Selden Furlex 104S Guide

1

Manual and Spare parts list

Furlex

104S

597-133-E

2015-11-12

104S

2

Contents

Page

1 Introduction 3

1.2 What’s included? 4

1.3 Main dimensions 4

1.4 Safety precautions 5

1.5 Sail information 6

2 Assembly preparations 7

2.2 Mast and deck attachment 7

2.3 Wire length calculation 8

2.4 Top extrusions - length calculation 9

3 Assembly 11

3.1 Luff assembly 11

3.2 Fitting Sta-lok eye terminal 13

3.3 Fitting eye terminal to swaged 15

stud (Stud/Eye)

4 Installation 17

4.1 Mast attachment 17

4.2 Deck attachment 18

4.3 Installation on a stepped mast 19

4.4 Installation on an un-stepped mast 19

4.5 Furling line installation 19

4.6 Adjusting the forestay length 21

4.7 Checklist 22

5 Operation 23

5.1 Hoisting 23

5.2 Unfurling the sail 24

5.3 Furling the sail 24

5.4 Reeng 25

5.5 Racing 25

6 Maintenance 26

6.1 Inspection 26

6.2 Service 26

6.3 Storage 26

6.4 Dismantling 27

6.5 Troubleshooting 31

6.6 Spares & Accessories 33

6.7 Toggles & links 37

7 Warranty 38

3

1 Introduction

1.1 Key features

Congratulations on the purchase of your new Furlex jib furling system. Furlex jib furlers have been engineered

and manufactured by Seldén Mast since 1983. The system has been continuously developed over the years and

we are now launching the fourth generation Furlex, the most sophisticated single line jib furling system so far.

Maximized luff length

The luff extrusion foil shape remains unchanged all the way down the furling unit. This allows the whole sail

to be furled in an even roll - right down to the tack of the sail. This is essential to acheive an efcient sail shape

when the sail is reefed.

Load distributors

The patented load distribution technology of the Furlex system distributes loads over the entire ball race. This

reduces friction, provides smoother furling and considerably reduces bearing wear.

Compact halyard swivel

The all new halyard swivel design uses an HMPE textile loop that allows the halyard load to act in the centre of

the swivel instead of pulling on an offset eye. This reduces bearing loads and minimizes any wobbling tenden-

cies.

Low torque tack ring

The tack ring ”free turn” allows for the luff to be furled one turn before the tack. This makes for a atter and

more efcient sail shape when the sail is reefed. Reduced tack ring diameter in combination with a low prole

shackle – or an optional soft shackle – reduces the amount of effort needed to furl in that rst turn signicantly

compared to earlier models.

Soft shackle ready

The tack ring is prepared for using a textile loop instead of a stainless steel shackle. All surfaces are smooth and

nicely rounded.

Aero grooves

Similar to the dimples on a golf ball, the Furlex AERO groove system reduces drag and creates better

aero dynamic ow around the luff extrusion.

Third bearing

By the addition of a third roller bearing between the main ball bearings of the drum unit, the load from the

furling line is distributed over a large bearing area, reducing furling friction even further compared to earlier

models.

Floating connectors

The 316 stainless steel connectors are subjected to vertical loads only and no torsional loads.

Torsional loads are now taken by the join pieces alone which leaves the connectors “oating” inside the join

thus reducing wear inside the joins.

Air gaps

Every join in the system is made with a nominal gap which means the extrusion ends will never get in contact

with each other. This way there will be minimum chafe and no aluminum deposits staining on your new sail.

Mobile swivels

Both the halyard swivel and the drum unit can be easily removed from the foil for off-season storage. This

facilitates storing the foil with the mast and makes handling easier.

4

TED

TET

DD

DW DH

HO

Basic pack / Extended pack Foil pack Wire pack / Eye pack

• Drum unit

• Halyard swivel

• Furling rope

• Bearing halves

• Top guard

• Sail feeder

• Manual

Extended pack also includes:

• Halyard leads

• Stanchion blocks

• Prefeeder pack

• Torx bit set

• Luff extrusions

• Distance tubes

• Joining sleeves

• Connecting plates

• Wire with swaged eye

• Eye terminal (with or

without rigging screw)

Basic pack / Extended pack

The Furlex system consists of a basic pack with drum unit, halyard swivel, sail feeder, bearing halves, top guard

and furling rope. The Extended pack also includes halyard leads, stanchion blocks and prefeeder pack -

accessories that will make your system work even better on your boat.

Foil pack, wire pack and eye pack

The Furlex system also includes a foil pack with luff extrusions, distance tubes and connectors. A complete

forestay is also supplied with every Furlex, including a swaged stud/eye solution (no adjuster) or a Sta-Lok eye

terminal tting which may come with or without rigging screw. On new boats delivered with a complete new

Seldén rig, the forestay is usually included in the standing rigging and does not come as a separate wire pack.

1.2 What’s included?

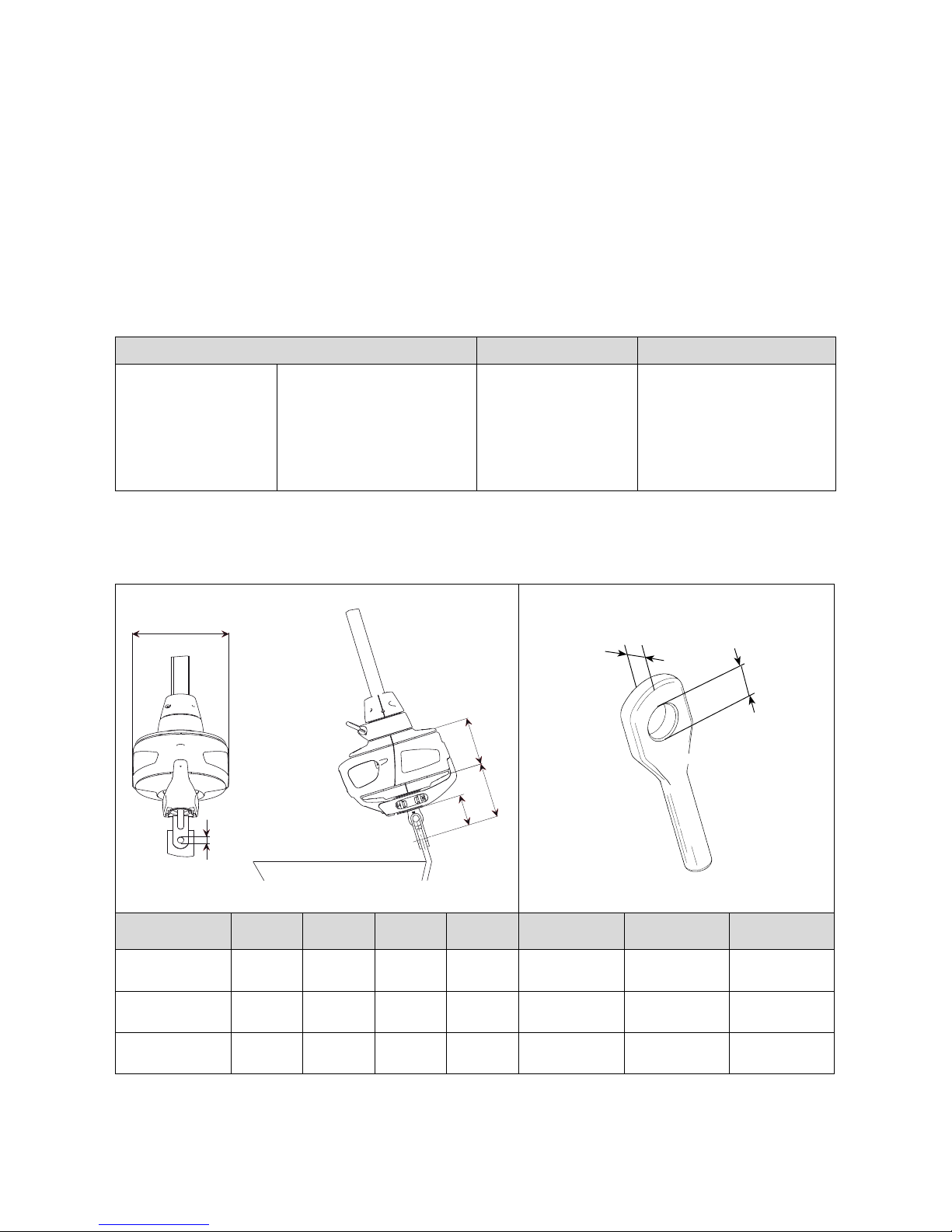

All dimensions are given in millimeters and inches.

