Sensia CALDON SVM 289Ci User manual

CALDON SVM 289Ci

Self-Verifying Ultrasonic Meter with G3

Transmitter

User Manual

MA23102, Rev. 01

Important Safety Information CALDON SVM 289Ci

ii

IMPORTANT SAFETY INFORMATION

SYMBOLS AND TERMS

Read user instructions carefully and visually inspect the equipment to become familiar with the device

before installing, operating, or maintaining it.

Equipment should be installed, operated, serviced, and maintained only by qualified personnel. Sensia

assumes no responsibility for consequences arising from the use of this material.

The following messages may be used in this document to help ensure personal safety and efficient

handling of equipment.

DANGER

A hazardous situation which, if not avoided, will result in serious injury or death.

WARNING

A hazardous situation which, if not avoided, can result in serious injury or death, major loss

of property, or catastrophic business risk.

WARNING – ELECTRICAL SHOCK

An electrical hazard which will result in personal injury if instructions are not followed.

CAUTION

A hazardous situation which, if not avoided, can result in minor or moderate injury, loss of

property, or business risk.

Important

Non

-urgent information that may impact the outcome of a process or procedure.

Note

Additional information or a tip

that may help the user to work more efficiently.

DO NOT DISCARD IN TRASH BIN

Product should not be discarded as unsorted waste. It must be sent to separate collection

facilities for recovery and recycling.

CONTACT SENSIA

For technical support, please refer to https://www.sensiaglobal.com/Technical-Support.

For all other inquiries, please refer to https://www.sensiaglobal.com/Customer-Care or dial 1-866-773-

6742.

REVISION HISTORY

Revision

Description of Change

Issuer

Approver

Date

1

Release to production

KM

BG

5-17-2023

CALDON SVM 289Ci Publisher Notes

iii

PUBLISHER NOTES

DISCLAIMER

While Sensia has taken every care in the preparation of this document, it cannot accept responsibility for

printing errors or omissions and does not warrant that it is correct and comprehensive in every particular

instance. Equipment supplied should always be operated by persons with an appropriate level of skill and

training.

Sensia shall not be liable for incidental or consequential damages resulting from the furnishing,

performance or use of this material.

Sensia pursues a policy of continuous improvement, and information given herein may be updated

without notice. Further, this information is proprietary to Sensia, and must not be disclosed to any third

party except as may be required to operate the equipment supplied in accordance with the purposes for

which it was sold by the persons properly licensed to operate it.

COPYRIGHT NOTICE

Copyright © 2023 Sensia. All rights reserved.

This work contains the confidential and proprietary trade secrets of Sensia and may not be copied or

stored in an information retrieval system, transferred, used, distributed, translated or retransmitted in any

form or by any means, electronic or mechanical, in whole or in part, without the express written

permission of the copyright owner.

TRADEMARKS & SERVICE MARKS

An asterisk (*) is used throughout this document to designate marks of Sensia. Other company, product,

and service names are the properties of their respective owners.

Sensia, the Sensia logotype, and other words or symbols used to identify the products and services

described herein are either trademarks, trade names or service marks of Sensia and its licensors, or the

property of their respective owners. These marks may not be copied, imitated or used, in whole or in part,

without the express prior written permission of Sensia. In addition, covers, page headers, custom

graphics, icons, and other design elements may be service marks, trademarks, and/or trade names of

Sensia and may not be copied, imitated, or used, in whole or in part, without the express prior written

permission of Sensia.

WARRANTY

Product warranty is specified in Sensia Terms and Conditions at the time of purchase.

SECURITY NOTICE FOR SOFTWARE PRODUCTS

The software described herein is designed to operate with the minimum hardware and operating system

specifications recommended by Sensia. The software should be operated in a secure environment

whether operation is performed across a network, on a single system and/or on multiple systems.

The end user is responsible for configuring and maintaining networks and/or system(s) in a secure

manner. The end user is also responsible for obtaining, installing, operating and maintaining all hardware,

other equipment and third-party software required for use of the software. Sensia is not responsible for

data loss arising as a result of software use or interaction of the software with any third-party software.

For more information about recommended security practices, please contact Sensia Technical Support

via https://www.sensiaglobal.com/Technical-Support.

