Selden Furlex 100 S User manual

Manual

Furlex

100 S

595-102-E

2011-04-15

100 S

2

To derive the maximum benefit and enjoyment from your Furlex system, we recommend that you

study this manual carefully.

The manual is divided into two sections, one dealing with ASSEMBLY and one with

OPERATION.

Each section contains references to the other. It is very important to read and note these cross

references.

All safety-related information is indicated by the following symbol:

The manual covers one Furlex size, 100 S.

The model designation can be found on the line drum top.

Furlex is specified and manufactured using Metric dimensions. To assist owners unfamiliar with

this system, the approximate equivalent Imperial dimensions are given in brackets.

The screws used for the halyard swivel and lower bearing assembly have a Torx socket.

The Torx type socket has an excellent grip but is not yet in common use. The necessary torx bits

are included with the Furlex. The Torx socket sizes are:

This information must be followed to avoid damage to the system and the risk of

personal injury. The 5-year guarantee on the Furlex system is only valid if the system

is assembled and operated correctly according to the manual.

1 Introduction

PLEASE read the entire manual prior to assembly!

Seldén Mast AB guarantees the Furlex system for 5 years. The guarantee covers faults arising from

defective design, materials or workmanship.

The guarantee is only valid if the Furlex system is assembled, operated and maintained in accordance

with this manual and is not subjected to loads in excess of those indicated in the brochure and

instructions.

If the system is repaired by anyone other than Seldén Mast AB or one of our authorized dealers, the

guarantee ceases to be valid.

Seldén Mast AB reserves the right to alter the content and design without prior warning.

Torx SocketScrew Size

M5 T 25

M6 T 30

M8 T 40 Fig. 1.1.a

1.1 The manual

3

1 Introduction

1.1 The manual 2

1.2 Product information 4

ASSEMBLY

2 Checklist

2.1 Furlex box 6

2.2 Foil pack 8

2.3 Tools 8

3 Assembly preparations

3.1 Forestay attachment - guiding principle 9

3.2 Mast attachment 9

3.3 Deck attachment 9

3.3.1 Dimension of lower bearing assembly 10

3.3.2 Dimension of top eye terminal 10

3.3.3 Table of measurements for toggles 11

3.4 Assembly below deck 12

3.5 Calculating the length of the forestay wire 13

3.5.1 Table 1:

Calculation of forestay wire length 13

3.6 Calculating the length of the luff extrusion 14

3.6.1 Table 2: Calculation of luff extrusion length 14

4 Assembly of the Furlex-system

4.1 Assembly of the luff section 16

4.2 Fitting the wire terminal 17

4.3 Fitting the line drum and line guide 20

5 Halyard routing

5.1 Halyard leads 22

5.2 Halyard sheave box 23

5.2.1 Sheave boxes 23

5.3 Spinnaker halyard 23

5.4 Fitting the halyard lead 23

6 Furling line arrangement

6.1 Functional description 25

6.2 Winding the line onto the line drum 25

6.3 Routing of the furling line 26

6.4 Fitting the stanchion blocks 27

7 The Sail

7.1 Adapting the sail to the Furlex system 28

7.1.1 Table of sail measurements 29

7.2 Sail shape 29

7.3 Determining the length of the pendant 30

OPERATION 31

10 Halyard routing

10.1 Summary 32

10.2 Halyard sheave box 33

10.3 Spinnaker halyard 33

11 Sailing with Furlex

11.1 To hoist the sail 34

11.2 Unfurling the sail 35

11.3 Furling the sail 36

12 Reefing

12.1 Free turn 37

12.2 Reefing under sail 37

12.3 Setting a reefed sail from the furled position 38

12.4 Adjusting the sheeting position 38

13 Furlex for racing 39

14 Adjusting the forestay length

14.1 Furlex with rigging screw 40

14.1.1 Rigging Screw adjustment 40

14.2 Furlex without rigging screw 41

15 Maintaining your Furlex system

15.1 Lubricating the lower bearing assembly 42

15.2 Lubricating the halyard swivel 42

15.3 Cleaning the Furlex 43

15.4 Storage 43

16 Rigging

16.1 Fitting the Furlex on a stepped mast 44

16.2 Stepping the mast with Furlex fitted 45

17 Dismantling

17.1 Halyard swivel 46

17.2 Sail feeder 46

17.3 Line guide / Line drum 47

17.4 Forestay 48

17.5 Lower bearing assembly 49

17.6 Luff extrusion system 49

18 Troubleshooting 50

19 Checklist

19.1 Points to check before sailing 52

Contents

PagePage

4

When the original Furlex was introduced in 1983, it was not a pioneering project. The design included

features which improved on other manufacturers’ products to increase performance, function and

reliability. The first systems sold are still functioning well, providing ample proof of the design’s

effectiveness and long-term staying power. Furlex quickly became the market leader, a position it

still occupies today. Our success can also be put down to how we select a system for a specific yacht.

First we calculate the boat’s righting moment, which is a function of its displacement, ballast, beam

and draft. Then we use righting moment in combination with the rig type to calculate its power when

sailing, and the likely loads on the Furlex system.

Furlex is only sold through authorized local dealers who are able to cover all service requirements for

the customer, including assistance with assembly, the modification of sails or the production of new

sails.

This new Furlex model range incorporates improvements based on our extensive experience, and

represents the very latest development of the jib furling and reefing concept.

Furlex is supplied as a complete assembly kit containing all the components required.

The ball-bearing system of the halyard swivel features a load distribution facility, a unique

patented system which distributes loads over the entire ball race. This permits smoother furling

and considerably reduces bearing wear.

Furlex 100 S for Ø 6 mm forestay can be supplied with an optional external rigging screw.

The Furlex luff section has the same dimensions over its whole length. The entire luff is furled

in an even roll, right down to the tack of the sail. This is a requirement for satisfactory sail shape

when reefed.

The tack ring’s ”free turn” flattens out the sail, promoting an efficient shape when reefed.

Furlex is suited to both cruising and racing. The line drum and line guide are easy to remove if

you want to utilize the entire forestay length for racing.

The luff section has two luff grooves, allowing two jibs to be goose-winged when running down-

wind and facilitating fast sail changes for racing yachtsmen.

The prefeeder is always on hand to help when hoisting the sail.

The line guide fitting centres the line as it is wound onto the drum, and the flexible internal line

guard maintains light pressure on the line to ensure even distribution on the drum.

Furlex is manufactured by Seldén Mast, the world’s leading manufacturer of masts and rigging

systems.

1.2 Product information

Follow the instructions carefully when fitting.