1.3 Main dimensions

Pin

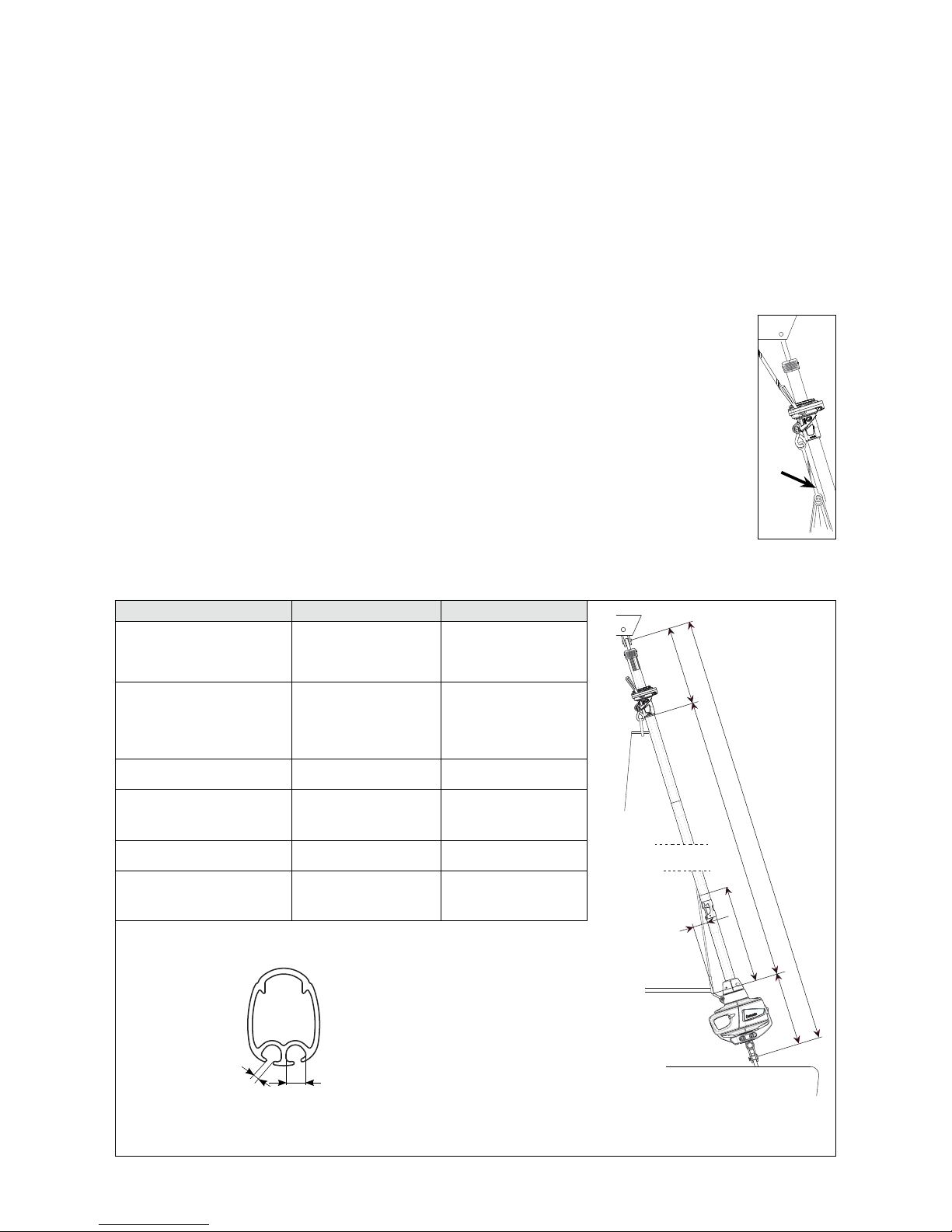

Wire dim. DD DH DW HO Pin TED TET

Ø4

(5/32”)

Ø155

(6 7/64”)

85

(3 11/32”)

65

(2 9/16”)

40

(1 37/64”)

Ø8

(5/16”)

Ø8.5

(21/64”)

4.5

(11/64”)

Ø5

(13/64”)

Ø155

(6 7/64”)

90

(3 35/64”)

65

(2 9/16”)

45

(1 49/64”)

Ø10

(25/64”)

Ø10.5

(13/32”)

5.3

(13/64”)

Ø6

(15/64”)

Ø155

(6 7/64”)

100

(3 15/16”)

65

(2 9/16”)

55

(2 11/64”)

Ø10

(25/64”)

Ø12.5

(31/64”)

7.0

(9/32”)

Fig. 1.3.b

Fig. 1.3.a

Pin

5

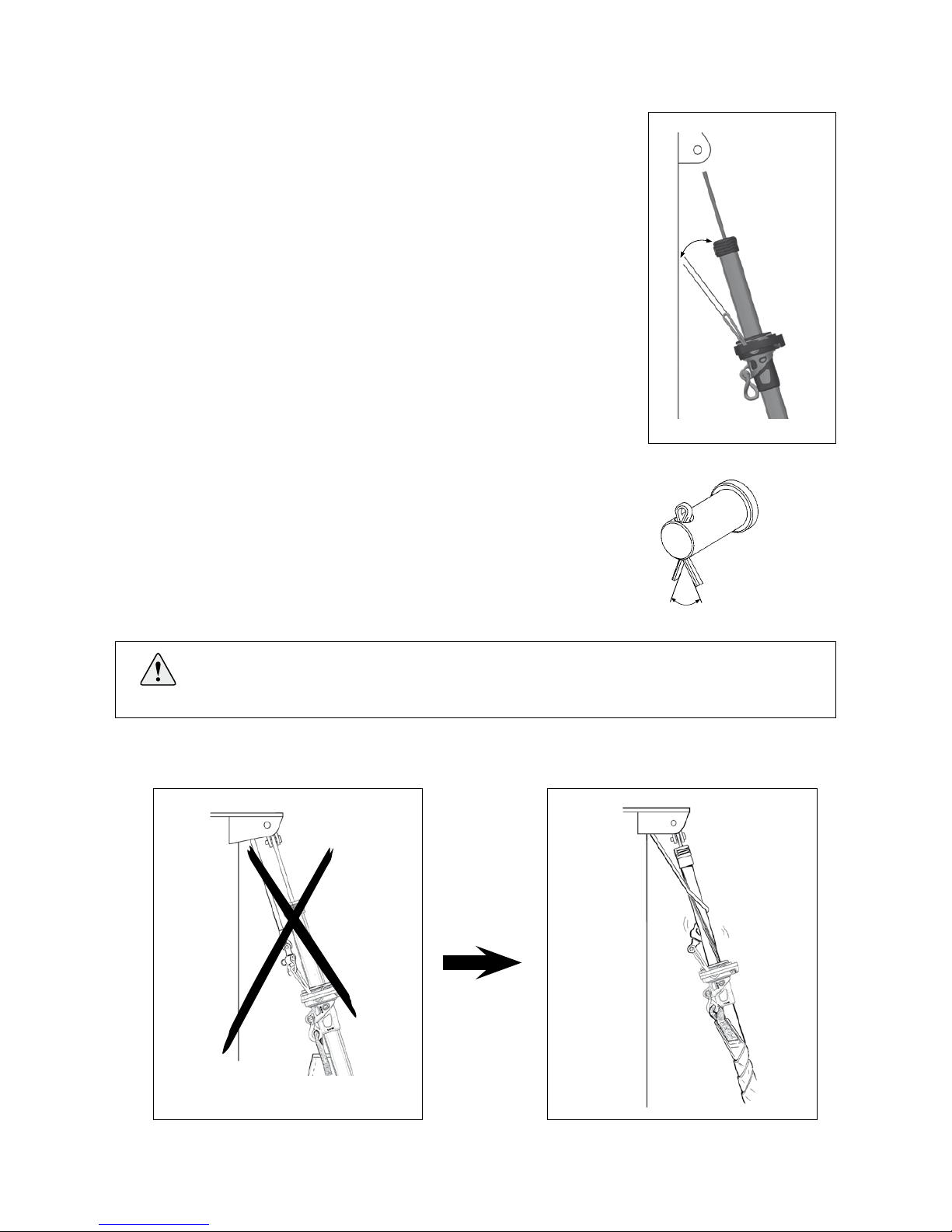

15-20°

The information in this manual must be followed carefully to avoid damage

to the system and to aviod the risk of personal injury. The warranty is only

valid if the system is assembled and operated according to this manual.

Please read the entire manual before assembly!

• Be very careful when you open the wire coil! It may spring open and

cause damage and/or personal injury.

• Never use a snap shackle to secure the standing rigging, not even tempo-

rarily. When installing the system on a rigged boat, always use a strong

screw pin shackle or tie the spinnaker halyard to a strong point on the boat

before removing the existing forestay.

