Bennett H35 Series User manual

H35 Series Operation Manual

Operation Manual

High Flow H35 Hydrogen Series

Dual Cabinet Configuration

154807 Rev. B, 12.20.2023

H35 Series Operation Manual i

READ THIS MANUAL

Only Trained Personnel May Work on This Equipment

This manual contains important information for the safe operation of this equipment. Read and

understand this manual before applying power. All service personnel should read this manual prior to

performing service activities. The material included in this installation manual is accurate at the date of

publication. Failure to follow these instructions can cause bodily injury, damage to the equipment, or

death.

NOTE:Inspect shipped materials for damage or missing equipment. Bennett Pump Company is not

liable for the hazards of transportation. Please address damage claims directly to the delivery company.

NOTE: This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept

interference received, including interference that may cause undesired operation.

NOTE: Not all equipment covered in this manual is listed by Underwriters Laboratories.

REV LEVEL DATE DESCRIPTION

A

11/22/2023

Release

B 12/20/2023 Revised Safety Instructions. Revised Error Code Table. 6.3 Safety Device Fault

Response created. Updated all section and figure references.

H35 Series Operation Manual ii

1SAFETY INSTRUCTIONS .......................................1

1.1 SAFETY MESSAGES ...........................................1

2OVERVIEW AND FEATURES.................................3

2.1 EXTERIOR LAYOUT ............................................3

2.2 ELECTRONICS UNIT INTERIOR DOOR LAYOUT.........4

2.3 MANAGER’S KEYPAD.........................................5

2.4 POWER SWITCH ...............................................5

2.5 MAIN DISPLAY REED SWITCHES ..........................6

2.6 ELECTRO-MECHANICAL TOTALIZER -OPTIONAL......7

3HOW TO OPERATE ..............................................8

3.1 DISPENSING FUEL .............................................8

3.2 ERROR MESSAGES ..........................................10

3.3 AC OFF MESSAGE .........................................11

4SETUP AND PROGRAMMING ............................12

4.1 BATTERY DISCONNECT BUTTON ........................13

4.2 DEFAULT SETTINGS .........................................13

4.3 INITIAL SETUP SEQUENCE.................................14

4.4 DISPENSER DISPLAY ........................................15

4.5 MANAGER’S KEYPAD OPERATION......................16

4.6 MANAGER’S ACCESS .......................................17

4.7 SELECT THE DISPENSER DISPLAY TYPE .................17

4.8 MENU CODE 0: DIAGNOSTICS ..........................18

4.9 MENU CODE 1: HOSE TOTALS ..........................18

4.10 MENU CODE 2: TOTALIZER TOTALS ...................19

4.11 MENU CODE 3: MANAGER’S ACCESS .................20

4.12 MENU CODE 4: PRICING..................................21

4.13 MENU CODE 5: TOTALIZER VALUE.....................22

4.14 MENU CODE 6: SPEED PROGRAMMING..............23

4.15 MENU CODE 7: DISPENSER TYPE.......................24

4.16 MENU CODE 8: DECIMAL LOCATION ..................26

4.17 MENU CODE 9: NO FLOW TIMEOUT ..................27

4.18 MENU CODE 11: MASS ALLOCATION.................28

4.19 MENU CODE 12: PRE-CHARGE TIME .................28

4.20 MENU CODE 13: BEEPER.................................30

4.21 MENU CODE 14: PPM DISPLAY OPTIONS ..........31

4.22 MENU CODE 15: FLEET OPTION .......................33

4.23 MENU CODE 16: PUMP HANDLE INPUTS ............34

4.24 MENU CODE 18: MONEY TOTALS .....................35

4.25 MENU CODE 21: COMMUNICATION TYPE...........36

4.26 MENU CODE 22: DISPENSER ADDRESS,PLC, PLC

LOWEST........................................................37

4.27 MENU CODE 26: SHIFT TOTALS ........................40

4.28 MENU CODE 27: ELECTRONIC CALIBRATION........43

4.29 MENU CODE 28: ROUNDING............................45

4.30 MENU CODE 29: RESETTABLE TOTALS ...............46

4.31 MENU CODE 30: REAL TIME CLOCK ..................47

4.32 MENU CODE 49: SOFTWARE REBOOT ................48

4.33 MENU CODE 50: PULSE OUTPUT ......................49

4.34 MENU CODE 51: NOZZLE DRYER CONFIGURATION

AND TIMING..................................................51

4.35 MENU CODE 66: NOZZLE TIME OUT..................52

4.36 MENU CODE 80: NOZZLE DRYER VALVE TEST ......53

4.37 MENU CODE 94: WEIGHTS AND MEASURES

TIMEOUT DELAY.............................................54

4.38 MENU CODE 99: VIEW E-CAL .........................55

5DIAGNOSTICS ................................................... 56

5.1 DIAGNOSTIC CODE 0.......................................56

5.2 DIAGNOSTIC CODE 1: DISPLAY SEGMENT TEST.....58

5.3 DIAGNOSTIC CODE 2: ERROR HISTORY ...............58

5.4 DIAGNOSTIC CODE 3: CPU TEST .......................59

5.5 DIAGNOSTIC CODE 4: FAULT HISTORY ................59

5.6 DIAGNOSTIC CODE 5: PUMP HANDLE TEST .........59

5.7 DIAGNOSTIC CODE 6: NOT USED.......................60

5.8 DIAGNOSTIC CODE 7: PRODUCT SELECT,KEYPAD

TEST ............................................................60

5.9 DIAGNOSTIC CODE 8: LAST SALE LIMIT ...............60

5.10 DIAGNOSTIC CODE 9: NOT USED.......................61

5.11 ERROR CODES................................................62

6APPENDIX ........................................................ 64

6.1 DISPENSER IDENTIFICATION NUMBER (DIN)........64

6.2 PULSE OUTPUT ..............................................65

6.3 SAFETY DEVICE FAULT RESPONSE ......................68

TABLE OF CONTENTS

Safety Instructions

H35 Series Operation Manual Back to TOC 1

1SAFETY INSTRUCTIONS

Please read and understand the following grouped safety messages that contain safety symbols and

safety words. They are defined as:

RED AND WHITE.IF YOU DO NOT FOLLOW THE INSTRUCTIONS, SEVERE INJURY OR DEATH WILL

OCCUR.

