Senix GTBCU4QL-M User manual

4-Cycle 1.9 cu in. (31 cc) Engine Gasoline

Powered Grass Trimmer/Brush Cutter 2 in 1

Model: GTBCU4QL-M

Operator's manual

TM

For customer support, please call 1-800-261-3981 or send email to:

SAVE THIS MANUAL FOR FUTURE REFERENCE

EN - 2 WWW.SENIXTOOLS.COM

4

2

1

3

8

6

5

9

7

15

16

18

17

12

19

13

11

10

14

1

23

Mount Bracket

Mounting Disc

Blade

Washer

Floating Disc

Locknut

Screw

Tab

Cutting Head Shield

3 - EN

WWW.SENIXTOOLS.COM

4

6

98

7

5

Mounting Disc

Cutting Head

Upper Fixed Cover

Tighten

Loosen

Knob

Lower Fixed Cover

Locating Hole

Low Shaft

Coupler

Knob

Locating Button

Oil Fill Plug

O-Ring

Oil Fill Hole

Handle Support

EN - 4 WWW.SENIXTOOLS.COM

滚滚长江东逝水

滚滚长江东逝水

Starter rope

10

13

15

12

14

On/Off Switch

Throttle Lockout

Choke Button

Throttle Control

Primer Bulb

Starter Rope

Base of Fuel Tank Spout

11

5 - EN

WWW.SENIXTOOLS.COM

17

19

19

21

21

18

18

20

20

Bump Knob

Holding Slot

Split Wall

Oil Visible on First Thread

16

Eyelet

Spring

Washer

Spool Retainer

Holding Slots

Eyelet

Tabs

EN - 6 WWW.SENIXTOOLS.COM

22

24

23

Idle Speed Screw

0.60mm - 0.80mm

0.025in. - 0.031in.

Primer Bulb

Cover Rotary Knob

Air Filter Housing Air Filter Cover

Air Filter

7 - EN

WWW.SENIXTOOLS.COM

TABLE OF CONTENTS

SAFETY & INTERNATIONAL SYMBOLS ...........................7

SAFETY INSTRUCTIONS...................................................8

KNOW YOUR UNIT............................................................13

SPECIFICATIONS*............................................................13

ASSEMBLY.........................................................................13

OIL AND FUEL...................................................................14

OPERATION.......................................................................15

MAINTENANCE..................................................................17

TROUBLESHOOTING.......................................................20

PARTS................................................................................21

WARRANTY.......................................................................23

SAFETY & INTERNATIONAL

SYMBOLS

Explanation of Safety & international symbols describes

safety and international symbols and pictographs that may

appear on this product. Read the operator’s manual for

complete safety, assembly, operating and maintenance and

repair information.

This graphic accompanied by the words

WARNING, DANGER OR CAUTION calls

attention to an act of a condition which can

lead to SERIOUS INJURY.

Read the operator’s manual(s) and follow all

warnings and safety instructions. Failure to do

so can result in serious injury to the operator

and/or bystanders.

Always wear eye protection, ear protection and

head protection meeting ANSI Z87.1 standards.

Wear gloves.

Wear foot protection.

Beware of foot injury by cutting attachment.

Keep 15 meters or 50 feet away from any other

person.

Beware of objects ung by cutting

attachments.

Never use without properly mounted protection

guard.

Beware of objects ung by cutting

attachments.

Never use without properly mounted protection

guard.

Don’t install or use any type of blade on the unit

displaying this symbol.

Bystander sound pressure level: 75dB(A).

Maximum permitted revolutions of the cutting

head.

Maximum permitted revolutions of the blade.

75dB(A)

MEASURED AT 50FT. (15M)

PER ANSI B175.3

5700

5700

EN - 8 WWW.SENIXTOOLS.COM

SAFETY INSTRUCTIONS

WARNING!

Signals a SERIOUS hazard.

Failure to obey a safety WARNING

symbol CAN result in serious injury

to yourself or to others.

NOTE:

Advises you of information or

instructions vital to the operation or

maintenance of the equipment.

WARNING!

Crude oil, gasoline, diesel fuel

and other petroleum products can

expose you to chemicals including

toluene and benzene, which are

known to the State of California to

cause cancer and birth defects or

other reproductive harm. These

exposures can occur in and around

oil elds, reneries, chemical plants,

transport and storage operations

such as pipelines, marine terminals,

tank trucks and other facilities and

equipment. For more information

go to: www.P65Warnings.ca.gov/

petroleum.

WARNING!

CALIFORNIA PROPOSITION 65

This product contains a chemical

known to the state of California to

cause cancer, birth defects or other

reproductive harm.

Read the operator’s manual and

follow all warnings and safety

instructions. Failure to do so

can result in serious injury to the

operator and/or bystanders.

SAFETY WARNINGS

1. Proper safety precautions must

be observed. Like all power

equipment this unit must be

handled carefully. DO NOT

EXPOSE YOURSELF OR

OTHERS TO DANGER. Follow

these general rules. Do not

permit others to use this unit

unless they are thoroughly

responsible and have read, and

understood the string trimmer

manual and are trained in its

operation.

2. Always wear heavy, long pants,

boots, gloves, and a long-sleeve

shirt. Do not wear loose clothing,

jewelry, short pants, sandals, or

go barefoot. Secure hair so it is

above shoulder level.

3. Inspect unit before each use.

Replace damaged parts.

Check for fuel leaks. Make

sure all fasteners are in place

and secure. Replace cutting

attachment parts that are

cracked, chipped, or damaged in

any way. Make sure the cutting

9 - EN

WWW.SENIXTOOLS.COM

7. Do not operate the unit in

insufcient lighting conditions.

8. Do not operate this unit when

tired, ill, or under the inuence of

alcohol, drugs, or medication.

9. Always use proper handles when

trimming.

10. Do not smoke while lling tank.

11. Do not ll fuel in an enclosed

room or near open ames.

Ensure adequte ventilation.

12. Always store fuel in a properly

marked container that is

approved by local codes and

ordinances for such usage.

13. Never remove the fuel tank cap

while the engine is running.