5

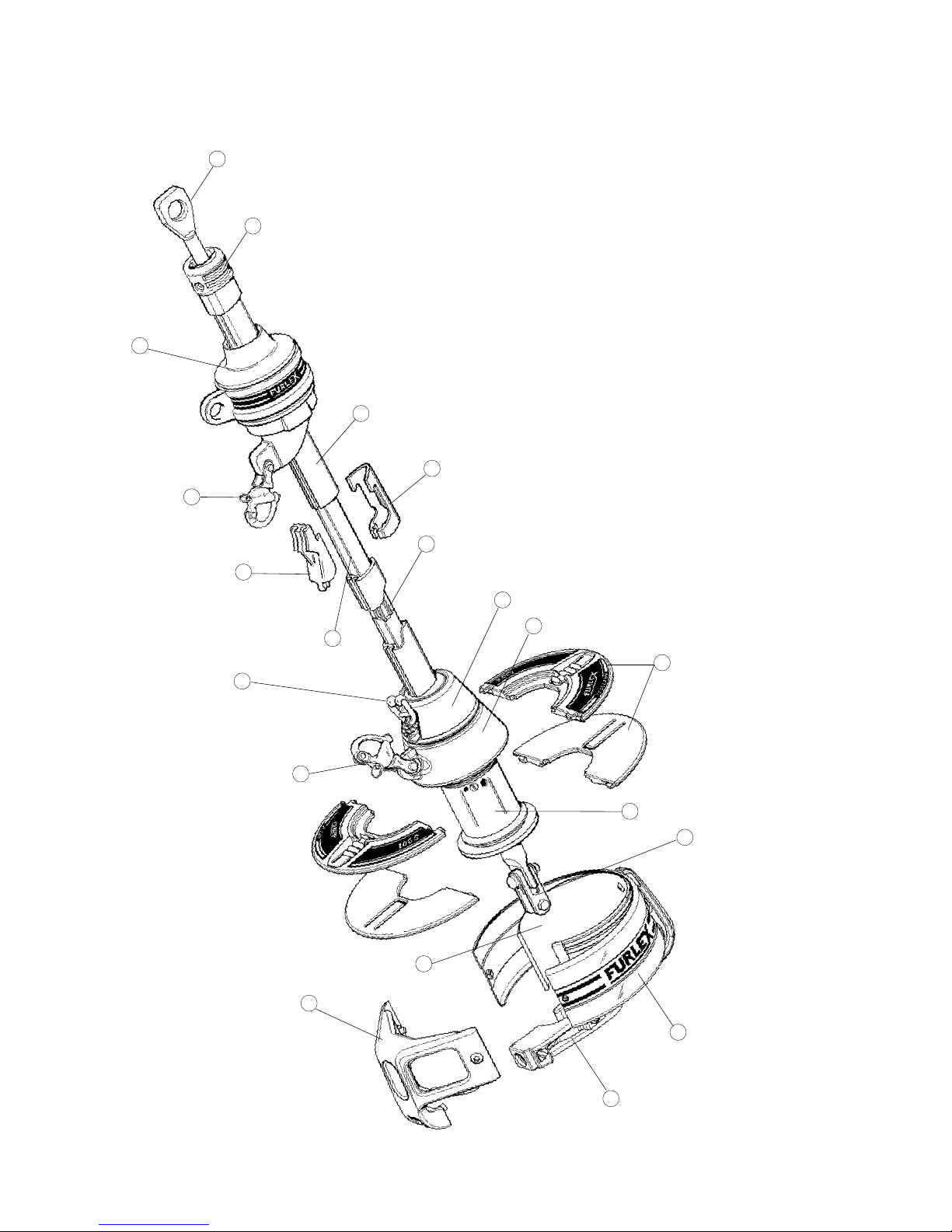

1. Forestay /eye terminal

2. Top guard

3. Halyard swivel

4. Snap shackle

5. Luff extrusion

6. Distance tube

7. Joining sleeve

8. Sail feeder

9. Sail feeder connector

10. Lower bearing assembly

11. Tack ring

12. Adapter

13. Fork / fork toggle

14. Line drum flange halves

15. Line guard housing

16. Line guard

17. Line guard bracket

18. Line guide fitting

19. Prefeeder

1

2

3

4

5

9

8

7

6

12

11

14

19

4

13

10

16

18

17

15

6

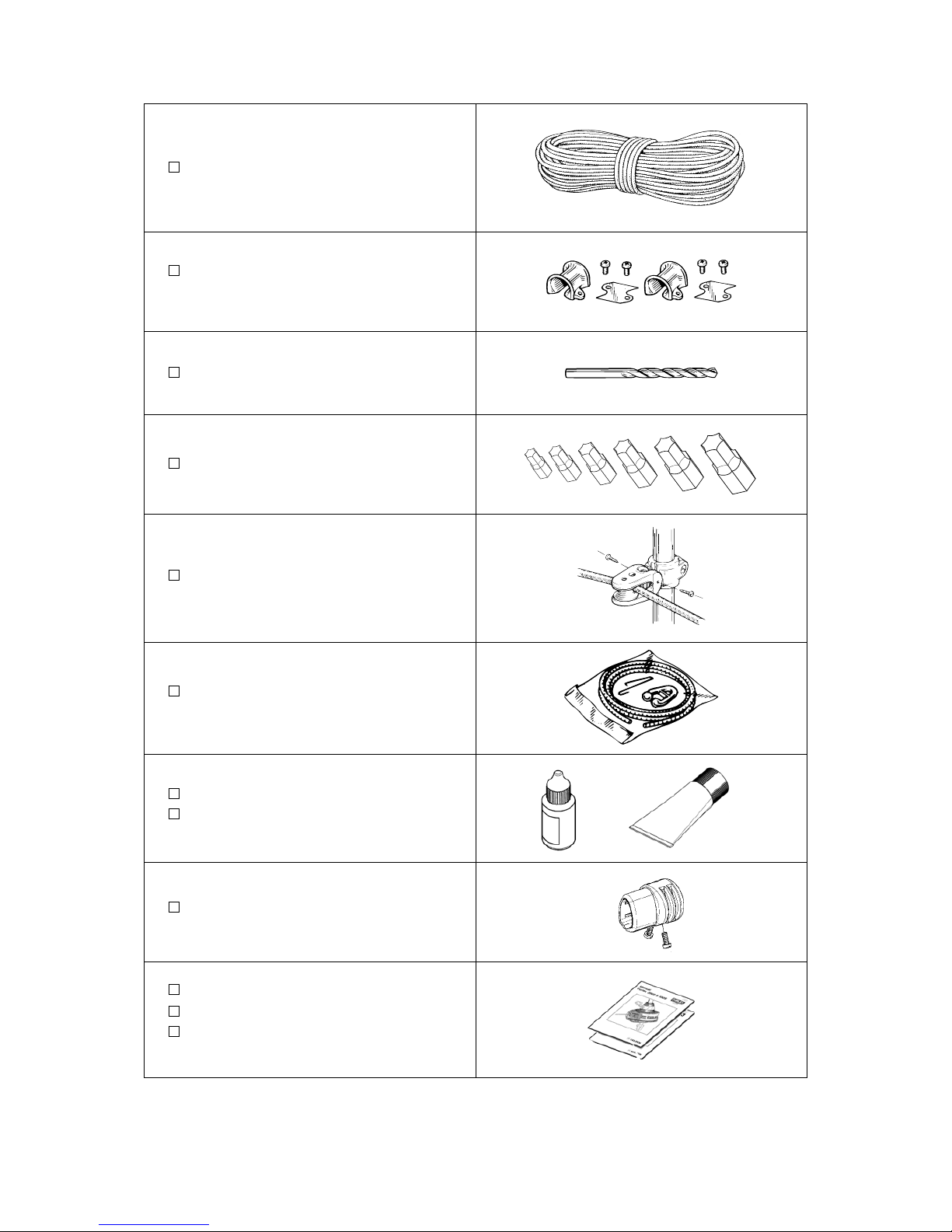

2 Checklist

2.1 Furlex box

Forestay wire

Halyard Swivel (with snap shackle)