Orange and black. If you do not follow the instructions, severe injury or death can occur.

Yellow and Black. If you do not follow the instructions, damage can occur to the dispenser.

White italic NOTICE over blue. Indicates important information that should be observed.

1.1 SAFETY MESSAGES

1. DANGER: HYDROGEN IS FLAMMABLE. NO SMOKING OR OPEN FLAME.

2. DANGER: ALWAYS PLACE A PHYSICAL BARRIER AROUND THE WORK AREA BEFORE

PERFORMING SERVICE OR MAINTENANCE.

3. DANGER: DISCONNECT ALL POWER TO THIS EQUIPMENT DURING INSTALLATION, SERVICE,

OR ANY MAINTENANCE.

1. WARNING: To prevent electric shock, keep the electrical parts of the dispenser dry.

2. WARNING: Electronic components are static sensitive. Use proper static precautions (static

straps) before working on the equipment.

3. WARNING: Only technicians who have been trained in operation and programming of this

dispenser should perform programming and maintenance.

Overview and Features

H35 Series Operation Manual Back to TOC 3

2OVERVIEW AND FEATURES

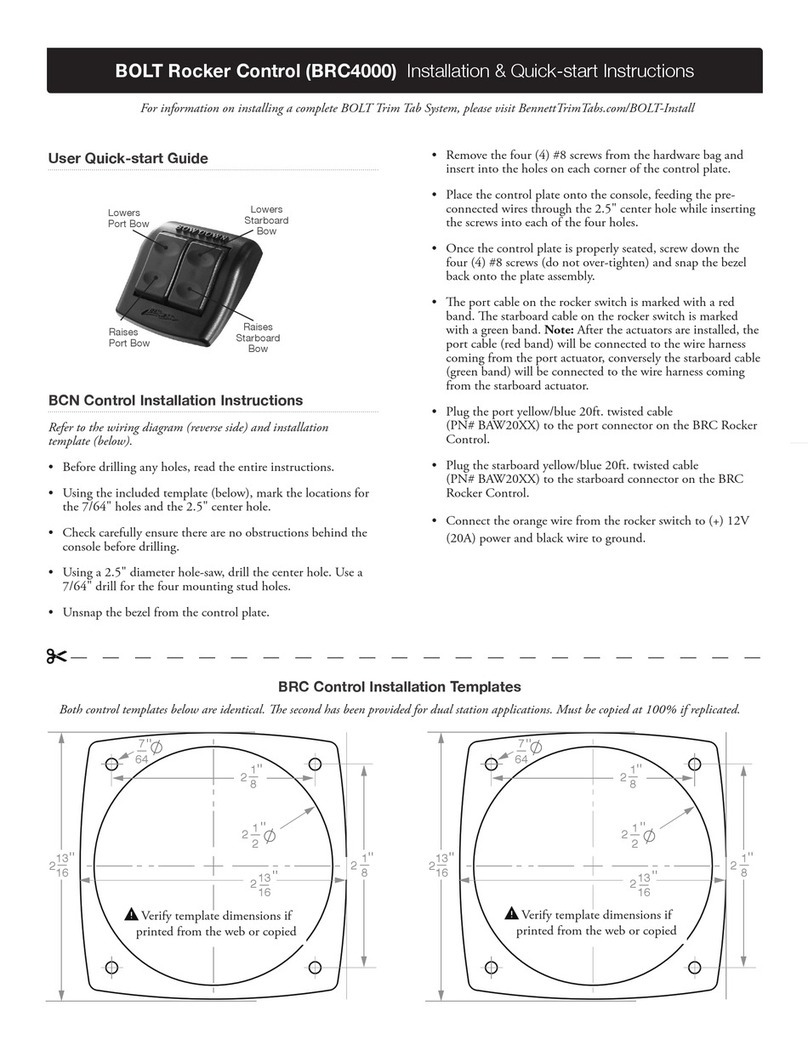

2.1 EXTERIOR LAYOUT

1. Main Display

2. Payment Panel Display (optional)

3. Nozzle Boot

4. Handle Switch

5. Locks (5 places each side each unit).

6. Electro-Mechanical Totalizer (optional)

7. Price Per Mass Displays (PPM) and

Product Select Buttons

Figure 1.1. H35 Dual Layout

Dispenser Unit

Electronics Unit

Overview and Features

H35 Series Operation Manual Back to TOC 4

2.2 ELECTRONICS UNIT INTERIOR DOOR LAYOUT

1. Main Display Board

2. NFC Reader (optional)

3. Payment Card Reader (optional)

4. Keyboard (optional)

5. Payment Panel Display Board (optional)

6. Printer (optional)

7. Price Per Mass Board

Figure 1.2. Interior Door Layout

Overview and Features

H35 Series Operation Manual Back to TOC 5

2.3 MANAGER’S KEYPAD

•The Manager’s Keypad allows users to program and access data, see Figure 1.3.

•Various modes are available to configure and calibrate the dispenser for specific applications.