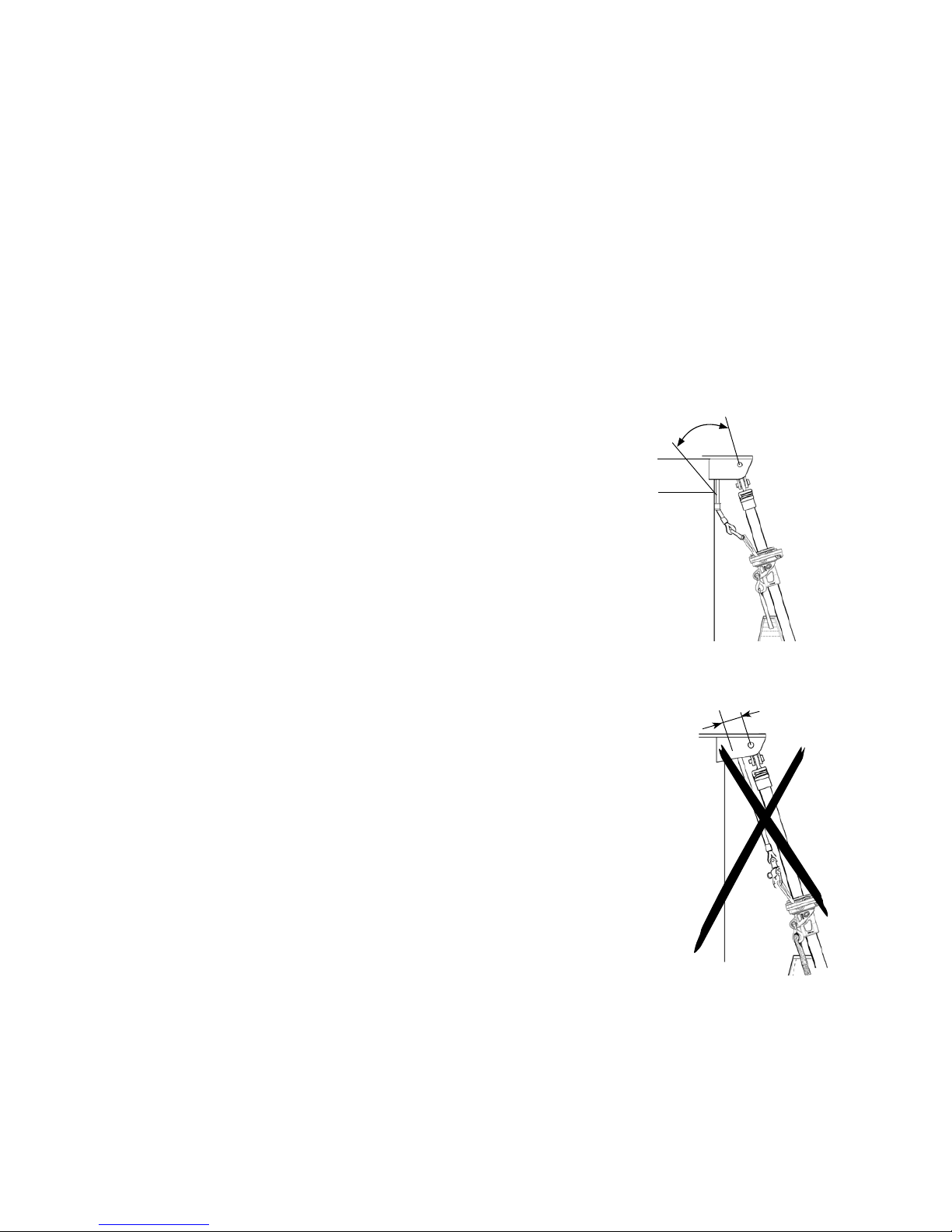

• Incorrect halyard routing can result in ”halyard wrap” which may cause

severe damage to the forestay, and put the entire rig at risk. The angle

between the halyard and the forestay must never be less than 15°. In-

correct halyard routing can also cause the halyard shackle to wear against

the luff extrusion.

• If using a winch for the furling line, rst check that there is no obstruction

which may interrupt the furling operation and possibly cause damage.

• Take care to ensure that all split pins are secured properly after installa-

tion.

1.4 Safety precautions

Fig. 1.3.cFig. 1.3.b

Fig. 1.3.d

Fig. 1.3.a

May lead to

Incorrect halyard routing can result in ”halyard wrap” which may cause severe damage to

the forestay, and put the entire rig at risk. The angle between the halyard and the forestay

must never be less than 15°!

6

FL

1100 mm

CB

E

F

Furlex type Ø4 & 5 Ø6

Head deduction F 440 (17 21/64”) 440 (17 21/64”)

Tack deduction E

(Any additional toggle or link

must be added to E) 205 (8 5/64”) 220 (8 21/32”)

Cutback CB 60 (2 23/64”) 60 (2 23/64”)

Internal diameter of luff groove

DLG Ø6 (15/64”) Ø6 (15/64”)

Width of luff groove WLG 2.75 (7/64”) 2.75 (7/64”)

Overall luff extrusion

dimensions

30x20

(1 3/16” x 25/32”)

30x20

(1 3/16” x 25/32”)

Your sailmaker has all the necessary sailmaker information through the Seldén Sailmakers guide. The

Sailmakers guide can be downloaded from www.seldenmast.com

Note that if you want to use an existing sail, it will need some modications.

• The luff length needs to be adjusted.

• A luff tape is required. The luff tape must be compatible with the Furlex luff extrusion geometry.

• Use webbing loops at the sail head and tack instead of grommets (cringles). The sail will then form tightly

round the luff extrusion when furling, and achieve a better shape when reefed.

1.5 Sail information

Fig. 1.5.a

Fig. 1.5.c

It is most important that the halyard swivel is located so that the halyard satises the 15–20°

angle requirement. If the sail prevents the swivel from reaching the

correct position, the luff length needs to be adjusted.

IF THE SAIL IS TOO LONG: Shorten the sail, e.g. in conjunction with changing to a luff

tape compatible with Furlex.

IF THE SAIL IS TOO SHORT: Lengthen the sail by means of a HMPE or wire pendant

tted to the head of the sail. Attach the pendant directly to the sail to prevent unintentional

removal, loss or exchange.

Fig. 1.5.b

Luff groove

Luff tape

chamber

Max sailspace FL -(F+E)

7

2 Assembly preparations

2.1. Tools

2.2 Mast and deck attachment

Before starting with the assembly, make sure you have the following tools available:

• Socket screw driver

• Hack saw

• Torx bits

• Measuring tape

• Knife

• Hammer

• Pencil

If Sta-lok is to be tted you will also need:

• Two adjustable spanners

• Polygrip

• Tape

• File

• Locking adhesive (included in the eye tting pack)

