Senju Sprinkler RC-QR User manual

www.senjusprinkler.com Document No. U03688A • 01-06-2022Page 1 of 8

The Model RC-QR Commercial Flat Concealed Sprinklers are automatic sprinklers of the compressed fusible solder type.

They are decorative and quick responding. The Cover Plate Assembly hides the Deector, Heat Responsive Element

etc., which is concealed above the ceiling. The cover plate has a at prole, and its diameter is extremely small (2-5/8

inch, 68mm). The push-on and/or thread-on, thread-off design of the concealed cover plate assembly allows for easy

installation of the cover plate.

Therefore, the Model RC-QR should be your rst choice when aesthetics is the major consideration for ultimate appeal

and unbeatable performance is desired.

They are to be installed per NFPA 13 guidelines.

The Model RC-QR has a 5.6 (80.6 LPM/bar1/2) K-factor.

For extended installation exibility, the Model RC-QR provides 1/2 inch (12.8mm) vertical adjustment. This adjustment in

installation decreases the need for precise cutting of the pipe that drops to the sprinkler and allows for a perfect t with

a range of pipe lengths.

The heat sensitivity and water distribution design of Model RC-QR allows for an increased chance of occupants to escape

or evacuate in case of a re. However, re sprinkler systems are not a substitute for re safety awareness or re safety

construction required by building codes.

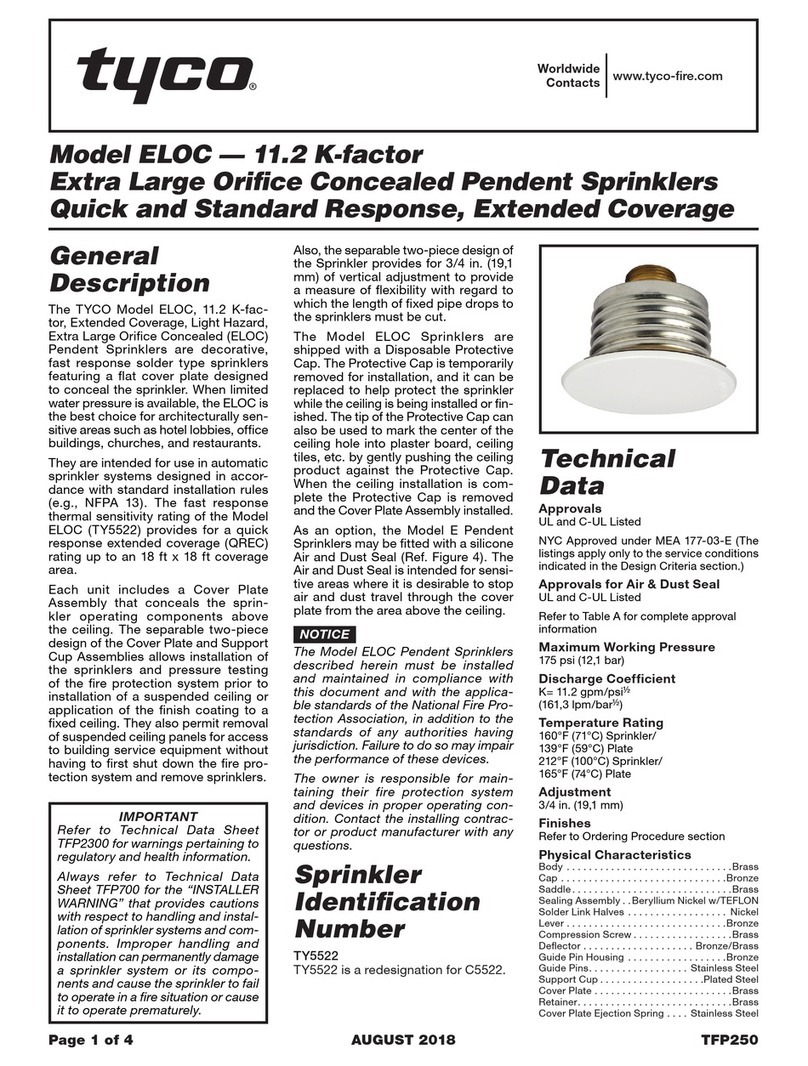

GENERAL DESCRIPTION

Commercial Flat Concealed Sprinkler, Pendent

Quick Response, Standard Coverage

Model RC-QR

K-Factor: 5.6 •SIN: SS9561

WARNINGS

The Model RC-QR must be installed and maintained in accordance with the rules stated herein as well as in compliance

with the applicable standards of the National Fire Protection Association regulations and the standards of any other

authorities having jurisdiction.

