Seiko 5M42A Quick start guide

Other Seiko Watch manuals

Seiko

Seiko S149 User manual

Seiko

Seiko 8R28 User manual

Seiko

Seiko 8X53 Series User manual

Seiko

Seiko 7002 User manual

Seiko

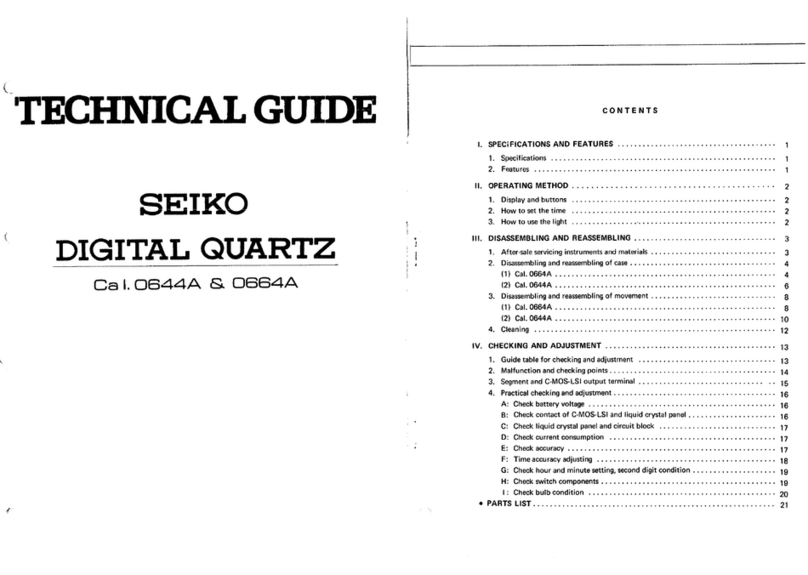

Seiko 0664A Quick start guide

Seiko

Seiko Presage SPB305 User manual

Seiko