14. Do not operate the unit inside

a closed environment, such as

a room or building; breathing

carbon monoxide from exhaust

fumes can kill.

15. Never attempt to make engine

adjustments while the unit is

running. Always make engine

adjustments with the unit resting

on a at, clear surface.

16. Do not use the unit if it is

damaged or poorly adjusted.

Never remove the unit’s guard.

Serious injury to the operator or

bystanders could result as well

as damage to the machine.

17. Clear the area to be cut before

attachment is properly installed

and securely fastened. Be sure

the cutting attachment shield

is properly attached and in the

position recommended by the

manufacturer. Use only exible,

nonmetallic line recommended

by the manufacturer. Never use,

for example, wire or wire-rope,

which can break off and become

a dangerous projectile.

4. DO NOT USE any attachment

with this power head other than

the ones recommended by the

manufacturer. Serious injury to

the operator or bystanders could

result as well as damage to the

machine.

5. The handles shall be mounted

in accordance with the

manufacturer’s instructions.

Do not attach any blade to a

unit without proper installation

of all required parts. Failure

to use the proper parts can

cause the blade to y off and

seriously injure the operator and/

or bystanders. Discard blades

that are bent, warped, cracked,

broken, or damaged in any way.

Use a sharp blade. A dull blade

is more likely to snag and thrust.

6. Keep the handles free from oil

and fuel.

EN - 10 WWW.SENIXTOOLS.COM

each use. Remove all objects

such as rocks, broken glass,

nails, wire, or string, which can

be thrown or become entangled

in the cutting attachment. Clear

the area of children, bystanders

and pets. At a minimum, keep

all children, bystanders and pets

outside a 15 m (50 ft) radius;

outside the 15 m (50 ft) zone,

there is still a risk of injury from

thrown objects. Bystanders

should be encouraged to wear

eye protection.

18. Never leave the unit unattended

while the engine is running.

19. Do not use this unit for any job

other than those for which it is

intended as described in this

manual.

20. Maintain rm footing and

balance. Do not over-reach.

Keep cutting attachment below

waist level. Maintain all parts of

your body away from the rotating

cutting attachment and hot

surfaces.

21. Do not use this type of unit for

sweeping away debris.

22. Use nylon cutting head which

is free of damage. If a stone

or any other obstacle is hit,

stop the engine and check the

nylon cutting head. A broken or

unbalanced nylon cutting head

must never be used.

23. FOLLOW INSTRUCTIONS for

assembling and operation.

24. Do not store the unit in a closed

area where fuel vapors can

reach an open ame from hot

water heaters, furnaces, etc.

Store in a locked, well ventilated

area only.

25. Ensure safe and proper

performance of your unit. Please

only use original accessories.

The use of any other

accessories or attachments

may cause a potential hazard or

injury to the user, damage to the

unit, and void the warranty.

26. If the unit will not be used for

a long time, clean the unit

completely, especially the fuel/oil

tank, its surroundings, and the

air lter.

27. When refueling, stop the engine

and conrm that it is cooled

down. Never refuel when the

engine is running or hot. When

gasoline spills, be sure to wipe

it up completely and dispose of

those materials before starting

the engine.

28. Mix and pour fuel outdoors

where there are no sparks and

flames. Slowly remove the fuel

11 - EN

WWW.SENIXTOOLS.COM

34. Pay attention to loosening and

overheating parts. If there is

any abnormality of the unit, stop

operation immediately and check

the unit carefully. If necessary,

have the unit serviced. Never

continue to operate a unit which

may be malfunctioning.

35. In start-up or during operation

of the engine, never touch hot

parts such as the mufer, the

high voltage wire, or the spark

plug.

36. After the engine has stopped,

the mufer is still hot. Never

place the unit in any places

where there are ammable

materials (dry grass, etc.),

combustible gasses, or

combustible liquids.

37. Pay special attention to

operation in the rain or just after

the rain as the ground may be

slippery.

38. If you slip or fall to the ground,

release the throttle lever

immediately.

39. Be careful not to drop the unit or

hit it against obstacles.

40. Before proceeding to adjust or

repair the unit, be sure to stop

the engine and detach the spark

plug.

41. When the machine is placed in

cap only after stopping the

engine. Do not smoke while

fueling or mixing fuel. Wipe

spilled fuel from the unit. Move

at least 3 m (10 ft) away from

the fueling source and site

before starting engine.

29. Stay clear of other workers

or bystanders by at least 15

meters/50 feet.

30. Whenever approaching an

operator of the unit, Be careful

not to startle or distract the

operator which can cause an

unsafe situation.

31. Never touch the nylon cutting

head or cutting blade whenever

the engine is running. If it is

necessary to adjust the protector

or nylon cutting head, make sure

to stop the engine and conrm

that the nylon cutting head or

blade has stopped running.

32. The engine should be turned off

when the unit is moved between

work areas.

33. Be careful not to hit the

nylon cutting head or blade

against stones, or the ground.

Unreasonable rough operation

will shorten the life of the unit

as well as create an unsafe

environment for yourself and

those around you.

EN - 12 WWW.SENIXTOOLS.COM

storage for a long time, drain

fuel/oil from the fuel/oil tank and

carburetor, clean the parts, and

move the machine to a safe

place.

42. Make periodic inspections

to ensure safe and efcient

operation.

43. Keep the unit away from re or

sparks.

44. Keep your body warm, especially

the head, neck, feet, ankles,

hands, and wrists.

45. Maintain good blood circulation

by performing vigorous arm

exercises during frequent work

breaks and also by not smoking.

46. Limit the hours of operation.

47. If you experience discomfort,

redness and swelling of the

ngers followed by whitening

and loss of feeling, consult

your physician before further

exposing yourself to cold and

vibration.

48. Always wear ear protection.

Loud noises for long periods

can cause hearing loss, even

permanent deafness.

49. Wear no-slip heavy duty work

gloves to improve your grip on

the handle. Gloves also reduce

the transmission of machine

vibration to your hands.

WARNING!

The string head is still dangerous

while the machine is coasting to a

stop.

