Seltron AHC40 User manual

AHC40

ENG Compact controller

DEU Kompaktregler

ITA Regolatore compatto

SLO Kompaktni regulator

English 3

AHC40

COMPACT CONTROLLER

AHC40 is a modern weather-compensated heating controller. Its design is compact and it

comes with a mixing valve actuator.

INTRODUCTION

4 English

CONTENTS

Introduction............................................................................................................................3

INSTRUCTIONS FOR USE

Appearance of the controller .................................................................................................5

Controller setup at the rst start-up .......................................................................................6

Step 1 – Language selection........................................................................................6

Step 2 – Selection of hydraulic schematic....................................................................6

Step 3 – setup of heating curve slope ..........................................................................7

Step 4 – selection of opening direction of the mixing valve..........................................7

Graphic LCD..........................................................................................................................8

Description and appearance of the display ..................................................................8

Symbols for the description of the operating mode ......................................................9

Symbols of user functions ............................................................................................9

Symbols for the display of temperatures and other data............................................10

Symbols of protection functions .................................................................................10

Symbols for the display of communication between

interconnected devices...............................................................................................10

Symbols for notications and warnings ......................................................................11

Display for help, notications and ERRORS .......................................................................11

Menu entry and navigation ..................................................................................................12

Building and menu description ............................................................................................12

Temperature setup .....................................................................................................14

User functions ............................................................................................................15

Operating mode selection ..........................................................................................16

Selection and setup of time programs........................................................................17

Basic settings .............................................................................................................19

Data review ................................................................................................................21

INSTRUCTIONS FOR SERVICE SETTINGS

Controller parameters..........................................................................................................22

User parameters.........................................................................................................22

Heating curve .............................................................................................................24

Service parameters ....................................................................................................27

SPECIAL PARAMETERS...........................................................................................31

Factory settings ..........................................................................................................32

Description of the mixing cycle operation...................................................................32

Operating modes in the event of sensor failure..........................................................34

INSTALLATION INSTRUCTIONS

Controller installation...........................................................................................................35

Electrical connection of the controller..................................................................................36

Connection of temperature sensors ...........................................................................36

Connection of the RCD room unit ..............................................................................37

BUS connection of the AHC controllers......................................................................37

BUS connection of the WDC and AHC controllers .....................................................38

BUS connection of the WXD and AHC controllers .....................................................38

Technical data: ...........................................................................................................39

Disposal of the old electrical and electronic equipment.......................................................40

Hydraulic schemes ...........................................................................................................155

