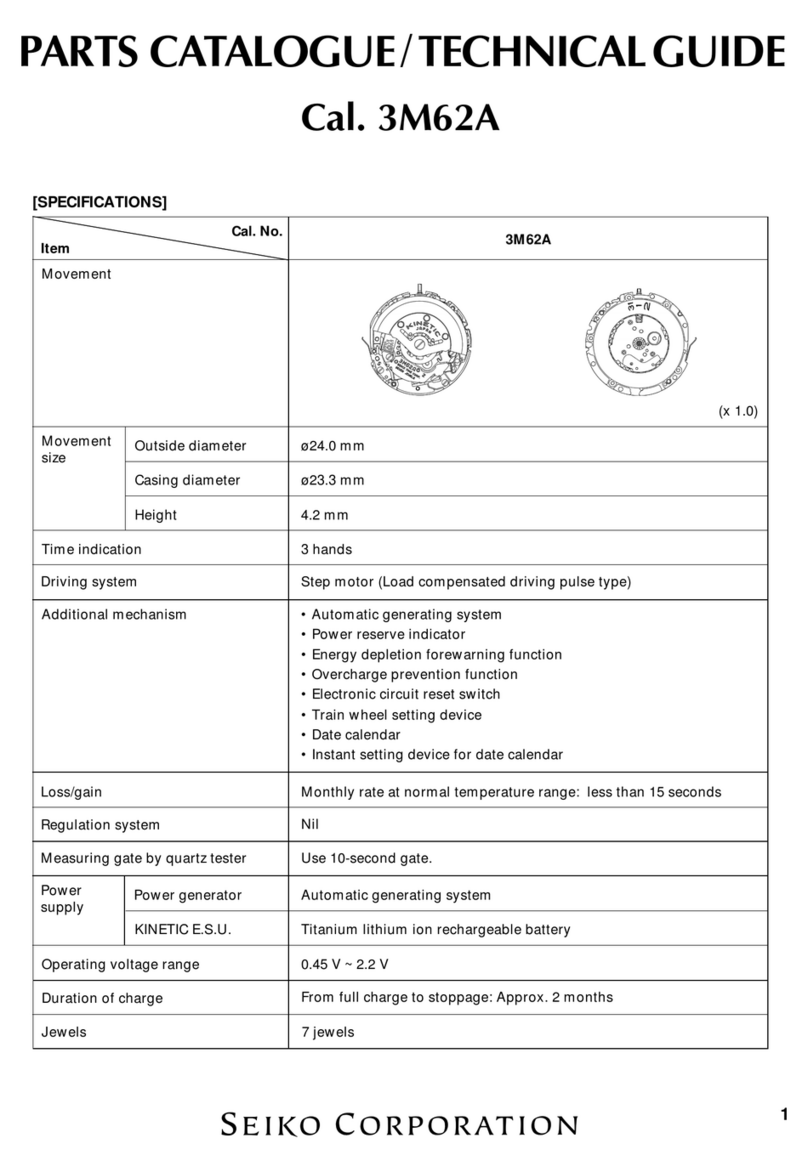

Seiko 3M62A Installer manual

Seiko

Seiko Spectrum SVRD001 G510 User manual

Seiko

Seiko 5D22 User manual

Seiko

Seiko Cal. 9F83 User manual

Seiko

Seiko 1E20 User manual

Seiko

Seiko S141 User manual

Seiko

Seiko S141 User manual

Seiko

Seiko V116A Quick start guide

Seiko

Seiko AUTO CALENDAR J User manual

Seiko

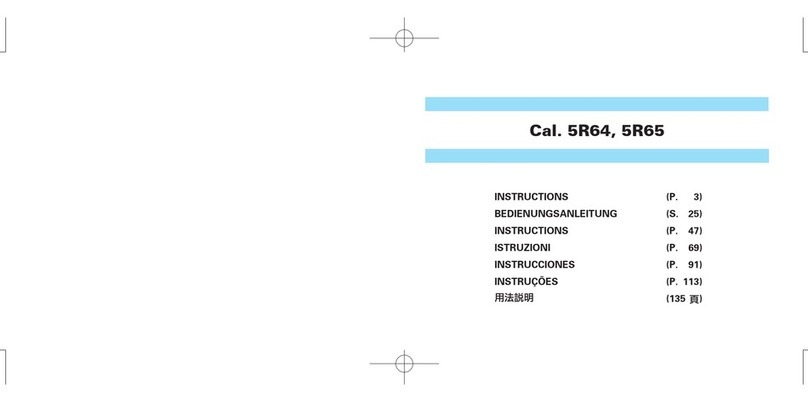

Seiko 5R64 User manual