50. Do not lay the machine on the

side; otherwise the fuel could

spill out.

51. Fuel evaporation during refueling

and exhaust gases are harmful

to the operator and people

around the unit.

52. Make sure that the fuel

evaporation and exhaust gases

will not drift to the face of

operator and keep other people

away from your working area.

53. Do not allow children or

untrained individuals to use this

unit.

54. Do not allow familiarity with this

product to make you careless.

Remember that a careless

fraction of a second is sufcient

to inict serious injury.

55. The cutting attachment may

be spinning during carburetor

adjustments. Wear your

protective equipment and

observe all safety instructions.

For units equipped with a clutch,

be sure the cutting attachment

stops turning when the engine

idles. When the unit is turned

13 - EN

WWW.SENIXTOOLS.COM

off, make sure the cutting

attachment has stopped before

the unit is set down.

RESIDUAL RISKS

WARNING!

Even when the unit is used as

prescribed it is not possible to

eliminate all residual risk factors.

The following hazards may arise

in connection with the unit’s

construction and design:

• Damage to lungs if an effective

dust mask is not worn.

• Damage to hearing if effective

hearing protection is not worn.

• Health defects resulting from

vibration emission if the unit is

being used over long periods of

time or not adequately managed

and properly maintained.

WARNING!

This unit produces an

electromagnetic eld during

operation. This eld may, under

some circumstances, interfere with

active or passive medical implants.

To reduce the risk of serious or fatal

injury, we recommend persons with

medical implants to consult their

physician and the medical implant

manufacturer before operating this

unit.

ADDITONAL SAFETY WARNING

FOR BRUSH CUTTER

1. Take not of all warnings and

instructions relating to operating

and tting the blade.

2. The blade can recoil suddenly

from objects if it cannot cut or

mow through them.This can

cause injuries to the arms or

legs.

3. Keep bystanders and animals

at least 15 meters or 50 feet

away from where you are

working. If the equipment strikes

a foreign body, stop the engine

immediately and wait for the

blade to come to a standstill.

Check the blade for signs of

damage. Always replace the

blade if it is bent or cracked.

4. The blade is liable to catapult

away objects with high force.

This can cause blindness or

injuries. Wear protection on your

eyes, face and legs. Always

remove objects from your

working area before you use the

blade.

5. If you are approached, stop the

engine and cutting attachment.

In the case of bladed units,

there is the added risk of injury

to bystanders from being struck

with the moving blade in the

EN - 14 WWW.SENIXTOOLS.COM

event of a blade thrust or other

unexpected reaction of the saw.

Take care of blade thrust.

• Blade thrust may occur when

the spinning blade contacts

an object that it does not

immediately cut.

• Blade thrust can be violent

enough to cause the unit and/

or operator to be propelled in

any direction, and possibly lose

control of the unit.

• Blade thrust can occur without

warning if the blade snags, stalls

or binds.

• Blade thrust is more likely to

occur in areas where it is difcult

to see the material being cut.

6. Carefully check the equipment

and its ttings for signs of

damage every time before

use. Do not use the equipment

unless all the blade ttings are

installed correctly.

7. When you release the throttle

control, the blade will continue

to rotate and will only gradually

come to a standstill. A blade

which is in the process of

rotating to a standstill can cause

you or bystanders injuries

through cutting. Before you start

any work on the blade, switch off

the engine and ensure that the

blade has come to a standstill.

8. Wear protective gloves

when handling or performing

maintenance on the blade.

9. A coasting blade can cause

injury while it continues to spin

after the engine is stopped

or throttle trigger is released.

Maintain proper control until the

blade has completely stopped

rotating.

WARNING!

Take care of the thrown objects

during operation when using the tool

with blade. Any inattention will cause

injury.

15 - EN

WWW.SENIXTOOLS.COM

KNOW YOUR UNIT

APPLICATIONS

Model:GTBCU4QL-M

As a trimmer and a brush cutter:

• Cutting grass and light weeds

• Decorative trimming around trees, fences, etc.

Other optional attachments may be used with this unit.