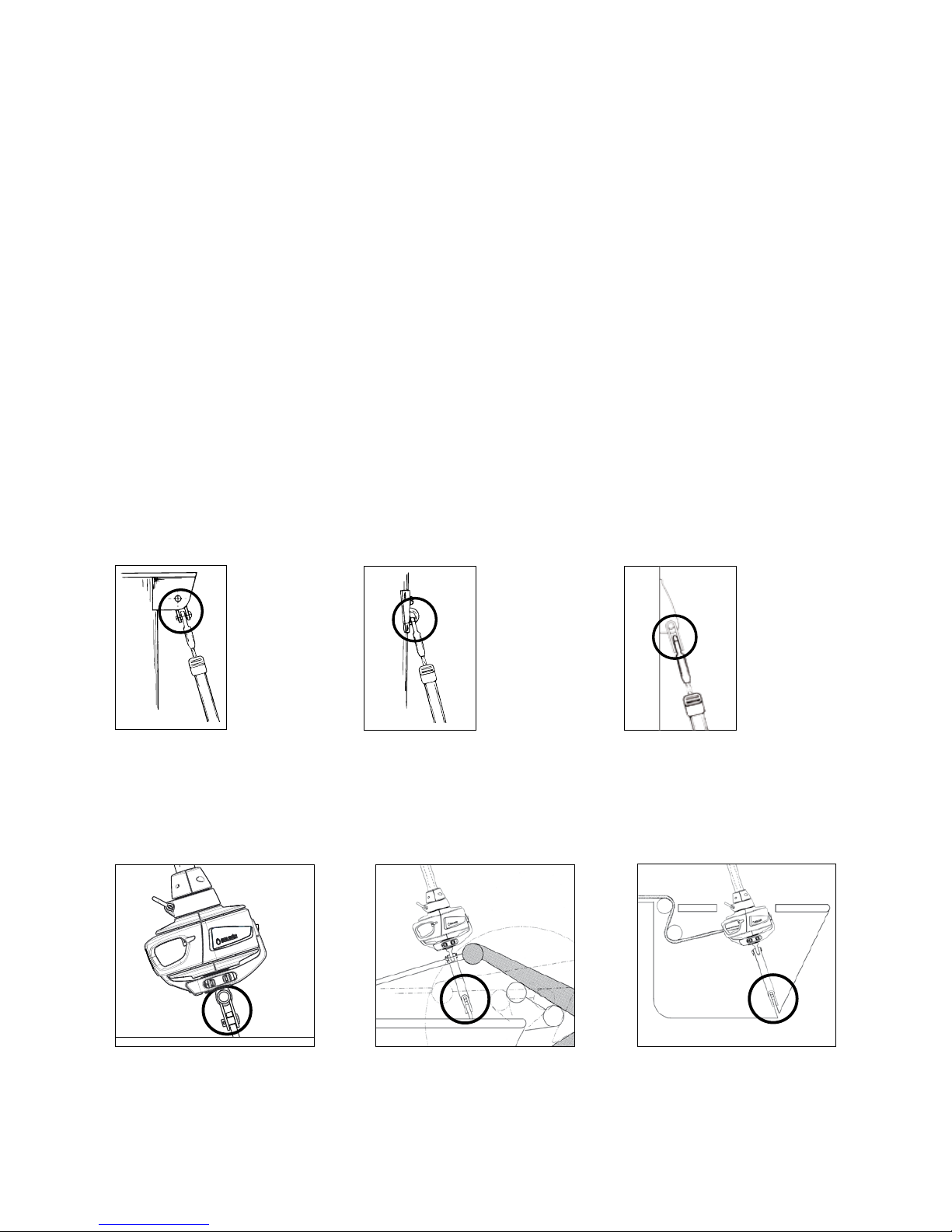

Always make sure that the forestay can articulate in all directions, both in the top and at deck level. Toggles

must be used in most cases to ensure sufcient articulation.

The toggle on the furling unit should always be tted directly to the chain plate. If the unit is to be tted below

deck or if it needs to be raised, an extension toggle can be used but always make sure that the toggle that

comes with the drum unit is attached to the chain plate.

For available toggles and extension links, see “Spares and accessories”.

Fig. 2.2.a

Fig. 2.2.d Fig. 2.2.e Fig. 2.2.f

Fig. 2.2.b Fig. 2.2.c

8

2.3 Wire length calculation

1. Slacken the backstay and/or the cap shrouds as much as possible, but make sure that no rigging screws are

unscrewed so far that the threads are no longer visible ”on the inside” of the rigging screw body. The

forestay setting should not be adjusted. Ideally the forestay setting should not be adjusted. However, if there

is insufcient adjustment in the backstay, and the forestay has a rigging screw, this can be adjusted as well.

Just make sure to mark the thread with tape before adjusting.

2. Pull the top of the mast forward using the genoa or spinnaker halyard. Secure the halyard using a ”D”

shackle or tie the halyard to a strong deck tting. For safety reasons, do not use any halyard snap shackles.

Secure the halyard tail after the halyard has been tensioned.

3. Go up the mast. Connect a free halyard to the forestay. Then detach the forestay and lower it using the free

halyard. Bring the stay down and place it on a at surface. If the forestay rigging screw was slackened,

adjust it back to the tape mark.

4. Measure the forestay length (FL) with just enough tension to keep the forestay straight on the ground.

Forestay length (FL) is the distance between the hole in the swaged top terminal and the hole in whatever

lower part that was attached directly to the hole in the chain plate. Enter the measurement into

”Table 1” below, in the row marked FL.

If a Sta-lok terminal (with or without rigging screw) is included, the wire is supplied over-length. The wire has

a swaged eye terminal on one end while the other end is open (= without terminal). If your Furlex is supplied

with a xed-length forestay, with a swaged eye on one end and a swaged stud in the other end, skip this part

and go directly to 2.4.

If a stud-terminated stay is to be manufactured by a local rigger it is important to note that WL in this case

equals the length of the nished stay, from eye to end of stud, as shown in g. 2.4.a. WL is calculated in table 1.

Before assembly, an over-length wire (for Stalok) must be marked and nally cut to the correct length to t the

boat’s actual forestay length. To nd out the correct measurement, follow the steps below. If the mast is not

stepped, you can jump directly to step 4.

You can use the FURLEX CALCULATOR on our web site. Go directly to the calculator by

scanning the QR-code with your mobile device or visit www.seldenmast.com.

Table 1: Calculation of forestay wire cutting length Your

forestay

Example

(104S/Ø5)

with rigging screw

50% extended

FL Existing forestay length (FL), including rigging screw (See g. 2.4.a) 10 000

TDeduction for lower terminal - - 150

HIf links or extra toggles are to be used, deduct this length (H) from FL.

(See table 6.7).

- - 0

WL Cutting measurement. The new forestay wire is to be marked at this point.

(For stays with swaged stud, WL equals the length of the nished stay as

shown in g 2.4.a. and NOT the cutting length)

= = 9850

WIRE Without rigging screw: With rigging screw:

104S Ø4 mm wire: 60 mm (2 23/64”)

Ø5 mm wire: 65 mm (2 9/16”)

Ø6 mm wire: 75 mm (2 61/64”)

Ø4 mm wire: 147 mm (5 25/32”)

Ø5 mm wire: 150 mm (5 29/32”)

Ø6 mm wire: 155 mm (6 7/64”)

9

A

E

200

CB

D

WL T

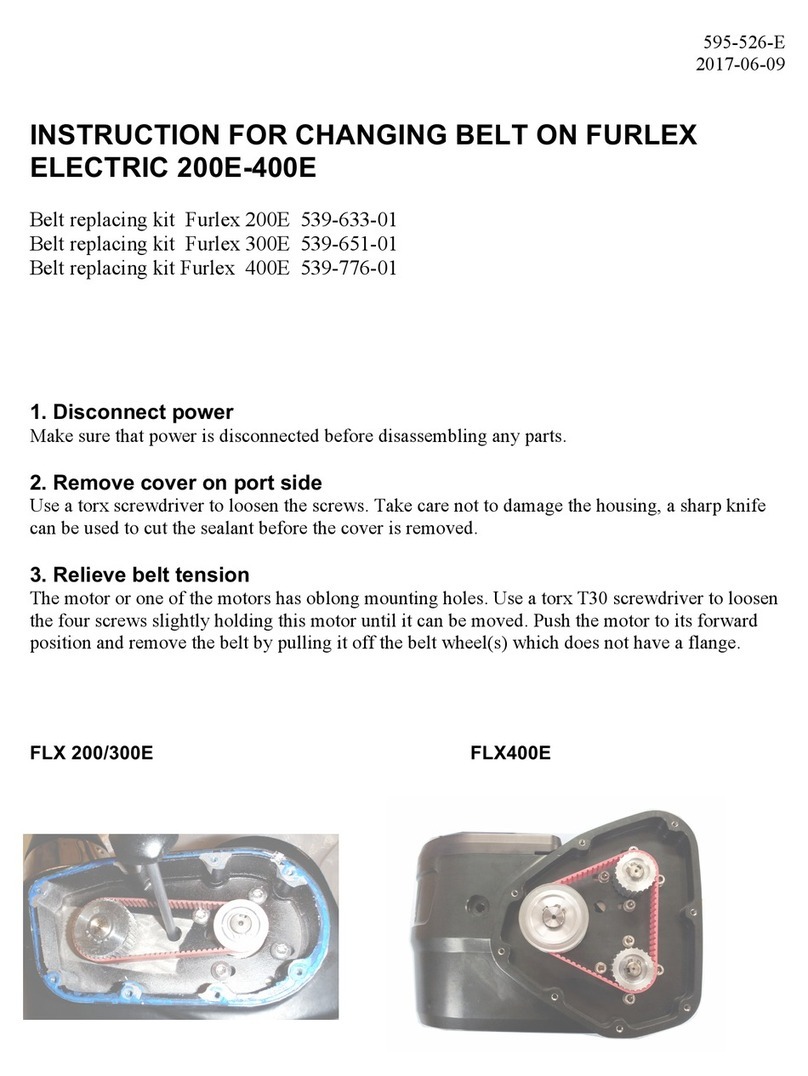

2.4 Top extrusions - length calculation

The Furlex luff extrusion consists of a number of shorter pieces. Starting from the bottom there is a 1000 mm

luff extrusion connected to the drum unit and extending up to the sail feeder. Then, from the sail feeder and up

there are a number of full length luff extrusions (L=2400 mm) and nally there is a top extrusion that has to be

cut to length to suite the actual forestay length.

Note! If the calculation gives a top extrusion length (D) that is shorter than 400 mm, the

calculation must be reworked by exchanging one of the 2400 mm (94 1/2”) extrusions with

the uncut 2000 mm (78 47/64”) top extrusion. By doing so the top extrusion will be cut from

a 2400 mm length and its length will then exceed 400 mm (15 3/4”). If the calculation gives

a top extrusion length (D) that exceedes 2000 mm (78 47/64), the top extrusion must be cut

from one of the 2400 mm (94 1/2”) extrusions. In this case the 2000 mm (78 47/64) extrusion

will not be used.