English 5

INSTRUCTIONS FOR USE

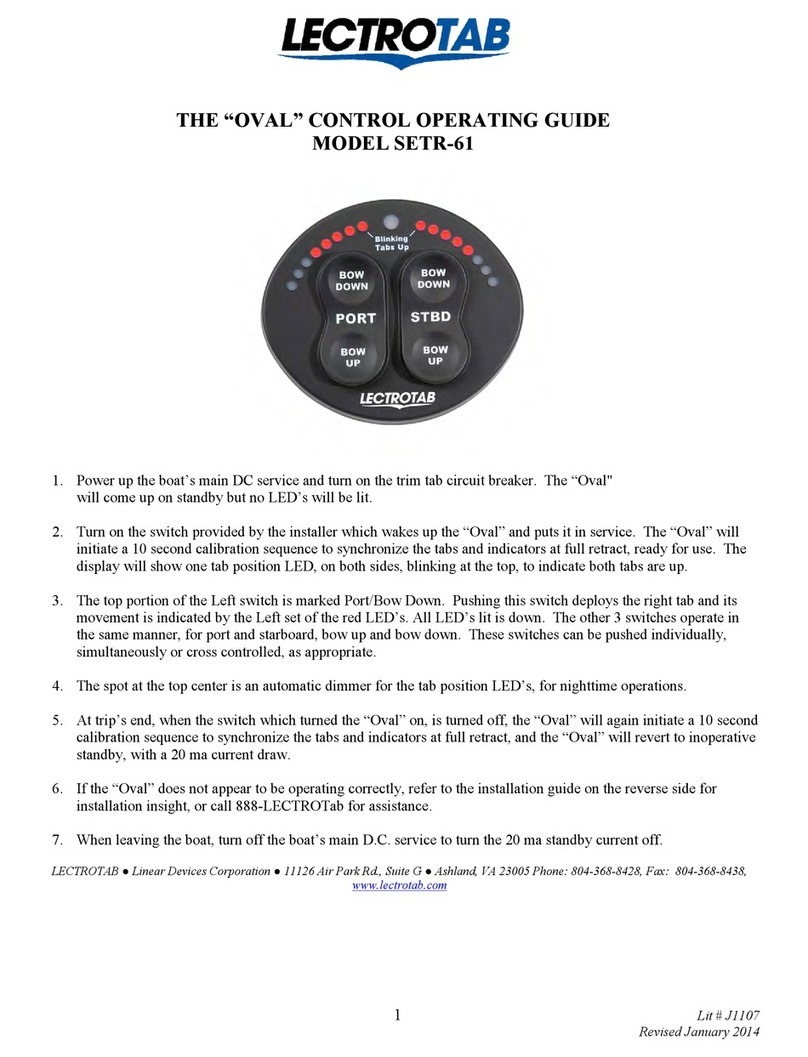

APPEARANCE OF THE CONTROLLER

1

2

3

4

5

8

9

10

6 7

1. Graphic display

2. Manual operation clutch

3. Key Move backwards

4. Key Move left or reduction

5. Key Menu entry or selection conrmation

6. Key Move right or increase

7. Key Help

8. LED display – Rotation of the valve to the right

9. LED display – Operating status of the controller

– Green light: normal functioning of the controller

– Red light: error

10. LED display – Rotation of the valve to the left

6 English

CONTROLLER SETUP AT THE FIRST START-UP

The controller features an innovative solution “Easy start" allowing the initial setup of the

controller in only four steps.

Upon the rst connection of the controller to the power supply network, the rst step of the

controller setup is displayed after the program version and logo.

STEP 1 – LANGUAGE SELECTION

Select the preferred display language. Move among

languages with the keys and .

Conrm the selected language with the key .

Conrm the correct language selection by pressing .

If the wrong language has been selected in error,

return to language re-selection by pressing .

STEP 2 – SELECTION OF HYDRAULIC SCHEMATIC

Select the hydraulic schematic for the operation of the

controller. Move among schematics with the keys

and .

Conrm the selected schematic by pressing .

Conrm the correct schematic selection by pressing

.

If the wrong schematic has been selected in error,

return to schematic re-selection by pressing .

Hydraulic schematic can later be changed with the S1.1 service parameter.

English 7

STEP 4 – SELECTION OF OPENING DIRECTION OF THE MIXING VALVE

Select the right direction of opening the mixing valve.

Move between the directions with the keys and .

Conrm the selected direction with the key .

Conrm the correct direction by pressing .

If the wrong direction has been selected in error, return

to direction re-selection by pressing .

Opening direction of the mixing valve can be changed with the S1.4 service

parameter later on.

STEP 3 – SETUP OF HEATING CURVE SLOPE

Setup the heating curve slope. Change the value with

the keys and .

Conrm the selected value by pressing .

Conrm the heating curve slope with the key .

If the wrong value has been selected in error, return to

slope re-selection by pressing .

The heating curve slope can be changed with the P2.1 user parameter later

on.