In the event of this condition, consult the authorities having jurisdiction for guidance and approval. Failure to do so may

impair the integrity of these devices.

www.senjusprinkler.com Document No. U03688A • 01-06-2022Page 2 of 8

• Approvals:

{cULUS Listed / as Quick Response

{FM Approved / as Standard Response

• Sprinkler Identication Number (SIN): SS9561

• Maximum Working Pressure: 175 psi (12.1 bar)

• Discharge Coefcient (Nominal K-Factor):

{K = 5.6 GPM / psi1/2 (80.6 LPM / bar1/2)

• Temperature Rating:

{162°F (72°C) Sprinkler with 140°F (60°C) Cover Plate

{205°F (96°C) Sprinkler with 140°F (60°C) Cover Plate

{205°F (96°C) Sprinkler with 162°F (72°C) Cover Plate

• Color Code:

{162°F (72°C): Uncolored

{205°F (96°C): White

• Color Code (Cover Plate):

{140°F (60°C): No Mark

{162°F (72°C): White-Colored Mark

• Vertical Adjustment: 1/2 inch (12.8 mm)

• Cover Plate Finishes:

{Standard Finishes: White, Ivory, Beige, Brown, Black,

Nickel, Copper, Wood Grain

{Custom Finishes: Custom color and custom pattern

cover plates are available on special order. Contact a

Senju Sprinkler representative with any custom orders.

Please see chart on page 8 for more detail.