Fig. 2.4.a

FL = existing forestay length

10

To nd out the cutting length of the top extrusion (D) and the length of the top distance tube

(E), start with the length of the forestay wire (WL) that was calculated in table 1. Then

follow the steps in table 2 below. On xed length forestays, verify WL by measuring the

stay length from centre of eye to end of stud (wire).

You can also use the FURLEX CALCULATOR on our web site. Go directly to the

calculator by scanning the QR-code with your mobile device.

Table 2: Calculation of top luff extrusion length and top distance tube length Your forestay

Example

(104S/Ø5)

with rigging screw

50% extended

WL Length of the new forestay wire (as per Table 1). 9850

A+B 1190

NNumber of full length extrusions to be used:

N = ( WL - (A+B) ) / 2400 (94 1/2”)

(9850-1190)

/2400=3.6

N=3

CTotal length of the number of full length extrusions (2400 mm) to be used:

C = N x 2400 (94 1/2”)

3 x 2400 =

7200

D* Length of top luff extrusion:

D = WL – (A+B) – C

9850-1190

-7200 = 1460

E* Length of the top distance tube:

E=D-200 (7 7/8”)

1460-200 =

1260

WIRE Without rigging screw: With rigging screw:

104S Ø4 mm wire: 1260 mm (49 39/64”)

Ø5 mm wire: 1275 mm (50 13/64”)

Ø6 mm wire: 1290 mm (50 25/32”)

Ø4 mm wire: 1175 mm (46 17/64”)

Ø5 mm wire: 1190 mm (46 27/32”)

Ø6 mm wire: 1210 mm (47 41/64”)

*) If D becomes less than 400 mm it is necessary to recalculate as below and cut one of the full length luff

extrusions according to Dnew and one of the full length distance tubes according to Enew.

Note that the original top luff extrusion and the original top distance tube will now be used as intermediate

extrusions.

Table 2B: Recalculation if D<400 mm Your forestay Example

Nnew Reduce the number of full length extrusions by one.

Nnew = N-1

Cnew Cnew = Nnew x 2400 + 2000 (94 1/2” + 78 47/64”)

Dnew Dnew = D + 400 (15 3/4”)

Enew Enew = E + 400 (15 3/4”)

11

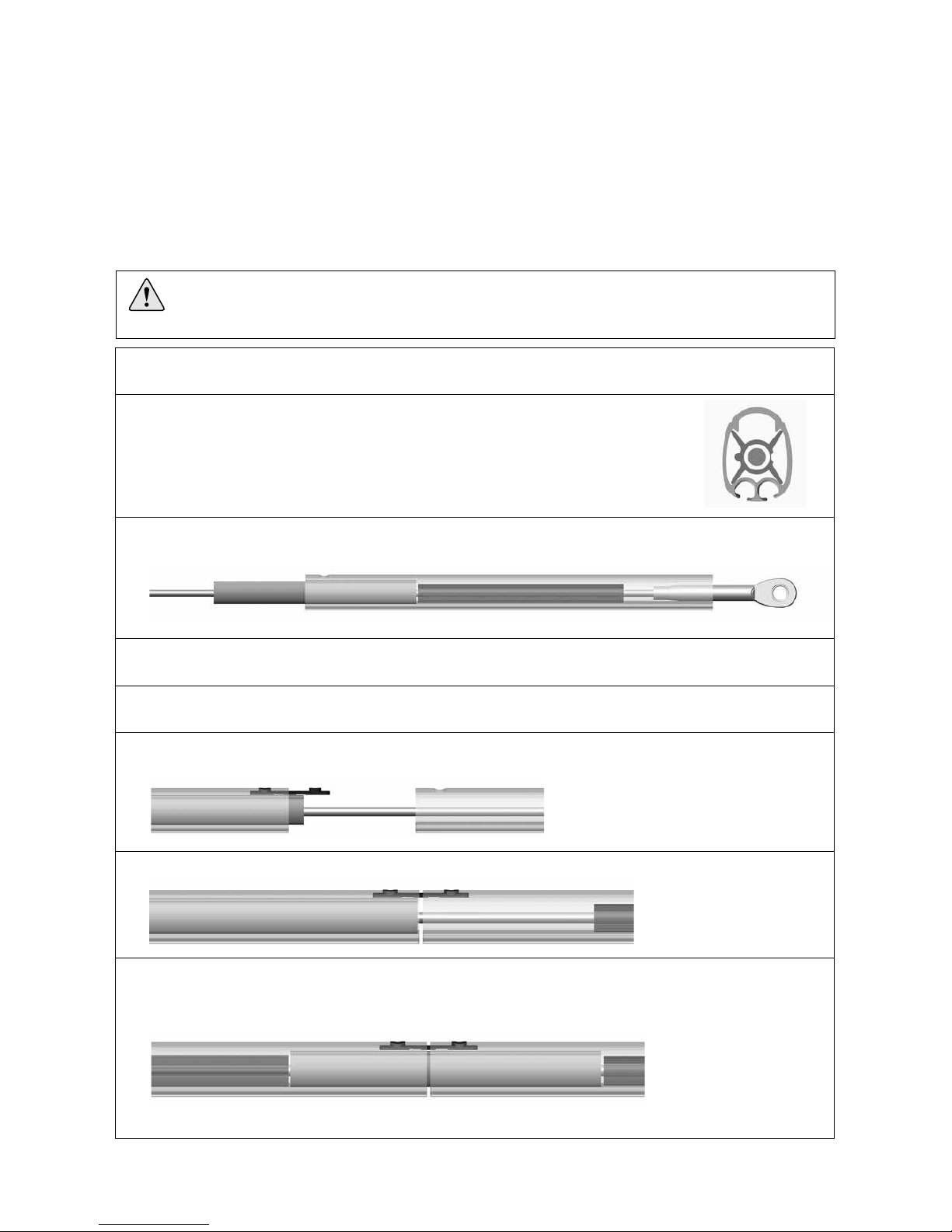

1. Stretch out the wire on a at, clean surface. On stays with swaged lower terminal, be careful not to

damage the terminal thread. The thread can be protected with tape or similar.

2. Start by feeding the top luff extrusion and the top distance tube onto the forestay wire.

The distance tubes are welded shut but are easily opened by hand. Note the correct

orientation of the distance tube - hinge to be sideways.

3. Add a short joining sleeve and use it to push the distance tube up into the top luff extrusion. The

distance tube should be pushed in approximately half the length of a joining sleeve.

4. On Sta-lok terminated systems, the halyard swivel and the top guard can be tted at this point, see

below. On stud terminated systems, the top guard must be tted after the sail feeder has been mounted.

5. Add another luff extrusion and another distance tube. Make sure the distance tube is oriented correctly. Also

add another short joining sleeve.

6. Fit a short connecting plate into the second luff extrusion as shown. Push the rst joining sleeve down

into the second luff extrusion to lock the connector.

7. Connect the two luff extrusions.

8. Push the rst joining sleeve back up into the rst luff extrusion to lock the join. Use the second joining

sleeve to push on the second distance tube. The second distance tube should be pushed in approximately

half the length of a joining sleeve. This will ensure correct location of the rst joining sleeve.

3 Assembly

3.1 Luff assembly

Luff assembly should be carried out on a clean, at surface. Make sure there is enough space for the entire

forestay length to be stretched out.

At this point the top luff section and the top distance tube should be cut to length according to table 2.

Notethattheluffextrusionsarettedontothewire,whereasonoldersystemsthewirewas

ttedasalaststep.Alsonotethattheluffisassembledfromtopdownasopposedtoolder

systems.

Fig. 3.1.a

Fig. 3.1.c

Fig. 3.1.d

Fig. 3.1.e

Fig. 3.1.b

12

9. Repeat for the remaining 2400 mm (94 1/2”) luff extrusions. Use short joining sleeves only.

10. Fit the long joining sleeve onto the wire. Then t the short distance tube and nally the short 1000 mm

(39 3/4”) luff extrusion. Make sure that the small hole end goes rst.

11. Connect the same way as previous joins but use the long connector this time. Push the short distance

tube in approximately 40 mm (1 37/64”), leaving space for the bearing plug halves, see below.

