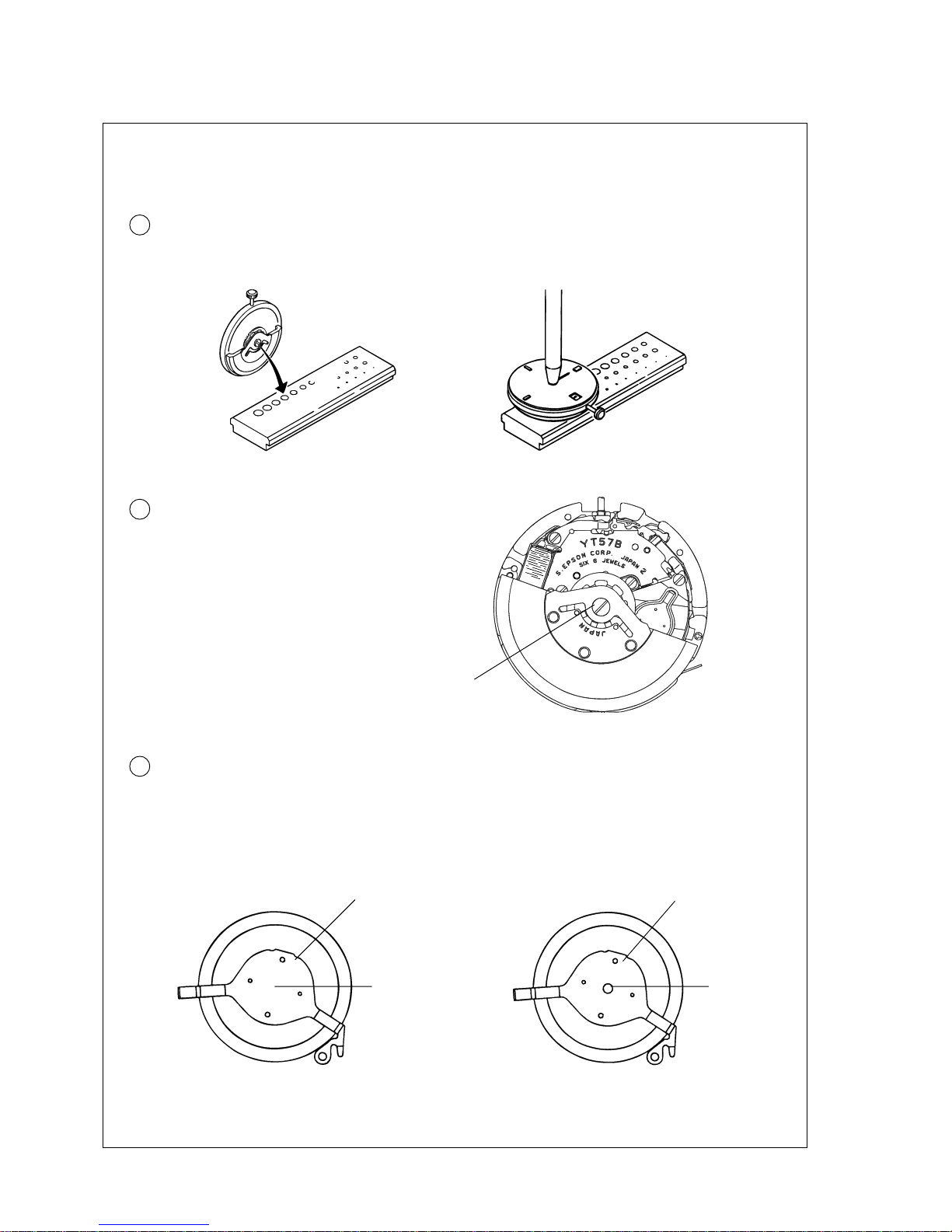

Seiko YT57B Quick start guide

Other Seiko Watch manuals

Seiko

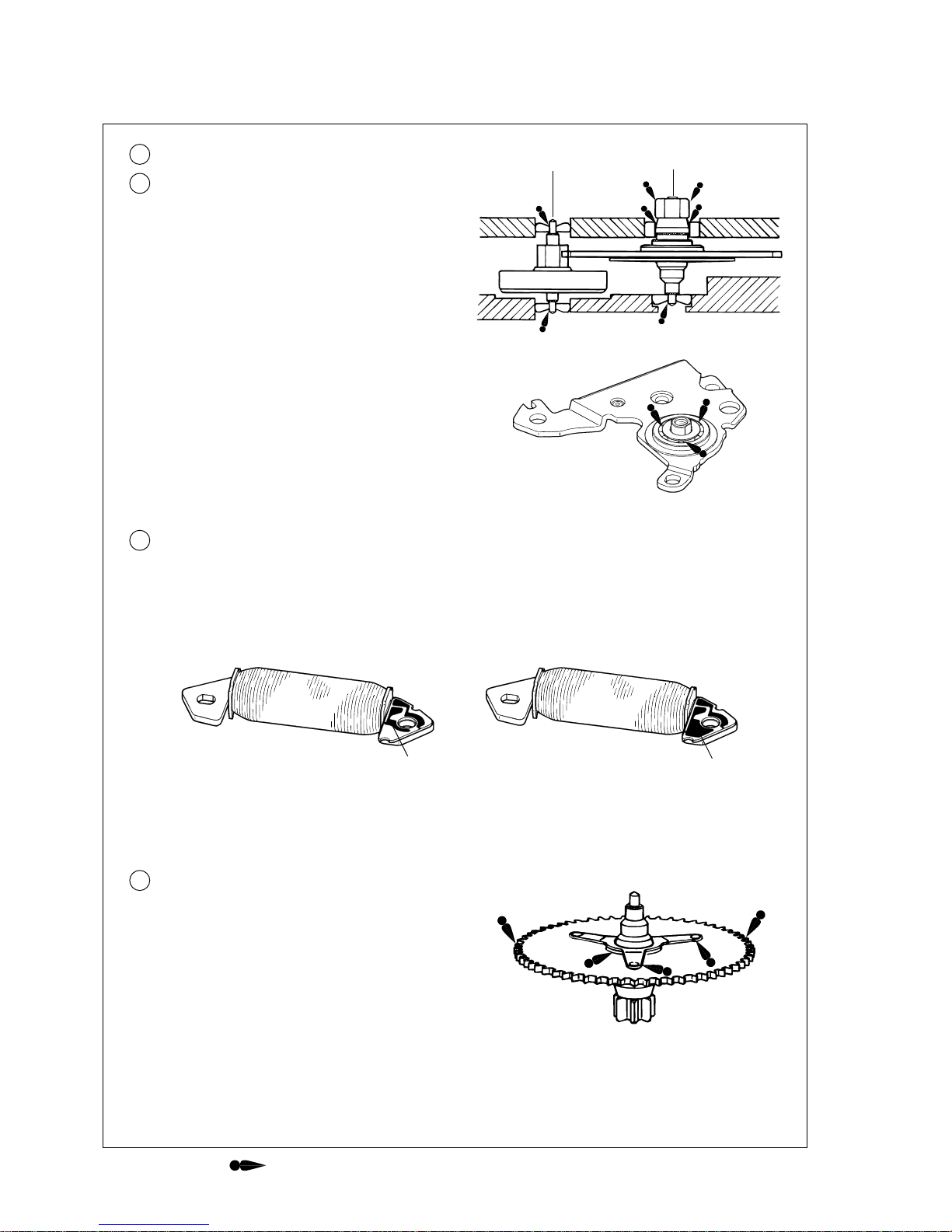

Seiko Astron 8X53 Assembly instructions

Seiko

Seiko Cal. 5M82 User manual

Seiko

Seiko 0664A Quick start guide

Seiko

Seiko 4F32A Quick start guide

Seiko

Seiko ASTRON 8X82 GPS SOLAR User manual