Publisher Notes CALDON SVM 289Ci

iv

Table of Contents

Section 1: Introduction...............................................................................................................8

1.1 Equipment Description 8

1.1.1 SVM 289Ci Meter Body ................................................................................................................. 8

1.1.2 G3 Transmitter............................................................................................................................... 9

1.2 Model Numbers 11

1.2.1 Meter Body Model Number.......................................................................................................... 11

1.2.2 Transmitter Model Number.......................................................................................................... 12

1.2.3 Transmitter Specifications ........................................................................................................... 13

1.2.4 Meter Markings............................................................................................................................ 14

Section 2: Meter Body Installation ..........................................................................................15

1.1 Lifting/Hoisting the Meter Body 15

2.1.1 Hoist Ring Installation.................................................................................................................. 15

2.1.2 Sling Attachment ......................................................................................................................... 16

2.2 Meter Installation 18

Section 3: Transmitter Connections .......................................................................................20

3.1 Transmitter Installation Procedure 20

3.1.1 Transmitter Location.................................................................................................................... 20

3.1.2 Transmitter Terminations............................................................................................................. 20

3.2 Wiring Instructions 22

3.2.1 Power Terminations (Terminal Block 1) ...................................................................................... 22

3.2.2 User 1 and User 2 Inputs/Outputs............................................................................................... 23

3.2.3 Analog Inputs (Terminal Block 2) ................................................................................................ 23

3.2.4 Analog Outputs (Terminal Block 2) ............................................................................................. 24

3.2.5 Optional HART (Terminal Block 2) .............................................................................................. 24

3.2.6 Digital Outputs (Terminal Block 2)............................................................................................... 24

3.2.7 Grounding.................................................................................................................................... 25

3.2.8 Remote Data Communications.................................................................................................... 27

3.2.9 Serial Communications................................................................................................................ 28

3.3 Meter Installation Check-Out 29

3.3.1 Output Test Mode........................................................................................................................ 29

Section 4: Understanding Flow Calculations ...................................................................................30

4.1 Measuring Flow Velocities 30

4.2 Measuring Flow Rate 31

4.2.1 Temperature Compensation........................................................................................................ 32

CALDON SVM 289Ci Publisher Notes

v

4.2.2 Conversion to Standard Conditions............................................................................................. 32

Section 5: Operations...............................................................................................................34

5.1 Definitions 34

5.2 Normal Operating Conditions 35

5.3 Display LEDs 35

5.4 Display 35

5.5 Alarm Conditions 37

Section 6: Maintenance ............................................................................................................39

6.1 Introduction 39

6.2 General Inspections and Preventative Maintenance Procedures 39

6.2.1 Electronic Enclosure Inspection .................................................................................................. 39

6.2.2 Internal Electronics Inspection..................................................................................................... 39

6.3 Transmitter Troubleshooting 40

6.4 Circuit Board Replacement 40

6.4.1 IOP – Input/Output and Power Supply Board or Power Fuse Replacement............................... 41

6.4.2 CTC and Display Replacement ................................................................................................... 43

6.4.3 MXR Replacement ...................................................................................................................... 46

6.5 Transducer Installation 48

6.6 Analog Input Verification 49

6.7 Analog Output and Pulse Output Verification 50

6.7.1 Force Output (Analog)................................................................................................................. 50

6.7.2 Force Output (Pulse) ................................................................................................................... 50

Section 7: Troubleshooting and Diagnostics......................................................................... 51

7.1 Diagnostics 51

7.1.1 Automatic Fault Detection ........................................................................................................... 52

Section 8: Metrological Seals .................................................................................................. 54

Section 9: Recommended Spare Parts ...................................................................................58