8 English

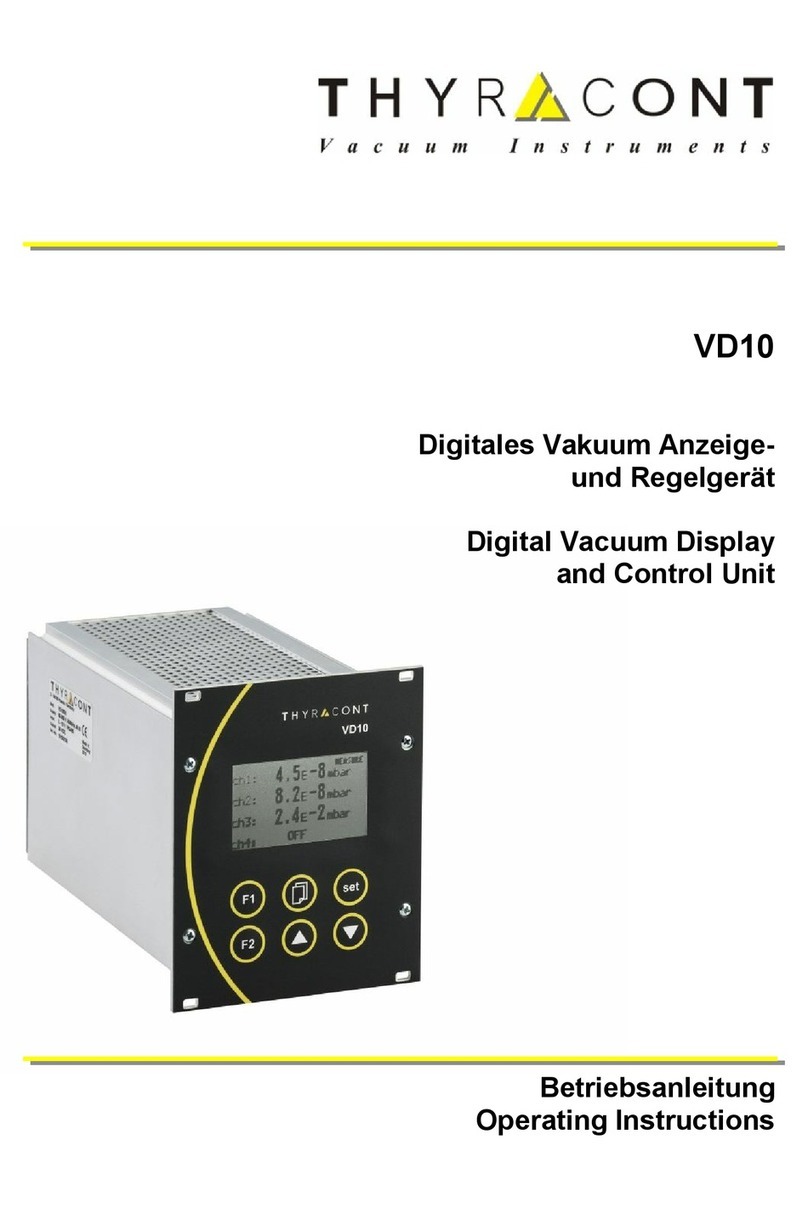

GRAPHIC LCD

All relevant data on the operation of the controller can be seen on the graphic LCD.

DESCRIPTION AND APPEARANCE OF THE DISPLAY

Notications and

errors

Operating mode and

user functions

Data display:

operating mode, user functions, notications and errors are shown in the upper half of the

display. To switch between the data display and display of the hydraulic schematic use the

key .

To review temperatures and other data use the keys and . The number of sensors

and other data that is displayed depends on the selected hydraulic schematic and control-

ler setup.

To recall certain data after the use of keyboard, search for it with the keys

and and conrm it by pressing and holding for 2 seconds.

By pressing and holding the key for 2 seconds, the temperature display

changes from one-line to two-line display or vice versa (only if the condition

P1.9=0 is met). In the two-line temperature display (P1.9=1), the rst line

shows the measured temperature value and the second one the preferred or

calculated temperature.

Hydraulic schematic with

the temperature display

Room unit

Temperature, protection functions and

display of other data

English 9

Symbol Description

Space heating

Cooling

Operation based on the time program – day intervals. *

Operation based on the time program – night intervals. *

Operation based on to the preferred day-time temperature.

Operation based on to the preferred night-time temperature.

Switch-o

Manual operation

* The number indicates the selected time program.

SYMBOLS FOR THE DESCRIPTION OF THE OPERATING MODE

Symbol Description

PARTY operating mode

ECO operating mode

Vacation operating mode

Automatic switch-o of heating

Floor foundation drying

Operation of the supply line with a constant temperature

Boost heating

SYMBOLS OF USER FUNCTIONS

10 English

SYMBOLS FOR THE DISPLAY OF TEMPERATURES AND OTHER DATA

Symbol Description

The measured temperature value

Room temperature

Outdoor temperature

Temperature of the boiler or heat source

Temperature of the supply line

The temperature of the return line

T1, T2, T3, T4

TR

TA

TQ

Temperature value measured with sensors T1, T2, T3 and T4

Temperature value measured with a room sensor or room unit

Outdoor temperature, obtained through the BUS connection

Temperature of the heat source, obtained through the BUS connec-

tion

SYMBOLS OF PROTECTION FUNCTIONS

Symbol Description

Protection of the heat source against overheating

Protection against freezing due to low room temperature

Protection against freezing due to low outdoor temperature

SYMBOLS FOR THE DISPLAY OF COMMUNICATION BETWEEN

INTERCONNECTED DEVICES

Symbol Description

Devices, connected to the COM communication line

Room unit is connected. The number of the room unit indicates

whether it is the rst or the second room unit.

Controller status of the BUS connection

First controller of the BUS connection

Interim controller of the BUS connection

Last controller of the BUS connection

English 11

DISPLAY FOR HELP, NOTIFICATIONS AND ERRORS

Recall the display for help, notications and error by pressing . The display oers the

following options:

Brief instructions

Brief instructions for use of the controller.

