Seiwa LCIP79 User manual

Thank you very much for purchasing our LED lighting fittings.

Please read this instruction manual to use the product properly.

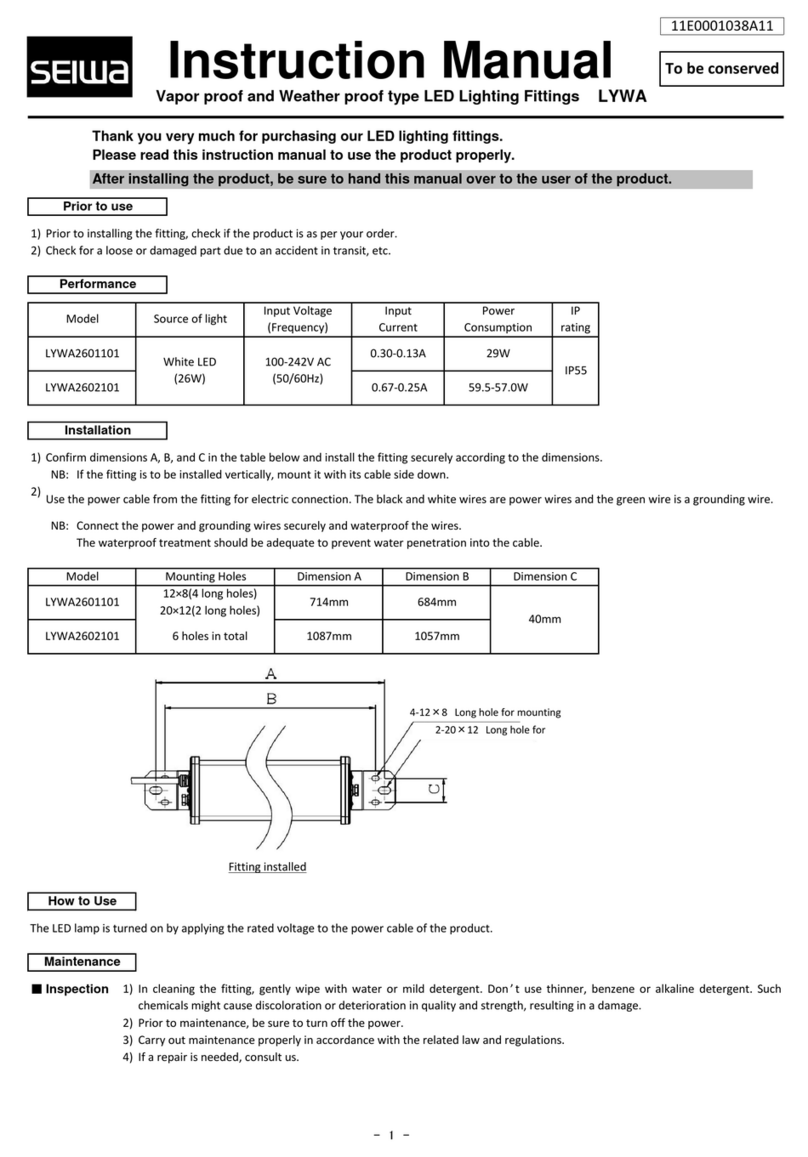

1) Prior to installing the fitting, check if the product is as per your order.

2) Check for a loose or damaged part due to an accident in transit, etc.

1)

- Installation work should be done properly by a ualified electrician in accordance with the related laws and the instruction manual.

- For safety, Installation work should be done by at least two workers.

- Related laws and regulations refer to the Industrial Safety and Health Act and the Electrical E uipment Technical Standards.