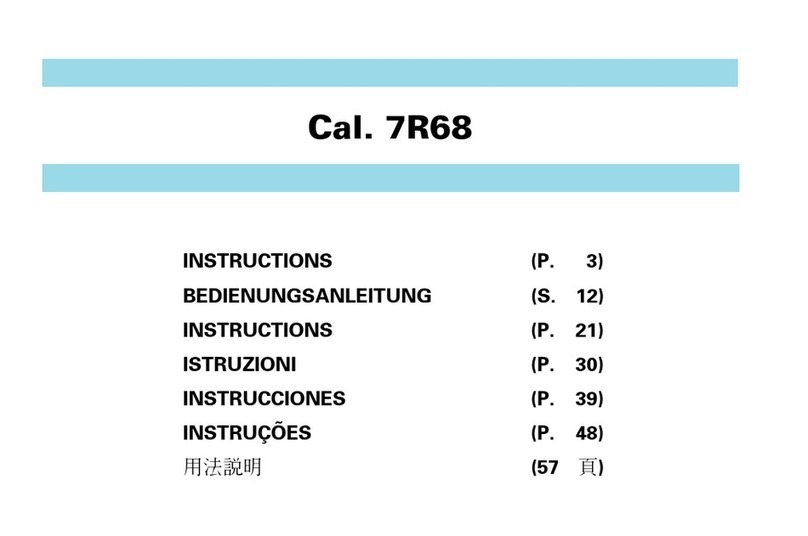

Seiko 7R68 User manual

Seiko

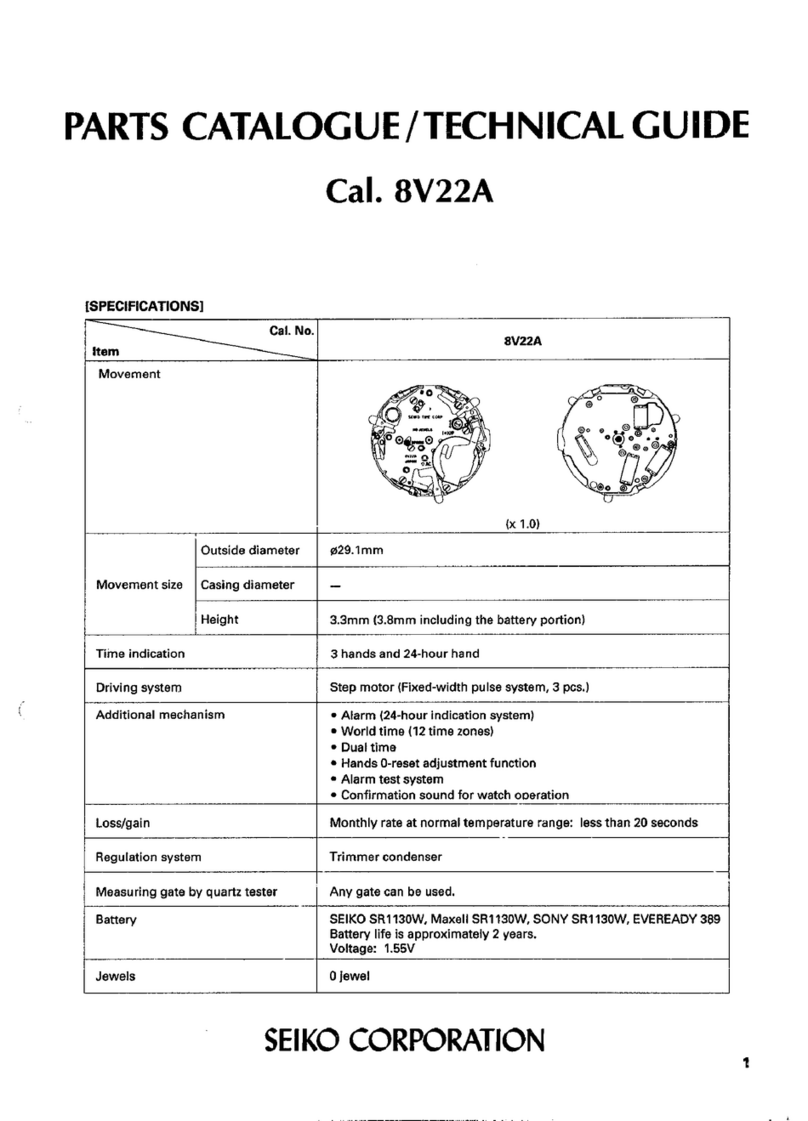

Seiko 8V22A Installer manual

Seiko

Seiko 4F56 User manual

Seiko

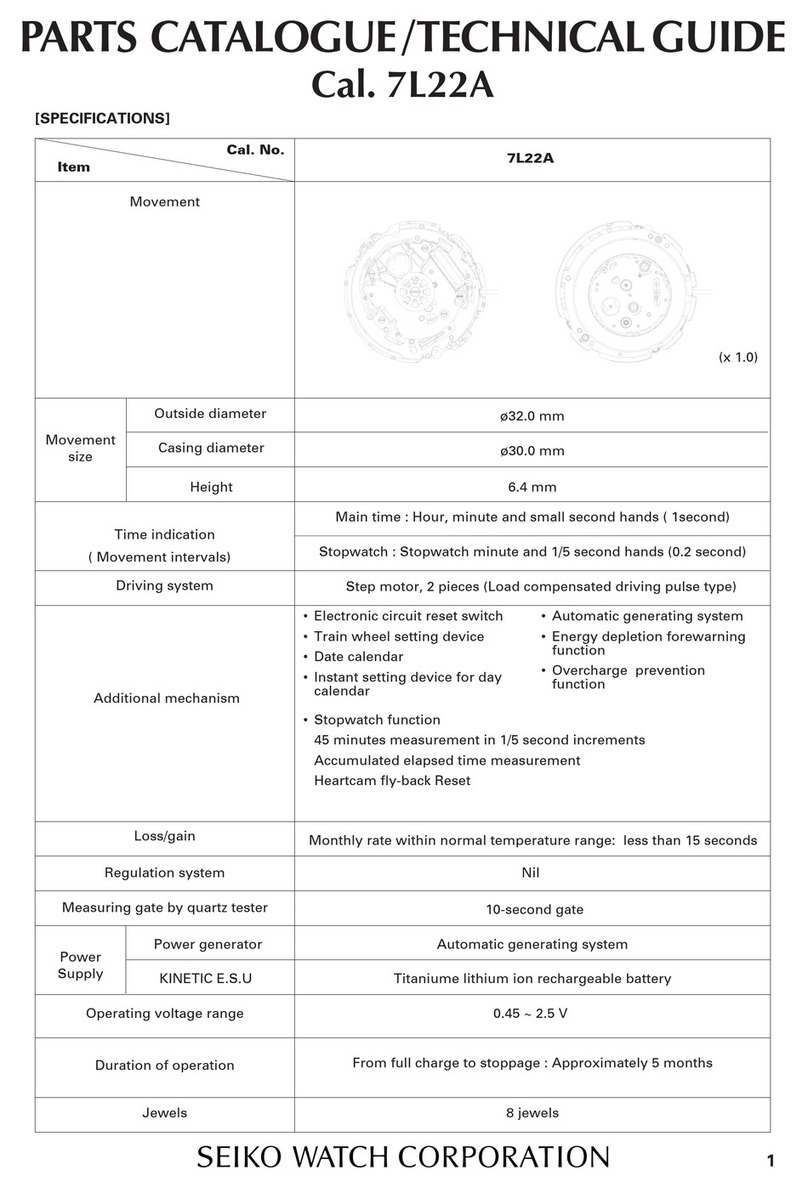

Seiko KINETIC 7L22A Installer manual

Seiko

Seiko 6M13 User manual

Seiko

Seiko Presage SPB417J User manual