•The Manager’s Keypad connects to the PPM Circuit Board, refer to Section 4.5 Manager’s Keypad

Operation.

2.4 POWER SWITCH

4. WARNING: To prevent electric shock, make sure the circuit breaker(s) are OFF and locked

and tagged out before doing any repairs or maintenance to the dispenser.

The power switch on the 819 Power

Board turns the dispenser power ON and

OFF, see Figure 1.4. If the Power Board is

switched to OFF, the displays in the

dispenser remain illuminated for 30

seconds with power supplied by the 12-

volt battery.

Figure 1.3. Manager’s Keypad

Figure 1.4. 819 Power Board.

Top arrow - battery disconnect button.

Bottom arrow - ON/OFF switch.

Overview and Features

H35 Series Operation Manual Back to TOC 6

2.5 MAIN DISPLAY REED SWITCHES

The Reed Switches access electronic totals, the last sale, and audit trail

information. They are activated with the Access Magnet provided with the

dispenser, see Figure 1.5.

The reed switch locations are shown on Figure 1.6.

2.5.1 TOTALS SWITCH

To access totals:

1. Hold the Access Magnet over the location on Figure 1.6.

2. After a few seconds, “Prev” will be displayed on the

Price Per Mass (PPM) display.

3. Lift the magnet away.

4. The Main Display will show the previous sale amount

that occurred prior to the transaction that had appeared

on the display while idle.

5. To view the Totals, tap the magnet over the Totals Reed

Switch again. When the first money totals appear,

remove the magnet. The PPM display indicates the first

money total for product.

6. Tap the magnet over the Totals Reed Switch to view all totals from Mode 1 Hose Totals, Mode 2

Totalizer Totals, and Mode 26 Shift Totals.

Figure 1.5. Access Magnet

Battery Recall Reed Switch

Totals Recall Reed Switch

Figure 1.6. Magnet Reed Switch Locations.

Sale $

Kilograms

Overview and Features

H35 Series Operation Manual Back to TOC 7

To obtain Audit Trail information:

1. Hold the black Access Magnet over the Kilograms text (Totals Reed Switch) for a longer period of

time after the Totals Mode is displayed.

2. Once the data scrolls past the Totals Mode the Audit Trail information will appear. Lift and

return the magnet to cycle through:

2.5.2 LAST SALE RECALL SWITCH

The recall switch is behind the “SALE $” print. If dispenser AC power is OFF the recall switch connects the

displays to the battery and displays the last sale.

NOTE: If a pump handle is lifted and the dispenser is activated during this operation, the display returns

to idle.

To recall the last sale with battery power:

•Hold the Access Magnet over the “SALE $” print for approximately 2 seconds.

•The last sale in progress will display for 30 seconds.

2.6 ELECTRO-MECHANICAL TOTALIZER - OPTIONAL

The electro-mechanical totalizer displays cumulative totals in gallon or liter increments for each meter

and therefore each product being dispensed, see Figure 1.1. The totalizer is located below the product

select buttons on each side of the dispenser.

NOTE: Because of rounding methods used in electronic totals, over time electronic totals and electro-

mechanical totals will not match exactly.

Magnet Action Dispenser Display Audit Trail Sub-Menu Description

Touch magnet to Totals

Reed Switch

ECAL 1A, b, c

000001

E-Cal changes for Side 1 meters.

Lift away reengage ECAL 2A, b, c

000001

E-Cal changes for Side 2 meters.

Lift away reengage unitch

00000

Mass Unit Changes (gallons to liters to

imperial gallons).

Lift away reengage 4olrES

0000

Mass resolution changes (0.001 or

0.01).

How to Operate

H35 Series Operation Manual Back to TOC 8

3HOW TO OPERATE

NOTE: If the dispenser ends a sale early, verify that no error code is shown on the main display before

trying again. Refer to Section 5.11 Error Codes for more details.

NOTE: The dispenser must be authorized by the console or set to operate in stand-alone mode, see

Section 4.25 Menu Code 21: Communication Type.

3.1 DISPENSING FUEL

To activate the dispenser (Please also see Section 3.1.1 Fueling Steps):

1. Pay if necessary.

2. Lift the nozzle from the nozzle boot.

3. Attach nozzle to vehicle receptacle.

4. Lift the nozzle handle switch.

5. The dispenser will check for IR communication from vehicle.

a. If communications are established, the dispenser will automatically proceed to the next step.

b. If communications are not detected, the payment screen will instruct user to either abort or

continue without communication.

6. The payment screen will instruct user to press the grade select button.

7. The dispenser will proceed with fueling protocol to dispense hydrogen to the vehicle.

8. The payment screen will display a message to inform the user when fueling has been completed

and instruct them to replace the nozzle.