1 Engine Cover Screw Cap

2 Air Filter Cover

3Mufer

4 Choke

5 Spark Plug

6 Starter Rope Grip

7 Primer Bulb

8 Fuel Cap

9 Oil Fill Plug

10 Hook

11 Harness

12 Handle

13 Throttle Grip

14 Shaft Housing

15 Coupler

16 Cutting Head Shield

17 Line Cutting Blade

18 Cutting Head

19 Blade

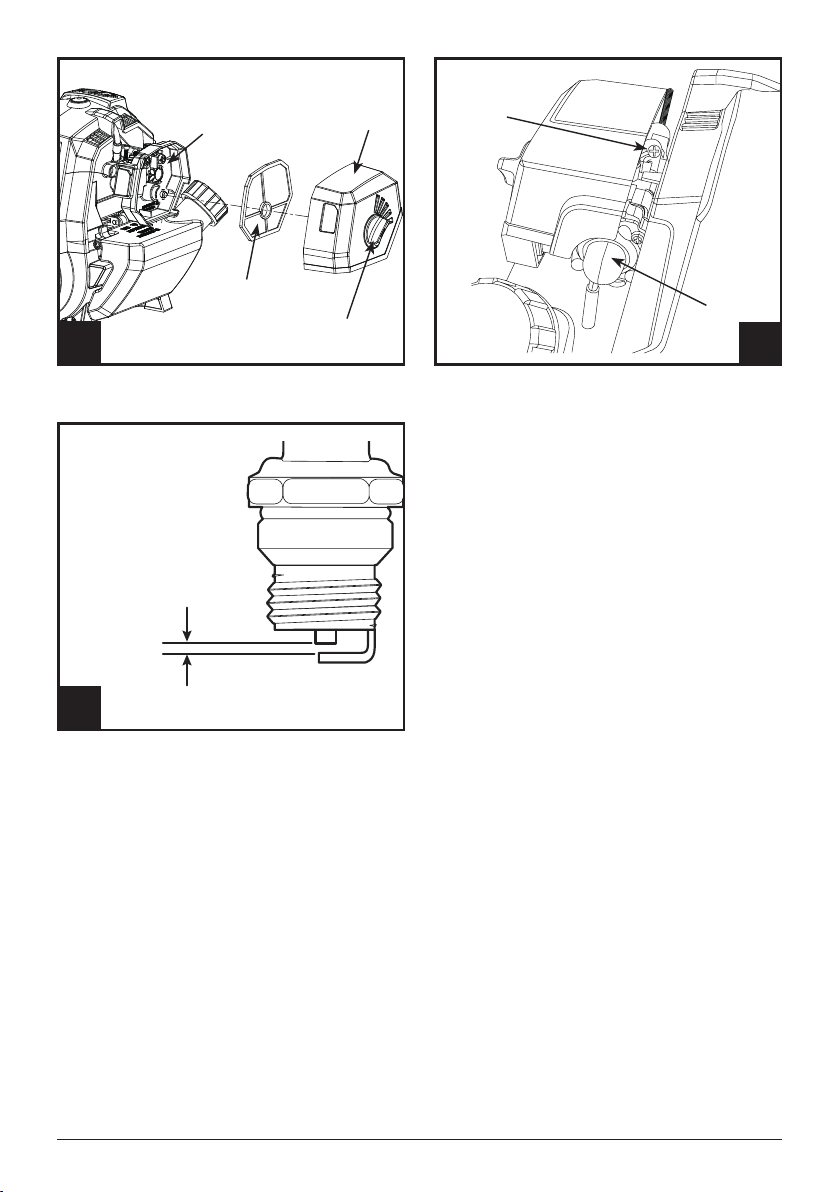

SPECIFICATIONS*

Model GTBCU4QL-M

Engine type Air-Cooled, 4-Cycle

Displacement 1.9 cu in. (31 cc)

Spark plug gap 0.025 in. - 0.031 in.

(0.6 - 0.8 mm)

Lubrication SAE 10W-30

Crankcase lubrication capacity 2.01 oz. (60 ml)

Fuel tank capacity 10.93 oz. (320 ml)

Weight with blade(No fuel) 11.84 lbs (5.37 kg)

Trimming line Spiral trimming line

Trimming line diameter 0.095 in. (2.4 mm)

Cutting diameter with trimmer head 17.7 in. (450 mm)

Cutting diameter with blade 10.04 in. (255mm)

* All specications are based on the latest product

information available at the time of printing. We reserve the

right to make changes at any time without notice.

ASSEMBLY

1. Unpack all parts and lay them on a at, stable surface:

2. Remove all packing materials and shipping devices, if

applicable.

3. The scope of delivery varies depending on the country

and purchased variant:

Model of GTBCU4QL-M

• Power tool x1

• Instruction manual x1

• Fast start guide x1

• Cutting head x1

• Blade and blade hardware (installed) x1

• Harness x1

• Cutting head shield and mounting screw x1

• Torx wrench x1

• Socket spanner x1

• 60 ml bottle of engine oil x1

EN - 16 WWW.SENIXTOOLS.COM

4. If you nd that parts are missing or show damage do

not use the product, please call 1-800-261-3981 for

assistance. Using an incomplete or damaged product

represents a hazard to people and property.

5. Ensure that you have all the accessories and tools

needed for assembly and operation. This also includes

suitable personal protective equipment.

WARNING:

Wear protective gloves for this assembly work

and always lay the product on a flat and stable

surface while assembling.

Follow the assembly instructions step-by-step

and use the pictures provided as a visual guide

to easily assemble the product!

WARNING:

To prevent an accidental start that could cause

serious personal injury, always disconnect the

engine spark plug wire from the spark plug when

assembling parts.

Never install, remove, or adjust any attachments

while power head is running. Failure to stop the

engine can cause serious personal injury.

INSTALLING THE CUTTING HEAD

SHIELD

1. Remove the screw from the cutting head shield.

2. Insert the tab on the mount bracket into the slot in the

cutting head shield (Fig. 2).

3. Rotate the cutting head shield until the hole on the

mount bracket aligns with the screw hole on the cutting

head shield.

4. Insert the screw and tighten until the cutting head shield

is rmly in place.

CHANGING THE CUTTING HEAD

TO THE CUTTING BLADE

1. Unscrew and detach the cutting head.

2. Insert a tool so the mounting disc does not move. Install

the blade, washer, concave to be upwards, and the

oating disc (Fig. 3).

NOTE:

The pit side of washer must be contacted with the blade.

3. Screw down the locknut and tighten it counterclockwise

by the socket spanner.

4. Remove the socket spanner and the wrench and check

for freedom of motion of the blade.

CHANGING THE CUTTING BLADE

TO THE CUTTING HEAD

1. Insert a tool so the mounting disc doesn't move.

2. Loosen the looknut and remove the oating disc,

washer and the cutting blade.

3. Attach the cutting head to the mounting disc (Fig.4).

3. Check for secure installation.

INSTALLING THE HANDLE

1. Align and screw upper xed cover and the handle

support.

2. Lock two screws between lower xed cover and handle

support until the tube is are rmly in place (Fig. 5).

INSTALLING/REMOVING THE

LOWER SHAFT ATTACHMENT

In addition to the supplied line trimmer lower shaft, the

coupler on the upper shaft enables the use of various other

lower shaft attachments, available for separate purchase.

WARNING:

Before using any attachment, read and

understand the manual that came with the

attachment. Follow all safety information

contained within.To avoid serious personal injury

and damage to the unit, shut the unit off before

removing or installing an attachment.

To intsall:

1. Set the unit on a at, level surface.

2. Loosen the coupler knob (Fig. 6).

3. Align the locating button on the lower shaft with the

locating hole of the coupler (Fig. 7).

4. Then insert the lower shaft (Fig. 8).

5. Pull the lower shaft to check if it is frimly in place.

6. Tighten the knob for securing (Fig. 6).

To remove:

1. Set the unit on a at, level surface.

2. Loosen the coupler knob.

3. Press and hold the release button.

4. Pull the lower shaft attachment straight out of the

coupler.