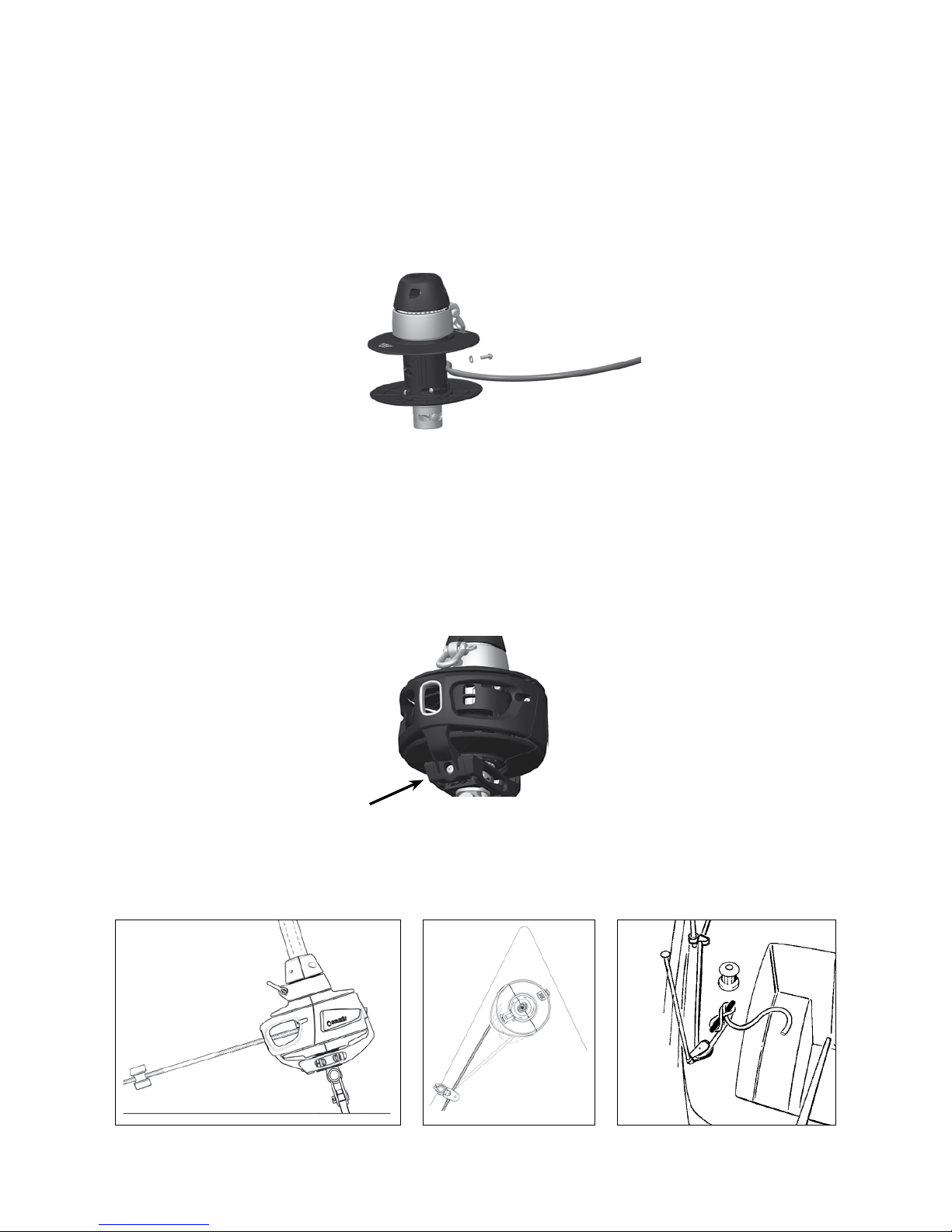

12. Snap on the sail feeder connector and put the sail feeder in position.

13. Fit the halyard swivel from the top and slide it down until it stops on top of the sail feeder. Then t

the top guard and push it into the top luff extrusion until it stops. Secure it with the two pre-tted

screws. Tighten the screws until they bottom, but do not over-tighten.

14. Fit the bearing plug halves as shown. Adjust so that the hole in the forward bearing plug aligns with the

forward hole in the 1000 mm (39 3/4”) luff extrusion.

This completes the luff assembly. Next step is to t the lower eye teminal to the stay. There are two types of eye

terminals; Stud/Eye terminal and Stalok eye terminal (with or without rigging screw).

Fig. 3.1.g

Fig. 3.1.h

Fig. 3.1.i

Fig. 3.1.f

13

2 mm

WL

1.

Before cutting the wire, measure the wire from the centre of the hole in the top swaged eye terminal. Mark the

measurement WL carefully on the wire using a marker pen. (The WL measurement was calculated in ”Table

1”, (Chapter 2.3).

2. Put adhesive tape around the wire on both sides of the cutting mark to assist cutting.

3 .

Unscrew the socket, wedge and former from the terminal part (or Furlex rigging screw if to be used).

4.

Thread the socket onto the wire.

5.

Slide the wedge over the core (7 strands) of the wire. The core of the wire should protrude approx. 2 mm

(5/64”) from the wedge.

3.2 Fitting Sta-lok eye terminal

Note! For systems with swaged stud terminal, skip this part and go directly to 3.3.

Fig. 3.2.b

Fig. 3.2.c

Former Wedge Socket

Terminal part (or rigging screw)

Fig. 3.2.d

Fig. 3.2.a

14

6 .

Space the outer strands of the wire evenly around the wedge and bring

down the socket so that the strands are held in place. Hold an adjustable

spanner between the 1000 mm (39 3/8”) extrusion and the socket.

Tapping the core of the wire, locate it firmly in the socket.

Check that the core of the wire protrudes approx. 2 mm (5/64”) from the

wedge. See fig. 3.2.d.

7.

Bend the outer strands inwards a little using a pair of pliers, or tap the

strands with a small hammer. In the latter case, rest the socket’s thread

on a soft surface (wood or similar) to prevent damage.

8.

Insert the former into the threaded hole of the terminal part (or rigging screw). Lubricate the socket´s thread

with a long bead of locking adhesive. Screw the terminal part onto the socket and tighten carefully, forcing

the wire further into the terminal.

9.

Unscrew and check that the outer strands are evenly

distributed around the wedge. If some strands are

crossed, correct their positions.

10.

If assembly is unsuccessful and needs to be repeated, refer to the relevant parts of extrusion 6.4

”Dismantling”.

11.

Apply another 2 or 3 drops of the locking adhesive to the

thread and screw the terminal together, tightening it firmly.

The terminal is now permanently locked.

NOTE! Check that no strands slip into the slot of the wedge.

Fig. 3.2.e

Fig. 3.2.h

Fig. 3.2.g

Fig. 3.2.f

NOTE! Check that no strand has slipped into the slot of the wedge!