How to Operate

H35 Series Operation Manual Back to TOC 9

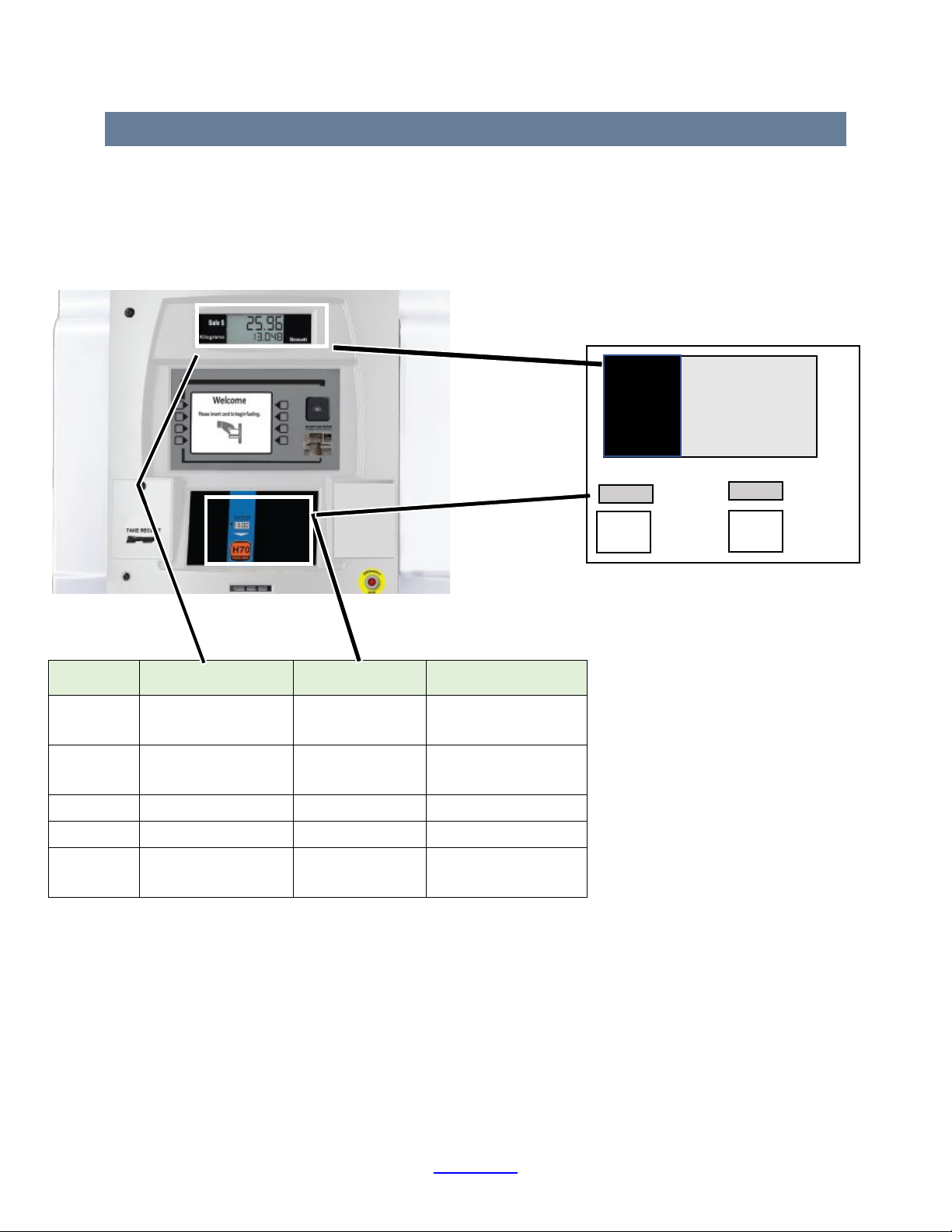

3.1.1 FUELING STEPS

Once authorized the dispenser will display the following fueling steps:

Timeout (15s) waiting for

vehicle communication.

Successful communication

with vehicle.

Pressed continue arrow.

Timeout waiting for nozzle

to be replaced.

Replaced nozzle.

*Displayed after PLC aborts sale, power failure

occurred during sale, or dispenser throws an error.

*Displayed after a dispenser throws an

error, or station or dispenser not ready for

sale.

How to Operate

H35 Series Operation Manual Back to TOC 10

3.2 ERROR MESSAGES

When an error message appears on the display, there is a fault condition in the dispenser. Two digits will

follow the error message to indicate the cause of the error. Refer to Section 5.11 Error Codes.

Recommended error message procedure:

1. Determine what caused the specific error.

2. Fix the issue.

3. Clear the error. To reset an error code, lift and lower the nozzle handle switch twice.

How to Operate

H35 Series Operation Manual Back to TOC 11

3.3 AC OFF MESSAGE

The AC OFF message will display during power interruption or disconnection. Depending on the display

configuration, the message will appear as shown in Figure 2.1.

If the power is OFF and the AC OFF message does not appear, the charge is low on the 12-volt battery.

Recharge or replace the battery. Failure to replace the battery could result in loss of dispenser electronic

totals and stand-alone operating data.