FIGURES

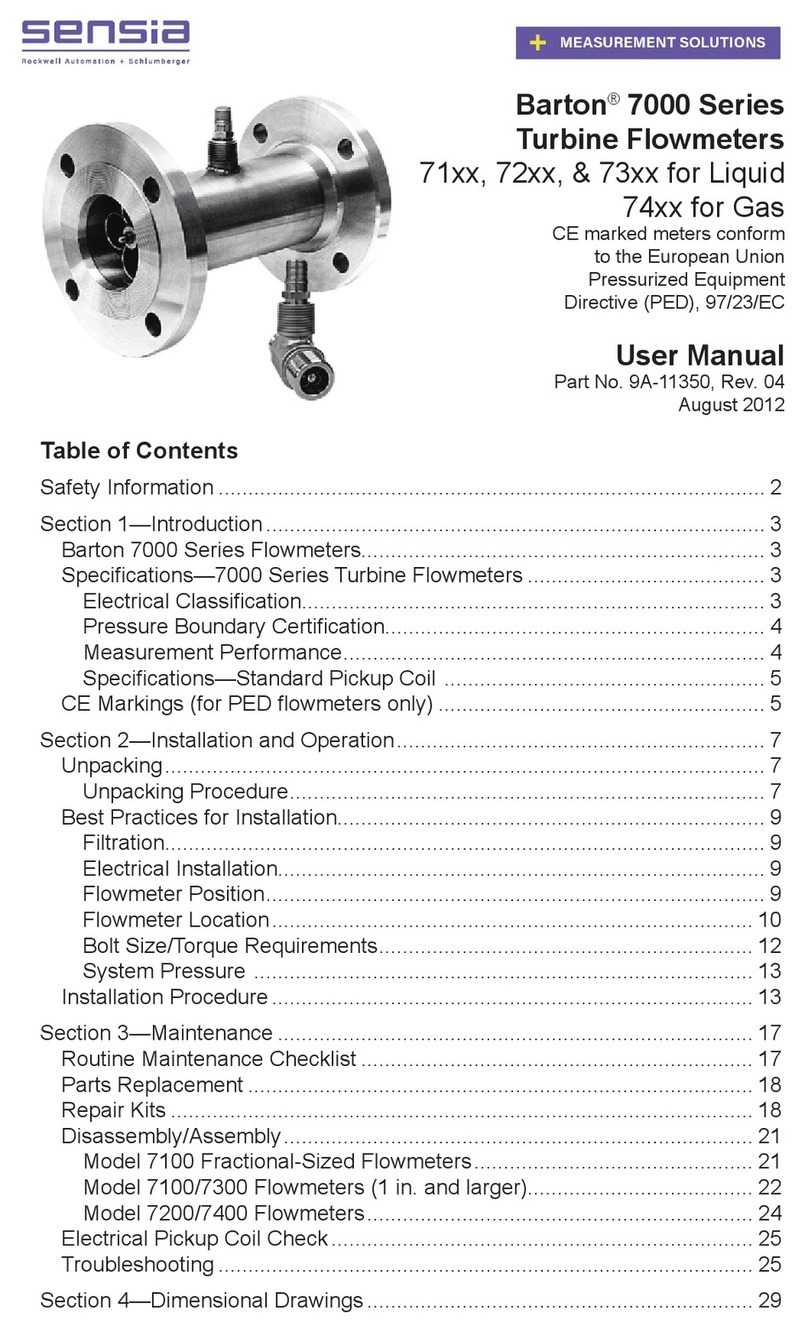

Figure 1.1—Example of meter body and transmitter assembly.................................................................... 9

Figure 1.2—Meter body approvals nameplate example ............................................................................. 14

Figure 1.3—Meter body serial number nameplate example....................................................................... 14

Figure 2.1—Stainless steel bolt and washer in tapped hole of meter body end flange.............................. 16

Figure 2.2—Proper sling attachment .......................................................................................................... 17

Publisher Notes CALDON SVM 289Ci

vi

Figure 2.3—Hoist rings with a lifting bar above the electronics unit allow for uniform lifting. ..................... 18

Figure 2.4—SVM 289Ci installation recommendations .............................................................................. 19

Figure 3.1—Fully assembled transmitter .................................................................................................... 21

Figure 3.2—User terminations, rear view ................................................................................................... 21

Figure 3.3—DC power terminations............................................................................................................ 22

Figure 3.4—AC power terminations............................................................................................................ 22

Figure 3.5—Power terminations (TB1 has terminals 1 and 2 only; safety earth/ground shown in two

places)......................................................................................................................................................... 23

Figure 3.6— Typical analog input ............................................................................................................... 23

Figure 3.7—Typical analog output .............................................................................................................. 24

Figure 3.8—Typical digital signals .............................................................................................................. 25

Figure 3.9—Earth points on transmitter body (refer to Table 3.7 for isolated ground connections to be

made by user) ............................................................................................................................................. 26

Figure 3.10—Ethernet locations ................................................................................................................. 28

Figure 3.11—Typical RS485 communications............................................................................................ 29

Figure 4.1—Illustration of the transit time principle..................................................................................... 30

Figure 4.2—Three paths per chordal plane as used in the Caldon SVM ................................................... 31

Figure 4.3— Chordal planes used for the primary velocity (4-chord) and velocity profile verification

(5-chord)...................................................................................................................................................... 32

Figure 5.1—Illustration of chord, plane, and path....................................................................................... 34

Figure 6.1—Transmitter components ......................................................................................................... 41

Figure 6.2— Disassembly views for IOP replacement ............................................................................... 41

Figure 6.3—Location of IOP/F25 fuse ........................................................................................................ 42

Figure 6.4—Disassembly views for CTC and display replacement............................................................ 43

Figure 6.5—SW3 setting for use with a 204B169 IOP................................................................................ 45

Figure 6.6—MXR-CTC ribbon cable routing path....................................................................................... 45

Figure 6.7—Disassembling the transmitter to access the MXR ................................................................. 47

Figure 6.8—Transducer Housing Access Cover......................................................................................... 48

Figure 6.9—Transducer housing cross-section .......................................................................................... 48

Figure 6.10—Transducer housing detail..................................................................................................... 49

Figure 7.1—Diagnostic screen.................................................................................................................... 51

Figure 8.1—Transmitter with CTC switch enabled to prevent configuration changes (shown without

tamper evident seal for clarity).................................................................................................................... 54

Figure 8.2—Seal wire on transmitter enclosure.......................................................................................... 55

Figure 8.3—Seal wire on both ends of a transmitter .................................................................................. 55

Figure 8.4—IOP tamper-evident seals........................................................................................................ 56