15

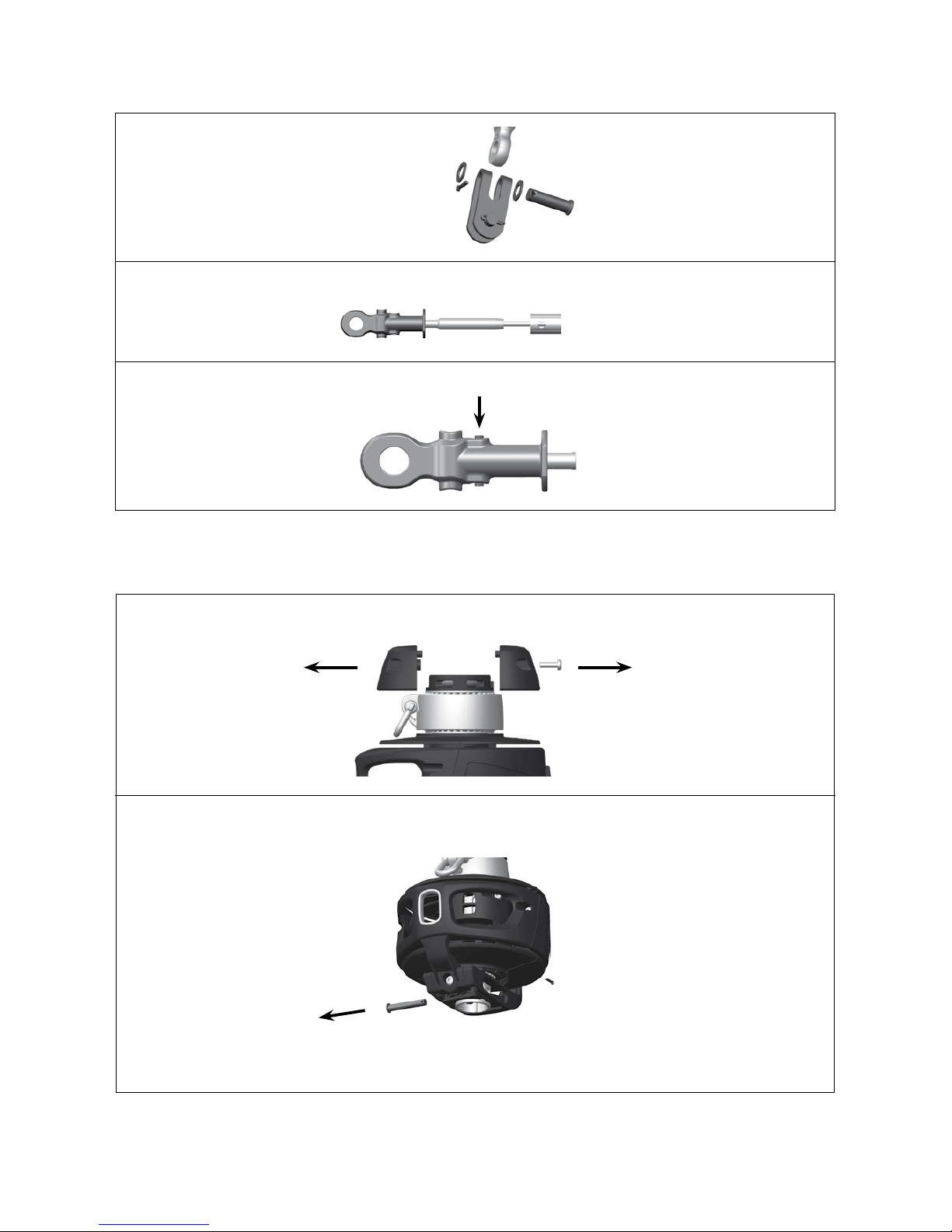

3.3 Fitting eye terminal to swaged stud (Stud/Eye)

Fig. 3.3.a

Fig. 3.3.b

Fig. 3.3.c

1. Remove the toggle from the eye fitting.

2. Screw the eye terminal part onto the stud terminal until the holes in stud and eye align.

3. Fit the spirol spring pin using a hammer to permanently lock the terminal.

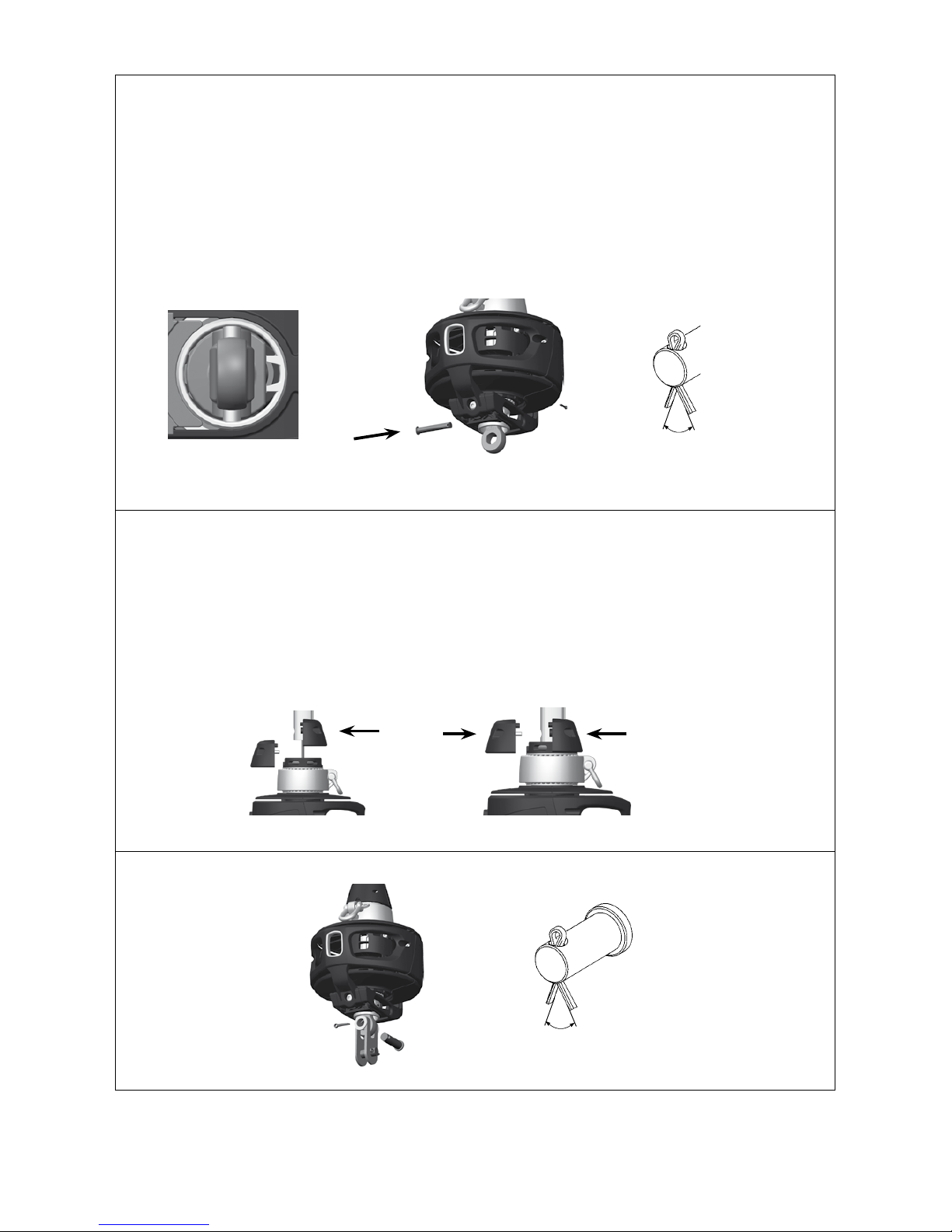

3.4 Drum unit assembly

1. Unscrew the two screws holding the adaptor halves together. Take care not to loose the the screws.

2. Remove the clevis pin that goes through the tube shaft in the drum unit.

Fig. 3.5.a

Fig. 3.5.b

16

20°

20°

Fig. 3.5.eFig. 3.5.dFig. 3.5.c

Fig. 3.5.g

Fig. 3.5.i

Fig. 3.5.h

3. Fit the drum unit over the eye terminal. Orient the drum unit so that the at surface on the eye

terminal meets the two ribs inside the drum unit tube shaft.

If a Furlex rigging screw is used, the at faces on all three components must be aligned. As the two ribs

on the inside of the tube shaft matches the at faces, it will securely lock the rigging screw.

When tting the drum unit, the rigging screw should be unscrewed halfways.

Ret the clevis pin through the tube shaft and the hole in the eye terminal. Secure with the split pin.

4. Fit the adaptor halves. The round boss in the forward adaptor half ts into the hole in the luff extrusion

lower end. Note that the halves can be tted one way only.

Best practice to t the adaptor hlaves is to start by pushing the forward adaptor half onto the luff

section and then connect to the upper hub . When the forward half is in postion, t the aft half

and click the halves together. Make sure that the screws go in smoothly so that the screw threads are not

damaged.

Tighten the screws rmly.

5. Ret the toggle. Secure the split pin.

17

0–10°

15–20°

4.1 Mast attachment

4.1.1 Halyard routing

The guiding principle for tting the Furlex to the mast is that the forestay connection should allow sufcient

articulation in all directions. In most cases a toggle must be tted between the Furlex stay and the forestay

attachment. For available toggles and extension links, see extrusion “Spares & accessories”.

The angle between the halyard and the forestay must be at least 15°. If the

angle is less than 15°, the halyard may wrap around the luff extrusion when

the sail is being furled, possibly damaging the halyard and the luff extrusion.

Failure to observe what is happening in this situation may even result in

damage to the forestay wire.

Before installing the Furlex on the boat, make sure that the 15–20° require-

ment is fullled. On new Seldén masts this is usually not an issue but on older

masts - or masts of other brands - it may be necessary to t halyard leads or to

t a new halyard box.

The Extended Pack includes two halyard leads. These are easy to install and

t on most mast brands. Halyard leads should be inspected once a year and

any sharp edges smoothed with a le. The halyard lead should be replaced

when wear reaches 50%.

Alternatively, a sheave box can be tted to the mast to meet the 15–20°

requirement. Installation is more complicated but the box will eliminate the

need to replace the halyard leads as they wear. Sheave box kits (with assembly

instructions) can be obtained from your Seldén dealer.

If the boat is equipped with a spinnaker halyard, this must be kept clear of the

Furlex-system when not in use to avoid halyard wrap. An effective solution

is to lead the halyard around the upper shroud and then down aft of the

spreaders.

4 Installation

Installation of the Furlex system on the boat requires a minimum of two persons, however it is recommended to

be at least three persons to do the job more easily.

Fig. 4.1.1.a

Fig. 4.1.1.b

18

Min. 300 mm

Min. 300 mm

4.2 Deck attachment

4.2.1 Attachment below deck

The lower end of the Furlex-system comes with a fork toggle

as standard. This can normally be attached directly to the boat’s

forestay tting at the stemhead. Check that the drum unit does not

interfere with the pulpit, navigation lights or other deck ttings.

For the furling line to be wound evenly onto the line drum, the rst

turning point (stantion block) must be at least 300 mm (11 13/16”)

away. The tack should be located as close to deck level as possible.

If the boat is tted with a bow anchor, it may be necessary to

permanently raise the drum unit to give the crew sufcient space for

anchor work.

If the drum unit is raised by means of an extension link, a toggle

must be tted between the link and the boat’s forestay attachment at

the stemhead.