Controller version

Display of the controller type and software version.

Notications

List of transgressions of maximum temperatures and activation of protection

functions. Press and to can move through the list of notications. Exit

the list by pressing .

Errors

List of errors of sensors and other assemblies.

Press and to can move through the list of errors. Exit the list by press-

ing .

Deleting notications and errors

List of notications and errors shall be deleted.

Caution: Sensor errors that are essential for controller operation cannot be

deleted.

Symbol Description

Notications

In case of a transgression of the maximum temperature or activation

of the protection function, the controller will trigger a warning with

ashing of the symbol on the display. If the maximum temperature is

no longer exceeded or if the protection function is already switched

o, the lit-up symbol will indicate a recent event. Recall the display for

the review of the list by pressing . After reviewing the list of notica-

tions, the notication symbol disappears.

Errors

In case of a failure of sensors or communication connections, the

controller will trigger a warning with ashing of the symbol on the

display. If the error is eliminated or no longer present, a non-ashing

symbol will indicate a recent event. Recall the display for error list re-

view by pressing . After reviewing the list of errors, the error symbol

disappears.

SYMBOLS FOR NOTIFICATIONS AND WARNINGS

12 English

MENU ENTRY AND NAVIGATION

To enter the menu press .

Use and to move around the menu, and to conrm your selection.

Return to the previous display by pressing .

If no key is pressed for 15 seconds, the display becomes dimmed. After the

delay of the display switch-o, the display will switch o. The time can be set

up in the menu Basic settings, Display settings.

BUILDING AND MENU DESCRIPTION

TEMPERATURE SETUP

Day-time temperature

Night-time temperature

USER FUNCTIONS

PARTY operating mode

ECO operating mode

Vacation operating mode

Function switch-off

OPERATING MODE SELECTION

Operation based on the selected time program

Operation based on the daily temperature

Operation based on the night-time temperature

English 13

Switch-off

Selection of cooling or heating operation

Manual operation

TIME PROGRAMS

First time program

Second time program

Third time program

Fourth time program

BASIC SETTINGS

User language

Time and date

Display settings

Delay for the switch-off of the display and automatic exit from the menu

DATA REVIEW

Graphic display of temperatures according to days of the last week

Detailed graphic display of temperatures for the current day

Meters of operating hours of controller outputs

Special service data

USER PARAMETERS

General settings

Heating circuit settings

Energy source settings

14 English

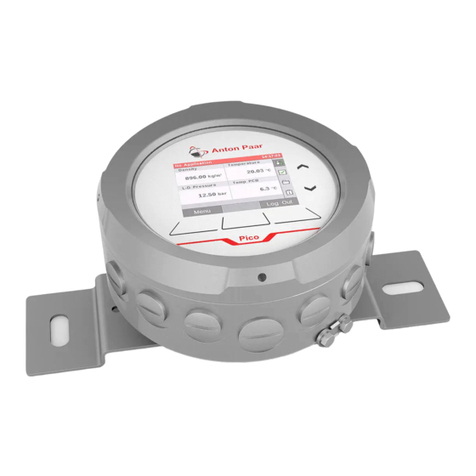

TEMPERATURE SETUP

The menu displays temperatures that can be set up as preferred in the selected hydraulic

schematic.

Select the preferred temperature with the keys , and . The display for the tem-

perature setup opens up:

Use the keys and to set up the preferred temperature and conrm it by pressing .

Exit the setup by pressing .

Factory value

Graphic

display of the

setup

Setup range

The last conrmed setup

value

Current value of the

preferred tem-

perature (numeric

display)

Current value of the

preferred temperature

SERVICE PARAMETERS

General service settings

Service settings for the heating circuit

Service settings for energy sources

SPECIAL PARAMETERS

Parameters for oor foundation drying

FACTORY SETTINGS

Reset of the controller parameters

Reset of the controller and restart of the rst setup

Reset of time programs

Save user settings

Load user settings

English 15

USER FUNCTIONS

PARTY function allows operation based on the preferred comfortable temperature.

Select the function PARTY with the keys and turn it on by pressing . To set up the

function time tracker and preferred temperature, re-select the icon .

With the keys and select the desired temperature to change and press . The

value starts to ash. Change the value with the keys and and conrm it by pressing

.

Exit the setup by pressing .

PARTY operating mode

User functions provide additional comfort and benets in using the controller. In the menu,

the following user functions are available:

ECO function allows operation based on the preferred saving temperature.