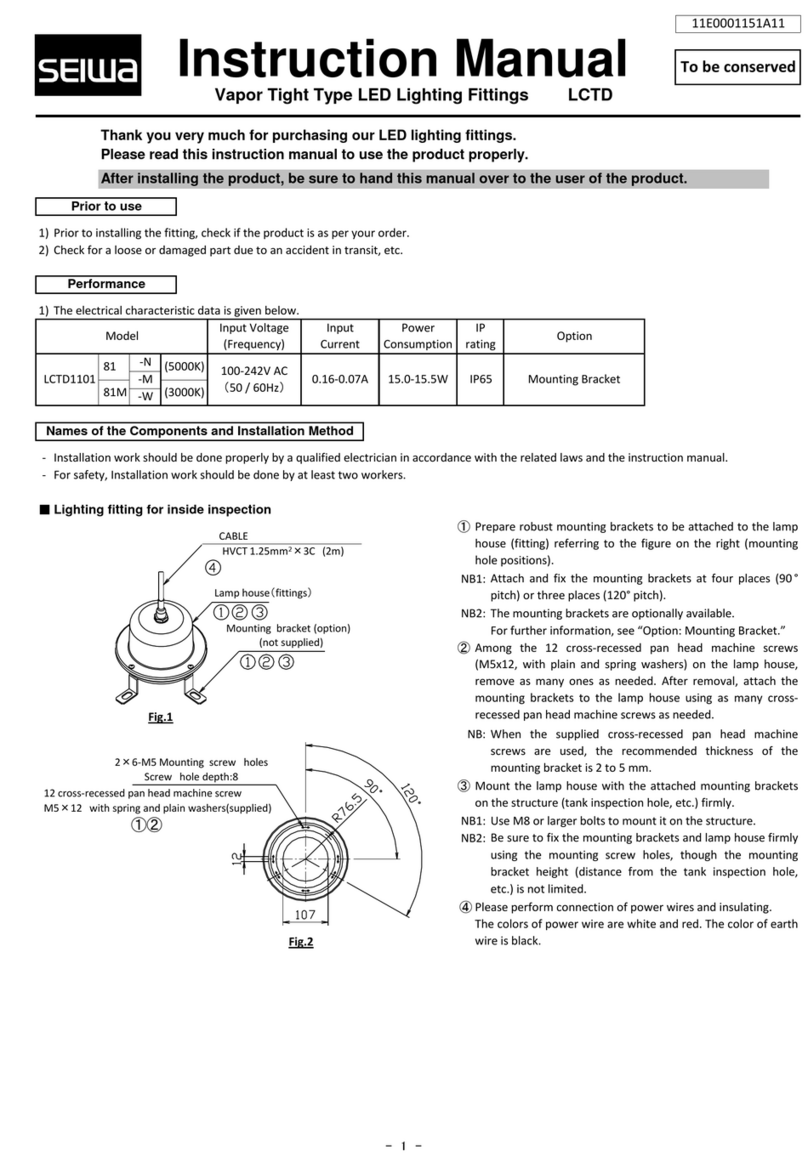

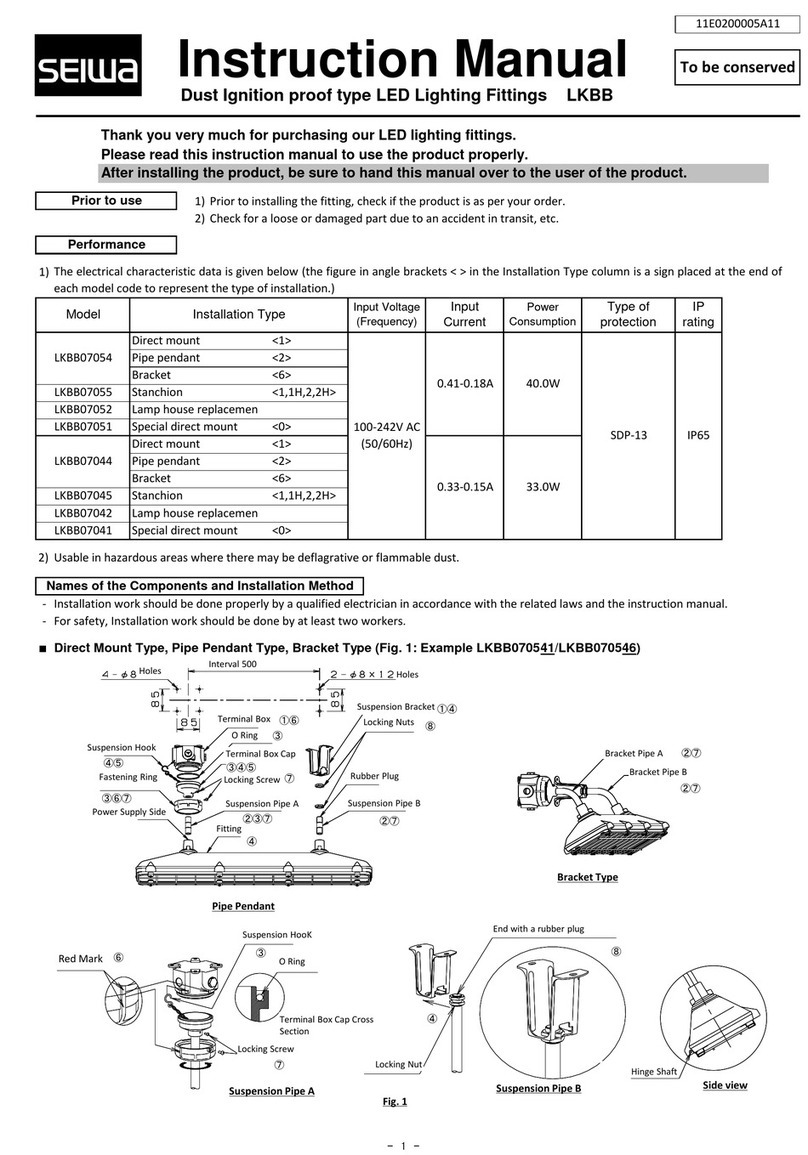

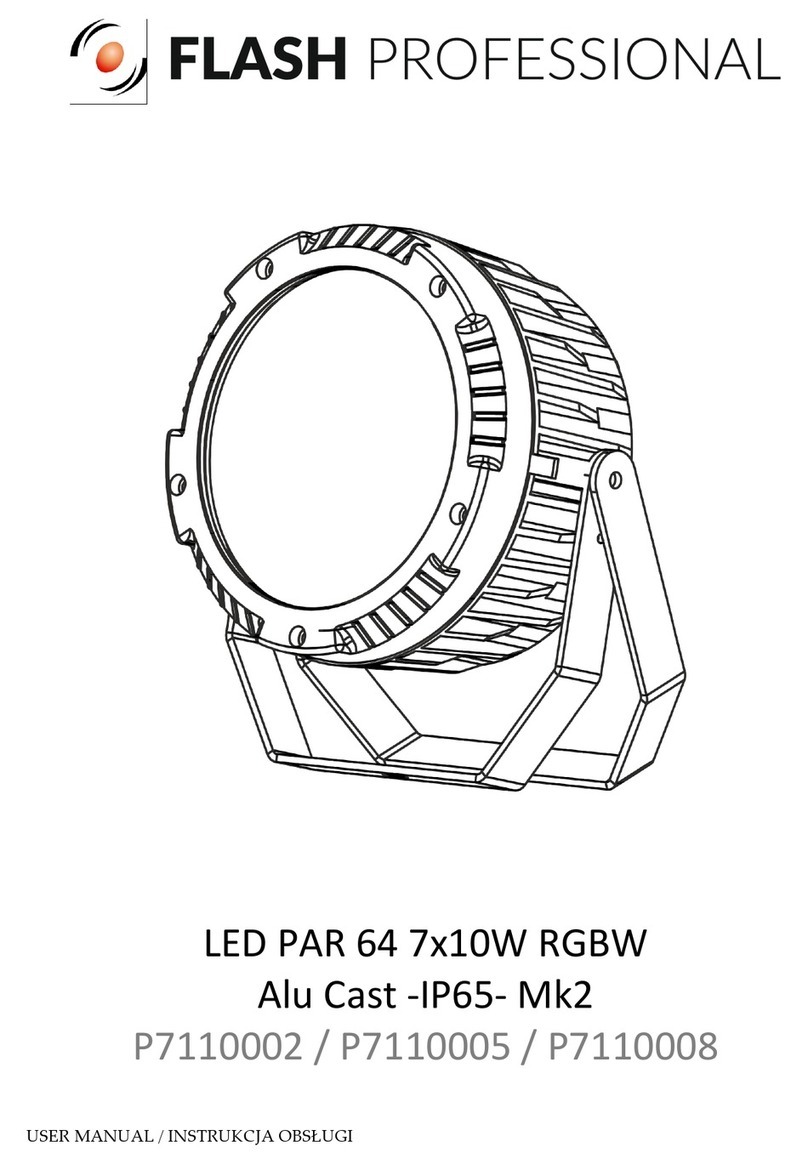

■Direct Mount Type, Pipe Pendant Type, Bracket Type

①

NB:

②

③

④

⑤

⑥

⑦

NB1:

NB2: Caulk the threaded connections.

NB3:

0.61-0.265A

After connecting the lamp power cable (black/white: power line,

green: ground line), remove the suspension hook from the hook

hole and store it in the junction box lid.

Attach the junction box cover to the junction box using the four

cross-recessed hex bolts.

For the bracket type, the lamp house may be installed within an

angle range of 0° (down) to 45° (obli ue).

For the direct mount and Pipe pendant type, The lamp house

may be installed within an angle range of 0° (down).

The electrical characteristic data is given below.

Ra73

-Guard

-Glare cut panel

-Fall prevention

wire

Option

Bracket

0.81-0.34A

Pole B type, C type

LCIP79 79.5-77.5W

Average Color

rendering index Installation Type

Direct mount

Pipe pendant

Floodlight

Model

11E0200776A11

To be conserved

Instruction Manual

Vapor Tight type LED Lighting Fittings LCIP

Performance

After installing the product, be sure to hand this manual over to the user of the product.

Prior to use

IP

rating

100-242V AC

(50/60Hz)

Replacement demand

Input

Current

Power

Consumption

Input Voltage

(Fre uency)

0.375-0.18A

59.5-59.0W

Highway type

IP65

After adjusting the rotational position of the fitting and junction box,

tighten the set screws (3 locations) to secure them.

Use tools to securely tighten the hanging pipe, locking screw, and

cross-recessed hex bolt. Insufficient tightening may cause the

device to fall.

Securely attach the junction box to a horizontal mounting surface

using M6 bolts or bolts of e uivalent strength.

For the bracket type, fix it on a vertical mounting surface

securely.

Screw the pipe into the retainer.

Screw the junction box lid onto the suspension pipe.

Lift the fitting and hook the hanging hook into the hanging hook

hook hole of the junction box.