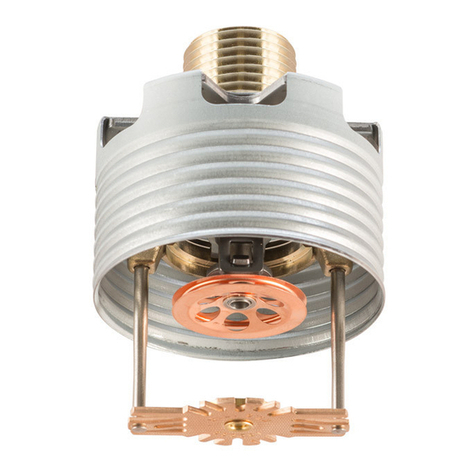

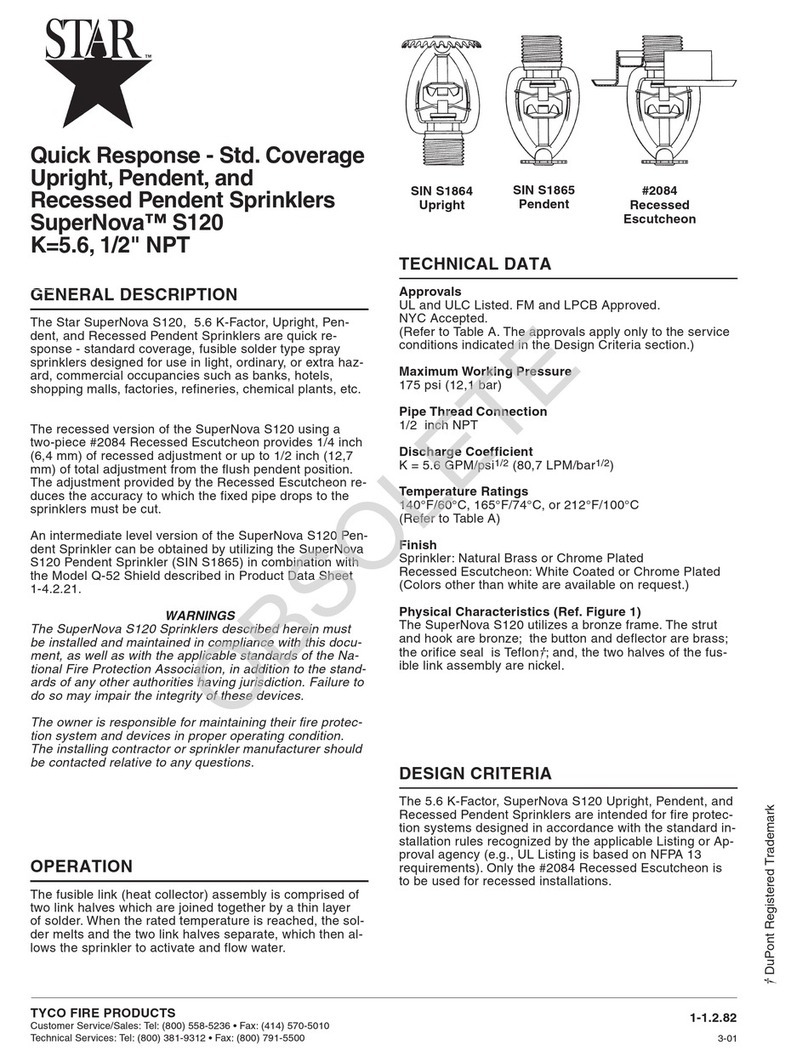

• Physical Characteristics: Ref. Figures 1 and 1.1

TECHNICAL DATA

Figure 1: Model RC-QR, K = 5.6

Figure 1.1: Marking (Color Code)

It is the responsibility of the installing contractor to provide a copy of this document to the owner or their representative,

and in turn, it is the obligation of the owner to provide a copy of this document to a succeeding owner.

The owner is responsible for maintaining their re protection system and devices in proper operating condition. The

installing contractor or sprinkler manufacturer should be contacted with any related questions.

OPERATION

In case of re, the solder component that holds together the Cover Plate and the Retainer melts. Then the Cover Plate is

released at once. As a result, the Deector drops down to the intended position. Two Heat Collectors are exposed to re,

and when sufcient heat from the re is reached, internal components of the sprinkler fall apart. This leads to the water

ow to be distributed on the affected re area. (Ref. Figure 2)

Color Code

Cover Plate

(Top View)

Sprinkler

(Bottom View)

Marking (Deflector)

SIN: SS9561

K-Factor: K5.6

Temperature Rating:

162°F (72°C) or

205°F (96°C)

UL Mark

FM Mark

①

③

②

④

⑤

⑥

1/2″ NPT

2-1/4″ (57.7 mm)

2-1/16″ (Ø52 mm) Marking

Lot No.

Year of Manufacture

SIN: SS9561

K-Factor: K5.6

Temperature Rating:

162°F (72°C) or

205°F (96°C)

Control No.: 177R

UL Mark

FM Mark

2-5/8″ (Ø68 mm)

or 3-1/4″ (Ø83 mm)

or UL only: 2-5/8″ square (□68 mm)

① Body (Copper Alloy)

② Deflector (Phosphor Bronze)

③ Gasket (PTFE)

④ Fusible Metal (Solder)

⑤ Heat Collector (Copper)

⑥ Cover Plate Assembly

www.senjusprinkler.com Document No. U03688A • 01-06-2022Page 3 of 8

The Model RC-QR sprinklers are listed by UL and C-UL as quick response / standard coverage for use in accordance

with NFPA.

Also the Model RC-QR is FM Approved as a Standard Response for Non-Corrosive Atmospheres. The herein stated rules

for use and installation of the Model RC-QR are provided by the manufacturer and must be strictly implemented for safe

and full results.

DESIGN CRITERIA

Notes

Fire Sprinkler Systems should only be designed and installed by individuals who are completely familiar with automatic

sprinkler system design, installation procedures, and techniques.

Several criteria may apply to the installation and usage of each sprinkler. Consequently, it is recommended that the sprinkler

system designer review and develop a working understanding of the complete list of criteria prior to initiating the design of the

sprinkler system.

Questions concerning sprinkler installation and usage criteria, which are not covered by the following instructions, should be

submitted to your contracted company. Include sketches and technical details, as appropriate.

In some instances, the requirements of this document may concern specications which are more stringent, and which take

precedence over those specied in NFPA 13 or by the authority having jurisdiction.

The Model RC-QR must not be used in applications where the air pressure above the ceiling is greater than that below.

Inspect all sprinklers after installation to ensure that both the gap between the cover plate, ceiling and the 6 slots in the cup

are open and free from any air ow impediment.

The spray from the sprinkler is distributed radially outward and downward from the sprinkler deector. Consequently, the

sprinklers must be located such that there will be no blind spaces shielded from spray by partitions, room dividers, overhangs

or other parts of the dwelling structure.