Select the function ECO with the keys and turn it on by pressing . To set up the

function time tracker and preferred temperature, re-select the icon .

With the keys and select the desired temperature to change and press . The

value starts to ash. Change the value with the keys and and conrm it by pressing

.

Exit the setup by pressing .

ECO operating mode

Vacation function allows operation based on the preferred saving temperature until the set

date.

Select the function Vacation with the keys and turn it on by pressing . To set up

the function date tracker and preferred temperature, re-select the icon .

Now select the temperature to change with the keys and and press . The value

starts to ash. With the keys and select the temperature to change and conrm it by

pressing .

Exit the setup by pressing .

Vacation operating mode

All user functions can be switched-o at anytime. This can be done by select-

ing the icon .

16 English

OPERATING MODE SELECTION

In the menu, choose the preferred operating mode of the controller.

Operation is based on the selected time program.

Operation based on the selected time program

Operation is based on to the preferred day-time temperature.

Operation based on the daily temperature

Operation is based on the preferred night-time temperature.

Operation based on the night-time temperature

The controller is switched o. In the "Heating” mode, the protection against freezing re-

mains active, and in the “Cooling” mode the protection against overheating.

Switch-o

If heating is selected, it is then switched to cooling.

If cooling is selected, it is then switched to heating.

By conrming the icon by pressing , the heating switches to cooling and vice versa.

Selection of cooling or heating operation

For the operation of cooling, the system for the intake of cooling water must be

on.

English 17

Use the keys and , to move among individual

outputs R1, M+ or M-. Select the output to change the

status of by pressing .

The value ON, OFF or AUTO starts to ash. Now the

output status can be changed by pressing and .

Conrm the setup by pressing .

Exit the list by pressing .

This mode is used for testing the control system or in the event of a failure. The control

output can be manually switched on, switched o or automatic operation can be selected.

Manual operating mode

SELECTION AND SETUP OF TIME PROGRAMS

Weekly time programs enable automatic switching between the preferred day and night-

time temperature. There are four time programs available. Use the keys and to

select the preferred time program and conrm it by pressing .

The selected time program can be changed by re-conrming it by pressing . A new

display will open up:

Changing the time program

First time program

Second time program

Third time program

Fourth time program

Time axis

Copying the time programEditing of the time program

Number of time program Selected day

18 English

With the keys , and , select the day to change the course of the program for or

the one to copy in other days. With the keys , and select the icon for edit-

ing and or the icon for copying the time program.

Editing of the time program

A new display will open up showing the time program

and three icons for changing the program.

With the keys and select the preferred command icon and conrm it by pressing

. A cursor appears on the time axis. With the keys and draw the preferred course of

the time interval. Finish drawing the interval by re-pressing .

Exit the editing of the time program by pressing .

- Free moving of the cursor.

- Drawing of the switch-o interval or night

temperature.

- Drawing of the switch-on interval or day

temperature.

Copying the time program

A new display will open up showing the time program

for the selected day. At the top of the display there is

a eld for the selection of the day or group of days to

copy the time program in. With the keys and

the day or group of days can be selected. For copying

press the key . Exit copying by pressing .

Initial settings of time programs

Time program Day Switch-on interval

MON–FRI 6am–10pm

SAT–SUN 7am–10pm

MON–FRI 5am–7.30am, 1.30pm–10pm

SAT–SUN 7am–10pm

MON–FRI 6am–8.30am, 11am–1.30pm, 4pm–10pm

SAT–SUN 7am–10pm

MON–FRI 2pm–10pm

SAT–SUN 7am–10pm

English 19

BASIC SETTINGS

The menu is intended for setting up the language, time, date and display.

User language

Select the preferred user language with the keys , and conrm it by pressing .

Exit the setup by pressing .

Time and date

Set up the exact time and date in the following way:

Use the keys and , to move among individual

data. Select the data to change by pressing . If

the data starts to ash, it can be changed with the

keys and and conrmed it by pressing .

Exit the setup by pressing .

20 English

The following setup is available:

delay for the switch-o of the display and automatic exit from the menu.

Display setup

Conrm the preferred setup by pressing .

A new display will open up:

Graphic

symbol

Factory value

Current setup value

Current value

setup (graphic dis-

play)

Setup range

The last conrmed setup

value

Current value

setup (numerical dis-

play)

Change the setup with the keys and conrm it by pressing .

Exit the setup by pressing .

The setup will be changed after it has been conrmed with key .

Table of contents

Languages:

Other Seltron Controllers manuals