Stanchion type

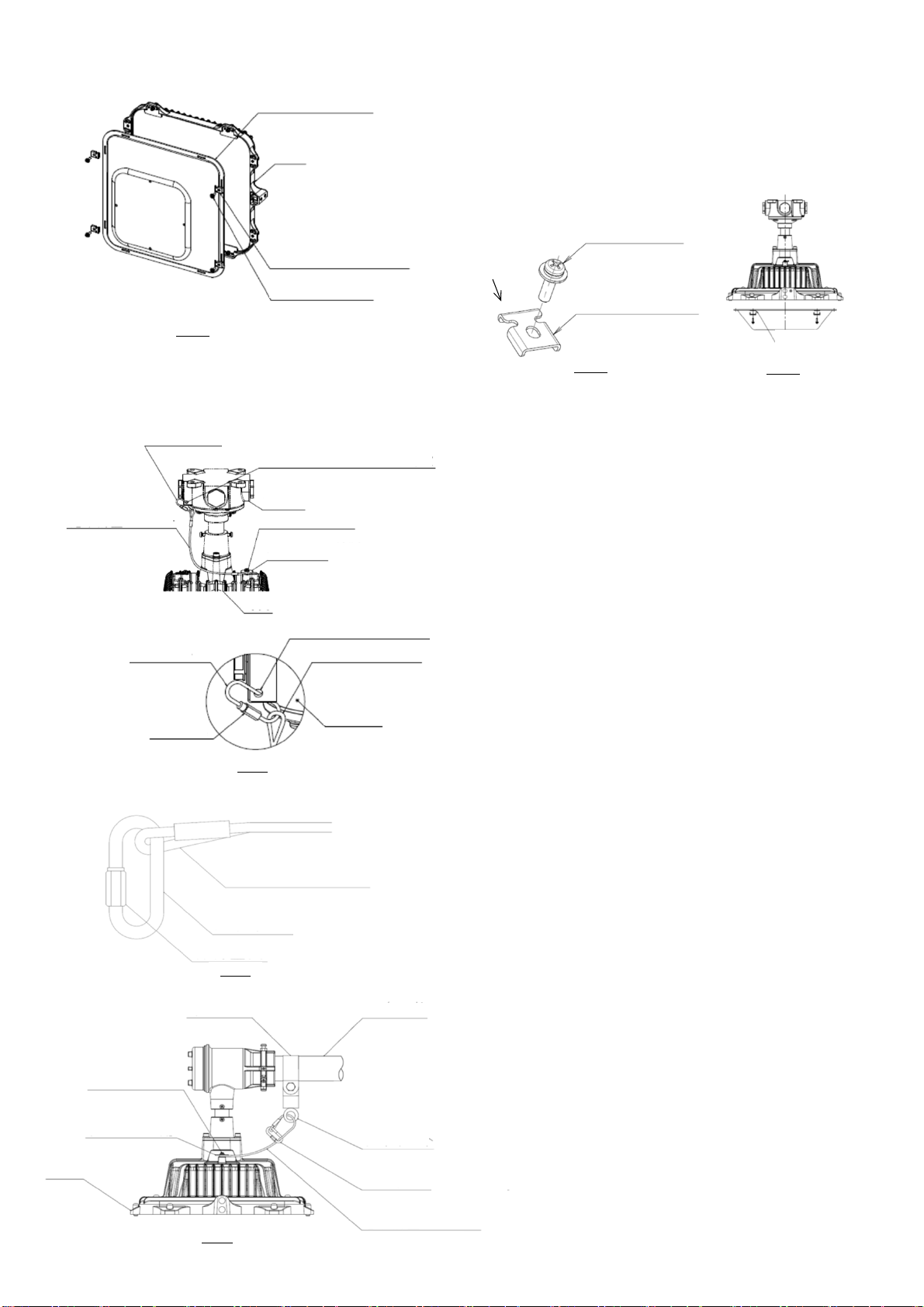

Names of the Components and Installation Method

Special Direct Mount type 36.5-37.5W

LCIP60

LCIP37

4-φ8 Mounting Holes

Fitting ④⑦

②③

③⑤⑥

Fig. 1

Junction

Box

①④⑥⑦

Suspension Hook ④⑤

Suspension

Pipe

Junction

Box

Lid

4-Locking Screws

Lid Packing

Retainer ②

Hanging Hook Hole

④

4

-

Cross Recessed Hex Bolt

⑥

⑦

- 1 -

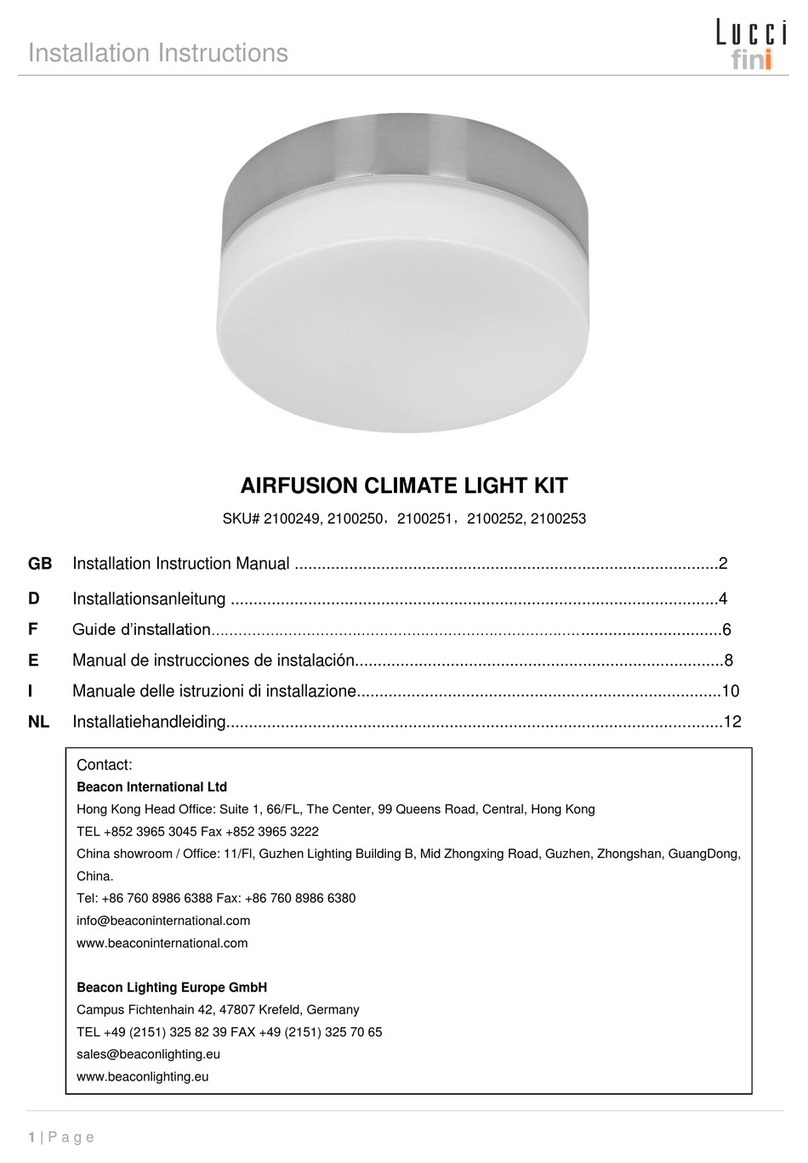

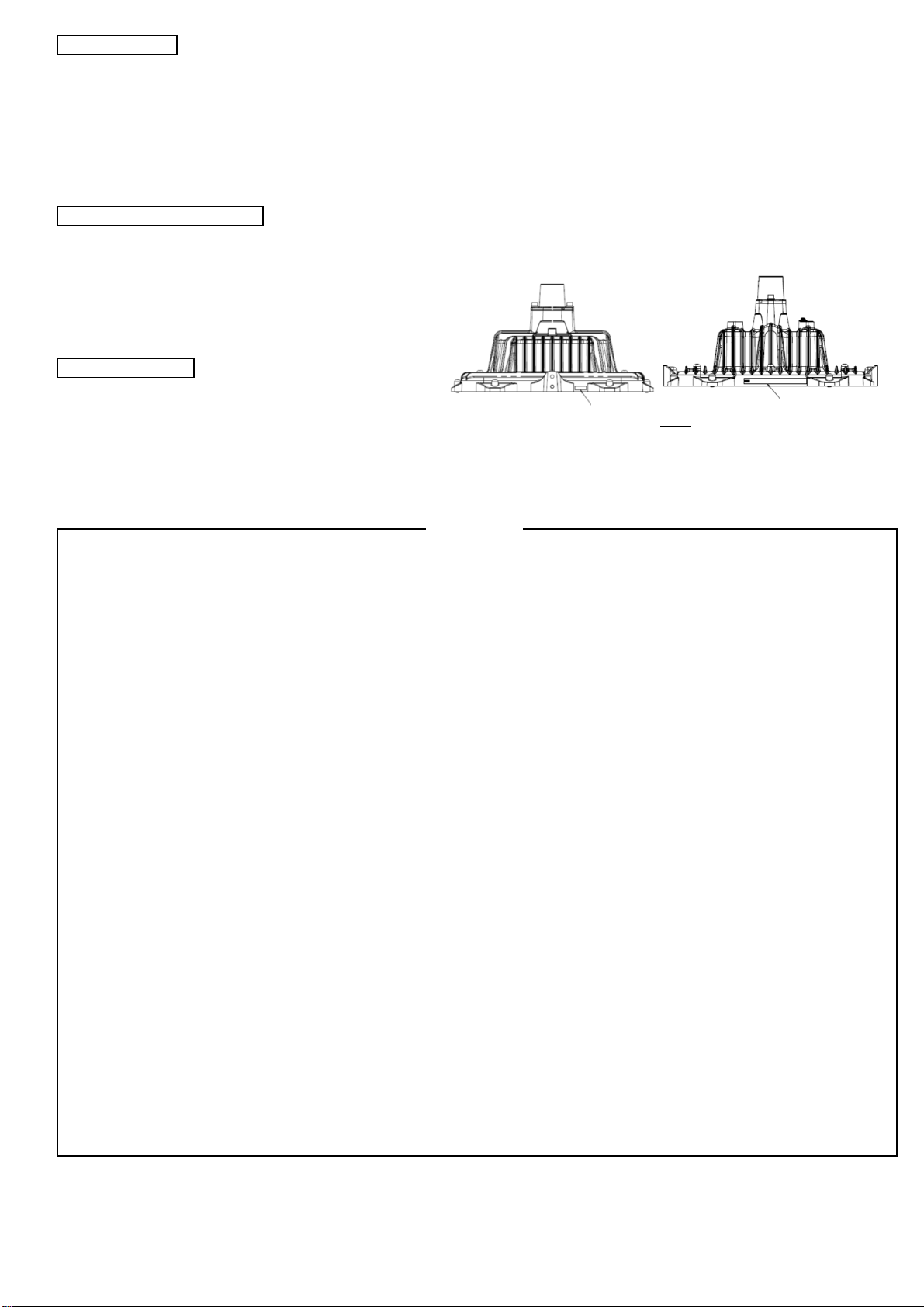

■Stanchion Type, Pole TypeB, TypeC

①

NB:

②

NB:

③

④

NB:

⑤

NB:

⑥

⑦

⑧

⑨

NB1:

NB2:

■Floodlight

①

②

③

④

NB1:

NB2:

The tilt of the fitting can be set within a range of 50° upwards to

60° downwards, and can be adjusted to the left and right within a

range of 45° each. See Fig.6 and 7.

Installation other than specified may cause explosion, fire, or

electric shock.

