STEREO AUDIO:

This signal produces equal

left and right modulation. When you inject

this signal into working Hi-Fi VCR circuits

you should obtain equal left and right output.

STEREO

R

ONLY AND STEREO L ONLY:

Use

these signals to isolate problems in the left or

rightaudiochannels. Bothchannelsare modu-

lated with the same tone, selected by the

MODULATION switch. When injecting into a

working Hi-Fi channel, you should obtain an

output only on the selected channel.

Using The Playback Signals

1.

Set up the VC93 as follows:

a. VCR FORMAT to desired format.

b. MODULATION to COLOR BARS.

c. PLAYBACK RANGE to level necessary.

d. PLAYBACK SIGNAL to desired signal.

2. Connect the HEAD SUBSTITUTION LEAD.

a. Red lead or leads to injection point. (Both

red leads have the same signal.)

b. Black lead to ground.

3. Adjust the PLAYBACK LEVEL control for

the best picture or audio on the playback

monitor.

When you inject the VC93 Playback Signals

after a defective stage, the playback monitor

will return to a good output. This indicates

that all

the circuits

after the

injection point are

good. If you do not obtain a good picture (or

audio) your injection point is before the

de-

fectivestage. Continue moving your injection

point to a later stage until a good output

returns. The stage before the injection point

that produces a good picture or audio con-

tains the defect.

Table 2 summarizes where to inject the VC93

Playback Signals on the Universal VCR Block

Diagrams. Use this table for a reference when

injecting the VC93 Playback Signals. For ad-

ditional troubleshooting information refer to

Tech Tip #194, “Troubleshooting “Bad Head”

Symptoms with the VC93 All Format VCR

Analyzer.”

DRIVE SIGNAL

The VC93 DRIVE SIGNAL switch and DRIVE

OUTPUT jack provide the proper signals for

injecting into the stages after the FM lumi-

nance detector, chromafrequency convertor

or FM audio detectors. The test points that

require the use of the Drive Signals are sum-

marized in Table 3.

Except for the HEADSWITCH Drive Signal,

the VCR FORMAT switch setting does not

affect the Drive Signals. The HEADSWITCH

Drive Signal changes from 30 Hz to 15 Hz

when the VHS-C Format is selected. The

detected video and audio signals are the

same in all

other VCR formats.

For simplicity,

always set the VCR FORMAT switch to match

the VCR format you are servicing.

The DRIVE SIGNAL switch selects the signal

available at the DRIVE OUTPUT jack. The

peak-to-peak level is adjustable with the

DRIVE LEVEL control, and is displayed in the

right-hand LCD display when the OUTPUT

SIGNAL

MONITOR/DVM

switch is set to

“Drive Signal”. The voltage is variable from

-

10 VPP to +1 0 VPP with the

"-"

signals being

inverted from the

"+"

signals. Use the DI-

RECT TEST LEAD to inject any of the Drive

Signals into the appropriate test point. Fol-

lowing is a summary of each Drive Signal.

COMPOSITE VIDEO: This is the standard

NTSC composite video waveform including

luminance, color, and sync. Use it to inject

into the RF modulator, Y/C mixer output, and

these test points. Universal VCR Block Diagram.

Table 2: Inject the VC93 Playback Signals at

other stages that normally have both lumi-

nance and color signals. The MODULATION

switch determinesthevideo pattern selected.

LUMINANCE: This signal is the

luminance-

only portion of the composite video signal

selected by the MODULATION switch. Use it

in the stages between the output of the FM

luminance detector and the input of the Y/C

mixer.