For available toggles and extension links, see extrusion “Spares and

accessories”.

The furling unit can be tted below deck inside an anchor well. The

advantage is that the sail’s luff length is maximized and the access

around the forestay is improved. The disadvantage is a more

complicated route for the furling line resulting in increased furling

resistance. The diagrams below illustrate various methods of

installation.

Regardless of which option is chosen, the Furlex-system must

always be kept clear of the deck well’s inside surfaces.

Avoid routing the line through an integral deck conduit, as this will

increase the friction on the furling line.

Use a large ball bearing block to minimize friction losses.

The anchor well must be well drained.

If the Furlex is tted above deck, but with the forestay tting in the

anchor well, a Furlex extension toggle can be used. For larger

distances, use a custom made stainless steel bar or rod stay. For

available toggles and extension links, see extrusion “Spares and

accessories”.

Fig. 4.2

Fig. 4.2.1.a

Fig. 4.2.1.b

19

4.3 Installation on a stepped mast

4.4 Installation on an un-stepped mast

1. Lay the dressed mast on trestles with the front facing up.

2. Connect the top end of the Furlex-system to the forestay attachment on the mast. Make sure that the stay is free

to move in all directions.

3. Lift the mast in the crane with the Furlex-system lying on the leading edge of the mast.

4. Have one person watching the Furlex-system to ensure that it does not get caught when lifting the mast.

5. Keep the end of the stay outside the deck area in order to avoid damage.

6. Attach the stay to the chain plate in the boat at the stemhead. Make sure that the stay is free to move in all

directions.

Fig. 4.3

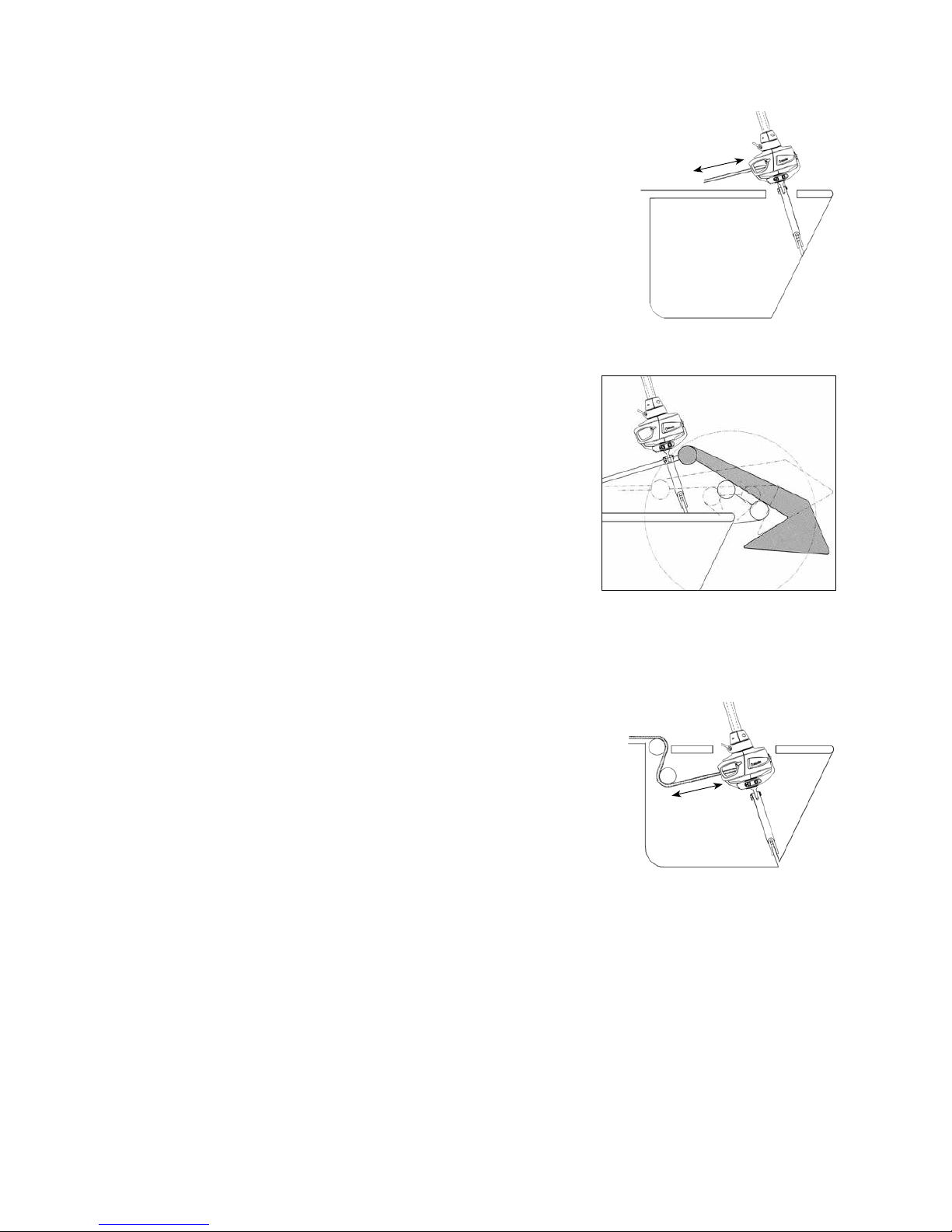

4.5 Furling line installation

1. Start by loosening the screw on the underside of the drum unit a few turns. Then loosen the two smaller

screws on each side of the line guide tting until the line guide tting and cover seperates. Remove the line

guide tting. It may be necessary to loosen the screw on the underside a few extra turns for the line guide

tting to come off.

2. Pull out the lock block.

3. Remove the cover.

4.5.1 Removing line guide fitting and cover

Fig. 4.5.1.a Fig. 4.5.1.b Fig. 4.5.1.c

1. Slacken the backstay as much as possible, but do not remove it.

2. Pull the mast forward using a genoa halyard or a spinnaker halyard. Secure the halyard to a strong deck

tting using a screw pin shackle or tie the halyard to a strong deck tting. For safety reasons, do not use

snap shackles.

3. Tie a strong, not too stiff, rope around the luff extrusion. Make two clove hitches and tape the knots over

carefully so that they cannot slide.

4. Hoist the stay using a spare halyard.

5. ”Go aloft” and attach the top end of the Furlex-

system to the forestay attachment. Always use a

proper bosun’s chair. If there are no free headsail

halyards, use the main halyard. For further information,

see the ”Working aloft” section in the brochure

”Hints and Advice” that can be downloaded on

www.seldenmast.com.

6. Finally attach the stay to the forestay attachment in the boat at the stemhead.

The furling line is best tted to the drum unit with cover and line guide removed.

20

To wind the line onto the drum, turn the luff extrusion by hand and wind approx. 30 turns onto the line drum.

Wind the line onto the drum before hoisting the sail.

The line should be led aft to the cockpit via lead blocks. Lead blocks are included in the Extended Pack. The

lead blocks are normally mounted on the pulpit and on the stanchions leading the line back to cockpit.

The forward lead block is tted so that the furling line exits the line guide tting in a straight line. Ease the

screw on the underside of the drum unit a little to be able to make the adjustments. Also adjust the line guide

and cover height so that the drum is allowed to rotate freely. Tighten the screw rmly when nished.

The nal turning block by the cockpit needs to be matched individually to each boat depending on the

attachment points, the line arrangement chosen and possibly also the type of other blocks on the boat. We

recommend a swivel block which is free to self-align. The maximum working load of the block should not be

less than 3000 N (300 kg/ 660lb).

Fig. 4.5.2.c Fig. 4.5.2.d Fig. 4.5.2.e

If the sail’s ultraviolet (UV) protection is tted on the starboard side of the sail, the furling line should exit on

the port side of the line drum. If the UV protection is tted on the port side, the furling line should exit on the

starboard side of the line drum.

Use an awl or similar tool to make a hole in the rope 10-15 mm (25/64” - 19/32”) from the rope end and t the

screw through the hole. Make sure that the washer is tted under the screw head, then tighten the screw rmly.

Use locking adhesive on the screw thread. Ret cover and line guide by doing a reverse dismantling, see pre-

vious section.

4.5.2 Fitting the furling line

Fig. 4.5.2.a

Fig. 4.5.2.b

Table of contents

Other Selden Marine Equipment manuals

Selden

Selden Furlex 200 TD User manual

Selden

Selden Furlex Electric 200E User manual

Selden

Selden Furlex 404TD Guide

Selden

Selden Furlex Electric 200E User manual

Selden

Selden Furlex 200 S User manual

Selden

Selden Furlex 400 S Supplement

Selden

Selden Furlex 204S Guide

Selden

Selden Furlex 204TD User manual

Selden

Selden Furlex 404S Guide

Selden

Selden Furlex 200 S User manual