The number of sprinklers within each compartment (as dened by NFPA 13) must be kept as few as possible while observing

all guidelines relating to obstructions and spacing.

Use only the Cover Plate provided for the Model RC-QR. The sprinkler must be secured in place by rmly fastening the

sprinkler system piping to the structure. If the sprinkler is not properly secured in position, reaction forces resulting from

sprinkler operation could alter its orientation and its water distribution pattern.

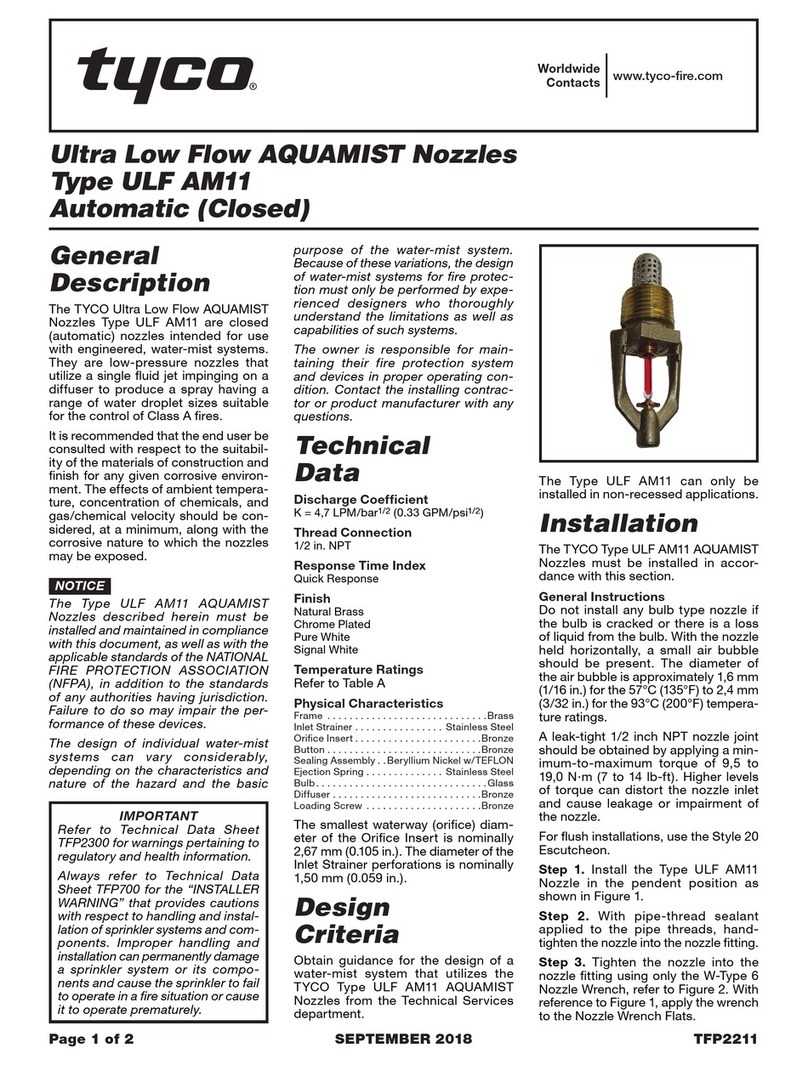

Normal Condition Cover Plate Operation Sprinkler Operation Water Discharge

Figure 2: Operation Process (For illustrative purposes only)

www.senjusprinkler.com Document No. U03688A • 01-06-2022Page 4 of 8

Obstruction to Water Distribution

Locations of sprinklers must follow the obstruction rules of NFPA 13.

General Service Conditions

The Model RC-QR must only be utilized in sprinkler systems per NFPA 13 guidelines.

Operational Sensitivity Criteria

For proper operational sensitivity, the Model RC-QR must be installed beneath a solid ceiling having a smooth or textured

surface.

Heat Source Criteria

Refer to NFPA 13 for the requirements relating to the prevention of possible activation of the Heat Responsive Element of

Model RC-QR, due to the exposure of a heat source other than an actual re.