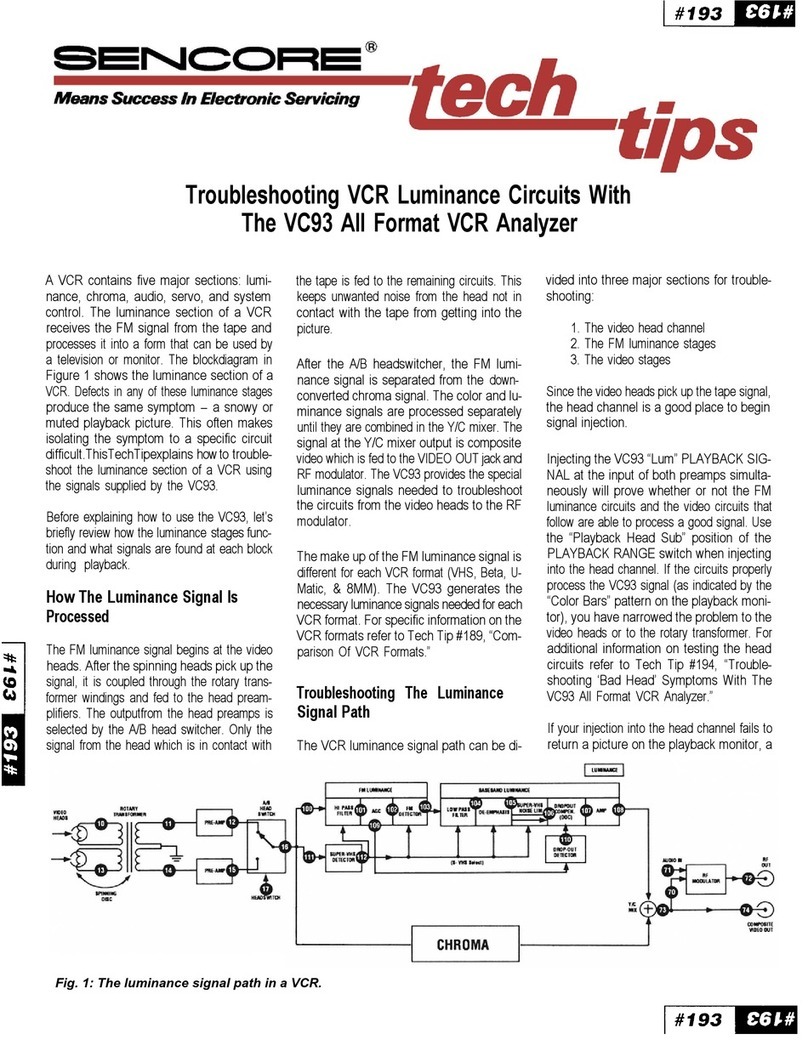

Tech Tip #193,

“Troubleshooting VCR

Luminance Circuits with the VC93 All Format

Analyzer,” provides additional information

on troubleshooting these stages.

CHROMA: This signal is the

chrominance-

only portion of the composite video selected

by the MODULATION switch. Use it in the

stages between the output of the frequency

converter (color detector) and the Y/C mixer

inputs. Tech Tip #198, "Troubleshooting VCR

Chroma Circuits with the VC93,” provides

additional information on troubleshooting

these stages.

AUDIO:

The Audio Drive Signal is a baseband

(20 Hz-15

kHz)

audio signal at the frequency

determined by the setting of the MODULA-

TION switch. Inject this signal into audio

stages after the FM audio detector.

3.58

MHz:

This Drive Signal is a continuous

sine wave that can be used to substitute for

the 3.58 (3.579545) MHz color oscillator, or

the 3.58 MHz reference for the servo circuits.

HEADSWITCH: This signal duplicates the

square wave signal found at the playback

A/B headswitcher. Most VCR formats use a

30 Hz headswitching signal. VHS-C format

VCRs, however, use both 15 Hz and 30 Hz

switching signals. When the VCR FORMAT

switch is set to VHS-C or SUPER VHS-C the

HEADSWITCH Drive Signal frequency is

15 Hz. The frequency is 30 Hz for all other

formats.

SW30:

This signal substitutes for the 30 Hz

(29.97 Hz) input to the chroma conversion

circuits. The actual frequency is the compos-

ite video frame rate, 29.97 Hz. Use the SW30

Drive Signal and the LUM

&

CHROMA Play-

back Signal when troubleshooting chroma

stages.

VCR to the VC93 using the CHROMA LOCK

CHROMA KEY PULSE:

The CHROMA KEY

PULSE Drive Signal provides a substitute for

the horizontal sync input to the chroma con-

version circuits. Always inject the LUM &

CHROMA Playback Signal and phase