Lower bearing assembly with snap shackle

4 Line drum flange halves

Line guard housing

Line guide fitting

ASSEMBLY

7

2 halyard leads 508-135 with insulator

sheets incl. 4 screws

Torx bit set (T15/20/25/30/40/45)

4 stanchion blocks

Top guard incl. 2 screws

Instructions

Spare parts list

Certificate of guarantee

Furling line

Drill bit Ø 5.3 mm (7/32”)

Prefeeder incl. shock cord and hook

Locking adhesive

Lubricating grease

8

Tools needed for assembly:

Screwdriver (standard tip)

Screwdriver for 1/4” bits

Hacksaw

2 adjustable spanners

Pair of pliers (“Polygrip”)

Adhesive tape

File

Marker pen (water-proof)

Torx bits (included in Furlex package)

Steel measuring tape (20 m) (60’7”)

Knife

For halyard leads:

Heavy-duty Philips screwdriver

Drill

Drill bit Ø 5.3 mm (7/32”) (included in package)

2.3 Tools

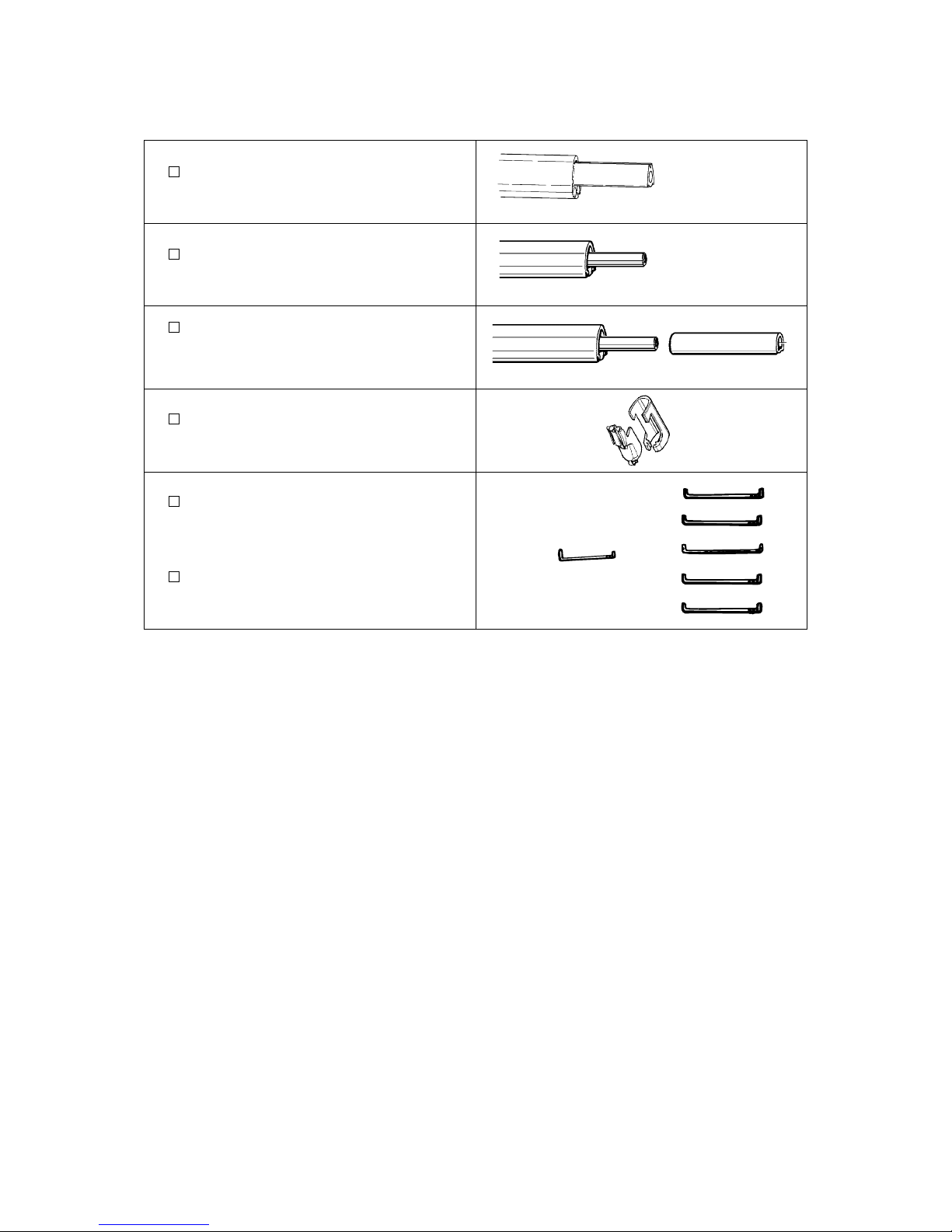

One x 1000 mm (39 3/8”) luff extrusion

with long joint sleeve.

One x 2000 mm (78 3/4”) luff extrusion

with distance tube.

2400 mm (94 1/2”) luff extrusions

with distance tube + joint sleeves.

(Number dependent on length ordered).

Sail feeder

(sail feeder + sailfeeder connector.)

One long connecting spring for each

2400 mm (94 1/2”) and 2000 mm (78 3/4”)

luff extrusion

One short connecting spring for the

1000 mm (39 3/8”) luff extrusion

2.2 Foil pack:

9

Forestay attachment on masthead rigs: Always

connect the stay with a toggle to give full

articulation.

Forestay attachment on fractional rigs, Seldén

triple combi box: 505-011; Ø4 & 5 mm wire:

Connect directly to fitting. 505-018; Ø6 mm

wire: Connect with an eye/fork toggle.

Forestay attachment Seldén’s fitting ”O - 22” /

”O - 35”: Connect directly to the fitting, which

provides full articulation.

Forestay attachment ”T-terminal” type:

Fit a T/fork toggle according to the table 3.3.3.

3 Assembly preparations

3.1 Forestay attachment - guiding principle

Some Seldén forestay attachment options are shown below, illustrating the rules and exceptions.

For H dimensions, see Table 3.3.3.

The lower end of the Furlex system is fitted with a fork toggle as standard. This can normally be

attached directly to the boat’s forestay fitting at the stemhead.

Check that the lower bearing assembly and line guide do not interfere with the pulpit, navigation

lights or other deck fittings.

Fig. 3.2.a Fig. 3.2.b

Fig. 3.2.c Fig. 3.2.d

The guiding principle is that the forestay connections should allow sufficient articulation

in all directions. In most cases a toggle should be fitted between the Furlex stay and

the forestay attachment.

