FASTFLEX

Model FB Flexible Braided Hose

Page 1 of 4 NOVEMBER 2014 TFP730

Worldwide

Contacts

www.tyco-fire.com

Technical

Data

Approvals

VdS Approved

(Refer to Table A for specic laboratory

approvals and the approvals apply to

the service conditions indicated in the

Design Criteria sections.)

CSTB accepted for all models and

assembly lengths.

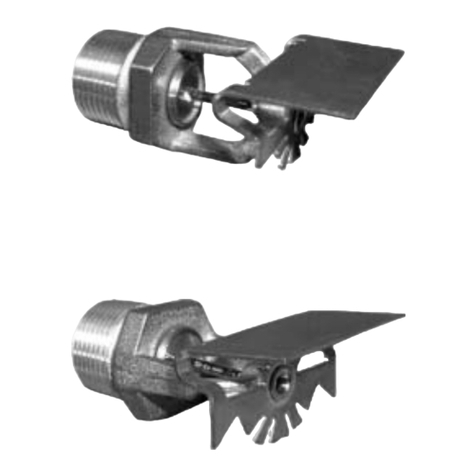

Inlet Connections (Ref Fig. 1)

ISO 7-R 1

Outlet Connections (Ref Fig. 2)

1/2 inch NPT

3/4 inch NPT

Nominal Assembly Lengths

Refer to Table A

Construction (Ref. Fig. 1)

The Inlet Nipple is mild steel, and the

Flexible Hose is SS AISI 304. The

Sprinkler Reducer is mild steel. The

Reducer Bracket, Bar Fixing Clamps,

and Support Bar are pressed steel.

Design Criteria

The TYCO FASTFLEX Model FB Flexible

Braided Hose is VdS Listed and used

with pendent sprinklers. The following

paragraph provides the design criteria

unique to VdS Approval listing.

