Fitting the Transducers

Before installing your Ultraguard transducers, plan out where the best location is for each transducer.

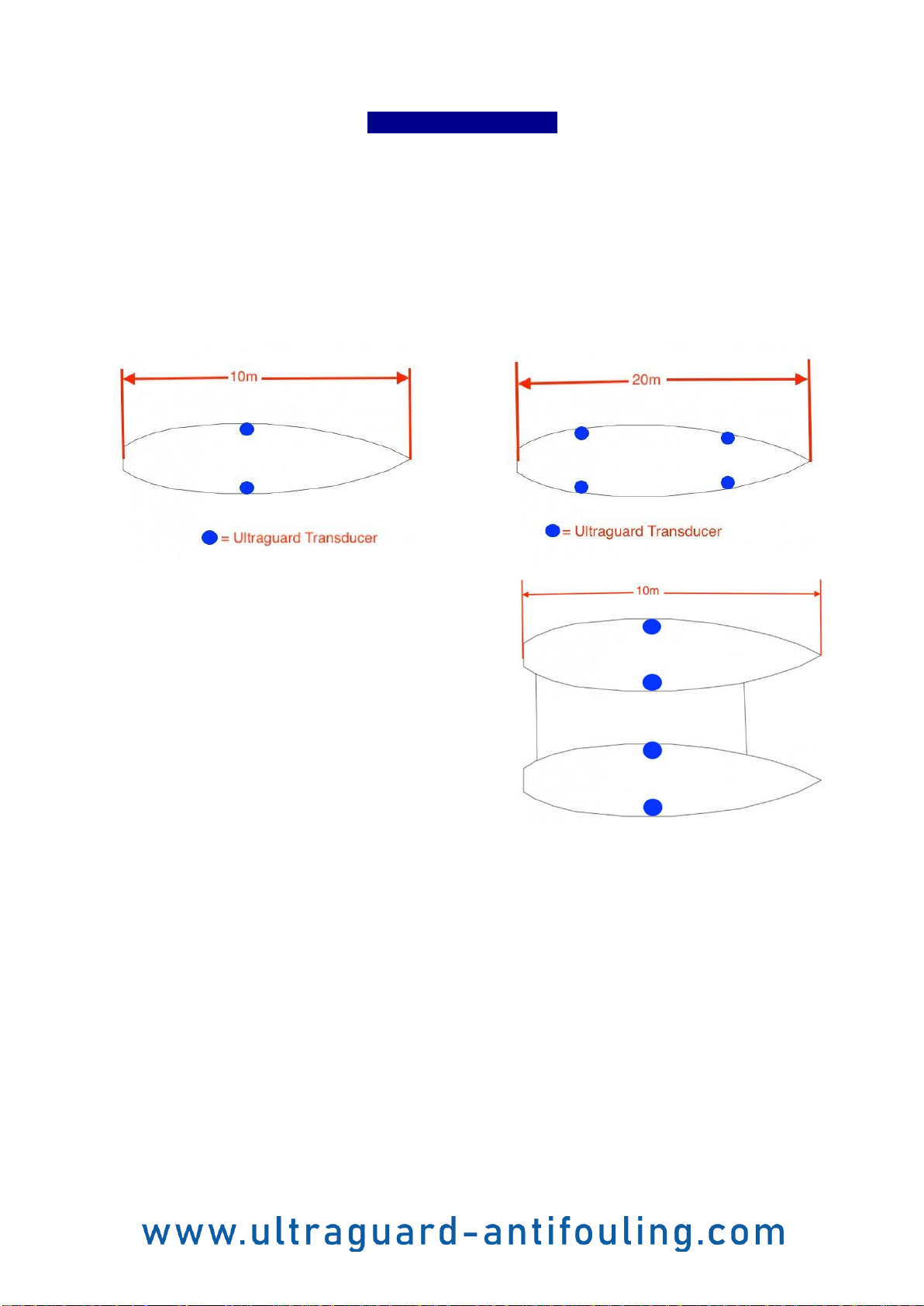

Transducers should be located directly onto the inside (dry side) of the hull’s outer shell. Each

transducer has an effective antifouling radius of five metres on uninterrupted surfaces. Acute angles

and reinforcements can reduce the transmission of the sound waves. For this reason, we recommend

locating transducers in pairs, one on each side of the vessel to ensure that the antifouling effect is not

lessened by the acoustic waves having to pass through the keel of the vessel. Each Ultraguard Master

Series control unit can operate two transducers. If your vessel’s underwater area is longer than ten

metres, you will need to add additional Ultraguard Master Series control panels to protect the entire

length of the underwater hull. For larger vessels and ships, Ultraguard’s AC powered commercial UG

series systems may be more suitable.

If your boat is a multi-hull vessel, you should treat each

hull sponson as an individual hull.

It is best to locate transducers as close as possible to

the halfway point between the waterline and the

moulded keel (not including attached keels, drop keels,

dagger boards etc).

Ideally, we recommend locating transducers away from

any framing there may be on the vessel. The object is to

set up a microvibratory response in the shell off the hull

and this is better achieved by locating the transducer as

equidistant as possible between frames, stringers and

bulkheads.

If your vessel’s hull has a sandwich laminate construction with a foam, plywood or honeycomb core

between an inner and outer skin of GRP/Carbon fibre/Kevlar, then a disk slightly larger than the

transducer head will need to be cut out of the inner skin and the sandwich core. This cut-out should

then be filled with solid resin/fibre laminates ensuring that there are no air gaps created to build a base

for the transducer that allows the transducer to transmit the acoustic waves directly to the outer shell of

the hull.

If the inner surface of your hull has a rough GRP finish that can’t be sanded smooth it may be necessary

to apply a skim of resin to the transducer locations before fitting the transducers. This is done to avoid

air gaps between the transducer head and the hull. This is extremely important as air gaps that are

subjected to powerful ultrasonic waves can cause erosion of the surface.