FL

FL

FL

H FL

3.2 Mast attachment

3.3 Deck attachment

10

3.3.1 Dimensions of lower bearing assembly (mm) 3.3.2 Dimensions of top eye terminal

Wire dim. DD DH DW TED TET

Ø 4 (5/32”)

Ø 152 (6”)

~ 100 (4 ”)

80 (3 1/8”)

ø 8.2 (5/16”) 4 (5/32”)

Ø 5 (3/16”) ~ 100 (4 ”) Ø 10.2 (3/8”) 4.5 (5/32”)

Ø 6 (1/4”) ~ 120 (4 3/4 ”) Ø 12.2 (31/64”) 6 (1/4”)

If the boat is fitted with a bow anchor, it may be

necessary to permanently raise the lower bearing

assembly to give the crew sufficient space for

anchor work. On Ø6 models, the adjuster shown

in table 14.1.1, or the extension link (table 3.3.3)

may be used for this purpose. Extension links for

Ø 4 & Ø 5 models are not stocked.

If the lower bearing assembly is raised by

means of an extension link, a Furlex toggle or

similar toggle with the same function should be

fitted between the link and the boat’s forestay

attachment.

Fig. 3.3.c

An extension link does not provide the necessary flexibility. It must always have a

toggle between it and the boat´s forestay attachment.

Fig. 3.3.a Fig. 3.3.b

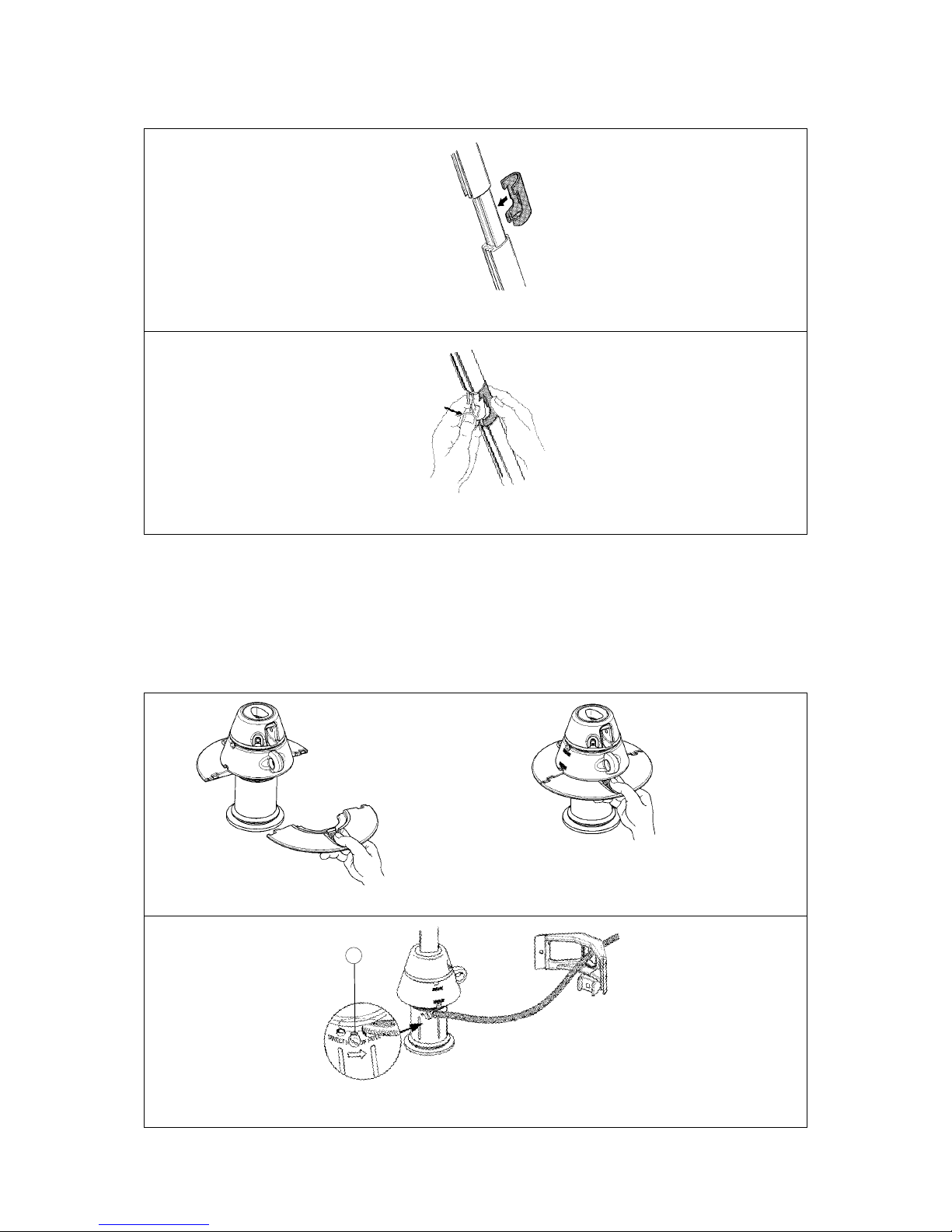

Take care to ensure that the toggle

split pins are secured as per fig.

3.3.d after fitting.

Fig. 3.3.d

TED

TET

DD

DW

DH

20°

11

Toggle type

Forestay Dimensions

Ø 4 (5/32”) Ø 5 (3/16”) Ø 6 (1/4”)

Article no. 174-102 174-103 174-104

Length (H) 25 (1”) 35 (1 3/8”) 40 (1 1/2”)

Ø Eye (D1) 8 (5/16”) 10 (3/8”) 11 (7/16”)

Ø Clevis pin (D2) 8 (5/16”) 9,5 (3/8”) 11 (7/16”)

Fork width (W2) 8 (5/16”) 10 (3/8”) 12 (1/2”)

Article no. 517-056-02 517-054-02 517-046-02

Length (H) 25 (1”) 30 (1 3/16”) 40 (1 1/2”)

Ø Clevis pin (D1) 8 (5/16”) 10 (3/8”) 12 (1/2”)

Fork width (W1) 7,5 (9/32”) 10 (3/8”) 11 (7/16”)

Ø Clevis pin (D2) 8 (5/16”) 10 (3/8”) 10 (3/8”)

Fork width (W2) 8 (5/16”) 11 (7/16”) 11 (7/16”)

Article no. 174-127 174-128 174-122

Length (H) 60 (2 3/8”) 70 (2 3/4”) 80 (3 1/4”)

Ø Clevis pin (D2) 8 (5/16”) 9,5 (3/8”) 11 (7/16”)

Fork width (W2) 8 (5/16”) 10 (3/8”) 12 (1/2”)

Article no. - 517-065-01 517-066-01

Length (H) - 138 (5 7/16”) 152 (6”)

Ø Stemball (D1) - 26 (1 1/32”) 26 (1 1/32”)

Height (HB) - 8,5 (1/3”) 8 (5/16”)

Radius (R) - 10 (3/8”) 10 (3/8”)

Ø Clevis pin (D2) - 10 (3/8”) 10 (3/8”)

Fork width (W2) - 11 (7/16”) 11 (7/16”)

Article no. - - 517-063-01

Length (H) - - 90 (3 9/16”)

Ø Clevis pin (D1) - - 12 (1/2”)

Fork width (W1) - - 11 (7/16”)

Ø Eye (D2) - - 12 (1/2”)

Gauge (W2) - - 6 (1/4”)

Furlex-rigging screw, see chap. 14.