Figure 8.5—Seal wire on meter body ......................................................................................................... 57

Figure 9.1—Transducer Equipment............................................................................................................ 58

Figure 9.2—Electronic Equipment .............................................................................................................. 58

CALDON SVM 289Ci Publisher Notes

vii

TABLES

Table 1.1 Standard K-Factors ..................................................................................................................... 10

Table 1.2 SVM 289 Transmitter Specifications........................................................................................... 13

Table 2.1 Hoist Ring Rated Weights and Part Numbers ............................................................................ 15

Table 3.1 Distance Required from Power Source ...................................................................................... 20

Table 3.2 Power Terminations – Recommended 16 to 20 AWG wire ........................................................ 22

Table 3.3 Analog Inputs (User 1) – Recommend 16 to 28 AWG wire ........................................................ 23

Table 3.4 Analog Outputs (User 2) – Recommended 16 to 28 AWG wire ................................................. 24

Table 3.5 Optional HART Output – Recommended 16 to 28 AWG wire .................................................... 24

Table 3.6 Digital Signals – Recommended 16 to 28 AWG wire ................................................................. 25

Table 3.7 Ground Connections Recommended 18 AWG wire (internal) and 16 AWG wire (external) ...... 26

Table 3.8 Ethernet Connections (IOP Comparison) ................................................................................... 27

Table 3.9 9A-204B169 – TB Copper Connections ..................................................................................... 27

Table 3.9 Terminations for Serial Communications – Recommended 16 to 28 AWG wire........................ 28

Table 5.1 LED Diagnostics.......................................................................................................................... 35

Table 5.2 Display Screens .......................................................................................................................... 35

Table 6.1 Circuit Boards.............................................................................................................................. 40

Table 7.1 Signal Diagnostics ...................................................................................................................... 52

Section 1: Introduction CALDON SVM 289Ci

8

Section 1: Introduction

1.1 EQUIPMENT DESCRIPTION

The CALDON*SVMError! Bookmark not defined.Error! Bookmark not defined. 289Ci*ultrasonic

flowmeter is a highly sophisticated bidirectional flow measurement system that employs ultrasonic transit

time to measure volumetric flow rate and evaluate the uncertainty in the measurement result. Its

advanced signal and data processing are designed to provide robust, high accuracy measurement and

unique self-verification capabilities.

CALDON SVM technology employs the proven Caldon 8-path configuration for its primary measurements.

The 8-path configuration uses pairs of crossed paths in each of four chordal planes to effectively cancel

non-axial velocities and accurately integrate the axial velocity profile. The 8-path primary measurement is

the foundation of our SVM 289Ci which has 16 paths in total and incorporates three significant features to

produce an ultrasonic meter with unique and unrivalled self-verification ability:

•Primary (axial velocity) measurement verification per chord

•Fifth chordal measurement plane to facilitate 4-chord vs 5-chord estimation of flow profile uncertainty

•Vertical reflective path for detection of entrained gas or contamination.

SVM technology enables the simultaneous calculation of measurement uncertainty alongside each flow

measurement calculation. In addition to the continuous and instantaneous output of uncertainty in terms

of volumetric flowrate or relative percentage value, the SVM totalizes uncertainty values internally. The

SVM 289Ci flowmeter contains an automatic fault detection system for verifying performance and alerting

personnel when abnormal operating conditions are detected. For ease of troubleshooting, the SVM 289Ci

flowmeter provides easy-to-interpret uncertainty and diagnostic information via Modbus communications

and the local display.

This manual provides detailed instructions on the installation and operation of the flowmeter including the

viewing of flow parameters and interpretation of diagnostic data viewed via the transmitter’s display.

Users who require a more detailed view of uncertainty, or diagnostic and signal data can access the data

via the CALDON USM Advisor software. The operation of this software is outside the scope of this

manual. See the USM Advisor User Manual for details.

The SVM 289Ci flowmeter has two key components: a meter body and a transmitter.

Typically, the transmitter is mounted to the meter body, tested at the factory, and shipped as a fully

assembled instrument, ready for installation.

1.1.1 SVM 289Ci METER BODY

The meter body contains 16 pairs of ultrasonic transducers and a temperature sensor (RTD). Refer to

Figure 1.1, page 9 for a depiction of the meter body and transmitter assembly.

The meter body is a specially designed flow conduit that contains multiple pairs of transducer housings

that are positioned to form ultrasonic paths at an angle to the flow direction. The transducers are installed

inside these housings and are isolated from the fluid and external to the pressure containment. The four

primary chordal planes are spaced in accordance with the Gaussian Method of flow integration.

Each transducer module contains a piezoelectric element that transmits and receives acoustic energy in

the form of ultrasonic pulses.

∗Mark of Sensia

* The SVM 289Ci is the latest addition to the Leading Edge Flow Meter (LEFM) family. It is designated SVM for Self-Verifying Meter.

