ESFR PENDENT SPRINKLER

UL: SPECIFIC APPLICATION ESFR SPRINKLER

FM: STORAGE SPRINKLER

NFPA: SPECIAL SPRINKLER

VK510 (K25.2)

TECHNICAL BULLETIN

Page 2 of 7

Form No. F_121022 Rev 01 December 2022

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

T

elephone:

269-945-9501

T

echnical

Services:

877-384-5464

Fax:

269-818-1680

Email:

[email protected]Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com

Compression Screw: Stainless Steel UNS-S31603

Trigger and Support: Stainless Steel UNS-S31600

Fusible Element Assembly: Beryllium nickel coated with black acrylic paint.

Ordering Information: Refer to Table 2

4. INSTALLATION

NOTICE

Viking sprinklers are manufactured and tested to meet rigid requirements of the approving agencies. The sprinklers are designed

to be installed in accordance with recognized installation standards or FM Global Loss Prevention Data Sheets. System design

must be based on guidelines described in the latest edition of the applicable FM Global Loss Prevention Data Sheets indicated for

Storage sprinklers, the latest NFPA Standards indicated for ESFR sprinklers, the Authority Having Jurisdiction, and also with the

provisions of government codes, ordinances, and standards whenever applicable. Deviation from the standards or any alteration

to the sprinkler after it leaves the factory including, but not limited to: painting, plating, coating, or modification, may render the

sprinkler inoperative and will automatically nullify the approval and any guarantee made by The Viking Corporation.

A. Sprinklers must be handled with care. They must be stored in a cool, dry place in their original shipping container. Never install

sprinklers that have been dropped or damaged in any way. Such sprinklers should be destroyed immediately.

B. The sprinklers must be installed after the piping is in place to prevent mechanical damage. Before installing, be sure to have the

appropriate sprinkler model and style, with the correct orifice size, temperature rating, and response characteristics.

C. With the sprinkler contained in the plastic protective cap, apply a small amount of pipe-joint compound or tape to the male threads

only, while taking care not to allow a build-up of compound in the sprinkler orifice.

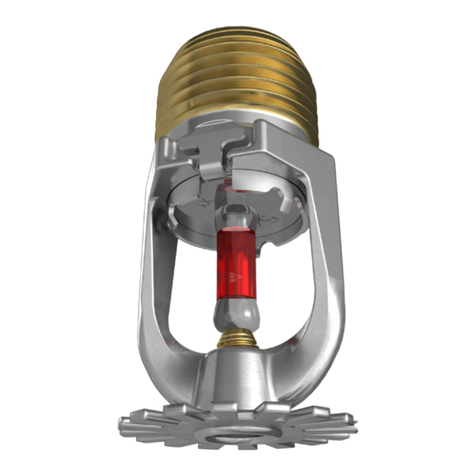

D. Use ONLY sprinkler wrench 13635W/B (shown in Figure 1) for installing VK510. With the sprinkler contained in the

protective cap, install the sprinkler onto the piping by applying the sprinkler wrench to the sprinkler wrench flats only,

while taking care not to damage the sprinkler operating parts.

• DO NOT use any other type of wrench, as this could damage the unit.

• DO NOT use the sprinkler deflector or fusible element to start or thread the sprinkler into a fitting.

• DO NOT exceep 30 ft. lbs. of torque (hand tight plus approximately 1 to 1-1/2 turns with the wrench) to install these sprinklers.

Over tightening may distort the sprinkler inlet with consequent leakage or impairment of the sprinkler.

E. After installation, the entire sprinkler system must be tested. The test must be conducted to comply with the Installation

Standards. Make sure the sprinkler has been properly tightened. If a thread leak occurs, normally the unit must be removed, new

pipe-joint compound or tape applied, and then reinstalled. This is due to the fact that when the joint seal is damaged, the sealing

compound or tape is washed out of the joint. Immediately replace any damaged units, using the special sprinkler wrench only.

F. After installation and testing and repairing of all leaks, remove the protective caps from the sprinklers. Do NOT use

any type of tool to remove the cap. Remove the cap by hand: turn it slightly and pull it off the sprinkler. When remov-

ing caps, use care to prevent dislodging or damaging sprinkler fusible element. THE CAPS MUST BE REMOVED FROM

SPRINKLERS BEFORE PLACING THE SYSTEM IN SERVICE.

5. OPERATION

During fire conditions, the heat-sensitive fusible element assembly disengages, releasing the seat and belleville spring assembly

to open the waterway. Water flowing through the sprinkler orifice strikes the sprinkler deflector, forming a uniform spray pattern to

suppress the fire.

6. INSPECTIONS, TESTS AND MAINTENANCE

NOTICE

The owner is responsible for maintaining the fire protection system and devices in proper operating condition. For

minimum maintenance and inspection requirements, refer to the NFPA standard that describes care and maintenance of

sprinkler systems. In addition, the Authorities Having Jurisdiction may have additional maintenance, testing, and inspec-

tion requirements that must be followed.

NOTE:Wet pipe systems must be provided with adequate heat.

A. The sprinklers must be inspected on a regular basis for corrosion, mechanical damage, obstructions, paint, etc. The frequency

of inspections may vary due to corrosive atmosphere, water supplies, and activity around the device.

B. Sprinklers that have been painted or mechanically damaged must be replaced immediately. Sprinklers showing signs of corrosion

shall be tested and/or replaced immediately as required. Installation standards require sprinklers to be tested and, if necessary, re-