17 - EN

WWW.SENIXTOOLS.COM

INSTALL THE HARNESS

The harness with quick release function can be hooked

on the shaft. You can wear it according to your using

preference.

OIL AND FUEL

ADDING OIL: INITIAL USE

Use a high-quality SAE 10W-30 weight oil. DO NOT use

dirty oil. Failure to use clean oil of the correct type can

cause premature engine wear and failure.

Attempting to start the engine before it has been properly

lled with lubricant will result in equipment failure not

covered by the warranty.

WARNING:

OVERFILLING THE CRANKCASE MAY

CAUSE excessive smoke, engine damage and

SERIOUS PERSONAL INJURY. Check the oil

level before each use.

NOTE:

This unit is shipped without oil in its crankcase but comes

with a 2.03 uid oz. (60 ml) container of oil seperately. Oil

must be added before starting the unit. Never add oil to the

fuel tank. This unit has a four-cycle engine. DO NOT mix oil

with gasoline.

1. Set the unit on a at, level surface.

2. Unscrew the oil ll plug (Fig. 9).

3. Pour the entire container of oil into the oil ll hole. Do

not overll. Refer to "CHECKING THE OIL LEVEL".

4. Wipe up any oil that may have spilled.

5. Reinstall the oil ll plug. Make sure the O-ring is in place

on the oil ll plug (Fig. 9).

FUELING THE UNIT

Gasoline and its vapors are highly ammable and

explosive. To prevent serious personal injury and property

damage during fueling, instructions listed below have to be

followed.

• Always wear safety protections to avoid injury.

• Add fuel in a clean, well-ventilated outdoor area and keep

sparks and open ames at a distance from the area.

• Always stop the engine and allow it to cool before lling

the fuel tank.

• Spilled fuel around the tank opening should be

immediately wiped off.

• Do not start the engine until fuel vapors dissipate.

• Do not smoke while fueling.

1. Position the unit with the fuel cap facing up.

2. Slowly remove the fuel cap. Handle it with care in case

of spray.

3. Place the fuel container spout into the fuel tank fill

hole and fill the tank. Stop when you see that the level

reaches the base of the tank spout (Fig. 10). Do not

overfill the tank.

4. Wipe up any fuel that may have spilled.

5. Reinstall the fuel cap.

6. Move the unit at least 30 ft. (9.1 m) from the fuel

container and the fueling site before starting the engine.

NOTE:

This unit has a four-cycle engine. DO NOT mix oil with

gasoline. The use of old fuel is the most common cause

of performance problems. Use only fresh, clean unleaded

gasoline.

DEFINITION OF BLENDED FUELS

Today’s fuels are often a blend of gasoline and oxygenates

such as ethanol, methanol or MTBE (ether). Alcohol-

blended fuel ab- sorbs water. As little as 1% water in the

fuel can make fuel and oil separate, forming acids when

stored. ALWAYS use fresh fuel (less than 30 days old) with

less than 10% ethanol.

NOTE:

Dispose of old fuel according to federal, state and local

regulations.

USING BLENDED FUELS

If using a blended fuel:

• Always use fresh unleaded gasoline

• Use the fuel additive STA-BIL® or an equivalent

WARNING:

DO NOT USE E85 or E15 FUEL IN THIS UNIT.

It has been proven that fuel containing greater

than 10% ethanol will likely damage this engine

and void the warranty.

USING FUEL ADDITIVES

Use a fuel additive, such as STA-BIL Fuel Stabilizer or an

equivalent, to inhibit corrosion and minimize gum deposits.

Add 0.8 oz. (23 ml) of fuel additive per gallon of fuel,

according to the instructions on the container. NEVER add

fuel additives directly to the unit’s fuel tank.

EN - 18 WWW.SENIXTOOLS.COM

OPERATION

WARNING:

Inspect unit before each start. Replace

damaged parts. Check for fuel leaks. Make sure

all fasteners are in place and secure. Replace

cutting attachment parts that are cracked,

chipped, or damaged in any way. Make sure

the cutting attachment is properly installed and

securely fastened and the cutting attachment

shield is properly attached.

STARTING INSTRUCTIONS

1. Check the oil level befor start.

2. Fill the fuel tank. Refer to "FUELING THE UNIT".

NOTE:

There is no need to turn the unit on. The On/Off switch is in

the On position at all times (Fig. 11).

3. Slowly press and release the primer bulb 10 times

(Fig. 12).

4. Push the choke button in until it clicks (Fig. 13).

5. Crouch in the starting position.To avoid serious injury,

the operator and the unit must be in a stable position

when pulling the starter rope (Fig. 14).

6. Pull the starter rope with a controlled and steady motion

5 times until you can hear the deagration of engine

(Fig. 12).

7. Press throttle control and throttle lockout at same time

to keep choke open (Fig. 11).

8. Pull the starter rope again to start the product. Allow the

engine to warm up for 30 to 60 seconds at idle speed

before increasing cutting speed.

9. When the product starts, press and hold throttle lockout

and squeeze the throttle lever to increase trimmer

cutting speed. The further you squeeze the throttle

control, the more the cutting speed will increase

(Fig. 11).

NOTE:

To prevent the throttle control from being squeezed

accidentally, this unit has a throttle lockout. The throttle

control cannot be squeezed unless the throttle lockout is

also engaged.

STOPPING INSTRUCTIONS

1. Release the throttle control and allow the engine to idle.

2. Press and hold the On/Off switch in the Off position until

the engine comes to a complete stop (Fig. 11). Make

sure the cutting attachment has stopped before the unit

is set down.

HOLDING THE UNIT

• Stand in the operating position. Stand up straight. Do not

bend over.

• Keep feet apart and rmly planted.

• Hold the handle withone hand while another on the

throttle grip.

• Hold the unit at waist level.

• Position the cutting head a few inches above the ground.

• Do not over-reach; Keep all parts of your body away from

the rotating cutting attachment and hot surfaces.

• To direct clippings away from you, whenever possible

swing the trimmer in a left to right cutting motion.