However, LEFM and SVM can be used interchangeably, e.g., the LEFM/SVM 289Ci is part of the LEFM 2xxCi family of meters.

CALDON SVM 289Ci Section 1: Introduction

9

Figure 1.1—Example of meter body and transmitter assembly

1.1.2 G3 TRANSMITTER

The transmitter houses the display that provides readouts of flow data including flow rate, total flow

volume, fluid properties, analog input data, alarm indication, fault detection, and diagnostic information.

The transmitter performs all control and timing for the generation and measurement of ultrasonic pulses.

Signal and data processing is performed by specialized proprietary circuit boards that are designed to

achieve high sampling rates, provide stable ultrasonic signals, and eliminate zero drift. The circuit boards

within the transmitter are programmed to perform the following functions:

•Step through the ultrasonic path cycles

•Measure meter body temperature (for thermal expansion correction, see Section 4: Understanding

Flow Calculations)

•Compute flow

•Communicate with external devices

•Generate pulse outputs and analog outputs

The transmitter offers the following inputs/outputs:

•Three optional 4-20 mA analog inputs can be mapped to any of the following:

−Product temperature

−Product pressure

−Product density

−Product viscosity

•Two optional 4-20 mA analog outputs

−Flow

−Product temperature

−Product pressure

•Communications

−Up to three RS485 ports (half duplex) – Modbus RTU

−Ethernet port (via copper or fiber) with Modbus TCPIP

−Optional HART channel (operates on second analog output)

Section 1: Introduction CALDON SVM 289Ci

10

•Four digital outputs

−Status

−Standard volume pulse outputs

The standard K-factors used to configure transmitters at the factory are listed in Table 1.1. The user may

optionally configure the K-factor to meet individual needs. Refer to the meter display or Modbus register

for the actual K-factor in use.

Table 1.1 Standard K-Factors

Size

K-Factor

(P/bbl)

K-Factor

(P/m3)

Inches

DN

8

200

500

3,150

10

250

350

2,200

12

300

250

1,570

14

350

200

1,000

16

400

150

940

18

450

100

630

20

500

85

530

24

600

60

380

26

650

45

280

28

700

40

240

30

750

35

220

32

800

30

185

34

850

25

165

36

900

25

145

40

1,000

20

125

CALDON SVM 289Ci Section 1: Introduction

11

1.2 MODEL NUMBERS

1.2.1 METER BODY MODEL NUMBER

The meter body model number defines construction and features of the meter body. From the model

number, a user can identify and verify the component type, meter size, piping thickness, construction

material, flange rating/style, and enclosure type.

MODEL NUMBER CODE: SVM ABC-X-D-E-F-G-H-J-K-L-M-N-P-Q-R

Example: For a carbon steel 289Ci meter with Schedule 40, 150# raised-face flanges and G3 electronics

mounted directly to the meter body, the model code is SVM 289Ci-G3-16-40-CF-150-A-W-L-A-N-A-1-L.

A =

2 FOR LIQUID METERS

B

=

89 FOR 16 PATH SVM METERS

C =

Ci-G3 FOR INTEGRAL ELECTRONICS

CiRN-G3 FOR INTEGRAL ELECTRONICS WITH REDUCED BORE

D =

NOMINAL PIPE SIZE (e.g., 08 = 8 INCH, 16 = 16 INCH …)

E =

PIPE SCHEDULE (SCHEDULE 5 THRU 160 AND XXS)

F =

CF FOR FORGED CARBON STEEL

CC FOR CAST CARBON STEEL

SF FOR FORGED STAINLESS STEEL

SC FOR CAST STAINLESS STEEL

DF FOR FORGED DUPLEX STEEL

DC FOR CAST DUPLEX STEEL

LF FOR FORGED LOW TEMPERATURE CARBON STEEL

LC FOR CAST LOW TEMPERATURE CARBON STEEL

HF FOR HASTELLOY

IF FOR INCONEL FORGED

G =

ASME FLANGE RATING (CLASS 150, 300, 600, 900, 1500, 2500)

H =

H FOR SINGLE TRANSDUCER ENCLOSURES INTEGRAL WITH METER BODY

J =

W FOR WELD NECK RAISED FACE FLANGES

R FOR WELD NECK RTJ FACE FLANGES

O FOR OTHER FLANGE VARIETY

K

=

L FOR LOCTITE E40 EXP POTTING MATERIAL

L =

B FOR SECONDARY SEAL DESIGN TRANSDUCER HOUSING IN ACCORDANCE WITH ISA 12.27.01 (DUAL SEAL)

C FOR DOUBLE O-RINGS

M =

N FOR NO PRESSURE PORT OPTION

P FOR PRESSURE PORT OPTION

N =

A FOR ALUMINUM TRANSDUCER COVERS

S FOR STAINLESS STEEL TRANSDUCER COVERS

P =

1 FOR ONE TRANSMITTER

Q =

L FOR LIQUID TRANSDUCER HOUSINGS

R =

"BLANK" FOR NO CUSTOM OPTION

C FOR CUSTOM OPTION

Section 1: Introduction CALDON SVM 289Ci

12

1.2.2 TRANSMITTER MODEL NUMBER

The transmitter model number includes information that defines construction and features of the

transmitter.