Figure 2.1. AC OFF Message

Sale $

Kilograms

AC

Off

Setup And Programming

H35 Series Operation Manual Back to TOC 12

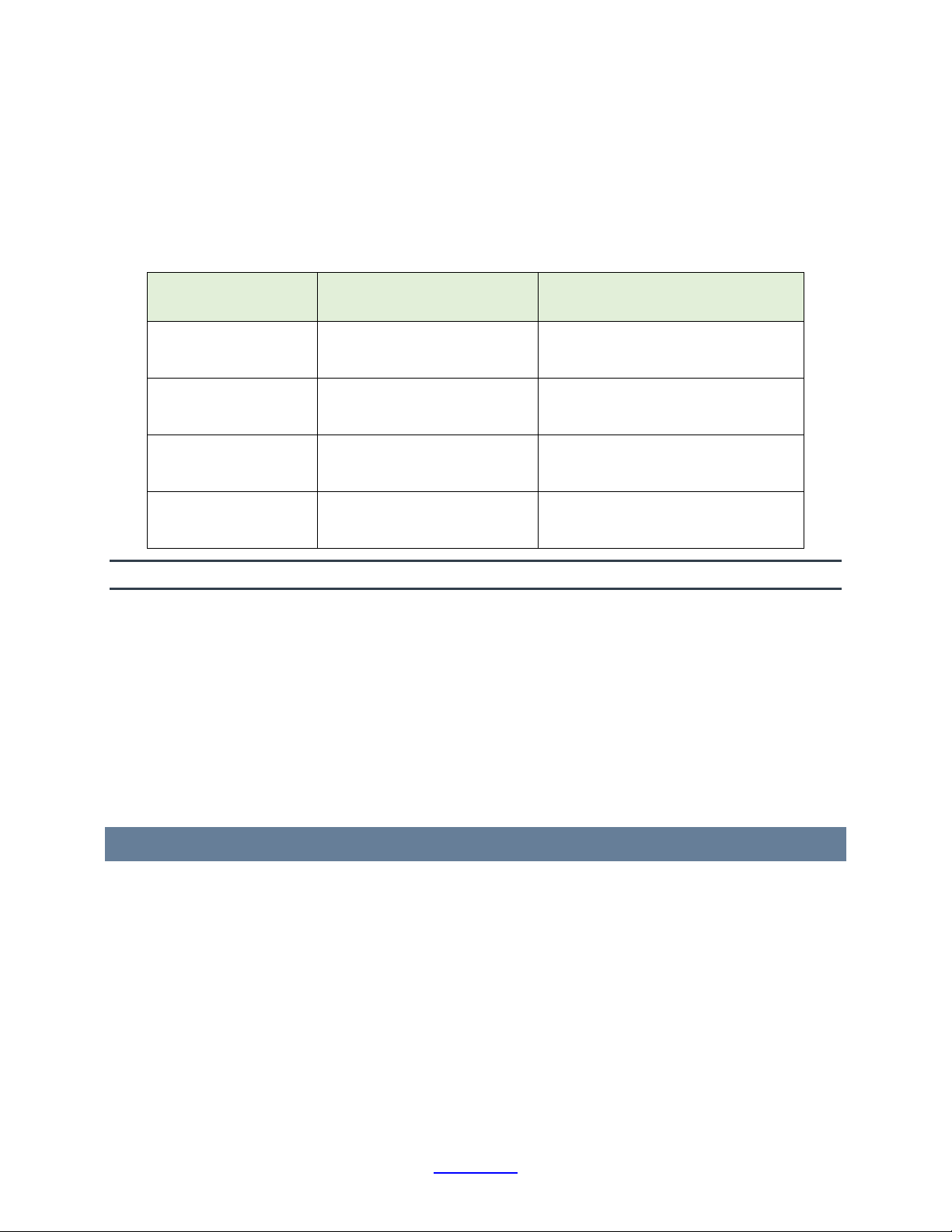

4SETUP AND PROGRAMMING

Menu Codes are accessed with the Manager’s Keypad. Menu Codes 0, 1, and 2 are diagnostic error

codes or totals. To access menu codes 4 - 99, follow the keypad sequence in Section 4.6 Manager’s

Access. In the menu code table below, Access Types are:

•Keypad Access: Data can be directly entered

•Passcode Access: The passcode is required, see Section 4.6 Manager’s Access

•Cal Switch: Setting the calibration switch is required, see Section 4.28 Menu Code 27

Menu

Code

Name Access

Type

Description

0

Diagnostics

Keypad

Diagnostic Tests

1

Hose Totals

Keypad

Displays money, mass, amounts of sales, and price changes.

2

Totalizer Totals

Keypad

Displays electronic totalizer totals only.

3

Manager Access

Keypad

Enter a four-digit access code to enter codes 4 and higher.

4

Pricing

Passcode

Set price per mass for each hose and one- or two-tier pricing.

5

Totalizer Value

Passcode

Enter a value for each electronic totalizer (mass total).

6

Programming

Passcode

Review and program the most common code settings.

7

Dispenser Type

Passcode

Set the number of sides and number of grades.

8

Decimal Location

Passcode

Change decimal placement for other than U.S. standard.

9

No Flow Time Out

Passcode

Set a time for the dispenser to turn off after flow stops.

11

Mass Allocation

Passcode

Control maximum mass of a single sale at one pump.

13

Beeper

Passcode

Set beeper tone options.

14

Price Display

Passcode

Set the way price displays operate.

15

Fleet Option

Passcode

Set the fleet system interface compatibility.

18

Money Totals

Passcode

Set the money totals calculation method.

21

Communication Type

Passcode

Set the dispenser in stand-alone or console modes.

22

Dispenser Address

Passcode

Set the dispenser address.

26

Shift Totals

Passcode

Reset shift totals.

27

Electronic Calibration

Cal Switch

Electronically calibrate the dispenser.

28

Rounding

Passcode

Set the sale amount to round or truncate.

29

Resettable Totals

Passcode

Enter a value for each meter on the dispenser (mass total).

30

Real Time Clock

Passcode

Set current time and date.

49

RAM Clear

Passcode

Reboots the system and clears

50

Pulse Output Config.

Passcode

Pulse output simulates a mechanical dispenser interface.

51

Nozzle Dryer

Passcode

Program the length of nozzle drying time.

66

Nozzle Time

Passcode

Sets nozzle timeout.

80

Valve Test

Passcode

Test the solenoid valves in the upper cabinet.

94

WM Timeout

Passcode

Set the Weights and Measures Timeout delay regulations.

99

View E-CAL

Passcode

View meter calibration and mass adjustment values.

Setup And Programming

H35 Series Operation Manual Back to TOC 13

4.1 BATTERY DISCONNECT BUTTON

To turn OFF the battery power after switching OFF the main power, wait 5 seconds, then press and hold

the battery disconnect button until the display is blank, see Figure 1.5.

4.2 DEFAULT SETTINGS

The software program for each new dispenser shipped from the factory is preprogrammed with default

settings in some of the Menu Codes. Some menu codes must be changed immediately to make the

dispenser operational, refer to Section 4.3 Initial Setup Sequence. The default listings are noted below:

Menu

Code

Name Default

3

Manager Access

2218

7

Dispenser Type

2 = Sides, 3 = Grades

8

Decimal Location

1 = U.S.A.