DECORATIVE TRIMMING

When trimming around trees, posts, fences, etc., rotate the

whole unit so that the cutting head is at a 30° angle to the

ground (Fig. 15).

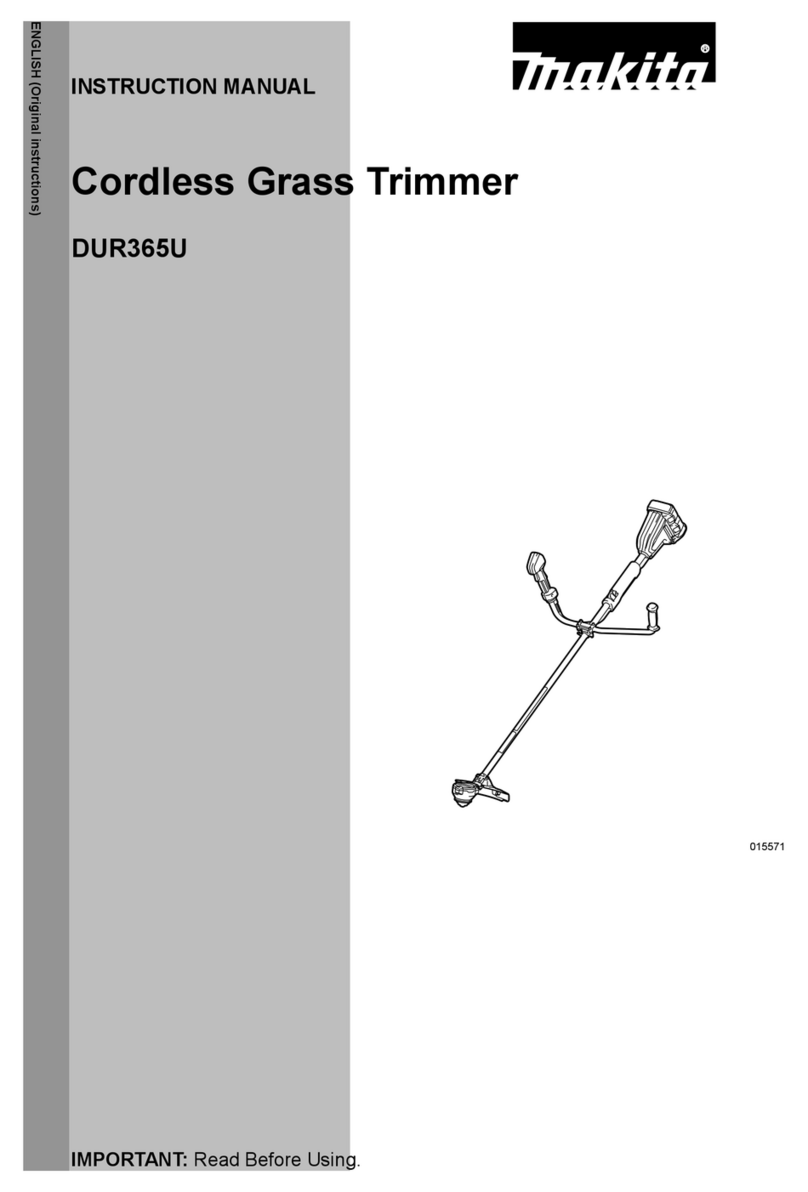

ADJUSTING THE TRIMMING LINE

This unit is equipped with a bump head. Trimming line can

be released from the cutting head without stopping the

engine. To release more line, lightly tap the bump knob on

the ground while operating the unit at high speed (Fig. 16).

For best results, tap the bump knob on bare ground or hard

soil. Attempting to release line in tall grass may stall the

engine.

NOTE:

Do not rest the cutting head on the ground while the unit is

running. Each time the bump knob is tapped, about 1 inch

(25.4 mm) of trimming line is released.

Always keep the trimming line fully extended. Line release

becomes more difcult when the cutting line gets shorter.

WARNING:

Do not remove or alter the line cutting blade

assembly. Excessive line length will make the

unit overheat. This may lead to serious personal

injury or damage to the unit.

19 - EN

WWW.SENIXTOOLS.COM

Maintaining the Trimming Line

Hard surfaces, such as sidewalks, can cause the trimming

line to wear down quickly or break.

• Frequently check the trimming line length. Replace the

trimming line as needed. Refer to Replacing the Trimming

Line.

• Do not force the unit. Make shallow cuts in as many

passes as are necessary to achieve the desired depth.

Cut at a slow, even pace.

CUTTING TIPS

• Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

• Operate this unit only in a well-ventilated outdoor area.

Carbon monoxide exhaust fumes can be lethal in a

conned area. Do not operate the unit inside a closed

environment, such as a room or building; breathing

carbon monoxide from exhaust fumes can kill.

• Clear the area to be cut before each use. Remove all

objects such as rocks, broken glass, nails, wire, or string

which can be thrown or become entangled in the cutting

attachment. Clear the area of children, bystanders, and

pets outside a 50 ft (15 m) radius.

• Avoid hot surfaces by always keeping the tool away from

your body.

• Cut all grass from top to down. This will prevent grass

from wrapping around the shaft housing and string head

which could cause damage from overheating.

• The preferred direction of trimmer operation is from left

to right .

• If grass becomes wrapped around the string head, stop

the engine, disconnect the spark plug wire, and remove

the grass.

• Use the tip of line to trim grass; do not force string head

into uncut grass.

• Avoid trees, owers, stones, walls and other objects which

can cause the line to break.

• Check and feed the line regularly to maintain full cutting

width and performance.

• Operation of this equipment could create sparks that

can start res around dry vegetation. A spark arrestor

may be required. The operator should contact local re

agencies for laws or regulations relating to re prevention

requirements.

TIPS FOR BEST RESULTS

• To direct clippings away from the operator, tilt the cutting

head slightly down to the right; whenever possible swing

the trimmer in a left to right cutting motion.

• Do not trim wet grass or weeds.