MODEL NUMBER CODE: G3MFFFCCPSEXYZ

MATERIAL

M =

A, ALUMINUM

S, STAINLESS STEEL

FREQUENCY

FFF =

BBS FOR A BROADBAND DESIGN

COMMUNICATIONS

CC =

HC FOR TWO RS

-485 PORTS, ONE HART PORT, AND ONE COPPER ETHERNET

SC FOR THREE RS

-485 PORTS (ONE MASTER) AND ONE COPPER ETHERNET

HF FOR TWO RS

-485 PORTS, ONE HART PORT, AND ONE FIBER ETHERNET

SF FOR THREE RS

-485 PORTS (ONE MASTER) AND ONE FIBER ETHERNET

POWER OPTIONS

P =

D FOR DC POWER

– 24 VOLTS

A FOR AC POWER

– 120/230 VAC

SUNSHIELD OPTIONS

S =

Y FOR WITH SUNSHIELD

N FOR WITHOUT SUNSHIELD

ENTRY PORT

E =

1 FOR NPT PORTS 3/4 INCH NPT

2 FOR M25

Adapters

3 FOR

M20 Adapters

APPROVALS

X =

0 FOR NO

Class/Div APPROVAL

C FOR

Class/Div APPROVAL

Y =

0 FOR NO ATEX APPROVAL

C FOR ATEX EXd

b IIB + H2APPROVAL

D FOR ATEX EXd

b IIC APPROVALS

Z =

0 FOR NO IEC APPROVAL

C FOR IECEX EXd

b IIB + H2APPROVALS

D FOR IECEX EXd

b IIC APPROVALS

CALDON SVM 289Ci Section 1: Introduction

13

1.2.3 TRANSMITTER SPECIFICATIONS

Table 1.2 SVM 289 Transmitter Specifications

Material

Standard Aluminum (coated)

Corrosion Resistant Stainless Steel

Size and Weight (if delivered separate from the meter body)

Dimensions

Net Weight

14”x 8” x 6” = 152mm x 356 mm x 203 mm

15 lb. (6.1 kg) Aluminum – Transmitter only

Note – When attached to an aluminum junction box, the total could

surpass 135 lbs (61 kg), depending on the junction box brand

40 lb. (15.9 kg) Stainless Steel – Transmitter only

Power Requirements – DC Power

Voltage 24 VDC (18 VDC to 30 VDC)

Current Draw 0.25 A at 24 VDC

Power Consumption 6 W

Power Requirements – AC Power

Voltage 120 (60 Hz) / 230 (50 Hz) VAC

Voltage Range 108 VAC to 253 VAC

Frequency Range 47 Hz to 63 Hz

Rated Current Draw 0.14 A

Nominal Power Consumption 7.3 W

Pulse Outputs/Alarm

Pulse/Direction Outputs (4 Total) 0-5 V or 0-12 V

Alarm Status (4 Total) 5V or 12 V = normal operation

0V = alarm condition

Communications

RS485 (up to 3 total) 2 Wire – Modbus RTU

Ethernet Copper (1 x RJ45 and TB2) and Fiber

HART Optional

Analog Outputs (2 total)

4-20 mA

(max load 650 Ohms)

Analog Inputs (3 total)

4-20 mA

Meter body RTD is standard

Environment Requirements

Storage Temperature -58°F (-50°C) to 185°F (85°C)

Operating Temperature -58°F (-50°C) to 158°F (70°C)

Altitude Up to 5000 meters for DC applications, 2000 meters for AC applications

(Contact Sensia for applications at higher elevations)

Section 1: Introduction CALDON SVM 289Ci

14

The intended use of this transmitter is a permanently connected installation, Equipment Class II, Pollution

Degree 2, Continuous operation.

1.2.4 METER MARKINGS

Figure 1.2—Meter body approvals nameplate example

Figure 1.3—Meter body serial number nameplate example

CALDON SVM 289Ci Section 2: Meter Body Installation

15

Section 2: Meter Body Installation

SVM 289Ci flowmeters are designed for use with a broad range of process and environmental conditions.

Durable construction permits conventional installation practices. The flowmeter body is typically fabricated

of stainless steel, carbon steel, or duplex steel, depending on customer requirements. The flowmeter is

designed to be as strong as or stronger than pipe and flanges of the same schedule, pressure class and

material. For site stress analysis, the meter can be conservatively treated as equivalent pipe.

