TFP332

Page 2 of 4

Design

Criteria

UL and C-UL Listing Requirements

The TYCO 16.8 K-factor, Model K17-231

(TY7151 & TY7251) Sprinklers may be

installed in accordance with NFPA 13

standard sprinkler position and area/

density ow calculation requirements

for light, ordinary, or extra hazard oc-

cupancies with a minimum residual

(owing) pressure of 7 psi (0,5 bar) in

wet or dry pipe sprinkler systems, or

they may be installed in accordance

with NFPA 13 standard sprinkler posi-

tion and area/density ow calculation

requirements for high piled storage oc-

cupancies (solid piled, palletized, rack

storage, bin box, and shelf storage in-

cluding but not limited to Class I-IV and

Group A plastics) with a minimum resid-

ual (owing) pressure of 7 psi (0,5 bar)

for wet or dry pipe systems.

The following two examples are typical

of the types of arrangements permit-

ted by NFPA 13. For all combinations

of lesser and greater building heights,

lesser and greater storage heights,

storage arrangements, commodity

classications, and lesser or greater re-

quired design densities, refer to NFPA

13 for specics.

Example 1: NFPA 13 provides ceil-

ing only protection (that is, no in-rack

sprinklers) criteria using open frame

(that is, no solid shelves) single, double,

multiple-row, or portable rack storage

(without the need for in-rack sprinkler

protection) of cartoned or uncartoned

unexpanded Group A or B plastics, or,

cartoned expanded Group A or B plas-

tics, with:

• a storage height of up to 20 feet

(6,1 m);

• a maximum ceiling height of 27 feet

(8,2 m);

• a minimum deector to top of

storage clearance of 18 inches

(457 mm);

• a minimum design density of 0.60

gpm/ft2(24,4 mm/min);

• a minimum residual (owing)

pressure of 7 psi (0,5 bar);

• a minimum design area of 2000 ft2

(186 m2) for wet systems or 2600 ft2

(242 m2) for dry pipe systems

Example 2: NFPA 13 provides ceil-

ing only protection (that is, no in-rack

sprinklers) criteria using open frame

(that is, no solid shelves) single, double,

multiple-row, or portable rack storage

(without the need for in-rack sprinkler

protection) of cartoned or uncartoned

unexpanded Group A or B plastics, or,

cartoned expanded Group A or B plas-

tics, with:

• a storage height of up to 25 feet

( 7, 6 m) ;

• a maximum ceiling height of 30 feet

(9,1 m);

• a minimum deector to top of

storage clearance of 18 inches

(457 mm);

• a minimum design density of

0.80 gpm/ft2(32,6 mm/min);

• a minimum residual (owing)

pressure of 7 psi (0,5 bar);

• a minimum design area of 2000 ft2

(186 m2) for wet systems or 4500 ft2

(418 m2) for dry pipe systems

FM Approval Requirements

The TYCO 16.8 K-factor, Model K17-231

(TY7151) Upright Sprinklers may be in-

stalled in accordance with the applica-

ble “control mode density/area” guide-

lines provided by Factory Mutual. (FM

guidelines may differ from UL and C-UL

Listing criteria.)

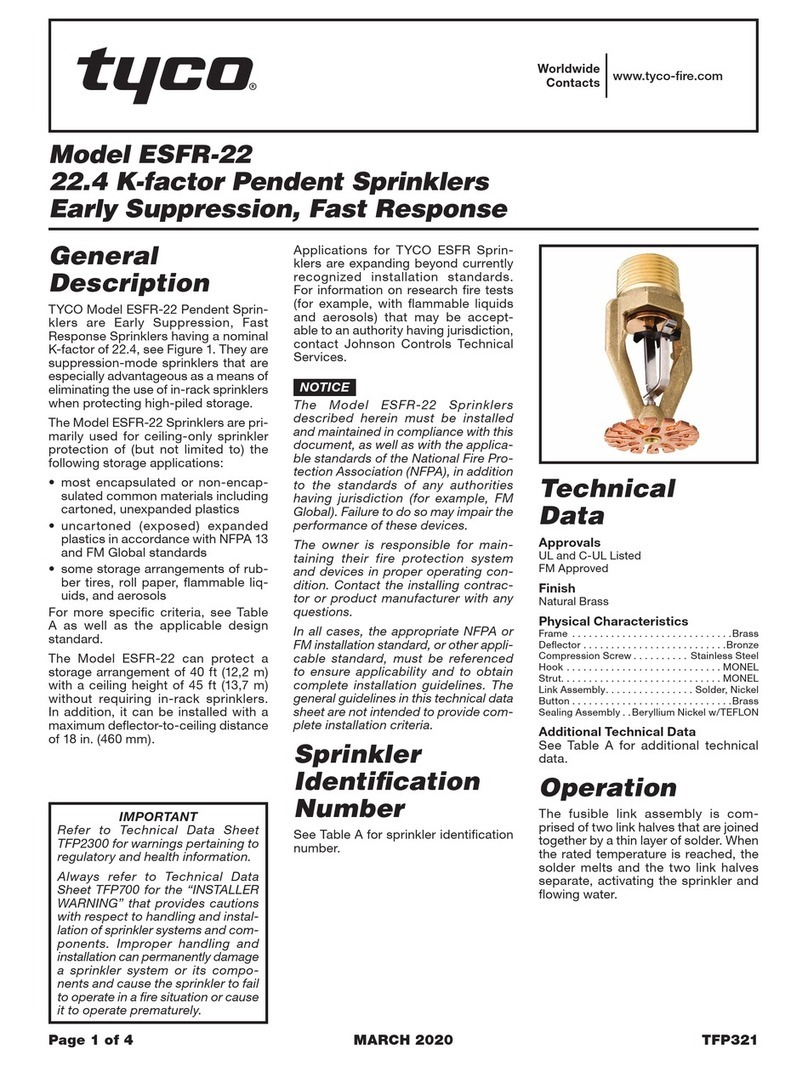

SPRINKLER FINISH

TYPE TEMPERATURE BULB

LIQUID NATURAL BRASS

UPRIGHT

K=16.8 (TY7151)

155°F (68°C) Red

1, 2, 3, 4200°F (93°C) Green

286°F (141°C) Blue

PENDENT

K=16.8 (TY7251)

155°F (68°C) Red

1, 2, 4200°F (93°C) Green

286°F (141°C) Blue

NOTES:

(1) Listed by Underwriters Laboratories, Inc. (UL Listed).

(2) Listed by Underwriters Laboratories, Inc. for use in

Canada (C-UL Listed).

(3) Approved by Factory Mutual Research Corporation (FM Approved).

(4) Approved by the City of New York under MEA 177-03-E.

TABLE A

LABORATORY LISTINGS AND APPROVALS

(Refer To The Design Criteria Section)