W2

HB

H

R

D1

D2

11

3.3.3 Table of measurements for toggles

(Toggles available from your Furlex dealer)

Eye / fork toggle

Fig. 3.3.e

Fig. 3.3.f

Fork / Fork toggle

Fig. 3.3.g

T / fork toggle

H

D2

W2

Fig. 3.3.h

H

D2

W2

D1

D2

W2

H

D1

W1

Stemball / Eye toggle

with Fork / fork toggle

Eye / fork Extension link

Fig. 3.3.i

D2

H

W2

D1

W1

Fig. 3.3.j

12

The lower bearing assembly can be fitted below deck inside an anchor well.

The advantage is that the sail’s luff length is maximized and the access around the forestay is improved.

The disadvantage is a more complicated route for the furling line, increasing furling resistance. The

diagrams below illustrate various methods of installation.

For the furling line to be wound evenly onto the line drum, the first turning point must be at least

250 mm (10”) away.

The tack should be located as close to deck level as possible.

Regardless of which option is chosen, the Furlex system must always be kept clear of the deck

well’s inside surfaces.

Avoid routing the line through an integral deck conduit, as this will increase the friction on the

furling line.

Use a large ball-bearing block to minimize friction losses.

The anchor well must be well drained.

To avoid damage to the Furlex system and the boat, the system must never be allowed

to come into contact with the edge of the deck or well when sailing.

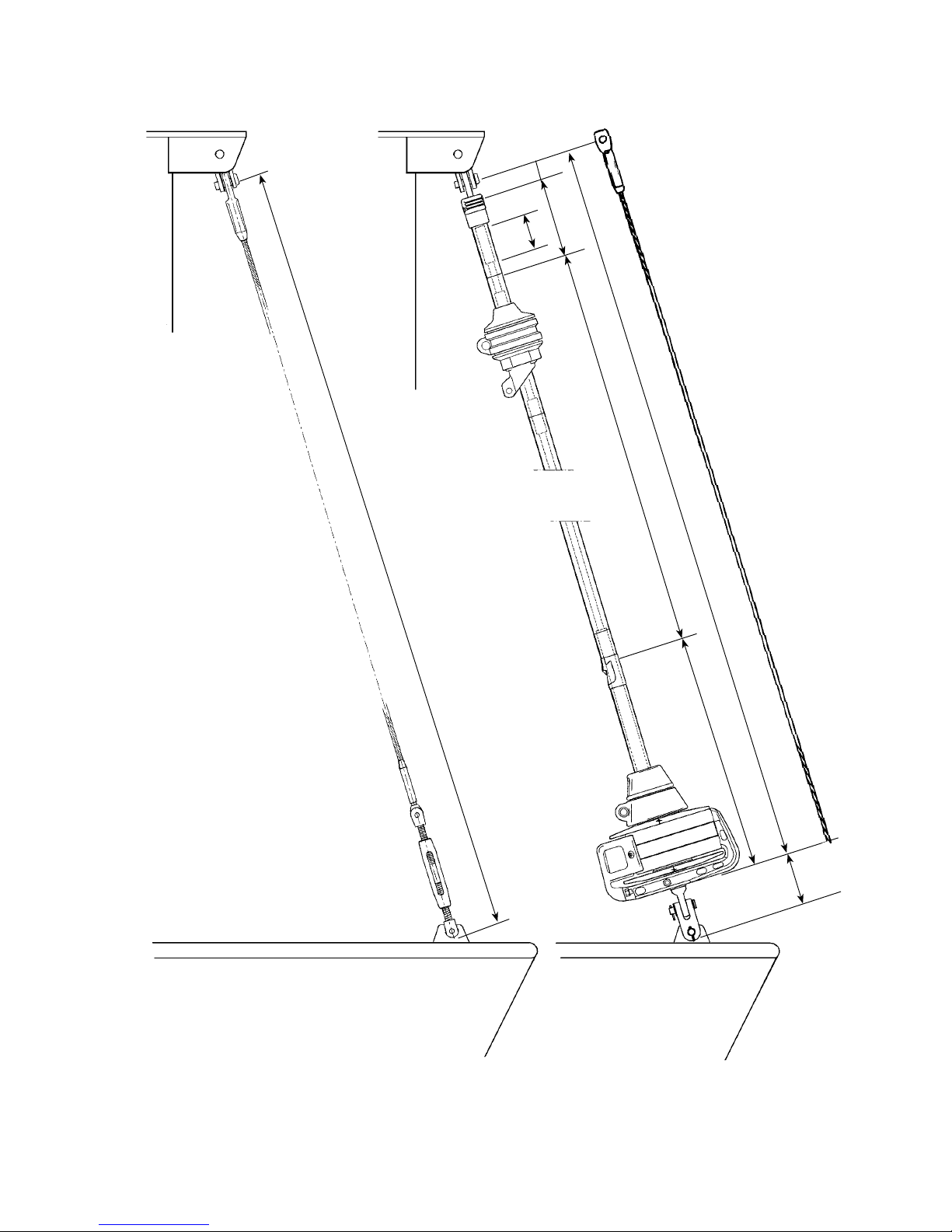

Top edge of drum at deck level.

Large deck hole required for line drum.

Furling line led aft via turning block

and inset deck sheave box, then aft

along the deck.

Tack snap shackle at deck level.

Requires smaller hole in deck.

Furling line leads forward to an inset

deck sheave box, alternatively aft via a

block + deck sheave box.

Lower bearing assembly in the bottom

of the anchor well. Long webbing band

attached around the extrusion

May put too much strain on the furling

extrusion.

Fig. 3.4.a

Fig. 3.4.b

Fig. 3.4.c.

3.4 Assembly below deck

13

Deduction for lower wire terminal:

Ø 4 mm wire: – 45 mm (1 3/4”)

Ø 5 mm wire: – 55 mm (2 5/32”)

Ø 6 mm wire: – 70 mm (2 3/4”)

T

Existing forestay length (FL), including rigging screw (See fig. 3.5.a)FL

=

Furlex fitted above deck, but with the forestay fitting

in the anchor well.

Use the Furlex extension toggle. For a larger gap, use

a custom-made stainless steel bar or rod stay. For Ø 6

only, the Furlex rigging screw or extension link may

also be used.

Short wire pendants are not recommended as forestay

forces may not be distributed evenly, and wire will not

resist the torque which may be produced.

1. Determine the rake of the mast with the fore-/backstay tensioned.

2. Slacken the backstay as much as possible, but make sure that any rigging screw is not unscrewed

so far that the threads are no longer visible ”on the inside”. The forestay setting should not be

adjusted. If there is insufficient adjustment in the backstay, and the forestay must be adjusted to allow

removal, first mark its thread with adhesive tape.

3. Pull the masthead forward using the genoa halyard. Secure the halyard using a ”D” shackle or tie it

to a strong deck fitting. For safety reasons, do not use the halyard snap shackle.

Always use a strong ”D” shackle or tie the halyard!

4. Take down the forestay. If it was slackened, adjust the rigging screw back to the tape marks.

5. Measure the forestay length (FL) with just enough tension to keep it straight.

6. Enter the measurement in Calculation Table 1 below, under the heading ”Your forestay”, in the row

marked FL.