Seiko

Seiko 5M62 User manual

Seiko

Seiko 4F32 User manual

Seiko

Seiko C-26 User manual

Seiko

Seiko 4R36 User manual

Seiko

Seiko 8T63A Quick start guide

Seiko

Seiko Cal. V175 User manual

Seiko

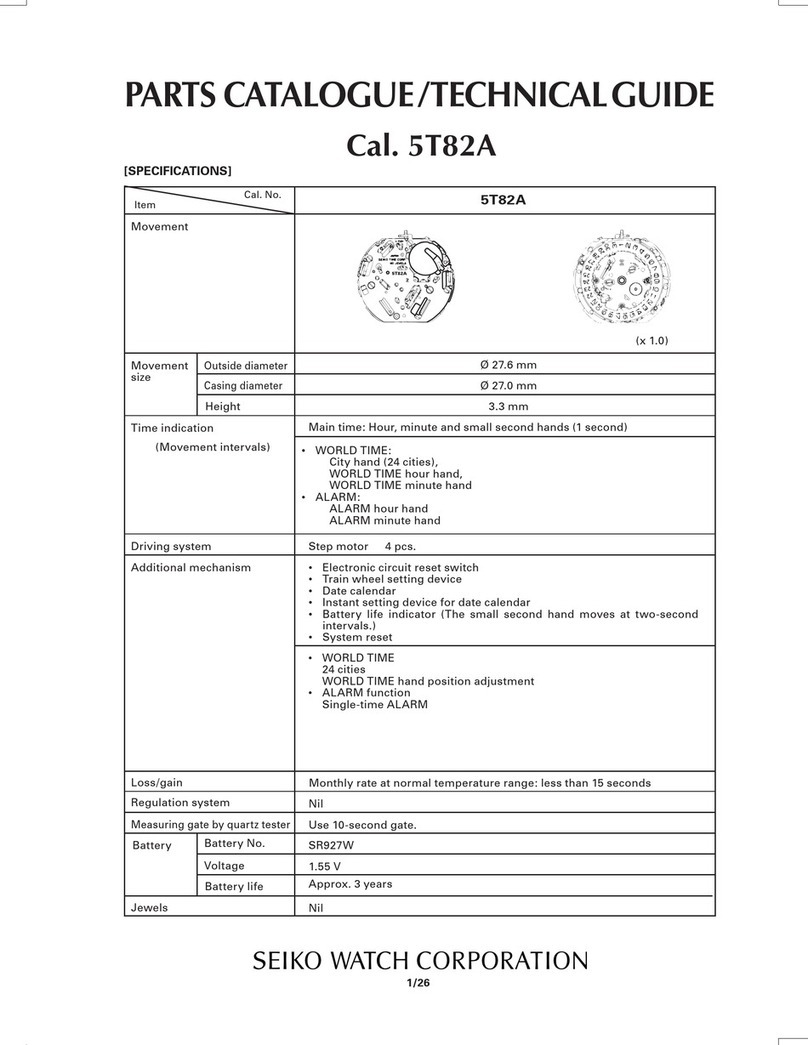

Seiko 5T82A Quick start guide

Seiko

Seiko 7C46 User manual