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick vegetation

• Forcing the line into objects such as walls or fence posts

MAINTENANCE

To avoid serious personal injury, always stop the engine

and allow it to cool before cleaning or maintaining the unit.

Never perform cleaning or maintenance while the unit is

running. Disconnect the spark plug wire to prevent the unit

from starting accidentally.

Wear protective clothing and observe all safety instructions

to prevent serious personal injury.

Do not use any attachments or accessories not

recommended by the manufacturer of this product. Never

use metal-reinforced line, wire, chain or rope. These can

break off and become dangerous projectiles. Only use the

trimming line described in the specications section.Other

types of trimming line may cause the unit to overheat or fail.

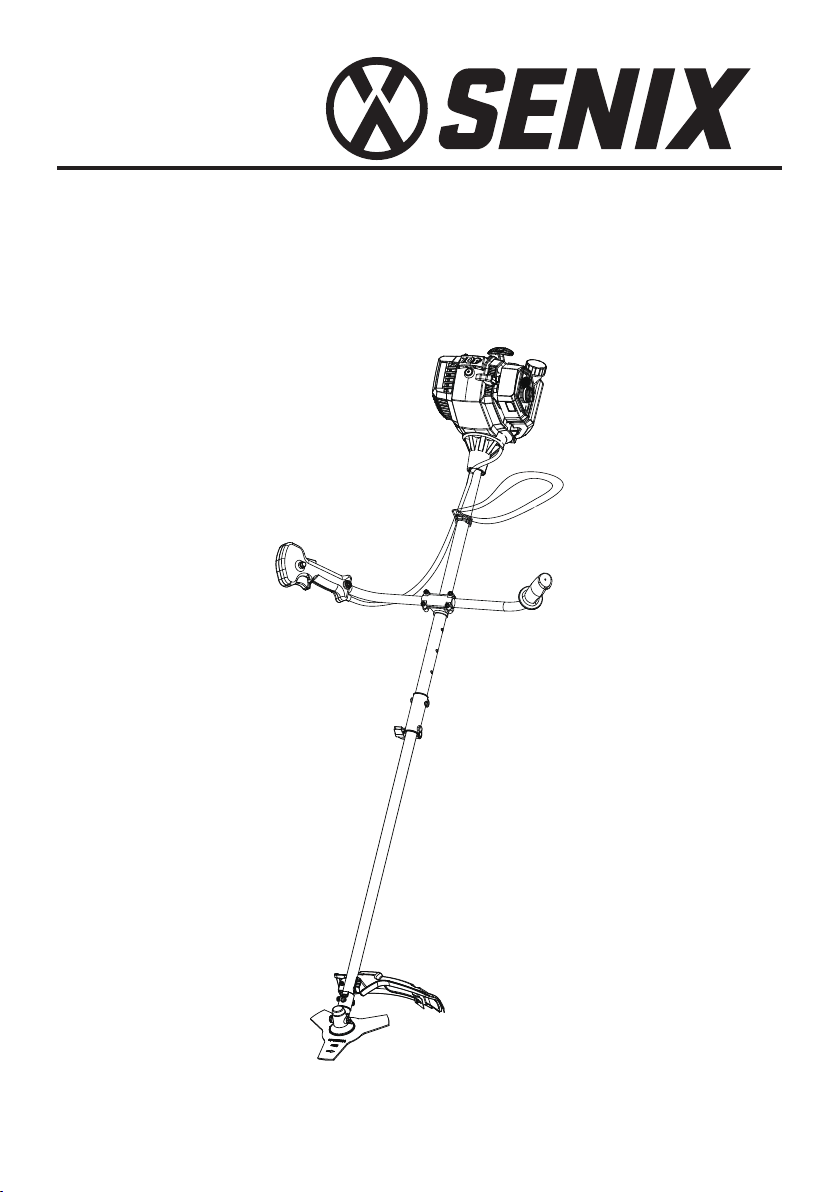

REPLACING THE SPOOL

1. Push in the tabs on the side of the spool retainer and

pull to remove (Fig. 17).

2. Install the spring, washer, and rewound spool, making

sure that the lines are captured in the holding slots on

the new spool.

NOTE:

Make sure that the ends of the lines extend approximately

6 in. (152 mm).

3. Install the new spool so that the line ends align with the

eyelets in the cutting head, and thread the line ends

through the eyelets.

4. Pull the lines extending from the cutting head so that the

strings release from the slots in the spool.

5. Install the spool retainer by pressing the tabs into the

slots and pushing down on the spool until the spool

retainer clicks into place (Fig. 17).

REPLACING THE TRIMMING LINE

1. Remove the spool from the cutting head.

2. Remove any old line from the spool. Use a clean cloth

to clean the surface of the cutting head.

3. Cut a 15 ft. (4.5 m) length of 0.095 in. (2.4 mm) diameter

trimming line.

4. Bend the line at the midpoint and insert the bend into

the holding slot on the spool (Fig. 18).

EN - 20 WWW.SENIXTOOLS.COM

5. Wrap the line evenly and rmly around the spool (Fig.

19).

6. Position the lines in the spool holding slots (Fig. 18).

7. Install the spool in the cutting head. See "REPLACING

THE SPOOL".

NOTE:

Use only exible, nonmetallic line recommended by the

manufacturer. Never use, for example, wire or wire-rope,

which can break off and become a dangerous projectile.

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should

also be a part of any seasonal tune-up. Some maintenance

procedures may require special tools or skills. If you are

unsure about these procedures, take the unit to a qualied

service dealer.

NOTE:

Maintenance, replacement, or repair of the emission control

devices and system may be performed by a qualied

service dealer.

NOTE:

Please read the California/EPA statement that came with

the unit for a complete listing of terms and coverage for

the emissions control devices, such as the spark arrestor,

mufer, carburetor, etc.

FREQUENCY MAINTENANCE REQUIRED

Every 10 hours • Clean the air lter. Refer to

"

MAINTAINING THE AIR FILTER".

Every 6 hours • Change the oil. Refer to "CHANGING

THE OIL".

After the rst 10

hours and at 38

hours

• Have the rocker arm clearance

checked by a qualied service

dealer.