7. Calculate the new wire length WL in Table 1. Refer to the column marked ”example” to see how

this is done.

Your

forestay

Example

Ø5

Table1: Calculation of forestay wire length

3.5.1

H

WL

If a Furlex rigging screw (Ø 6 mm forestay only), links or extra toggles

are to be used, deduct this length (H) from FL.

Cutting measurement. The new forestay wire is to be marked

at this point.

--190

=13100

Fig. 3.4 d.

9.675

55

9.620

3.5 Calculating the length of the forestay wire

14

If the top extrusion is shorter than 400 mm (15 3/4”), the joint

will be too near the top. In this case replace the uppermost full-

length 2400 mm extrusion with the 2000 mm extrusion. In this

way the joint is moved 400mm (15 3/4”) down the stay. Adjust

the C and D measurements as follows:

Deduct 400 mm (15 3/4”) from the C measurement.

Add 400 mm (15 3/4”) to the D measurement.

-

1. Insert the length of the new forestay wire (WL) as calculated in table 1 into table 2, in the row

marked WL.

2. Calculate the number of full length extrusions and the length of the top extrusion.

Fixed deduction (A+B):

C+D=

3.6.1

WL

A+B

C+D

C

D

Max. number of 2400 mm (7’ 10 1/2”) extrusions which together are

shorter than C+D: [ ............ x 2400 = C ] C=

Length of top extrusion =

The top extrusion is normally cut from the 2000 mm extrusion.

Round the edges of the cut end using a file.

Ø 4 mm wire: E = D – 120 mm (4 3/4”)

Ø 5 mm wire: E = D – 120 mm (4 3/4”)

Ø 6 mm wire: E = D – 200 mm (7 7/8”)

Cut the distance tube for the top extrusion in accordance with

the following fixed deduction:

E

Deduction:

Length of distance tube E =

-

=

Table 2: Calculation of luff extrusion length

Length of new forestay wire (as per Table 1)

Your

extrusion

Example

Ø 5

-1395

=1395

–1395

(3 extrusions)

-

=2115

=

Ø 4 mm wire: – 1340 mm (4’ 4 3/4”)

Ø 5 mm wire: – 1340 mm (4’ 4 3/4”)

Ø 6 mm wire: – 1290 mm (4’ 2 3/4”)

9.620

1.340

8.280

7.200

1.080

120

960

3.6 Calculating the length of the luff extrusion

15 15

FL = Existing forestay length

Fig. 3.5.a

A

E

CB

D

WL T

16

Insert one end of a 144 mm (5 11/16”) spring in the upper hole of the

1000 mm extrusion, and slide the long joining sleeve up to hold it in

place. Remove the 200 mm (7 7/8”) joining sleeve from a 2400 mm (94 1/2 ”) extrusion.

This will be used later in the 2000 mm (78 3/4”) extrusion. Connect the 2400 mm extrusion and

the 1000 mm extrusion. Push the long joining sleeve up into the 2400 mm extrusion to secure the

connection spring. Continue pushing until the bottom of the sleeve is 50mm inside lower end of

the 1000 mm extrusion. A 50 mm (2”) gap is formed at this joint (as shown in fig. 4.1.c.), where

the sail feeder is to be fitted later.

Fit the short connecting spring (L=103 mm/4 1/8”) to the 1000 mm (39 3/8”) extrusion. The larger

hook must be on the free end. Push the long joining sleeve (L=1168 mm/46”) down, to hold the

spring in place and make space for the next spring.

Connect the remaining extrusions as detailed in table 3.6.1.

Fig. 4.1.a

Fig. 4.1.c

Fig. 4.1.d

1.

2.

4.

3.

Assembly should be carried out on a horizontal surface. Connect the luff extrusions one by one,

starting at the lower bearing assembly.

90 mm (3 9/16”)

20 mm (13/16”)

The extrusions are then fitted to the adapter of the lower bearing assembly. Hook the connecting

spring to the internal hole in the adapter. Then push the distance tube in the 2400 mm extrusion

down so that the joining sleeve bottoms in the adapter. The distance tube should be buried

approximately 100 mm (4”), about equal to half a length of a joining sleeve.

≈ 50 mm (≈2”)

≈ 100 mm (≈2”)

Fig. 4.1.b

4 Assembly of the Furlex System

4.1 Assembly of the luff section

17

Fit the halyard swivel over the top end of the extrusion, slide it down as far as the sail feeder gap

and secure it in this position with adhesive tape. Fit the top guard and secure it with the two pre-

fitted screws. Tighten the screws until they bottom, but do not over-tighten.

5

1. Stretch the Furlex wire out by hand on a flat surface.

Be careful when you open the wire coil as it may uncoil quickly.

Note! Be careful when you open the wire coil !

2. Measure the wire from the centre of the hole in the terminal end fitting. Mark the measurement WL

carefully on the wire using a marker pen. (The WL measurement was calculated in Table 1 (3.5.1)

3. The wire is annealed and tapered, making it easier to fit into the extrusion. Do not cut the wire yet.

5. Feed the wire through the luff extrusions from the top until the eye of the end fitting stops against

the top guard. If the wire catches inside the extrusion, turn it counter-clockwise until it passes the

obstruction.

6. Put adhesive tape around the wire on both sides of the cutting mark to assist cutting. Check that

the distance between the cutting mark and the terminal’s lower edge is approx. 30-50 mm

(13/16”- 2”).