When adjusting the angle of the fitting or carrying the fixture,

be careful not to get your hands caught between the fitting

and the mounting legs.

Highway type have an up and down direction. Be sure to

install the lamp so that the installation direction sticker shown

in Fig.3 is on the top side of the lamp.

Connect the fitting power cable and pole junction box cable, and

after insulation treatment, screw the pole junction box lid onto

the pole junction box and tighten it completely.

Insert the cable of the pole junction box into the stand pole and

pull it out from the junction box. Insert the retaining screw into

the hole at the bottom of the pole tip and tighten.

Make sure that the fitting does not turn.

Pass the fitting power cable (black/white: power line, green:

ground line) through the pipe, screw the pipe into the holder

until the end, and fully tighten the suspension pipe rotation stop

screw on the fitting.

To adjust the angle of the fitting, loosen the hexagon socket head

bolts (4 locations) and adjust the angle.

See Fig.1 for mounting the junction box.

Connect the power cables (black/white: power wire, green:

ground wire) in the included junction box.

After tightening the five fixing screws on the pole junction box,

tighten the locking nut.

Make sure that the pole junction box does not rotate.

After connecting and insulating the power cables (black/white:

power wire, green: ground wire), attach the lid to the junction

box and tighten completely.

〜

The following applies only to the Stanchion Type

〜

Install the short nipple and junction box while referring to the

separate installation manual, "Short Nipple Installation Manual."

Please refer to Fig.1 for the mounting dimensions of the junction

box.

Completely fix the stand pole with the support bracket (not

supplied) and the specified junction box mounting screws.

Pass the power cable inside the pole (black/white: power wire,

green: ground wire) to the junction box and connect.

Waterproof the inside of the pole to prevent rainwater from

entering.

The installation direction of the device can be up to 15°,

assuming 0° is directly below.

As shown in Fig.6, securely attach the mounting legs of the device

to a horizontal mounting surface using M16 bolts (2pcs), nuts

(2pcs), spring washers (2pcs), and washers (2pcs). Wall mounting

is also possible.

Make sure that the pipe does not turn.

Insert the light power cable coming out of the pipe into the pole

junction box, then screw in the pipe.

After turning the pole junction box all the way, loosen it until the

stand pole can be attached. Fully tighten the pipe on the pole

junction box side with the anti-rotation screw.

灯具上側

④

①②

④

③

④

④

①

④

①

②③ ④

Fig. 2

Fig. 3

Fig. 4

Fig. 5 Fig. 6

Fig. 7 Fig. 8

5-Locking Screws

6

-

Locking Screws

Pole Junction Box

Pole Junction Box

Lid

Retaining Screw

Fitting

Retainer ①

Suspension Pipe

①②

Stand Pole

3

-

Locking Screws

Top of Lamp

Installation Direction Sticker

(Highway type only)

②

Support

(Not Supplied)

Short Nipple

Junction Box

⑥⑦⑧⑨

⑦

Fitting

Mounting

Legs

①

Scale

Plate

Scale Plate

Scale Plate

Mounting Legs

Mounting Legs

Hexagon Socket Head Bolt

Fitting

Fitting

Glass Surface

Junction Box

Cable and Protective Tube

φ18 Mounting

holes

φ18 Mounting

Long holes

①

⑤

⑤

②③⑤

⑧

- 2 -

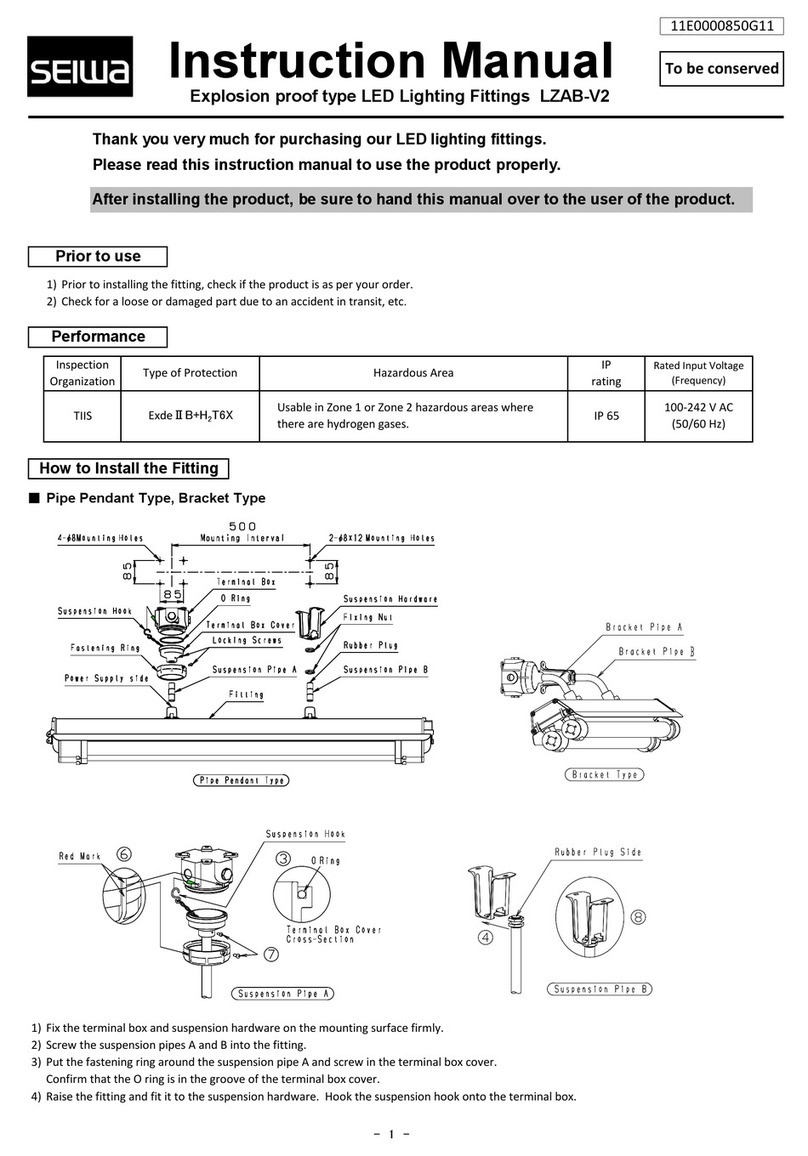

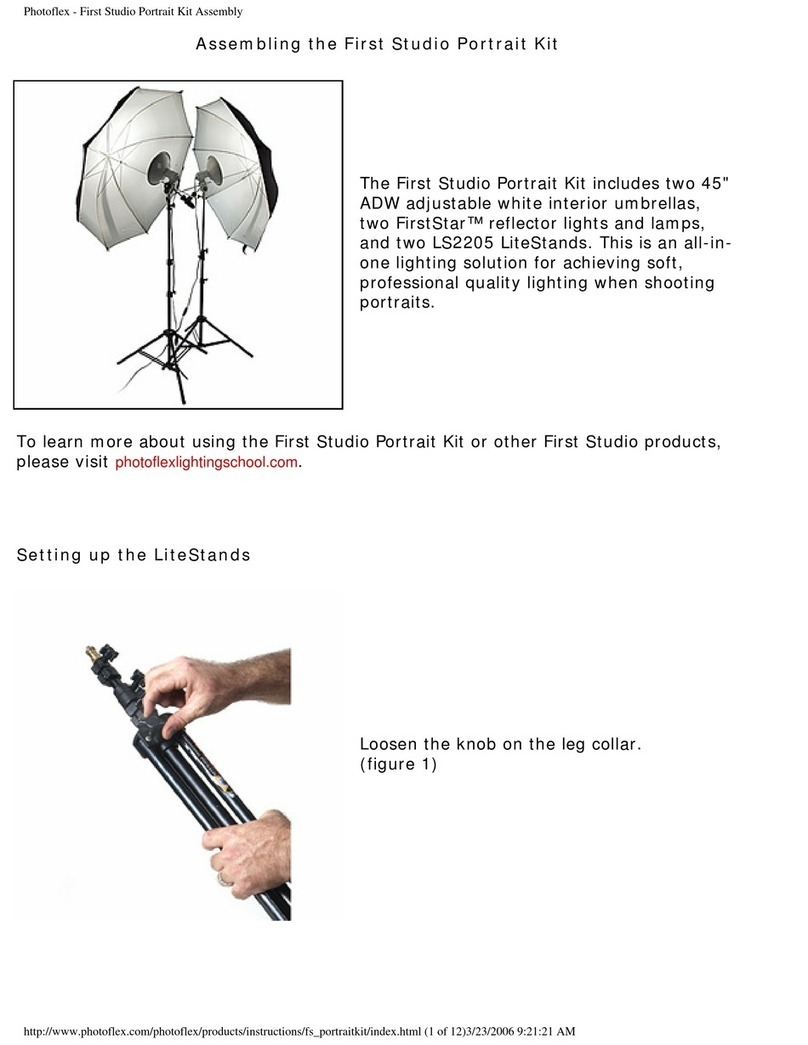

■Special Direct Mount Type

①

NB:

②

③

④

⑤

NB1:

NB2:

■Replacement demand

①

②

③

NB1:

NB2:

NB3:

■

Option 1: Guard

①

②

NB1:

NB2:

See Fig.1 for mounting the junction box.

