2

TABLE OF CONTENTS

SAFETY PRECAUTIONS ........ Inside Front Cover

DESCRIPTION

Introduction............................................................4

Features..................................................................4

Specifications ......................................................... 5

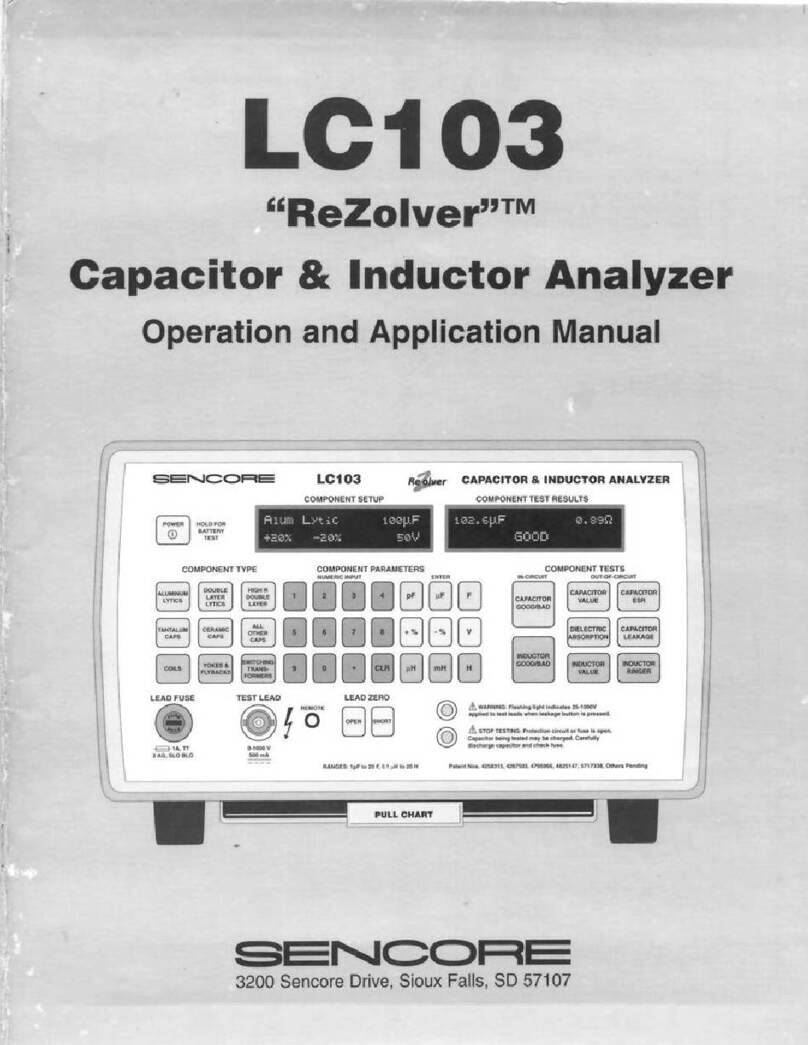

Front Panel Controls...............................................7

Rear Panel Controls................................................8

Supplied Accessories ..............................................8

Optional Accessories...............................................9

OPERATION

Introduction.......................................................... 10

AC Power Operation............................................. 10

Battery Operation.................................................. 11

Battery Test ....................................................... 12

Recharging the Battery....................................... 12

Auto-Off............................................................ 12

STOP TESTING Indication................................ 13

Test Lead Fuse................................................... 13

Test Leads........................................................... 13

Adjustable In-Circuit Test Probe......................... 13

Test Lead Mounting Clip.................................... 14

Lead and Probe Zeroing..................................... 14

Entering Component Data.................................. 15

Component Type................................................ 15

Component Value .............................................. 15

Tolerance........................................................... 15

Leakage Voltage ................................................ 16

In-Circuit Capacitor Testing.............................. 17

Value and ESR Testing ...................................... 17

Automatic EIA GOOD/BAD Testing.................. 17

SUGGEST REMOVAL Indication..................... 17

Out-of-Circuit Capacitor Testing....................... 18

Out-of-Circuit Capacitor Parameter Testing..... 18

Component Test Results..................................... 18

Measuring Capacitor Value................................ 18

Measuring Capacitor ESR .................................. 18

Measuring Capacitor D/A................................... 19

Measuring Capacitor Leakage ............................ 20

Leakage in Paper, Mica and Film Capacitors ...... 21

Leakage in Ceramic Capacitors .......................... 21

Leakage in Aluminum Electrolytics.................... 21

Leakage in Tantalum Electrolytics...................... 21

Leakage in Non-Polarized (bipolar) Electrolytics 21

Leakage Charts .................................................. 22

Automatic GOOD/BAD Capacitor Testing........ 24

In-Circuit Inductor Testing................................ 25

Out-of-Circuit Inductor Testing......................... 25

Measuring Inductor Value.................................. 25

Automatic GOOD/BAD Inductor Value Testing. 26

Inductor Ringer Test........................................... 26

Error Messages................................................... 27

RS-232 OPERATION.........................................28

Connecting to the Computer............................... 28

Sending Data to the LC103.................................28

Component Type Commands..............................29

Value Multipliers...............................................29

Setting the Leakage Voltage...............................30

Test Function Commands...................................30

General Codes....................................................30

Receiving Data from the LC103.......................... 31

Data Format.......................................................31

Error Testing...................................................... 32

Shorted Capacitors.............................................32

Open Inductors...................................................32

Making Leakage Tests........................................32

Making ESR Tests..............................................33

APPLICATIONS

Introduction ........................................................34

Identifying Capacitor Types............................... 34

Aluminum Electrolytics......................................35

Tantalum Electrolytics........................................35

Double Layer and “High R” Electrolytics ...........36

Ceramic Capacitors............................................36

Other Capacitor Types........................................ 36

Identifying Inductor Types.................................37

Yokes and Flybacks ...........................................37

Switching Transformers ..................................... 37

Coils.................................................................. 37

Identifying Unknown Components.....................38

Capacitor Testing................................................ 38

Capacitance Measurement Accuracy...................38

Measuring Small Capacitance Values

in Noisy Environments ....................................38

Interpreting Capacitor Value Readings................39

In-Circuit Capacitor Test....................................39

Testing Non-Polarized (Bi-Polar) Electrolytics ...40

Checking Leakage in a Multi-Section Electrolytic40

Dielectric Stress.................................................40

Intermittent Capacitors.......................................40

Checking Ceramic Capacitor

Temperature Characteristics.............................40

Inductor Testing..................................................41

In-Circuit Inductor Test......................................41

Mutual Inductance..............................................41

Ringing Peaking Coils........................................ 41

Ringing Metal Shielded Coils.............................41

Testing Flyback Transformers

and Deflection Yokes..................................... 41

Ringing Flyback Transformers.........................41

Leakage Testing Flyback Transformers............42