7. Cut the wire. Round the end of the wire using a file.

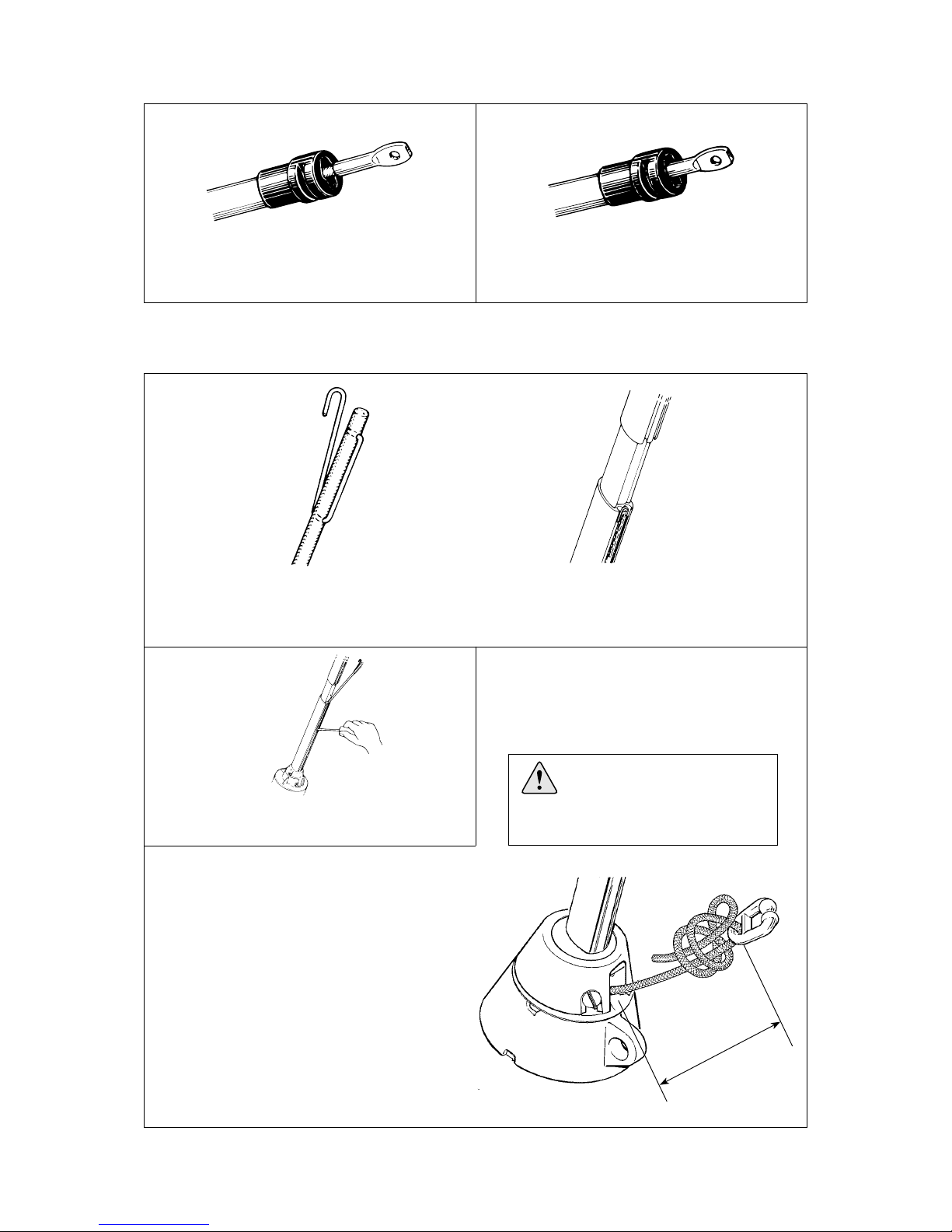

4.

Unscrew the eye, wedge and former from the terminal part.

Fig. 4.2.a

Fig. 4.2.c

8.

Slide the wedge over the core (7 strands) of the wire .

Eye Former Wedge

Fig. 4.1.e

4.2 Fitting the wire terminal (or rigging screw)

18

9.

The core of the wire should protrude approx. 2 mm (3/32”) from the wedge.

Space the outer strands of the wire evenly around the wedge and push it into the socket so that the

strands are held in place. Tap the wire lightly so the outerstrands jam in the seat.

NOTE! Check that no strands slip into the slot of the wedge.

Fig. 4.2.d

10. Bend the outer strands inwards a little using a pair of pliers, or tap the strands with a small

hammer. In the latter case, rest the socket’s thread on a soft surface (wood or similar) to prevent

damage.

12.

Unscrew and check that the outer strands are evenly distributed around the wedge. If some strands

are crossed, correct their positions.

NOTE! Check that no strand has slipped into the slot of the wedge!

13. If assembly is unsuccessful and needs to be repeated, refer to the relevant sections of chap.

17, ”Dismantling”.

Fig. 4.2.f

11.

Insert the former into the threaded hole of the eye part (or rigging screw). Screw the terminal part

onto the socket and tighten carefully, forcing the wire further into the terminal.

Fig. 4.2.e

14.

Apply 2 or 3 drops of the locking adhesive to the thread and screw the terminal together, tightening

it firmly. The terminal is now permanently locked.

Fig. 4.2.g

2 mm

19

15:1 15:2

Furlex 100 S with Ø 4 or Ø 5 mm wire:

The swaged end fitting will protrude completely.

Furlex 100 S with Ø 6 mm wire:

About half of the swaged fitting will be exposed.

Fig. 4.2.h Fig. 4.2.i

17.

18.

19.

Fig. 4.2.l

16. Check the length FL of the stay acc. Table 1 (3.5.1) & fig. 3.5.a. Check that the setting is the

same as the H-measurement as in table 1.

The hook is connected to the rubber cord acc. to fig. 11.1. Feed the cord through the starboard sail

groove as shown in fig. 4.2.k and then through the slot in the lower bearing assembly.

Fix the hook in position.

Use a small screwdriver to pull the top of the

rubber cord down the luff groove.

Fig. 4.2.j Fig. 4.2.k

It is most important that the

prefeeder is correctly fitted,

or it will not function

correctly.

Tension the cord as hard as possible and tie the

pre-feeder to the cord as shown, 300 mm (12”)

from it’s exit sheave. Tighten the knot and cut

off excess cord.

CAUTION: If the cord is too loose the pre-

feeder may be thrown out by centrifugal

force when the system rotates.

If the sail has a tendency to come out of the

pre-feeder, reduce the gap width by squeezing

the two arms toghether with a pair of pliers.

Max. 300 mm

Fig. 4.2.m

20

20.

21.

Installing the sail feeder:

22. We recommend fitting the Furlex system onto the boat at this stage.

See chap. 16, ”Rigging”.

Press on the sail feeder connector from the front of the luff extrusion.

Clip the sail feeder into the connector’s

top recess, then press the sail feeder’s lower edge until it snaps into place.