Seiko

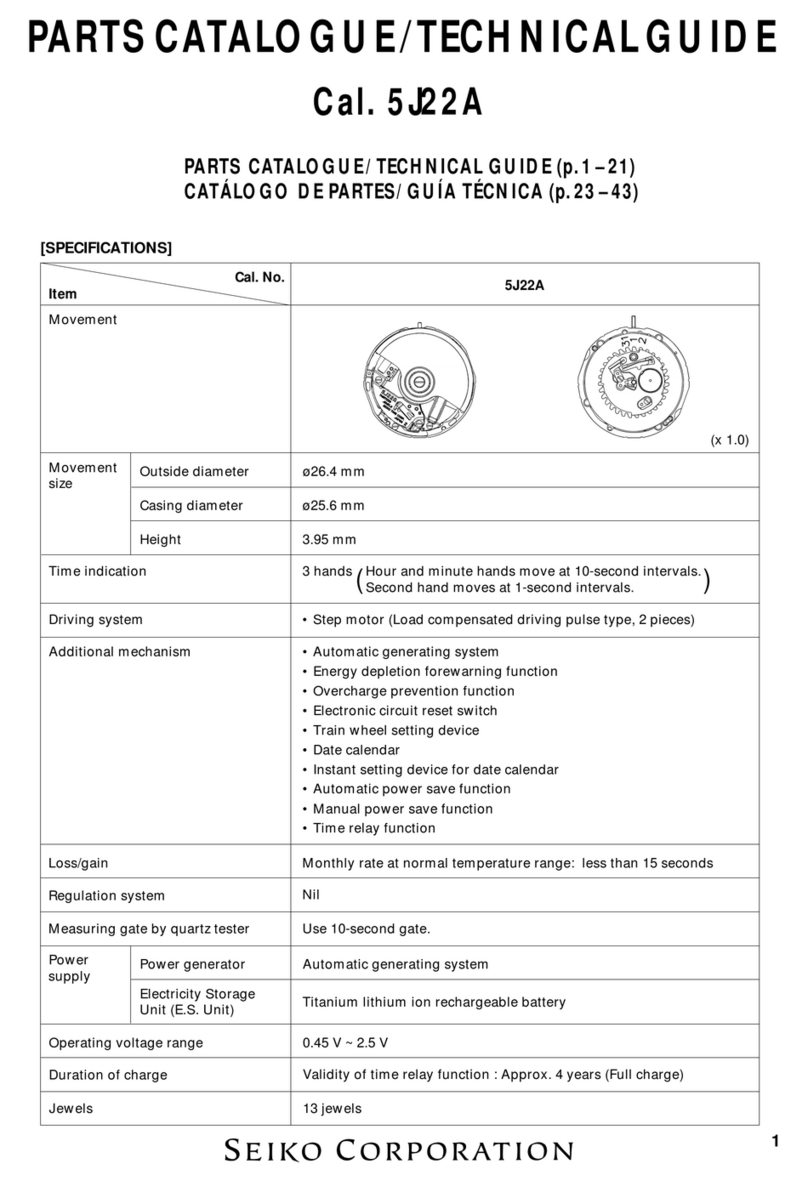

Seiko 5J22A Quick start guide

Seiko

Seiko 8F35 User manual

Seiko

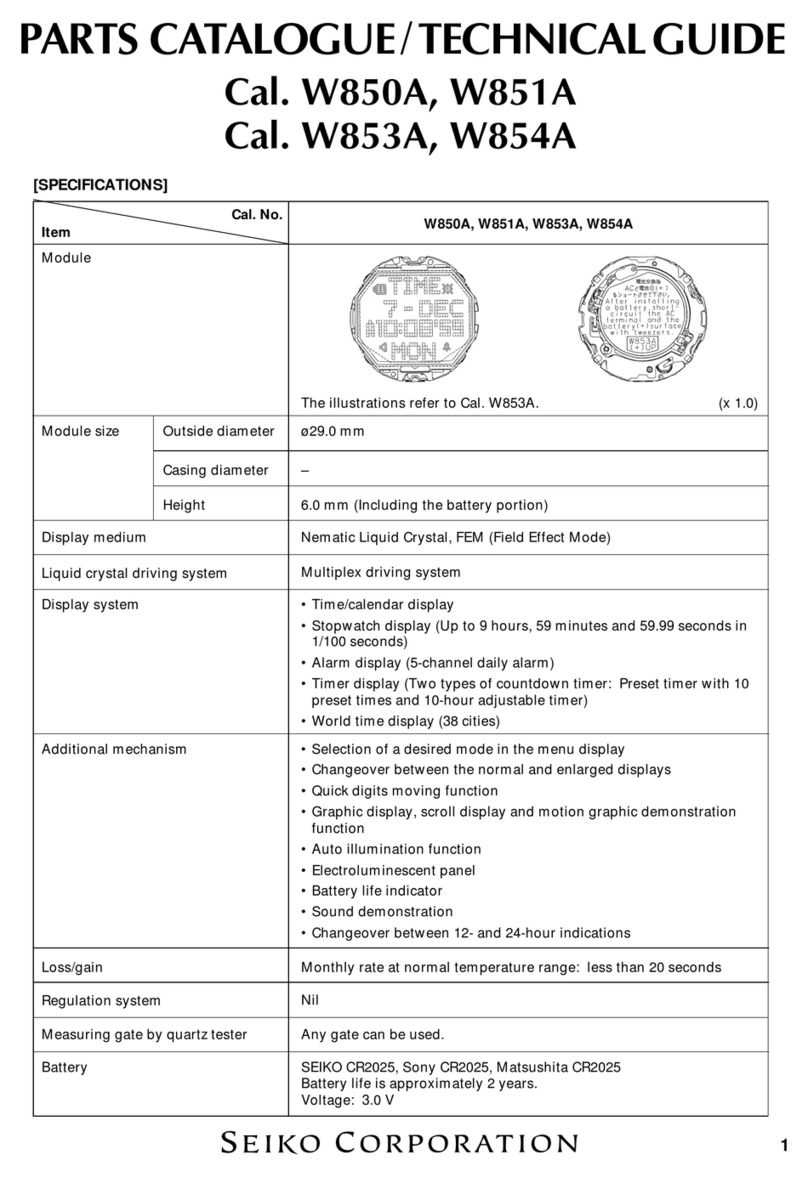

Seiko W850A Quick start guide

Seiko

Seiko V657 User manual

Seiko

Seiko Presage SRE010J User manual

Seiko

Seiko GPS SOLAR ASTRON 5X53 User manual

Seiko

Seiko 7T52B Quick start guide

Seiko

Seiko Cal. 9F83 User manual

Seiko

Seiko H021 User manual

Seiko

Seiko 8X53 Series User manual

Seiko

Seiko Astron 3X22 User manual

Seiko

Seiko ASTRON 8X42 GPS SOLAR User manual

Seiko

Seiko KINETIC 5M43 User manual

Seiko

Seiko 4F Series Use and care manual

Seiko

Seiko 7K52 User manual