Place the guard on the lamp house in Fig.14.

The tilt of the fitting can be set within a range of 60° upwards to

60° downwards, and can be adjusted left and right within a range

of 30° each. Please refer to Fig.10 and 11.

Installation other than specified may cause fire or electric

shock.

When adjusting the angle of the fitting or carrying the fixture,

be careful not to get your hands caught between the fitting

and the mounting legs.

Pipe thread diameter is G3/4.

Remove the existing fitting and pass the power cable coming out

of the fitting (black/white: power wire, green: ground wire)

through the existing pipe and existing junction Box.

Connect the power cable inside the existing junction box.

Screw the fitting into the existing suspension pipe.

Insert the guard mounting pieces(4 pieces) into the guard as

shown in Fig.15, and secure them to the fitting using M4

mounting screws (4pieces).

Regarding the mounting direction of the guard, as shown in

Fig.16, the guard protrusion is on the outside of the fitting.

Make sure the guard is securely fastened.

Before installing the fitting, make sure that there is no

corrosion in the existing piping (including junction box) before

installing the fixture.

If the product is to be used in a place where it will be splashed

with water, apply waterproof treatment to the joint between

the lamp fitting and the existing suspension pipe.

M12 bolt length should be up to 35mm.

Connect the power cables (black/white: power wire, green:

ground wire) in the included junction box.

To adjust the angle of the fitting, loosen the hexagon socket head

bolts (4 locations) and adjust the angle.

As shown in Fig.10, securely attach the mounting leg to a

horizontal mounting surface using M12 bolt (1 pc.), M8 bolt (2

pcs.), nuts (3 pcs.), spring washers (3 pcs.), and washers (3 pcs.).

Wall mounting is also possible.

①③

①

①

④⑤

Fig. 9 Fig. 10

Fig. 11 Fig. 12

Fig13

Fig. 14

Fig. 15

Fig. 16

Mounting

Legs

Glass

Fitting

φ14

Mounting Holes

2-φ10 Mounting

Long holes

Mounting

Legs

Fitting

④⑤

Cable and Protective Tube

Junction Box ②③

Fitting

Existing Junction Box(G3/4)

Cable Gland

Existing Suspension Pipe(G3/4) ①②

Cable

①②

Fitting

Guard ①②

4

-

Guard Mounting Pieces

②

Guard

Protrude

4-Mounting Screws ②

4

-

Guard Mounting Pieces

②

Place the guard mounting

pieces with its protrusions

on the inner side of the

Lamp house.

4-Mounting Screws ②

- 3 -

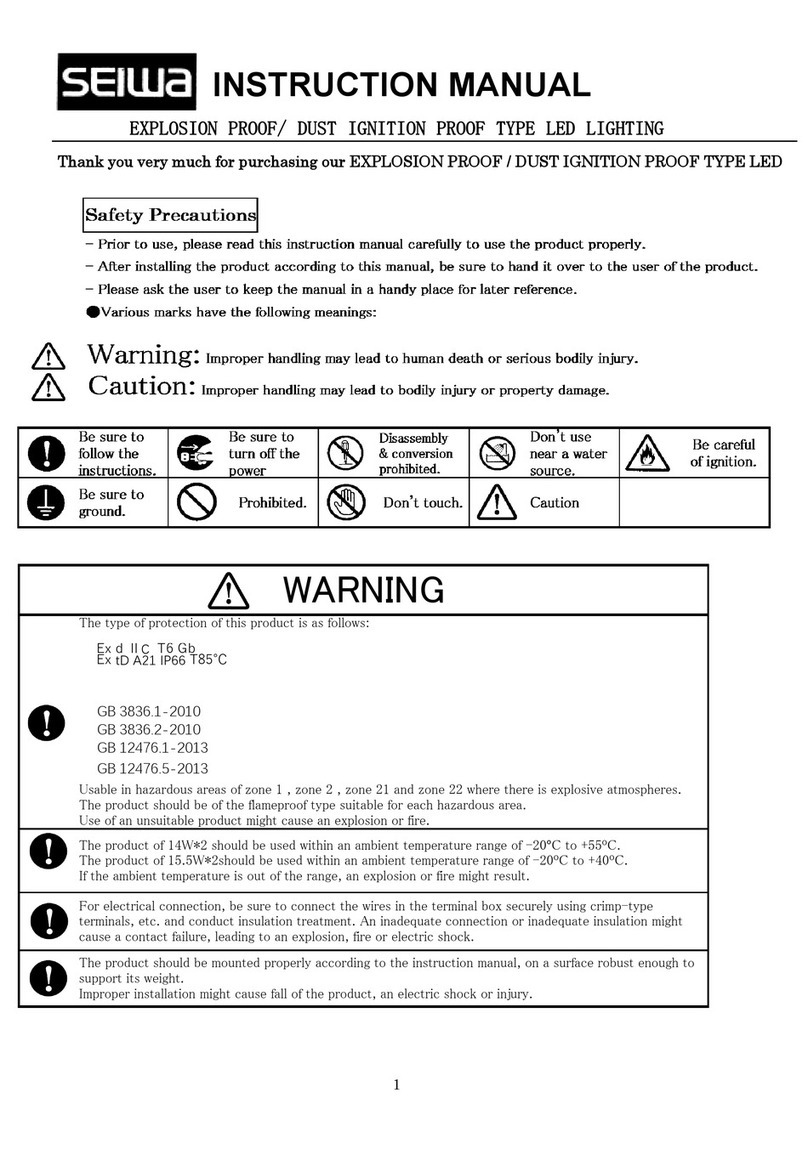

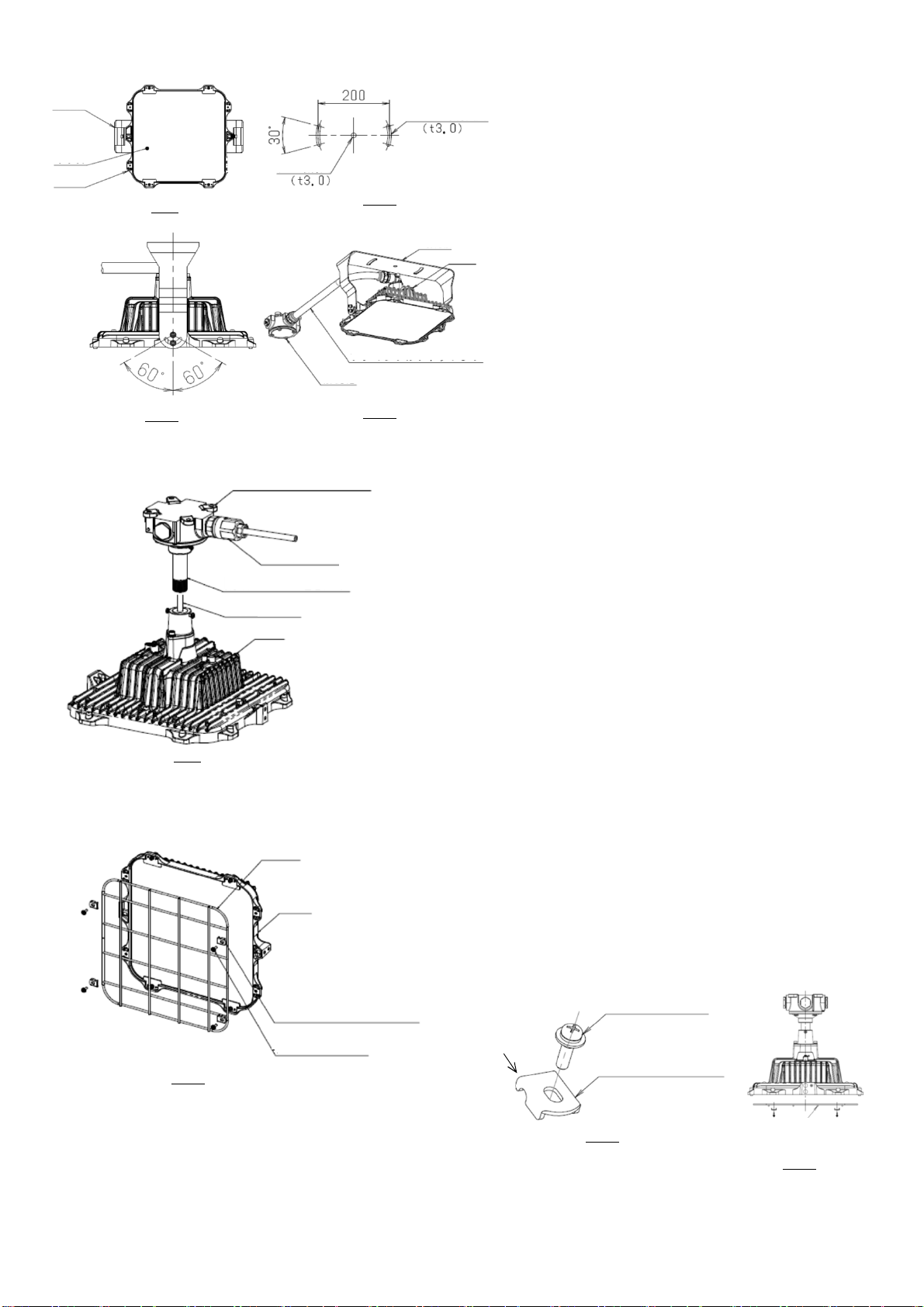

■

Option 2: Glare Cut Panel

①

②

NB1:

NB2:

■

Option 3: Fall prevention wire

1. For Direct Mount Type, Pipe Pendant Type, Bracket Type

①

NB:

②

NB:

③

NB:

④

2. For Stanction Type

①

NB:

②

③

④

After passing the fall prevention wire through the screw joint,

securely tighten the clamp using a tool.

Remove the screw attached to the fitting at the time of

shipment.

Do not use this screw.

As shown in Fig.21, pass the screw joint through one end of the

drop prevention wire, and then securely tighten the screw joint

clamp using a tool.

Using the screws supplied with the fall-prevention wire, attach

the fall-prevention wire, flat washer, and mounting screw to the

lamp fitting in that order.

As shown in Fig.22, pass the other end of the fall prevention wire

through the eyebolt (not supplied), etc., and then pass it through

the screw joint.

Using the mounting screws included with the fall prevention wire,

attach the fall prevention wire, washer, and mounting screw to

the fitting in this order.

Glare cut panel on the fitting as shown in Fig.17.

Remove the screw attached to the fitting at the time of

shipment.

Make sure the screws are securely fastened.

Pass the screw joint through the screw joint mounting hole in the

junction box.

There is directionality in the mounting direction of the screw

joint.

Do not use this screw.

Insert the panel mounting pieces(4 pieces) into the slits in the

panel as shown in Fig.18, and secure them to the fitting using M4

mounting screws(4 pieces).

Make sure the panel is securely fastened.

Please install the panel in the direction shown in Fig.19.

①

④

②④

②

①②

④

①

Fig.22

Fig.21

Fig.20

Fig. 17

Fig. 18

Fig. 19

Glare Cut Panel ①②

Fitting

4

-

Panel Mounting Pieces

②

4-Mounting Screws

4-Mounting Screws ②

4

-

Panel Mounting Pieces

②

Place the panel mounting

pieces with its protrusions

on the inner side of the

Lamp house.

Packing Pasted

(Silicon Rubber)

Screw Joint

Fall Prevention Wire

Junction Box

Mounting Screws

(Included)

Fitting

Screw Joint Mounting Hole

③

Screw Joint Mounting Hole

④

Junction Box

Fastener

Fall Prevention Wire ④

③④

Screw Joint

Fall Prevention Wire ②

Fastener ②

Screw Joint

Fitting

Fall Prevention Wire

②④

(Accessories)

(Accessories)

Screw Joint

Eyebolt

③

(Accessories)

(Accessories)

(not supplied)

(not supplied)

Hanging Band

Mounting Screws

①④

Washer

④

Stand/ Pole

②

Washer

②

②③

- 4 -

LED module is turned on by applying the rated voltage to the power cable of the product.

■

Inspection 1)

2) Prior to maintenance, be sure to turn off the power.

3) Carry out maintenance properly in accordance with the related law and regulations.

4) If a repair is needed, consult us.

1)

2) For disposal of the product, follow the regulations and rules of your local government.

When reordering, please let us know:

・Drawing or drawing No. for the delivered product

・Manufacturing lot number on the nameplate

1.

2. Prior to maintenance or inspection, be sure to turn off the power.

3. Confirm that the screws and bolts are fastened properly and tightly.

4. In the case of the stanchion type, be sure to provide a support at least 1500 mm above the bottom of the pole.

5. Can be used indoors and outdoors. However, it cannot be used in the following locations.

・Places where heat builds up, places with strong vibrations, places where corrosive gas is generated, places with constant high

temperature and humidity such as commercial bathrooms and saunas, places with constant low temperatures and condensation

such as freezers.

6. Cannot be used as a moving light.

7. In places where water is splashed, apply waterproof treatment to prevent water from entering the screw joint.

8.

9. The supply voltage variation should be within ±6% of the rating.

10. Close unused entries of the junctionl box with plugs (resin).

11. The ambient temperature should be within the range of -20°Cto +50°C. The use of the product out of this range may shorten

the service life.If the ambient temperature range is exceeded, the temperature protection function may dim the light.

The brightness will return to normal when the temperature returns to within the ambient temperature range.

12.

Be sure to ground the e uipment securely.

13. Prior to maintenance or inspection, be sure to turn off the power.

14. To prevent shortening of the service life and malfunction, avoid turning on the fitting in direct sunlight.

15. To avoid noise or malfunctioning, don't use a radio, television or wireless infrared remote control near the fitting.

16.

17.

18.

19.

20. Local replacement of lighting fixture parts such as the light source is not possible. Please contact our sales representative.

21. Do not look directly at the LED while it is lit. It can hurt your eyes.

Don’t open the front glass. The internal components such as the LED lamp become very hot. Don’t touch the LED lamp since a malfunction

or lighting failure might occur.

For white LED lamps, the luminescent color and brightness may vary with individual LEDs because of their nature. Also note that the rate

of attenuation with time varies with individual LED lamps.

How to Use

In cleaning the fitting, gently wipe with water or mild detergent. Don ’ t use thinner, benzene or alkaline detergent. Such

chemicals might cause discoloration or deterioration in uality and strength, resulting in a damage.

Disassembly and Disposal

If the above information is unavailable, give us any material showing the appearance of the product or details of the product specification

(dimensions, mounting interval, lamp type, etc.).

The product must be mounted on a sturdy wall surface or structure which is vibration-free and less susceptible to damage. Otherwise, it

might fall or be damaged.

For use in an unfavorable location (a very hot, cold or humid place or a place in which there is strong wind or vibration, a salt damage

environment or a dusty or corrosive gas atmosphere), a special countermeasure should be taken.

Please use e uipment installation within the installation range described in the range instruction manual. If the angle is out of the range,

an insulation failure or electric shock might result.

When installing the fitting, be sure to connect external wires inside a specified part of the fitting. Don't open any other part of the fitting

unless necessary.

In the period when the product is in use, never disassemble it.

