6.7.4 Traffic — Filter setup (AET Option) . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.7.5 Traffic — Microbitrate (AET Option) . . . . . . . . . . . . . . . . . . . . . . . . 92

6.8 Ethernet ........................................... 94

6.8.1 Ethernet — IGMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.8.2 Ethernet — FSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

6.8.2.1 Ethernet — FSM — Monitor . . . . . . . . . . . . . . . . . . . . . . . 95

6.8.2.2 Ethernet — FSM — Setup . . . . . . . . . . . . . . . . . . . . . . . 96

6.8.2.3 Ethernet — FSM — Syslog . . . . . . . . . . . . . . . . . . . . . . . 98

6.8.3 Ethernet — PCAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.9 ETR 290 (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6.9.1 ETR 290 — ETR Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

6.9.2 ETR 290 — ETR Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

6.9.3 ETR 290 — PIDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

6.9.4 ETR 290 — Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6.9.5 ETR 290 — Bitrates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.9.6 ETR 290 — Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.9.7 ETR 290 — PCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

6.9.8 ETR 290 — T2MI (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6.9.9 ETR 290 — SCTE 35 (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

6.9.10 ETR 290 — Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6.9.11 ETR 290 — Compare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

6.9.12 ETR 290 — ETR thr. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

6.9.13 ETR 290 — PID thresh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

6.9.14 ETR 290 — Service thresh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

6.9.15 Golden TS reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

6.10 Setup............................................. 146

6.10.1 Setup — Params . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

6.10.2 Setup — Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

6.10.3 Setup — Colors (requires EXTRACT-OPT) . . . . . . . . . . . . . . . . . . . . 149

6.10.4 Setup — Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

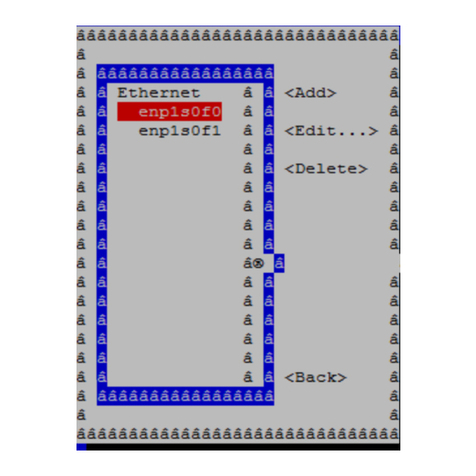

6.10.5 Setup — Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

6.10.5.1 Setup — Ethernet — IPv6 Settings . . . . . . . . . . . . . . . . . . . 152

6.10.5.2 Example 1 – Separate Management IPv4 . . . . . . . . . . . . . . . 153

6.10.5.3 Example 2 – In-Line Management IPv4 . . . . . . . . . . . . . . . . 154

6.10.5.4 Example 3 – Mixed Mode IPv4 . . . . . . . . . . . . . . . . . . . . . 154

6.10.6 Setup — VLANs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

6.10.7 Setup — VBC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

6.10.8 Setup — Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

6.10.9 Setup — ETR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

6.10.9.1 Parsing rules for private descriptors . . . . . . . . . . . . . . . . . . 158

6.10.9.2 ETR 290 tuning control . . . . . . . . . . . . . . . . . . . . . . . . . 159

6.10.9.3 ETR details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

6.10.9.4 EIT table IDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

6.10.9.5 Inactive inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

6.10.10 Setup — VBC thresh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

VB3xx 10G Probe User’s Manual version 5.2 5