Available Sprinkler Temperature Ratings

Sprinkler Temperature

Classication

Sprinkler Nominal

Temperature Rating

Maximum Ambient Ceiling

Temperature

Temperature Rating of the

Cover Plate Assembly

Ordinary 162°F (72°C) 100°F (38°C) 140°F (60°C)

Intermediate 205°F (96°C) 150°F (66°C) 140°F (60°C) 1)

Intermediate 205°F (96°C) 150°F (66°C) 162°F (72°C)

1) Maximum ambient temperature for the Cover Plate Assembly is 100°F (38°C).

Precautionary Warnings for Corrosive Environments

Model RC-QR sprinklers should not be installed where they may be subjected to a corrosive environment including the

following:

1. Chlorine ion and Chloride environment

Stress corrosion cracking may be caused by exposure to environments with Chlorine ion and Chloride. Exposure to

this environment may result in sprinklers operating under Non-Fire conditions or Not Operating when exposed to an

actual re.

2. Sprinkler system piping with Copper

Sprinkler systems should be constructed in compliance with the applicable standards and the requirements for

copper piping when copper piping is used in the sprinkler system. (Reference standards NFPA 13, ASTM B813, B828,

and CDA (Copper Development Association) – Solder Joint)

All residual ux must be removed from the interior and exterior of the copper piping by thoroughly ushing before

installation of the Sprinkler Heads. Otherwise, residues of ux may cause corrosion and/or leakage in the sprinkler

system.

INSTALLATION

The Model RC-QR must be installed in accordance with the following instructions:

NOTES

Do not use any sprinklers which have been subjected to potential mechanical damage. Do not use any sprinklers which show

deformation or cracking in either the Sprinkler or the Protective Cap.

Prior to installation, sprinklers should be maintained in the original cartons and packaging until used to minimize the potential for

damage to the sprinklers that could cause improper operation or non-operation.

www.senjusprinkler.com Document No. U03688A • 01-06-2022Page 5 of 8

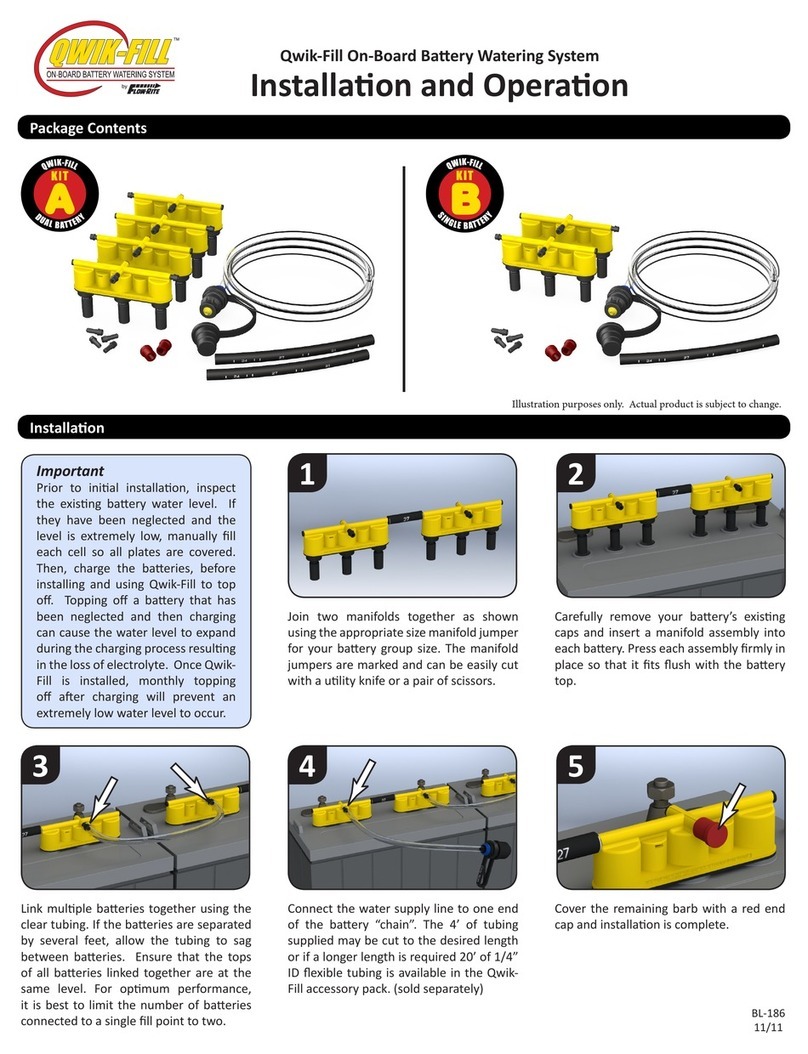

Installation Steps

Step 1: The installation requirements for the sprinkler are as follows: to be installed only in the pendent position with the

waterway perpendicular to the ceiling. Install the sprinkler tting so that the distance from the face of the tting to the

mounting surface will be nominally 2 inches (50.8mm) as shown in Figure 3.