CAUTION

The weights of the flowmeter body are listed on the customer-specific General Arrangement

Drawing. Never use the transmitter, conduit boxes or junction boxes for lifting or

maneuvering the meter body. These components are not designed for the forces required to

move the meter body and could be damaged.

CAUTION

If the equipment is likely to come into contact with aggressive substances, then it is the

responsibility of the user to take suitable precautions that prevent it from being adversely

affected, thus ensuring that the type of protection is not compromised.

No external supports or special mounting pads are required or recommended for the SVM meter body.

However, the piping immediately upstream and downstream of the flowmeter should be well supported in

accordance with good piping practices and site seismic requirements.

1.1 LIFTING/HOISTING THE METER BODY

WARNING

If the swivel hoist rings have been used previously, inspect them for signs of wear,

corrosion, or stress. If the rings appear damaged or corroded, DO NOT USE.

2.1.1 HOIST RING INSTALLATION

Use only Sensia swivel hoist rings (ordered separately; see Table 2.1) in the meter body end flanges.

DO NOT USE the following:

•Eyebolts

•Other hoist rings with the same screw size

•Heavy-duty hoist rings

Table 2.1 Hoist Ring Rated Weights and Part Numbers

Rated Weight (lbs)

Rated Weight (kg)

Thread

Sensia Part No.

1385 628 M8 9A-8504651

1980 898 M10 9A-8504652

2970 1347 M12 9A-8504653

4400 1996 M16 9A-8504655

7700 3493 M20 9A-8504657

9900 4491 M24 9A-8504659

14740 6686 M30 9A-8504661

17600 7983 M36 9A-7983553

Section 2: Meter Body Installation CALDON SVM 289Ci

16

1. Before installing hoist rings, refer to your company’s hoisting and rigging standards. If no such

company standards exist, refer to the Department of Energy (DOE) STD-1090-2011(Hoisting and

Rigging Standard). Additional information can be found in OSHA 29 CFR 1926.251 (Rigging

Equipment for Material Handling) and 1926.552 (Material Hoists, Personnel Hoists, and Elevators).

2. Identify the assembled weight of the meter body from the serial tag or by referencing the GA drawing.

3. Place the meter on a stable surface or platform capable of supporting its assembled weight.

WARNING

Failure to properly stabilize and support the meter body during installation or removal could

allow the meter to shift or roll, posing a hazard that may result in equipment damage or

serious injury, up to and including death.

4. Remove the plug bolts and sealing washers from the tapped holes on top of each meter body end

flange and set them aside. The plug bolts will be replaced after the hoist ring is no longer required, as

shown in Figure 2.1.

Figure 2.1—Stainless steel bolt and washer in tapped hole of meter body end flange

5. Screw the swivel hoist rings into the tapped holes. To ensure the hoist rings hold their rated load, the

base of the hoist ring must be in full contact with the surface of the tapped holes before attempting to

lift/hoist the meter body.

6. Torque the swivel hoist ring attachments to the site recommended limit for that bolt size. DO NOT

over-torque.

7. Verify that the rings move freely in all directions.

2.1.2 SLING ATTACHMENT

WARNING

Ensure that the meter body is detached from all piping, pipe fittings, and/or meter tubes

before lifting/hoisting the meter. Failure to take this precaution may result in damage to

equipment and/or personal injury, up to and including death.

Stainless Steel Bolt

Sealing Washer

CALDON SVM 289Ci Section 2: Meter Body Installation

17

WARNING

Failure to properly stabilize and support the meter body during installation or removal could

allow the meter to shift or roll, posing a hazard that may result in equipment damage or

serious injury, up to and including death.

WARNING

NEVER attempt to thread one sling through both hoist rings. DO NOT exceed an angle of

90 degrees between the slings. Choose slings that exceed the swivel hoist ring load rating.

Failure to follow these precautions may result in hoist ring failure, equipment damage, or

serious personal injury, up to and including death.

1. Select two slings of equal length that exceed the load rating for the weight of the assembled meter

body.

2. Visually inspect the slings for signs of wear, abrasion, or other damage. DO NOT USE if damage is

detected.

3. Attach the slings to the hoist rings (see Figure 2.2).

Figure 2.2—Proper sling attachment

Important Ensure that the angle between the slings is 90 degrees or less. DO NOT wrap slings around

the meter body or the transmitter enclosure.

To avoid damaging the transmitter, ensure that the slings do not come into contact with the

transmitter enclosure. Consider using a spreader bar (as shown in Figure 2.3, page 18) to

ensure that the angle relative to the vertical does not exceed 45 degrees.

Section 2: Meter Body Installation CALDON SVM 289Ci

18

Figure 2.3—Hoist rings with a lifting bar above the electronics unit allow for uniform lifting.

CAUTION

To avoid damaging the swivel hoist rings, never use cables, hooks, or chains to lift the meter

body. Lift the meter gradually. Exposing the swivel hoist rings to shock loads can result in

damage to the hoist ring. DO NOT USE any swivel hoist ring exposed to shock loads.