9

No Flow Time Out

--- = Infinite Time

11

Mass Allocation

0999 Mass Units

12

Pre-Charge Time

2 seconds

13

Beeper

3 = Combination of option 1 and 2 (Audio Tones)

14

Price Display

1 = Flashing, 0 = Blanks

15

Fleet Option

1 = Enabled

18

Money Totals

0 = Cash Drawer method

21

Communication Type

0 = Console Mode

22

Dispenser Address

0 = Only one dispenser on the communications loop

28

Rounding

1 = Rounding the Sale Amount

80

Cycle Valves

0 = Off

99

Unit of Measure

1 = Kilograms, 1 – Decimal position 3 places

Setup And Programming

H35 Series Operation Manual Back to TOC 14

4.3 INITIAL SETUP SEQUENCE

To program the dispenser’s memory for the first time or following a RAM memory clear, follow the

menu codes in the order listed in the “Initial Setup Sequence” table below. Verify the menu codes are

programmed before testing any dispenser operations.

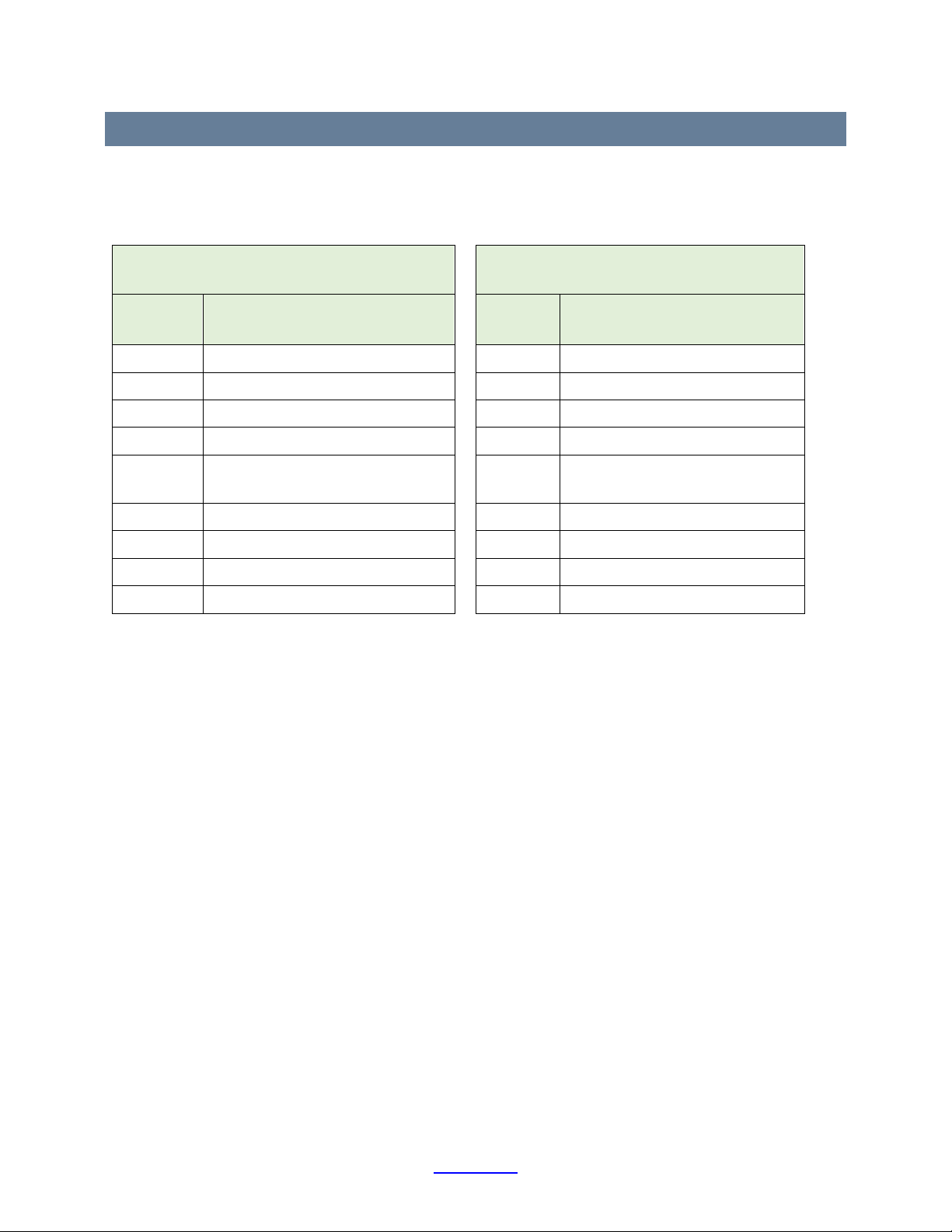

Initial Setup Sequence – Required Remaining Setup - Recommended

Menu

Code

Name Menu

Code

Name

3

Managers Access

5

Totalizer Value

7

Dispenser Type

8

Decimal Location

4

Pricing

12

Pre-Charge Time

9

No Flow Time Out

14

Price Display

11 Mass Allocation 15 Fleet Option

21

Communication Type

18

Money Totals

22

Dispenser Address

26

Shift Totals

28

Rounding

29

Resettable Totals

99

Unit of Measurement

30

Real Time Clock

Setup And Programming

H35 Series Operation Manual Back to TOC 15

4.4 DISPENSER DISPLAY

This manual uses two methods to describe the dispenser displays and what they will show when using

the Manager’s Keypad to access menu codes or modes. One method is a graphic, shown below to the

right, and the second method is a table, below. The upper graphic Sale and Kilograms represent the

upper display. The lower part of the graphic represents the lower PPM display. The table headers

describe the columns representation.