Step 2: With pipe thread sealant applied to the threads, hand tighten the sprinkler into the sprinkler tting. Then tighten it

with the Socket NR-H or Ratchet (3/8″drive) & Socket NR-H Combination (Ref. Figure 4). The teeth of the Socket must t

perfectly with the grooves on the Sprinkler for proper installation (Ref. Figure 4).

Step 3: If desired, the Protective Cap may also be used to locate the center of the clearance hole by gently pushing the

ceiling material against the center point of the Protective Cap. Before the installation of the ceiling, the sprinkler installation

can be started with a 2-3/8 inch (60mm) diameter clearance hole (Ref. Figure 3). Use the “Vertical Adjustment” indicator

on the Protective Cap to check for proper installation height (Ref. Figure 3).

Step 4: Use the Cap Removal Tool for RC to remove the Protective Cap (Ref. Figure 5), and then push or screw a Cover

Plate Assembly on the Cup of the Sprinkler by hand until its ange just has contact with the ceiling (Ref. Figure 6 and

Figure 7). Stop tightening the Cover Plate Assembly once the ange has contact with the ceiling. If the ceiling has been

lifted from its normal position in the process of tightening the Cover Plate Assembly, readjust the cover plate assembly as

necessary. If the ange of the Cover Plate Assembly cannot contact the ceiling sufciently, readjust the sprinkler tting as

necessary. When properly installed, there is a nominal 1/16 inch (1.6mm) air gap between the lip of the Cover Plate and

the ceiling, as shown in Figure 6.

The Protective Cap must remain on the sprinkler during installation. After the installation is completed, the Protective Cap must

be removed to place the sprinkler in service.

Use a torque of 7 to 14 ft·lbs (9.5 to 19.0 N·m) to achieve a 1/2 inch NPT sprinkler joint. If you exceed the recommended maximum

torque, this could result in damage to the sprinkler inlet, which may lead to leakage from the sprinkler.

Use only NR-H model wrench socket for installation of RC-QR sprinklers. Use of any other wrench or socket is prohibited and

may cause damage to the sprinkler.

In case of insufcient adjustment in Cover Plate installation, do not try to overly tighten, screw the sprinkler too loosely or make

any modication to the cover plate assembly. Readjust the sprinkler tting for a better t.

Do not rotate the Cap Removal Tool for RC to the left with force when placing the two hook arms into place. The installed sprinkler

may become loosened, which may cause water leakage.

2″ (50.8 mm)

Mounting

Surface

2-3/8″ (Ø60 mm)

Ceiling Hole Diameter

Correct Incorrect

Do Not

Over-Tighten

Mounting Surface

1/2″

(12.8 mm)

Vertical

Adjustment

Make a Space Here

Ave. 1/4″ (6.4 mm)

Min. 1/8″ (3.2 mm)

Socket NR-H

Ratchet

Groove on the Sprinkler

Protective Cap

Tooth on the Socket

Figure 3: Installation Figure 4: Ratchet & Socket

www.senjusprinkler.com Document No. U03688A • 01-06-2022Page 6 of 8

Protective Cap

Cap Removal Tool

Sprinkler Head Hook up

Step 1 Step 2 Step 3

Pull down

Figure 5: Protective Cap Removal

Deflector

5/8″ ± 1/4″

(16 ± 6.4 mm)

Mounting

Surface

2″ (50.8 mm)

Cup

Screw

2-5/8″ (Ø68 mm)

or 3-1/4″ (Ø83 mm)

or UL only: 2-5/8″ square (□68 mm)

2″ (50.8 mm)

Cover Plate Assembly

1/16″ (1.6 mm)

Figure 6: Installation (Cover Plate Assembly)

Incorrect Correct Incorrect

Less than

1-3/4″ (44.4 mm)

2 ± 1/4″ (50.8 ± 6.4 mm)

More than

2-1/4″ (57.2 mm)

Figure 7: Installation (Correct and Incorrect)

www.senjusprinkler.com Document No. U03688A • 01-06-2022Page 7 of 8

CARE & MAINTENANCE

ORDER PROCEDURE

The following instructions must be implemented for the maintenance and service of the Model RC-QR.