4. After lifting, remove the swivel hoist rings and store away from exposure to moisture, extreme

temperatures, and other adverse conditions.

5. Reinsert the plug bolts into the tapped holes to protect them from debris and corrosion.

2.2 METER INSTALLATION

Install the flowmeter so that:

•The primary measurement chords are horizontal (with the transmitter on top) to decrease the

likelihood of debris or air (gas) accumulating in the sensor wells.

•The meter is not located at a high point where air/gas could be trapped.

•The flow arrow should be pointing in the direction of “positive” flow.

•All wiring to the transmitter is routed in shielded conduit/armoured cable that meets site environment

specifications.

•All power connections from site shall go through a properly rated equipment switch or circuit breaker

employed as a disconnecting device (see Table 1.2, page 13, for ratings). This switch shall be easily

accessed and be marked as the disconnecting switch for the transmitter. This switch shall meet the

requirements of IEC 60947-1 and IEC 60947-3 and site electrical codes.

•If using DC power, power cable must be installed in separate conduit from all other cabling. This is to

meet the requirements of IEC 61000-4-4 (2004-07).

•To limit uncertainty caused by pipe fittings and fluid dynamic effects, install the SVM 289Ci model per

the following guidelines.

−The adjoining straight pipe should be of the same schedule as the meter.

−The SVM 289Ci does not normally require the use of a flow conditioning element. An

uninterrupted upstream pipe 5 diameters in length is adequate in most applications. In situations

where there is a constriction upstream of the meter that is smaller than the diameter of the meter

run piping (such as a reduced bore valve), it is recommended that this be separated from the

meter by a pipe at least 15 pipe diameters in length.

CALDON SVM 289Ci Section 2: Meter Body Installation

19

−Downstream of the meter there should be a straight length of at least 3 pipe diameters prior to

any bends, tees, reducers, expanders or valves etc.

−In uni-directional applications temperature elements and pressure connections should be located

downstream of the meter.

−Intrusive temperature elements should be at a distance of at least 2 pipe diameters from the

meter. Non-intrusive pressure connections may be located within 2 diameters of the meter.

Refer to Figure 2.4 for details. For application-specific recommendations or more detailed installation

guidance, contact Sensia.

Figure 2.4—SVM 289Ci installation recommendations

Section 3: Transmitter Connections CALDON SVM 289Ci

20

Section 3: Transmitter Connections

CAUTION

The physical properties, configuration settings, and calibration of the meter body are pre-

programmed into the transmitter; therefore, the meter body and transmitter are manufactured

as a matched set and must be installed as a pair. Failure to install transmitters and meter

bodies as matched sets can result in erroneous flow measurements.

3.1 TRANSMITTER INSTALLATION PROCEDURE

Important All equipment should be installed by a licensed electrician in accordance with NEC/CEC or

local codes. At a minimum, install a disconnect switch in series with the transmitter power

input.

All wiring to and from the transmitter must be routed through grounded/shielded metal

conduit or equivalent that meets site environment specifications.

All power connections from site shall go through a properly rated equipment switch or circuit

breaker employed as a disconnecting device (see Table 1.2, page 13, for ratings). This

switch shall be easily accessed for disconnecting and be marked as the disconnecting

switch for the transmitter. This switch shall meet the requirements of IEC 60947-1 and IEC

60947-3 and site electrical codes.

For Class I, Div 1 installations, conductor insulation for external circuits must be rated for

300V and a minimum temperature of 85ºC.

3.1.1 TRANSMITTER LOCATION

To ensure that the proper supply voltage reaches the transmitter, the distance between the transmitter

and its power source must not exceed the maximum distance indicated below (based on the wire gage

used):

Table 3.1 Distance Required from Power Source

Wire Gage Max Distance (m) Max Distance (ft)

12 1082.2 3550.4

14 679.7 2229.8

16 429.0 1407.3

18 269.1 882.9

20 169.1 554.6

22 106.3 348.6

24 66.9 219.6

3.1.2 TRANSMITTER TERMINATIONS

WARNING

Before inspecting components, open the power supply circuit breaker. Failure to do so can

result in electrical shock and/or explosion.

Table of contents

Other Sensia Measuring Instrument manuals

Sensia

Sensia NuFlo Scanner 2000 Instructions for use

Sensia

Sensia CamCor User manual

Sensia

Sensia NUFLO MC-I User manual

Sensia

Sensia TA-1000 Plus Instructions for use

Sensia

Sensia CALDON LEFM CheckPlus-C User manual

Sensia

Sensia LEFM 2010FE User manual

Sensia

Sensia Barton 7000 Series User manual

Sensia

Sensia CALDON SVM 389Ci User manual

Sensia

Sensia NuFlo User manual

Sensia

Sensia Barton 306 User manual