Reordering

CAUTIONS

Fig.23

Lot Number

Nameplate

- 5 -

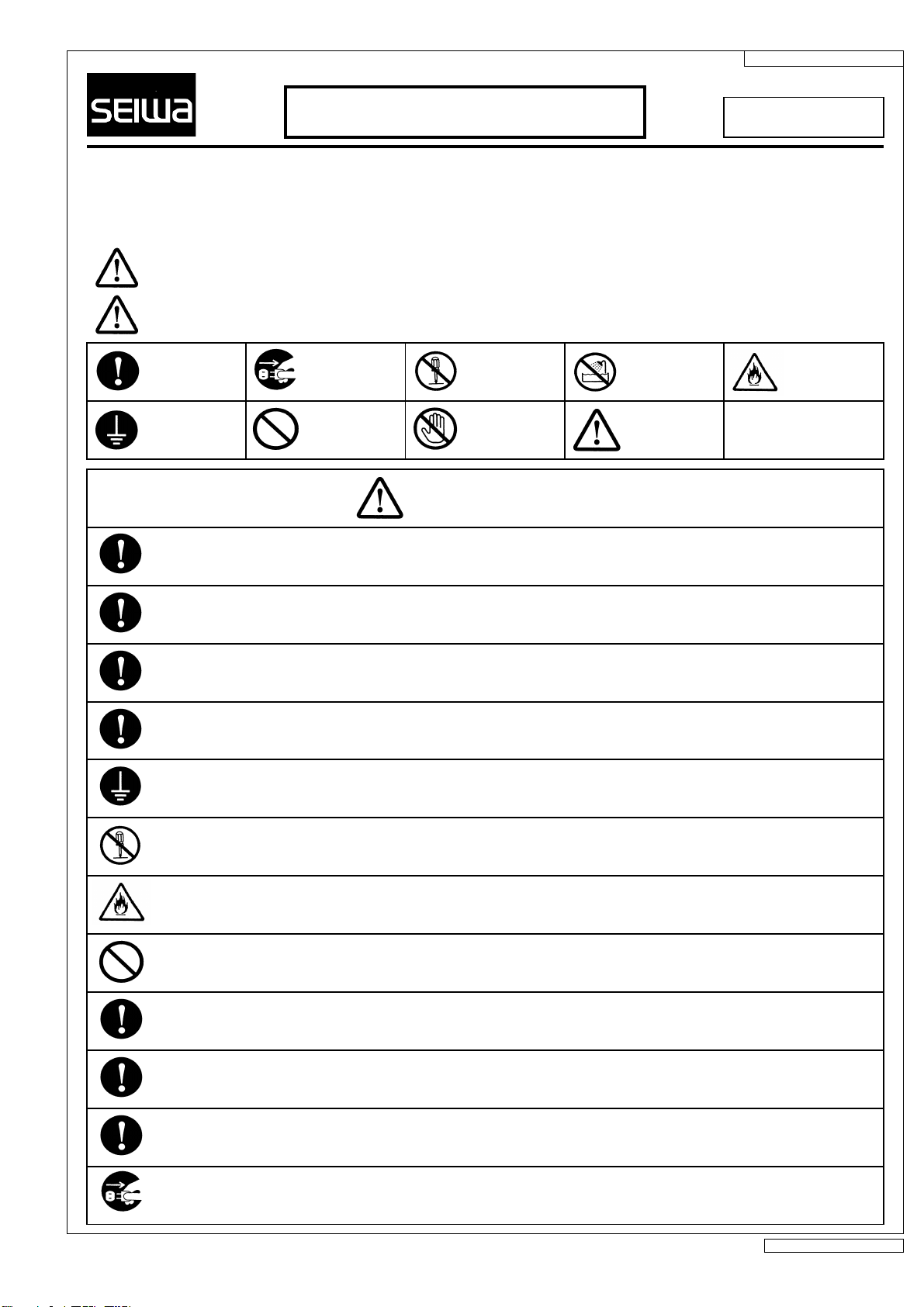

- Prior to use, please read the safety precautions and instruction manual thoroughly to use the product properly.

-

- Please keep the manual in a handy place for later reference.

●The various marks have the following meanings:

Don’t cover the product with an inflammable material such as cloth or paper nor put anything in the product.

uch a material or thing might cause a fire.

The parts once removed for cleaning should be replaced properly according to the instruction manual.

An improperly placed part might cause the product to fall, resultng in an injury or property damage.

Be sure to turn

off the power.

Don’t use the product in a hazardous location where a flammable or explosive atmosphere such as a gaseous, steamy or

dusty atmosphere may exist. Use in such a location might cause an explosion or fire.

The ambient temperature should be within the operating temperature range specified in the instruction manual. If the

product should be used at a temperature higher than specified, an early lighting failure or malfunction might occur or a fire

might result.

If a product must be oriented in a specific manner for use, install it properly according to the marking on its body or the

instruction manual. Otherwise, a fire or electric shock might result.

Don’t touch.

In grounding work, be sure to follow the technical standards for electrical equipmentof your country. Inadequate grounding

might cause a fire or electric shock.

Be sure to

follow the

instructions.

Be sure to

ground.

For electrical connections, use crimp-type terminals, etc. to secure the connections and conduct insulation treatment. An

inadequate connection or inadequate insulation might cause an imperfect contact, leading to a fire or electric shock.

When leading the power cable into the product through a conduit or the like, waterproof the connection and joint

adequately to prevent water infiltration. Inadequate waterproofing might cause a fire or electric shock.

Don’t open LED lamp protective covers such as the front glass and glass globe.

Don’t touch an LED lamp, otherwise a malfunction or lighting failure might occur.

Don’t bend, twist or pull the power cable by force.

Inadequate handling of the cable might damage it and result in a fire or electric shock.

Before cleaning, be sure to turn off the power.

Otherwise, a fire or electric shock might result.

Be careful of

ignition.

After installing the product, be sure to hand the safety precautions and instruction manual over to the user of the product.

Caution

WARNING:

CAUTION:

Improper handling may lead to a human death or serious bodily injury.

Improper handling may lead to a bodily injury or property damage.

Disassembly &

conversion

prohibited.

Don’t use near

a water source.

Prohibited.

11E0000742F11

Safety Precautions

To be conserved

WARNING

Don’t convert the product.

Conversion might cause the product to fall or result in a fire or electric shock.

L照般6

- 1 /2 -

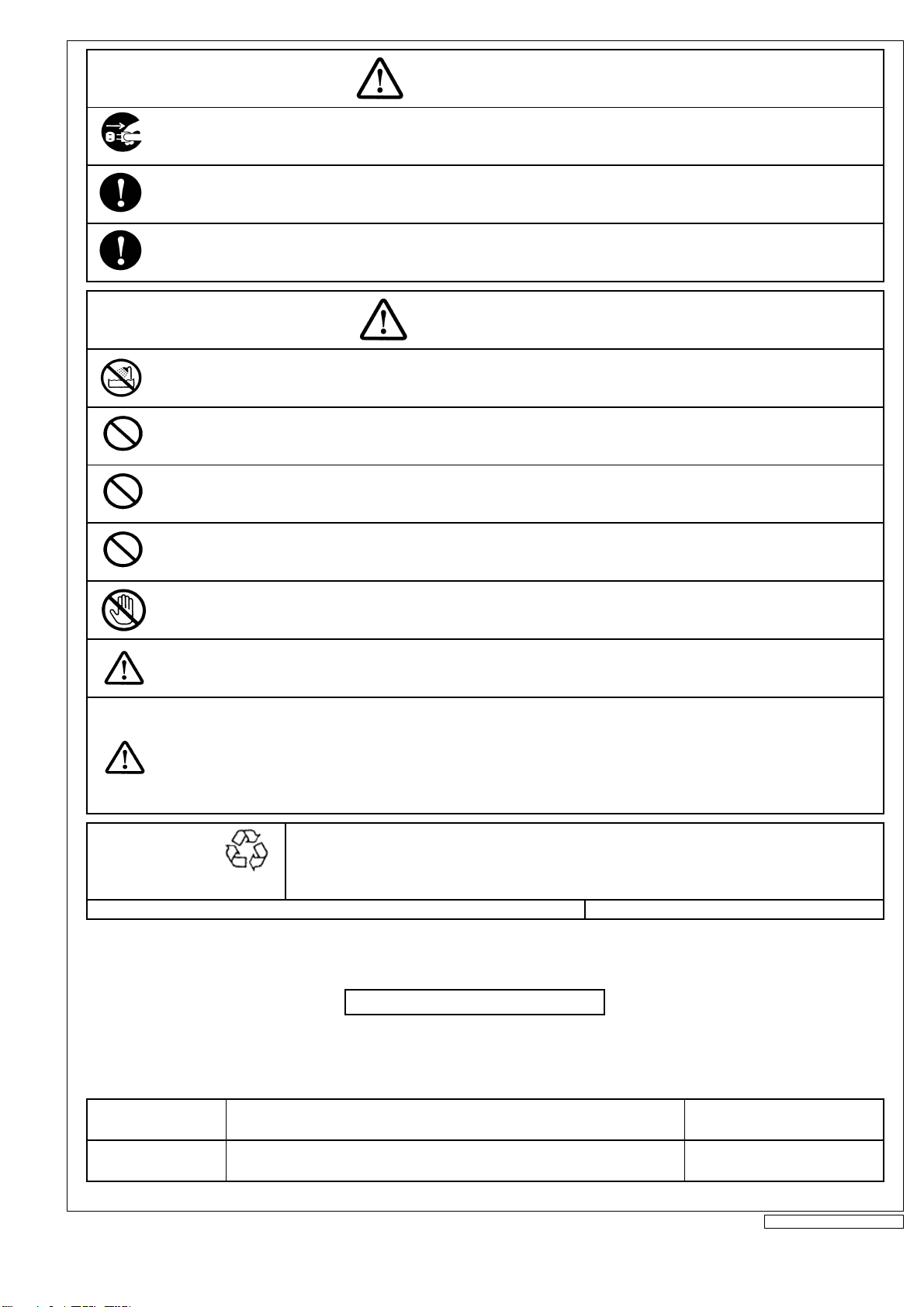

Please note that the above addresses and phone numbers may be changed.

Installation of the product should be carried out by a qualified person.

Installation by an unqualified person is legally prohibited.

Don’t use the product in a strong corrosive gas atmosphere which contains hydrochloric acid or chlorine gases or the like.

Use in a corrosive gas atmosphere might cause the product to corrode and fall, resulting in an injury.