Fig. 4.2.n

Fig. 4.2.o

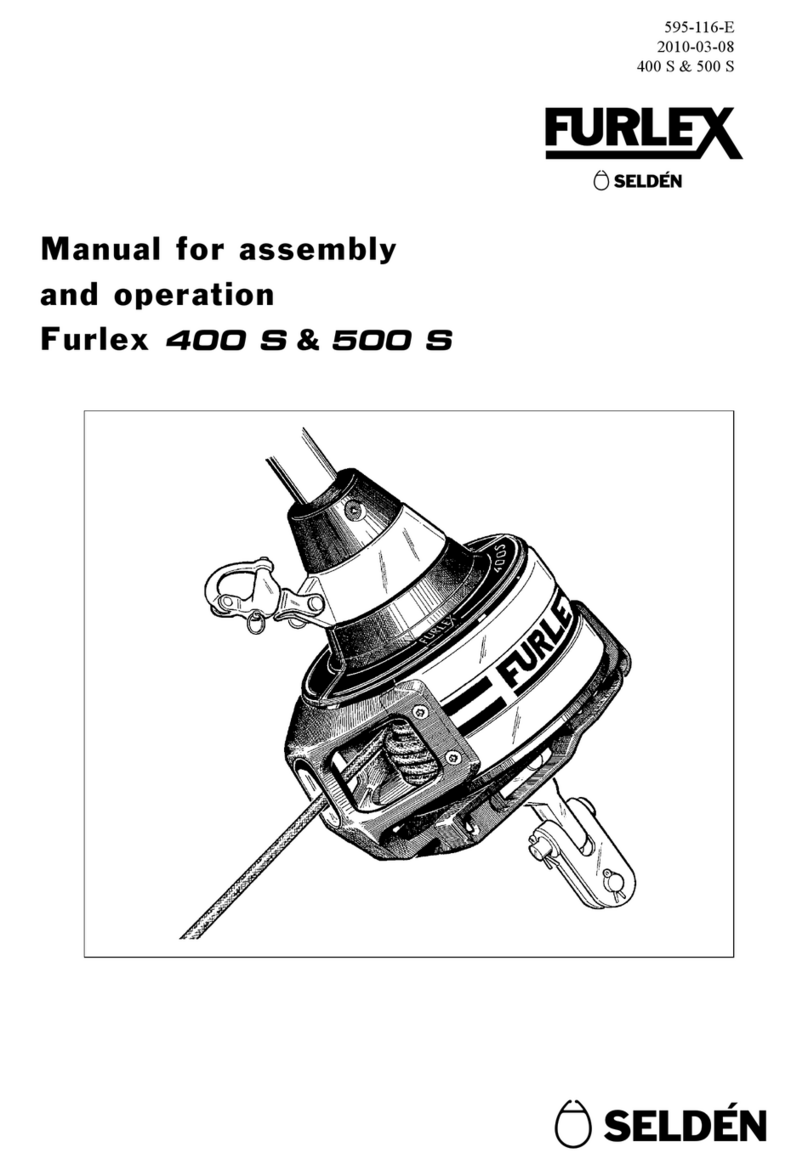

4.3 Fitting the line drum and line guide

These parts are easier to fit after the Furlex is fitted to the boat.

1.

2.

Fig. 4.3.c

Fit the two upper flange halves (with the labels) on the lower bearing.

Feed the furling line through the hole in the line guide fitting and into the oval hole in the lower

bearing assembly until it is just past the small sighting hole. Tighten the locking screw hard.

Fig. 4.3.a Fig. 4.3.b

1

Table of contents

Other Selden Marine Equipment manuals

Selden

Selden Furlex 200 S User manual

Selden

Selden Furlex 104S Guide

Selden

Selden Furlex 204S Guide

Selden

Selden Furlex 404S Guide

Selden

Selden Furlex 400 S Supplement

Selden

Selden Furlex Electric 200E User manual

Selden

Selden Furlex 200 TD User manual

Selden

Selden Furlex 200 S User manual

Selden

Selden Furlex 204TD User manual

Selden

Selden Furlex 404TD Guide

Popular Marine Equipment manuals by other brands

Ziton

Ziton ZP755W-2R Installation sheet

PRM NEWAGE

PRM NEWAGE PRM90 Workshop manual

PMG

PMG ULTRAGUARD Antifouling Master Series owner's manual

Furuno

Furuno LS-6100 Operator's manual

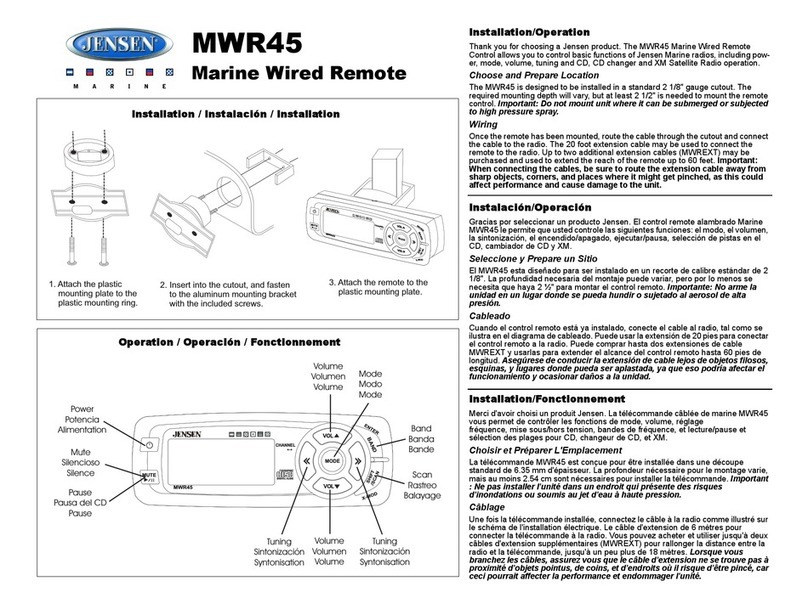

Jensen

Jensen MWR45 Installation & operation

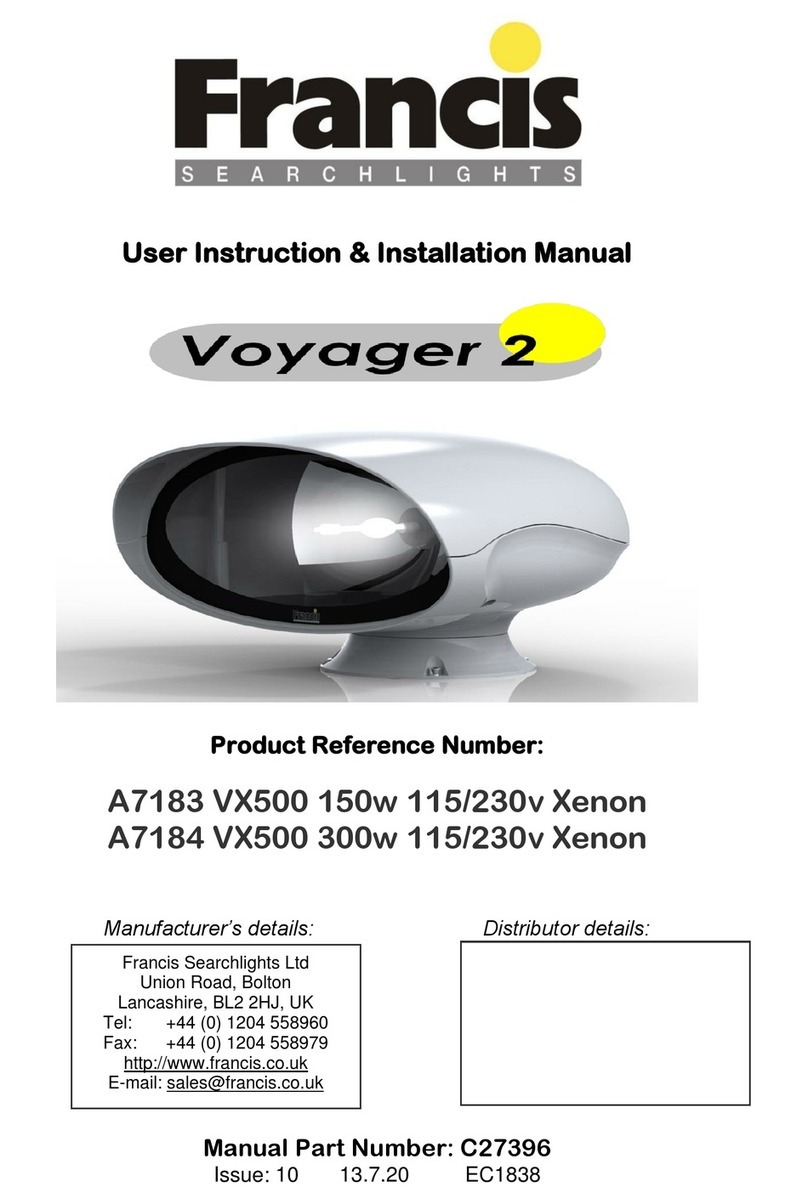

Francis

Francis A7183 VX500 150w 115/230v Xenon User instruction & installation manual