• Check the spark plug condition and

gap. Refer to"MAINTAINING THE

SPARK PLUG".

CHECKING THE OIL LEVEL

Check the oil level before each use. The importance of

maintaining the proper oil level cannot be overemphasized.

Failure to keep the engine level may result in a faulty oil

level reading.If the oil level is too high, tip the unit and drain

the excess oil into an appropriate container.

DO NOT overll the oil level. Overlling will result in too

much oil in the engine crankcase, and may cause smoke or

fumes that can injure the user.

Inspecting the Oil Level

1. Stop the engine and allow it to cool.

2. Set the unit on a at, level surface, such as a workbench

or table. The cutting head shield should hang over the

edge so that the engine is level.

3. Unscrew the oil ll plug. The oil level should be visible

on the rst thread of the oil reservior (Fig. 20). If the oil

level is too low, add oil. Refer to "ADDING OIL".

Adding Oil

1. Clean the area around the oil ll plug to prevent debris

from entering the oil ll hole.

2. Unscrew the oil ll plug.

3. Add oil to the oil ll hole until the oil level is visible on the

rst thread of the oil reservoir (Fig. 20).

4. Wipe up any oil that may have spilled.

5. Make sure the O-ring is in place on the oil ll plug.

6. Reinstall the oil ll plug.

Changing The Oil

Old engine oil is considered special waste and has to be

disposed according to your local environment protection

regulation. Do not pour the oil into a garbage can, sewer,

soil etc.Dispose of the old oil according to federal, state and

local regulations.

Change the oil while the engine is still warm. The oil will ow

freely and carry away more impurities.

1. Clean the area around the oil ll plug to prevent debris

from entering the oil ll hole.

2. Unscrew the oil ll plug.

3. Tip the unit vertically to pour the oil out of the oil ll

hole and into a container (Fig. 21). Allow ample time for

complete drainage.

4. Wipe up any oil that may have spilled.

5. Pour 2.03 .oz. (60 ml) of SAE 10W-30 oil into the oil

ll hole.

6. Wipe up any oil that may have spilled.

7. Make sure the O-ring is in place on the oil ll plug.

8. Reinstall the oil ll plug.

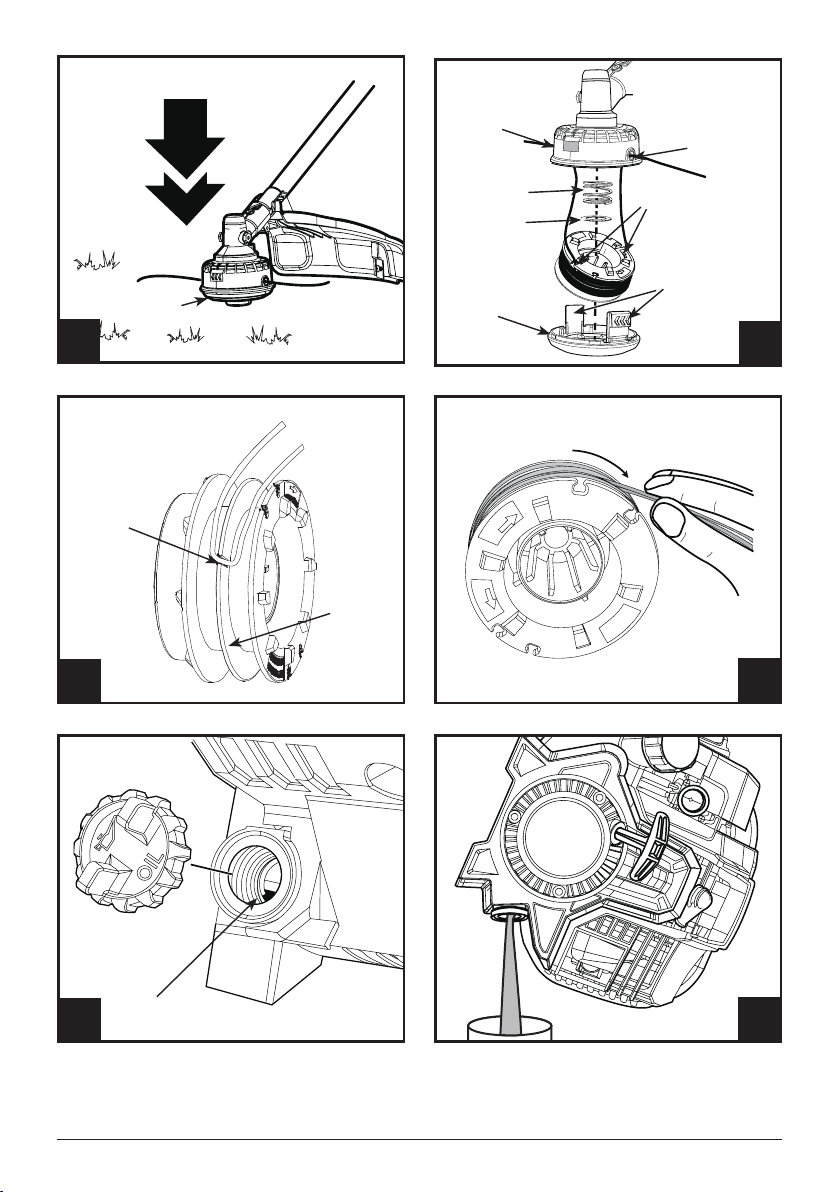

MAINTAINING THE AIR FILTER

Failure to maintain the air lter can result in poor

performance or can cause permanent damage to the

engine.

Table of contents

Languages:

Other Senix Trimmer manuals

Senix

Senix HTX2-M User manual

Senix

Senix GTSX5-M-0 User manual

Senix

Senix HTE3.8-L User manual

Senix

Senix HT4QL-L User manual

Senix

Senix GTC4QL-L User manual

Senix

Senix HTPX2-M User manual

Senix

Senix HTX5-M User manual

Senix

Senix GTE2.5-L-EU User manual

Senix

Senix GTX2-M User manual

Senix

Senix GTS4QL-M2 User manual