The product should be mounted on a surface robust enough to support its weight, properly according to the instruction

manual. Improper installation might cause the product to fall or result in an electric shock or injury.

WARNING

Fax

To ensure brightness and safety, carry out periodical cleaning and inspection.

If used in an extended period without maintenance or inspection, a smoke, fire or electric shock might result.

For a product marked with a frequency, don’t use the product at a frequency other than 50 or 60 Hz (local power supply

frequency). Use at a wrong frequency might cause a fire.

If you continue to use the product in an abnormal condition (smoke, odor, etc.), a fire or electric shock might result. If you

detect an abnormality, immediately turn off the power switch. Confirm that the abnormal condition has been eliminated and

make a repair call.

Fax

2-19-6 Yanagibashi, Taito-ku, Tokyo 111-0052 Japan +81 3 5833 8971

+81 774 58 2034

+81 3 5833 8946

Head Office +81 774 55 8181

Phone

36 hinike, Terada, Joyo, Kyoto Pref. 610-0192 Japan

Tokyo Branch

SEIWA ELECTRIC MFG.CO., LTD.

Phone

CAUTION

A lighting fitting has a service life. A product which has been used for eight to ten years may have degraded internal parts

even if it looks normal. For safety and energy saving, we recommend you check and replace it. The LED module design life is

60,000 hours (different from the lighting fitting life) when used at an ambient temperature of 30°C, 10 hours per day, 3,000

hours per year. If used at a higher temperature or more hours per year, the life would be shortened. Have a specialist inspect

the product every three years. If used for an extended period without inspection, a smoke, fire, or electric shock might result.

Never touch LED light sources and their surroundings.

The light sources and their surroundings are very hot, so an accidental touch might cause a burn.

Don’t use the product at a voltage other than the rated voltage indicated on the nameplate.

Otherwise, breakage, fire or electric shock might result.

Any product not marked as a product for outdoor use should not be used outdoors or in a humid place or near a water

source. Its use in such a place might cause a fire or electric shock.

Ni-Cd

Ni-MH

L照般6

Recycling

Please bring used econdary batteries to the recycling station for effective use of precious

resources and global environment conservation.

JBRC

(Japan Portable Rechargeable Battery Recycling Center)

Phone +81 3 6403 5673

For further information on the product, contact any of our offices listed below (if you like to make an inquiry, let us know the model name

indicated on the product nameplate).

CONTACT DETAILS

- 2 /2 -

This manual suits for next models

2

Table of contents

Other Seiwa Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

SGM

SGM LB-100 user manual

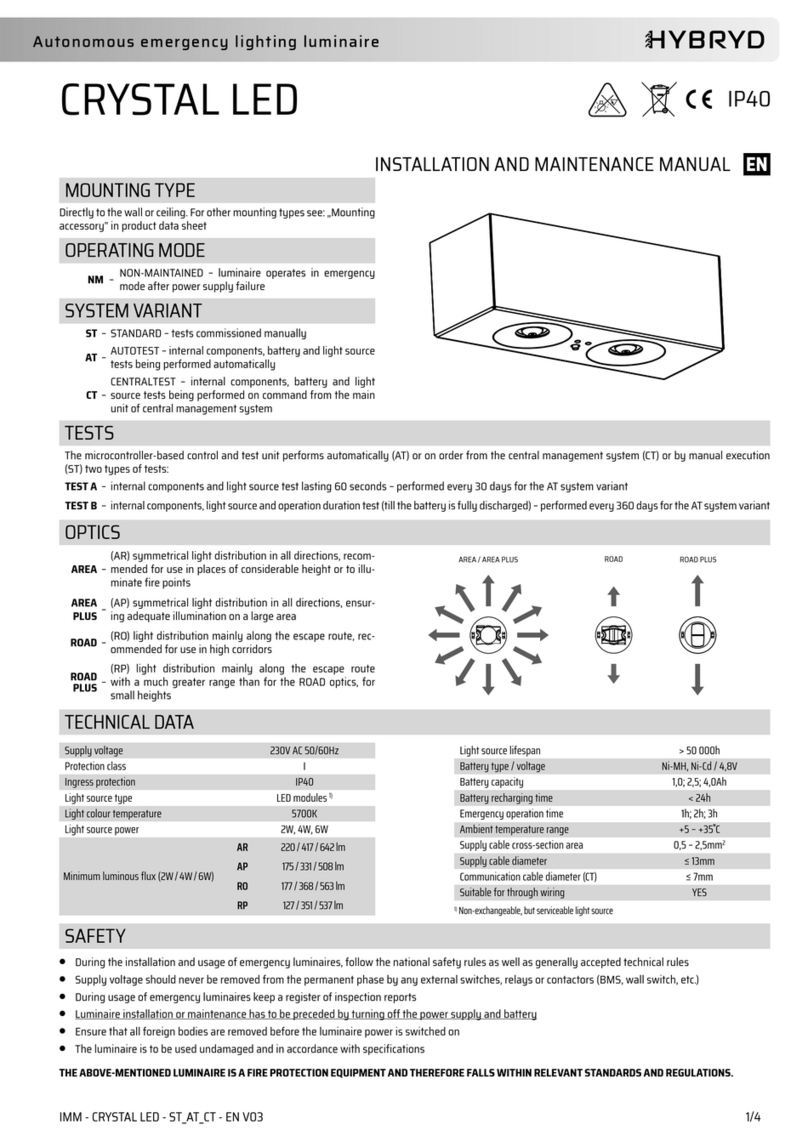

HYBRYD

HYBRYD CRYSTAL LED Installation and maintenance manual

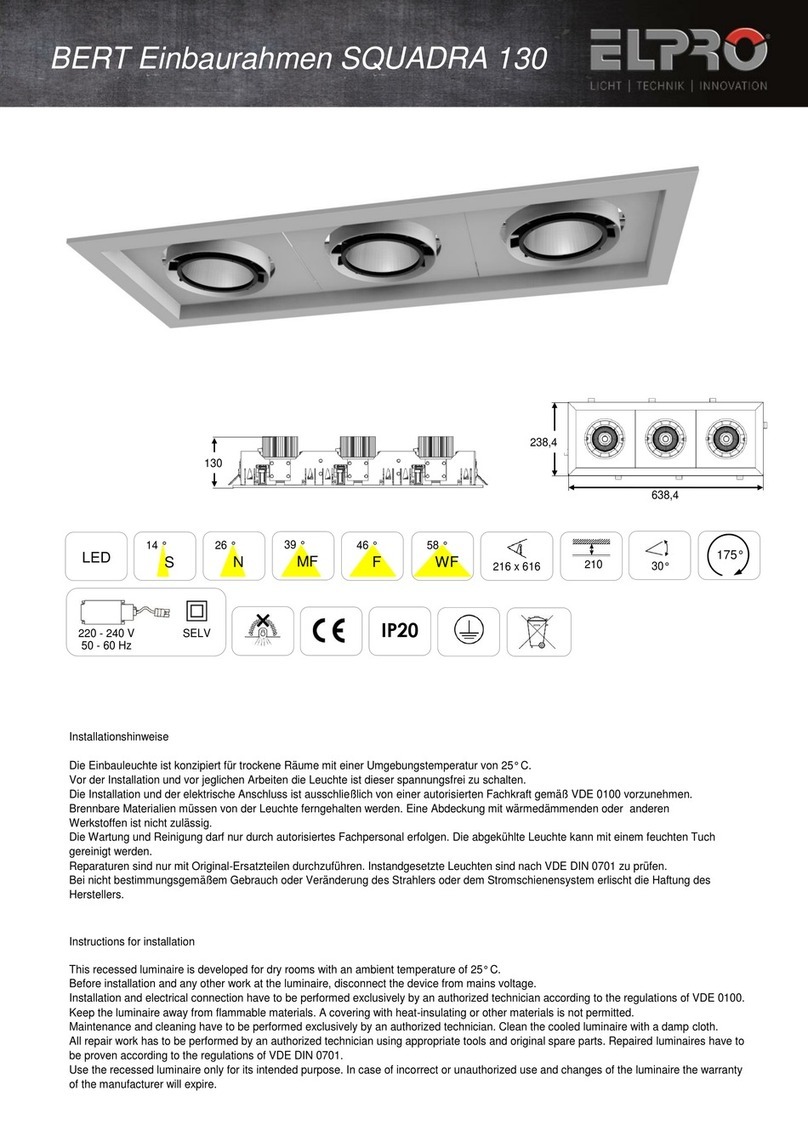

ELPRO

ELPRO BERT SQUADRA 130 installation instructions

Philips

Philips GreenPower TLED InstantFit Quick installation guide

Phottix

Phottix Kali50 user manual

Knightsbridge

Knightsbridge SPIKE5S Installation & maintenance manual