Keypad

Action

Main Display Results

Lower PPM Display

Results

Description

Plug in the

Keypad

EntEr

SidE 1 PC4P Select desired

programming side.

Enter COdE

00 SidE 1 Managers Access Ready

3, Mode PASS CodE 3 Password Ready

2218, Enter PASS CodE - - 3 Password Accepted

Cancel COdE

00 SidE - - 1 Exit

COdE

00

--1

Sale $

Kilograms

sidE

Setup And Programming

H35 Series Operation Manual Back to TOC 16

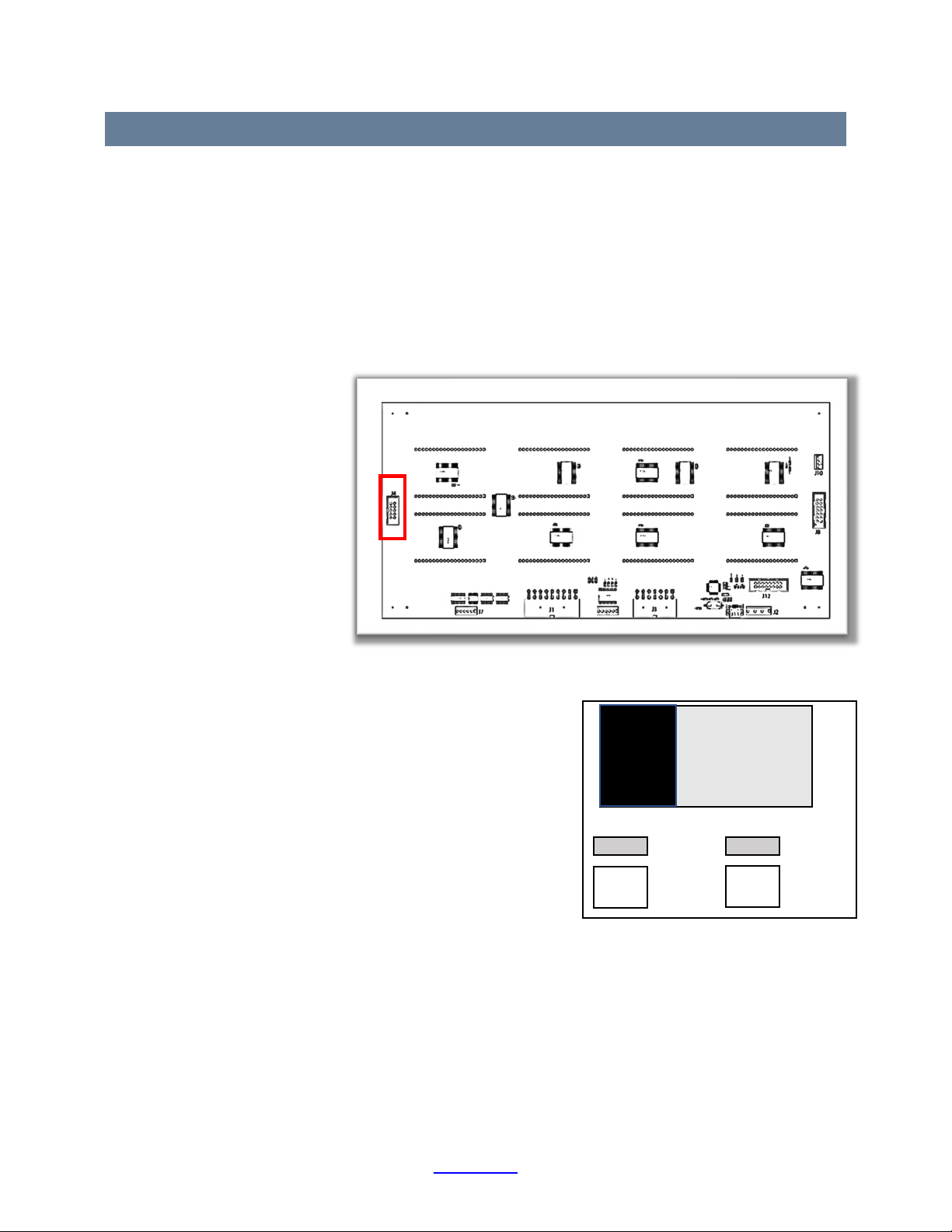

4.5 MANAGER’S KEYPAD OPERATION

To enable the dispenser for setup and programming, follow this procedure:

1. Hang up all nozzles in their boots. If any nozzle is not hung up, the dispenser will beep and not

enter manager mode.

2. Unlock and open the upper door of side one. Side one has louvered doors at the top of the

dispenser on the outside. On the inside, side one has the serial number tag on the left side, at

eye level.

3. The keypad receptacle is located on the Price Per Mass Board (J4), which is located on the lower

back of the side one

door, see Figures 1.6.

See Figure 3.1. for

keypad receptacle

location.

NOTE: Connecting the keypad

to the side two P.P.V.

Display Board will not

provide access to Menu

Codes.

4. Plug the keypad into

the receptacle.

5. After connecting the

keypad, the dispenser

will automatically enter the managers programming

mode. “Enter side 1” will be on the dispenser’s side 1

display. The side 2 screen will display “OFFLINE”.

6. On the keypad, press Enter to access Manager’s Mode.

The display appears as shown in Figure 3.2.

7. See Section 4.6 Manager’s Access. To program a specific

Menu Code, refer to the Table of Contents for the page

location.