Notes

Wet pipe sprinkler systems must be maintained at a minimum temperature of 40°F/4°C to prevent freezing and bursting of the

pipe and/or sprinklers.

Automatic sprinklers are not to be tested with a heat source. Operation of the heat responsive element can result.

Absence of a Cover Plate Assembly may delay the response time of the sprinkler in case of a re.

Install the cover plate assembly properly, as shown in Figure 6. Improper installation of the cover plate assembly may cause

improper operation or non-operation.

If the ceiling is to be repainted after the installation of the Sprinkler, care must be exercised to ensure that the new paint does not

seal off any of the air gap.

Factory painted Cover Plates must not be repainted. They should be replaced, if necessary, by factory painted cover plates. Non-

factory applied paint may adversely delay or prevent sprinkler operation in case of a re.

Do not pull the Cover Plate. Separation may result.

In preparation for maintenance of the re protection system, permission to close the main control valve must be obtained from the

proper authorities, and all affected parties by this action, and must be informed before the maintenance session can commence.

Do NOT enclose any sprinklers within drapes, curtains, or valances.

Do NOT hang anything from the sprinklers.

Do NOT clean the sprinklers with soap and/or water, detergents, ammonia, cleaning uids, or other chemicals. Remove dust,

lint, cobwebs, cocoons, insects, and larvae by gently brushing with a feather duster or gently vacuuming with a soft bristle (i.e.,

dusting) brush attachment.

Exercise suitable safety precautions in the use and storage of highly ammable materials. The rapid rate of re development and

spread of these materials can reduce the ability of the sprinkler system to aid in the control of a re involving such hazards.

Leaking or corroded sprinklers must be replaced.

Automatic Sprinklers must be kept in a cool and dry place.

Automatic sprinklers must never be physically altered, such as painted, plated, or coated, once shipped from the factory. If the

sprinklers have been in any way modied, they must be replaced.

Great caution must be applied to prevent damage to the sprinklers at all stages - before, during, and after installation. Damaged

units because of dropping, hitting, over-tightening, or wrench slippage, must be replaced.

When remodeling, such as by adding false beams or light xtures or changing the location of compartment walls, rst verify that

the new construction will not violate the installation requirements of the applicable standards of NFPA. Alter the new construction

and/or the sprinkler system to suit the requirements of this document and the applicable NFPA regulations.

The owner is responsible for the maintenance of the sprinkler system, including inspection and testing of its compliance with

this document, as well as the standards of the National Fire Protection Association (e.g., NFPA 25), and the regulations of any

other authorities having jurisdiction. The owner should direct any questions regarding the above rules and regulations to the

installing contractors or the sprinkler manufacturer. It is recommended that automatic sprinkler systems be inspected, tested,

and maintained by a qualied Inspection Service in accordance with NFPA 25.

When placing an order, please contact a local distributor with the following information (Model Name, Temperature Rating

and Finish).

www.senjusprinkler.com Document No. U03688A • 01-06-2022Page 8 of 8

Standard Finishes Custom

Finishes

White Ivory Beige Brown Black Nickel Copper Wood

Grain

Custom

Color

Custom

Pattern

2-5/8″Round, 140°F ------

3-1/4″Round, 140°F

2-5/8″Square, 140°F *1 -------

2-5/8″Round, 162°F -------

3-1/4″Round, 162°F - -

2-5/8″Square, 162°F *1 -------

*1: cULUS listed only

Tools & Accessories

• Socket NR-H

for use with a 3/8″drive ratchet (not included)

• Socket NR-H Plastic

for use with a 1/2″drive ratchet (not included)

• Cap Removal Tool for RC

• Cover Plate Installation Tool

Sprinkler

• Model: RC-QR

SIN: SS9561, Quick Response, Standard Coverage, Flat Concealed Sprinkler, Pendent, K5.6

• Temperature: 162°F (72°C) or 205°F (96°C)

Cover Plate Assembly

• cULUS Listed: 2-5/8 inch (φ68mm) or 3-1/4 inch (φ83mm) or 2-5/8 inch square (□68mm),

Order Separately from Sprinkler

• FM Approved: 2-5/8 inch (φ68mm) or 3-1/4 inch (φ83mm), Order Separately from Sprinkler

Please refer to the chart below for available sizes, temperature, and nishes.