VdS Listing Design Criteria

• Wet-pipe systems only

• Minimum bend radius of 55 mm

• Maximum service pressure of 16

bar

• Pendent sprinklers with nominal

K57, K80, or K115

• Maximum ambient temperature of

107°C

General

Description

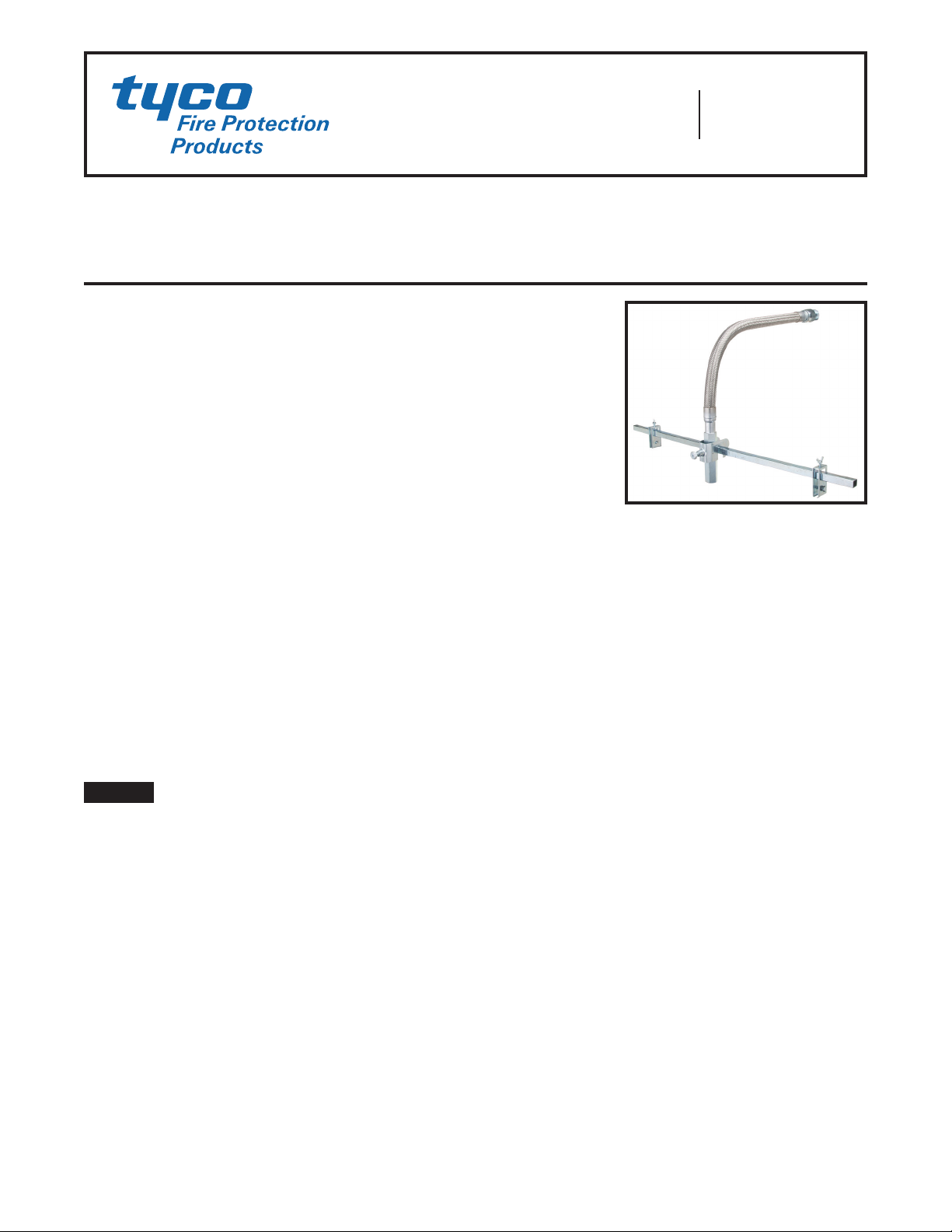

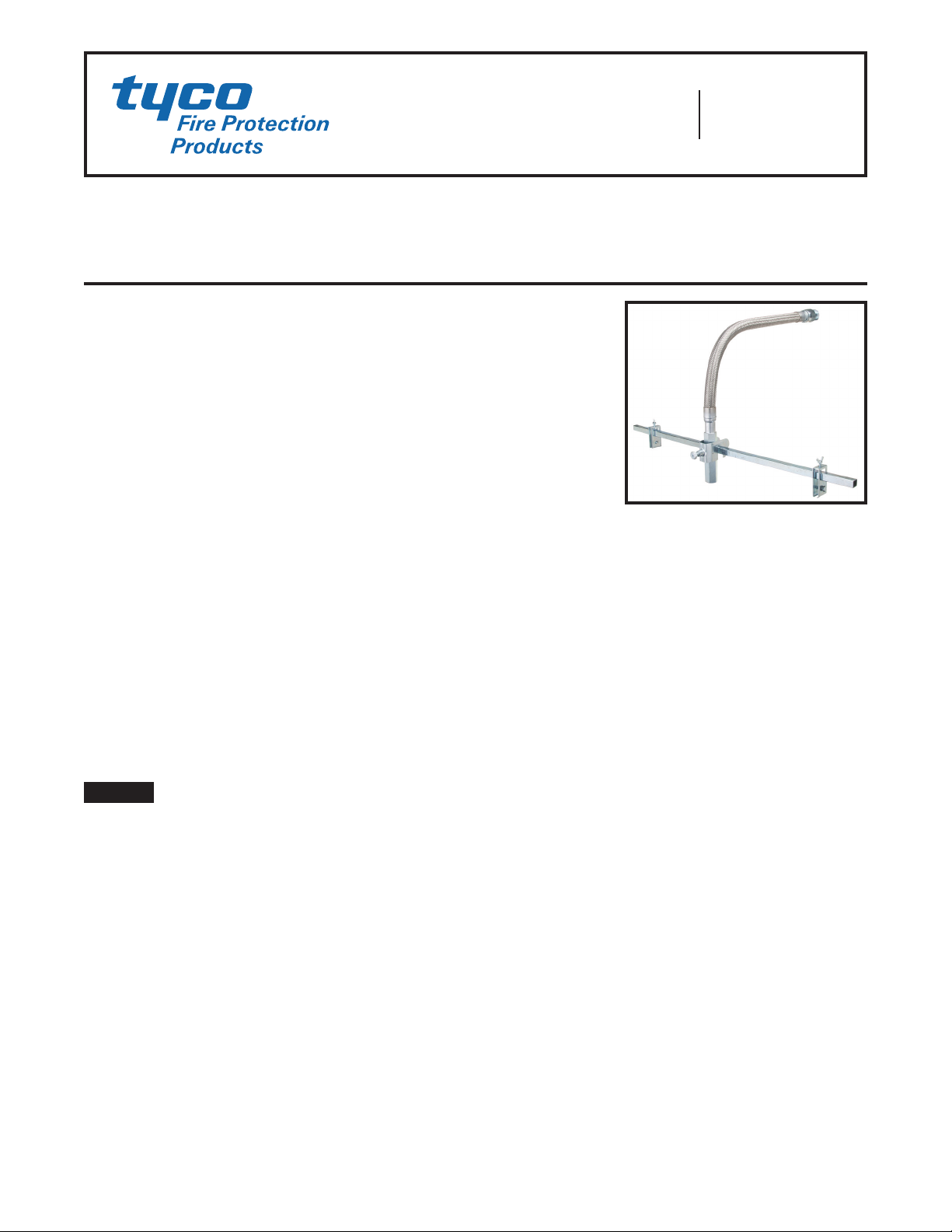

The TYCO FASTFLEX Model FB Flex-

ible Braided Hose is a unique sprinkler

drop assembly comprised of a stainless

steel exible hose a swivel inlet nipple,

a sprinkler reducer, and lightweight

ceiling bracket components. (Refer to

Figure 1.)

The FASTFLEX Model FB Flexible

Braided Hose can be installed in false

ceilings without cutting and thread-

ing pipes associated with installing a

drop, arm-over, and elbow. It provides

easier maneuverability around ducts

and trays in congested spaces and for

unusual ceiling types and curved plas-

terboard ceilings. The FASTFLEX Model

FB Flexible Braided Hose makes it pos-

sible to test and charge the system with

water before the ceiling grid is installed.

Once the ceiling grid is in position, the

hoses can be reshaped to suit the nal

sprinkler location without draining the

system.

The FASTFLEX Model FB Flexible

Braided Hose hoses are for use on wet

pipe sprinkler systems only.

NOTICE

The TYCO FASTFLEX Model FB Flexible

Braided Hose flexible sprinkler hoses

described herein must be installed

and maintained in compliance with

this document and with the applicable

standards recognized by the Approval

agency, in addition to the standards of

any other authorities having jurisdiction.

Failure to do so may impair the perfor-

mance of these devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Approved Ceiling Systems

FASTFLEX Model FB Flexible Braided

Hose is approved for use only in the

following manufacturers suspended

ceilings listed below on the condition

that the prole is based on a T-shaped

prole:

AMF

Odenwald

Richter

Armstrong

Rigips

Knauf

Chicago Metallic

Durlum

Geipel

Gema Armstrong

Suckow & Fischer

USG Donn

Daldrop & Dr. Huber

Rockfon Pagos

VdS Friction Loss

For compensation of pressure

loss, the nominal assembly length

is to be multiplied by 10. The re-

sulting length will provide pressure

drop in equivalent length DN25

(33,7 x 3,25 mm) metal tube per EN

10255.

• Add 2,3 m when using a 90° sprin-

kler reducer.