8. When the programming session is complete disconnect

the keypad from the receptacle, return to storage.

9. The dispenser will automatically enter the operating

mode.

Figure 3.2. Manager’s Mode

Figure 3.1. Keypad Receptacle (Red Rectangle) on the Price Per Mass Board.

Sale $

Kilograms

COdE

00

SidE

--1

Setup And Programming

H35 Series Operation Manual Back to TOC 17

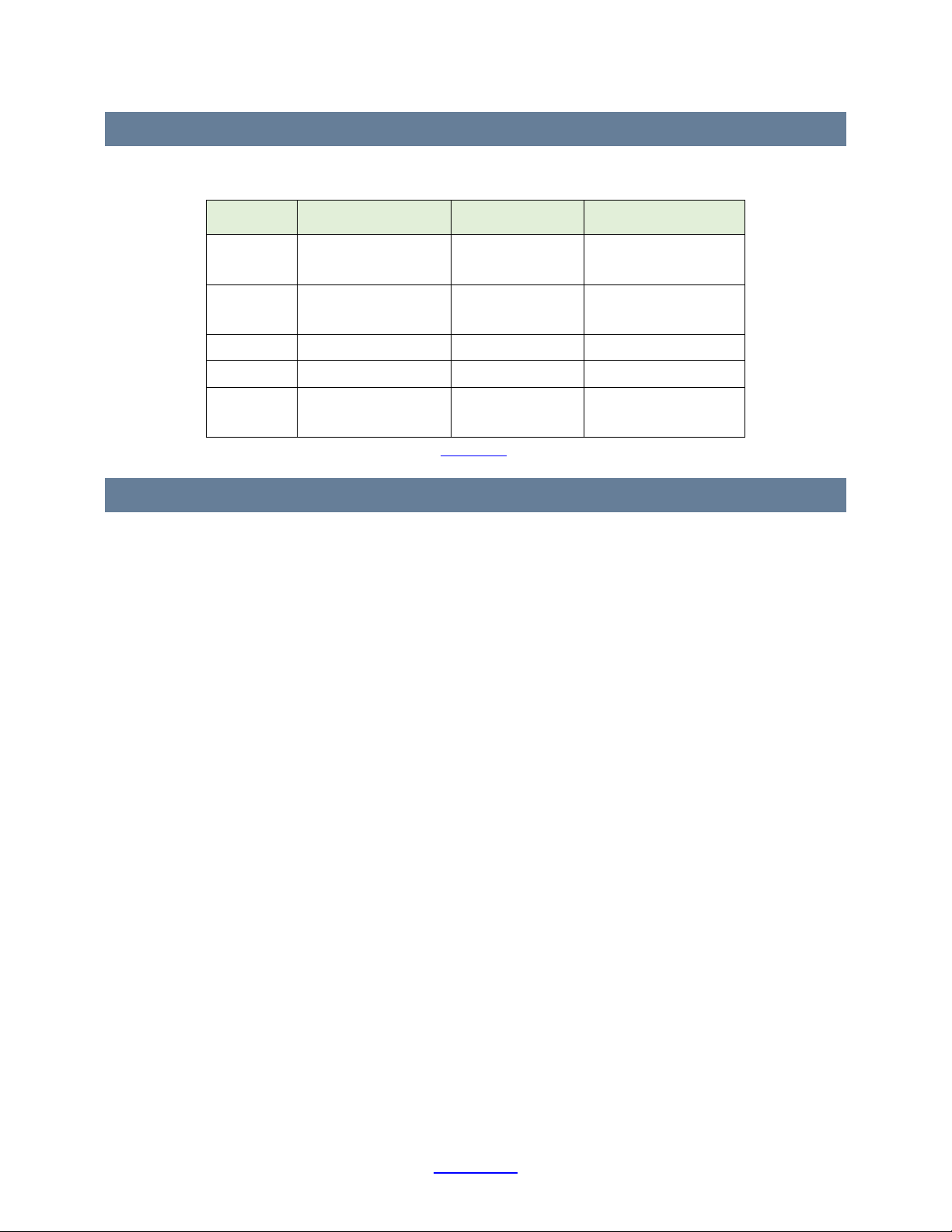

4.6 MANAGER’S ACCESS

The following keypad sequence is necessary to get access to any code that is three (3) or higher:

Keypad

Action

Main Display Results

Lower PPM Display

Results

Description

Plug in the

Keypad

EntEr

SidE 1 PC4P Select desired

programming side.

Enter COdE

00 SidE 1 Managers Access Ready

3, Mode PASS CodE 3 Password Ready

2218, Enter PASS CodE - - 3 Password Accepted

Cancel COdE

00 SidE - - 1 Exit

Table key.

4.7 SELECT THE DISPENSER DISPLAY TYPE

Upon receiving a new dispenser, the display should be factory pre-programmed and working as

expected. If the 819 Control Board has been replaced or the memory has been erased, the main display

may show distorted text. In this case follow this procedure:

1. Plug in the Manager’s Keypad

2. Press +/-five times. Each five or so cycles will change the display.

3. Stop cycling when appears on the main display.

4. Confirm that the main display and the price displays show real numbers and real letters.

EntEr

SidE l

Other manuals for H35 Series

2

Table of contents

Other Bennett Marine Equipment manuals

Bennett

Bennett BOLT Rocker BRC4000 User manual

Bennett

Bennett BOLT Control BCI8000 User manual

Bennett

Bennett H35 Series User manual

Bennett

Bennett SITE MASTER EMV User manual

Bennett

Bennett LNG Series User manual

Bennett

Bennett 621 User manual

Bennett

Bennett H35 Series User manual

Bennett

Bennett HIGH FLOW H35 User manual