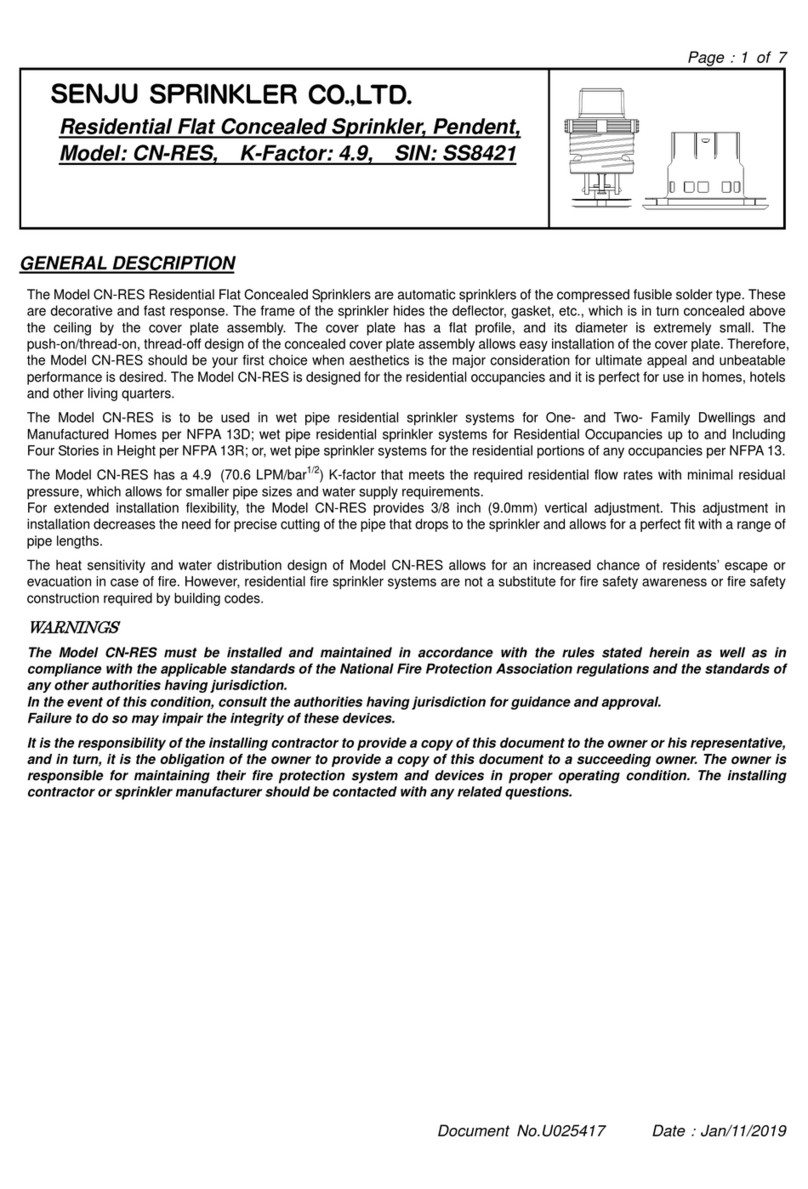

Table of contents

Other Senju Sprinkler Irrigation System manuals

Senju Sprinkler

Senju Sprinkler RC-QR-EC User manual

Senju Sprinkler

Senju Sprinkler CN-RES User manual

Senju Sprinkler

Senju Sprinkler FR-QR User manual

Senju Sprinkler

Senju Sprinkler SS8464 User manual

Senju Sprinkler

Senju Sprinkler RC-RES User manual

Senju Sprinkler

Senju Sprinkler HF-RES User manual

Senju Sprinkler

Senju Sprinkler ZN-RES User manual

Senju Sprinkler

Senju Sprinkler RC-RES User manual

Senju Sprinkler

Senju Sprinkler FR-RES User manual

Senju Sprinkler

Senju Sprinkler HF-RES User manual